Lubricant member and method of manufacturing the same

a technology of lubricant parts and parts, applied in the direction of lubricant composition, bearing components, shafts and bearings, etc., can solve the problems of affecting the lubricating performance of the sliding surface, poor sliding property, and seized regions, etc., to achieve the effect of maintaining certain lubricating performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

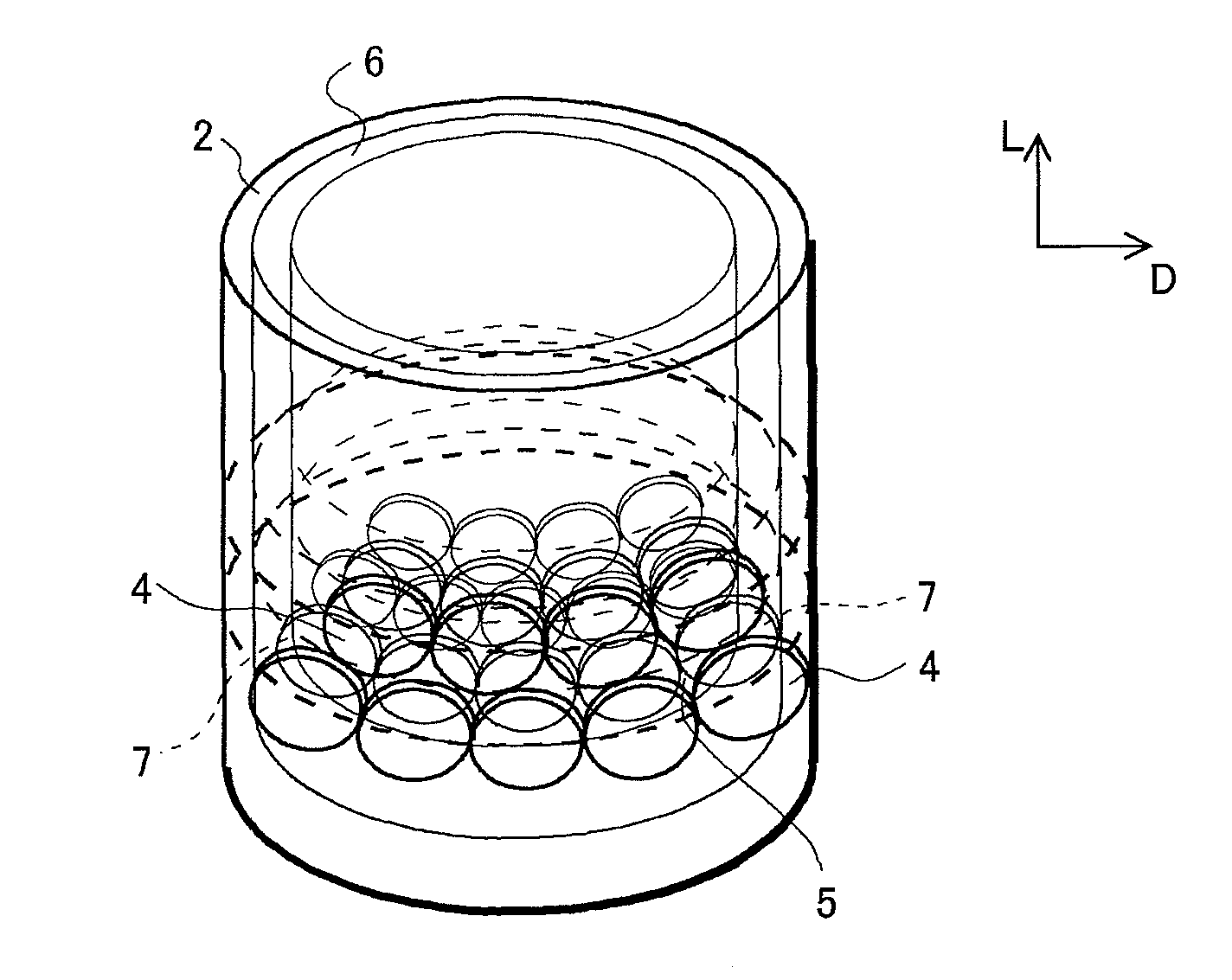

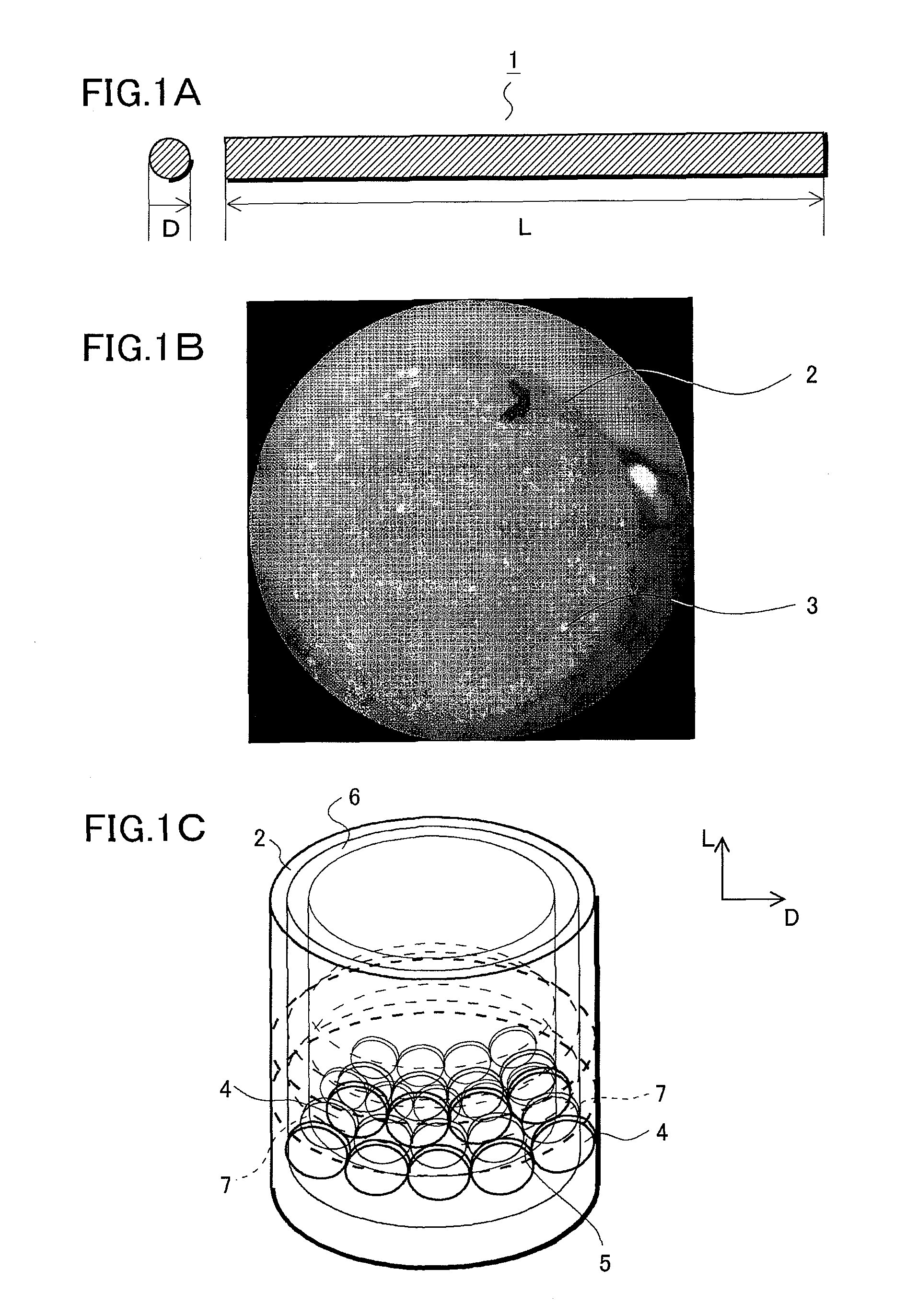

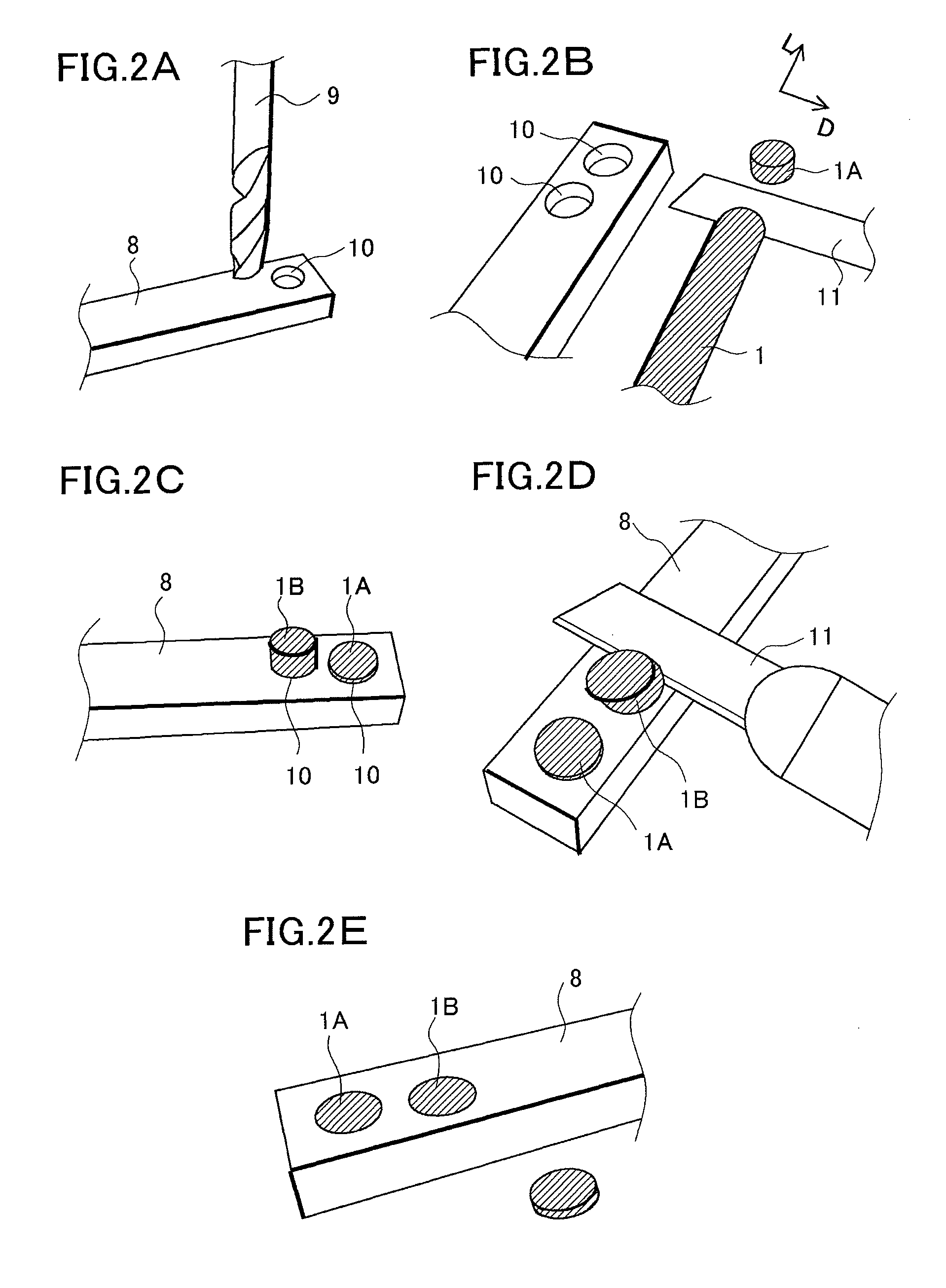

[0021]Description is given below of a lubricant member of a preferred embodiment of the invention. FIG. 1A is a sectional view to describe a lubricant member of the embodiment. FIG. 1B is a photograph taken of the lubricant member of the embodiment. FIG. 1C is a schematic view to describe the lubricant member of the embodiment. FIGS. 2A to 2E are perspective views to describe an example of how to use the lubricant member of the embodiment. FIGS. 3A to 3C and FIGS. 4A to 4C are photographs showing results of an experiment performed with the lubricant member.

[0022]As FIG. 1A shows, a lubricant member 1 is formed as a stick-shaped member longer in the lengthwise direction (L) than in the diametrical direction (D). The following description is based on an assumption that the lubricant member 1 has a columnar shape. The shape of the stick-shaped lubricant member 1, however, is not limited to a columnar one. A diametrical section may have a triangular, quadrangular, or other polygonal sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com