Upper vehicle-body structure of vehicle

a vehicle body and upper body technology, applied in the direction of roofs, vehicular safety arrangments, pedestrian/occupant safety arrangements, etc., can solve the problems of not being able to ensure the stability of curtain airbag inflation for both passengers seated in the front seat and the passenger seated in the rear seat, and the difference in gas supply time between the supply of front-seat airbag and the supply of rear-seat airbag, etc., to achieve the effect of stable airbag inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

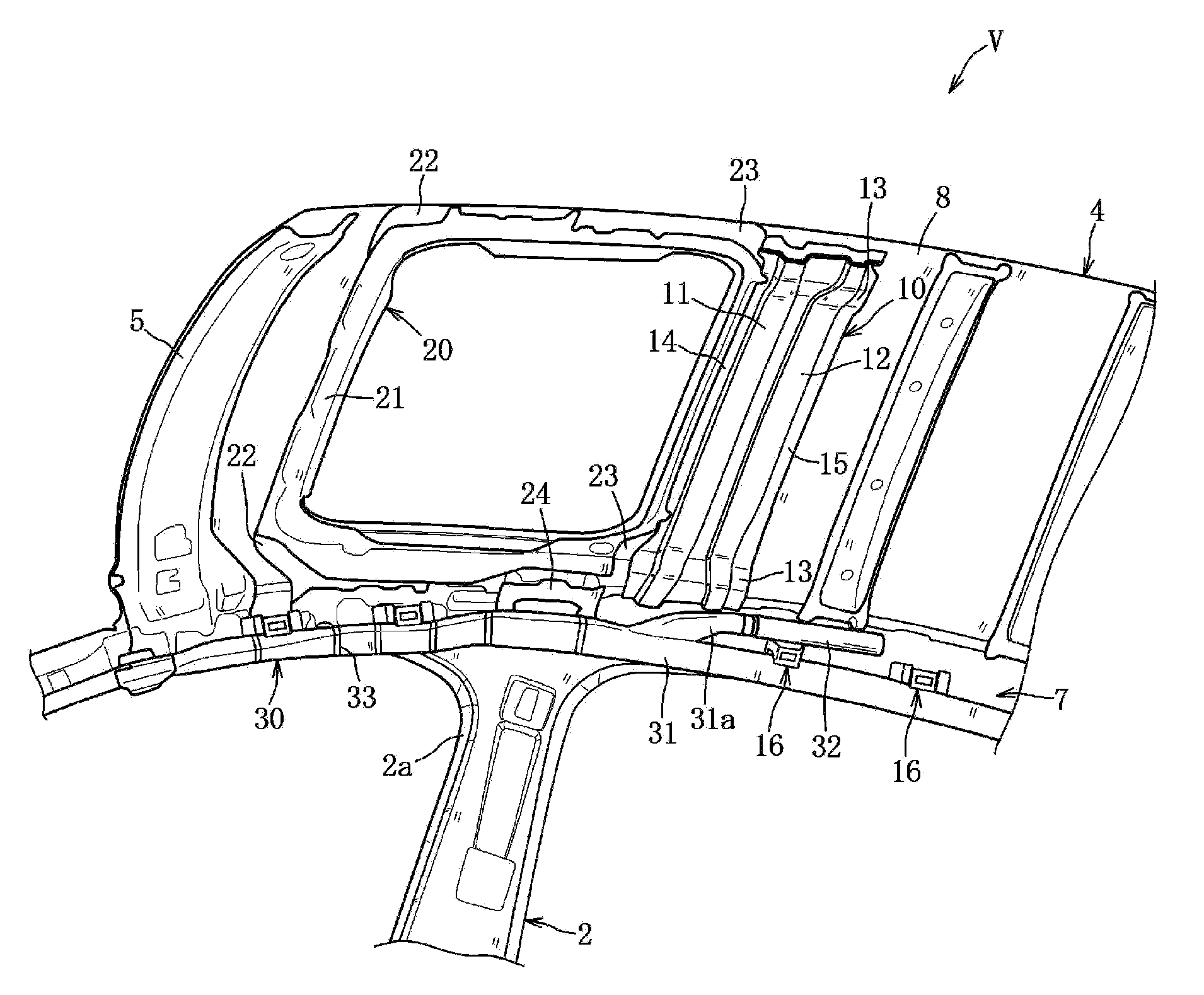

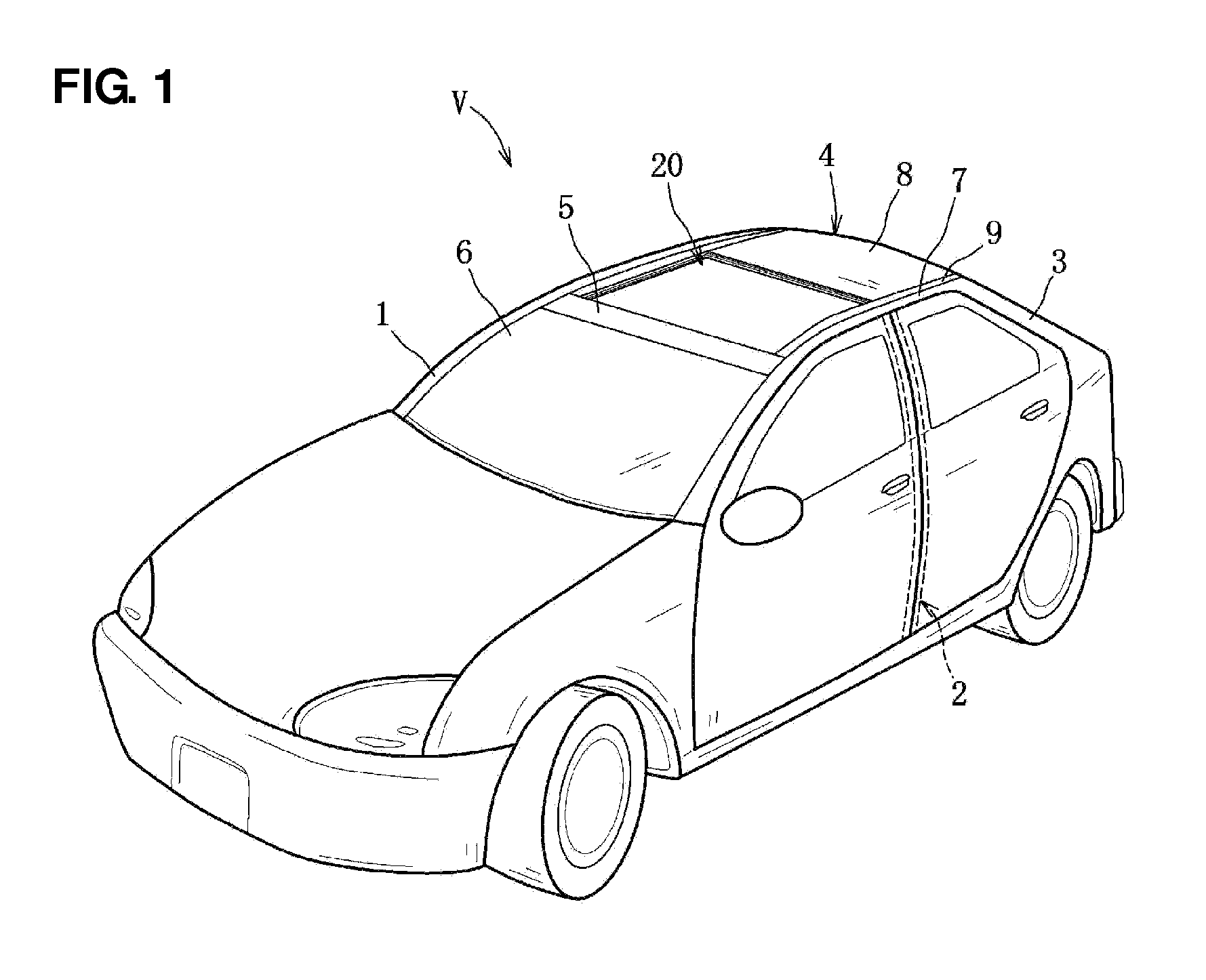

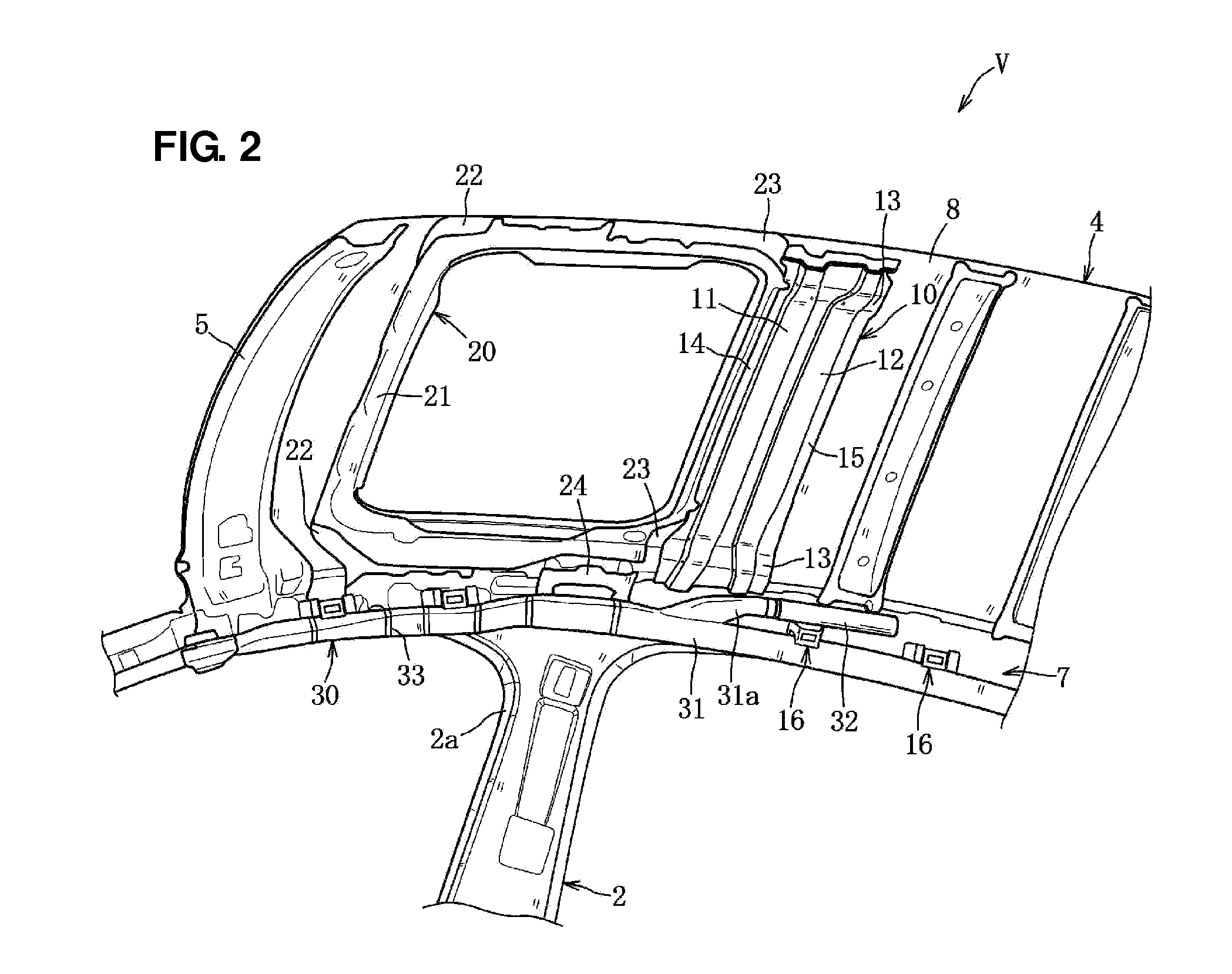

[0030]A first embodiment of the present invention will be described referring to FIGS. 1 through 10. As shown in FIGS. 1 and 2, a vehicle V of the present embodiment comprises a pair of right-and-left front pillars 1, a pair of right-and-left center pillars 2, a pair of right-and-left rear pillars 3, a roof 4 which is equipped with a sunroof unit 20 at its front-side portion, a pair of right-and-left curtain airbag unit 30, and others. As shown in FIG. 1, a front header 5 which extends in a vehicle width direction is provided at an upper end portion of the pair of front pillars 1, to which an upper portion of a windshield (front window glass) 6 is attached.

[0031]As shown in FIGS. 1 and 2, the pair of center pillars 2 is provided at a central position between a frond seat (not illustrated) and a rear seat (not illustrated). As shown in FIG. 6, the right-side center pillar 2 has a closed cross section extending vertically which is formed by a center pillar outer 2a and a center pillar...

embodiment 2

[0056]Next, an upper vehicle-body structure of the vehicle V according to a second embodiment 2 will be described referring to FIG. 11. Only structures of the second embodiment which are different from the above-described first embodiment will be described. The same references are used to denote the same members as the first embodiment, and descriptions of those are omitted.

[0057]A roof reinforcement 10A is arranged in back of the pair of center pillars 2 with an offset distance, and includes a wedge-shaped concave portion 17 which has a wedge-shaped section extending over a vehicle-width-direction whole width. The wedge-shaped concave portion 17 is configured such that its bottom portion slants obliquely rearward and upward, that is—its rear depth is becomes shallower. A front flange 14A and a rear flange 15A are provided at a front end portion and a rear end portion of the wedge-shaped concave portion 17, and joined to a back face of the rear peripheral-frame reinforcing member 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com