Gold-tin solder suitable for self-aligning applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

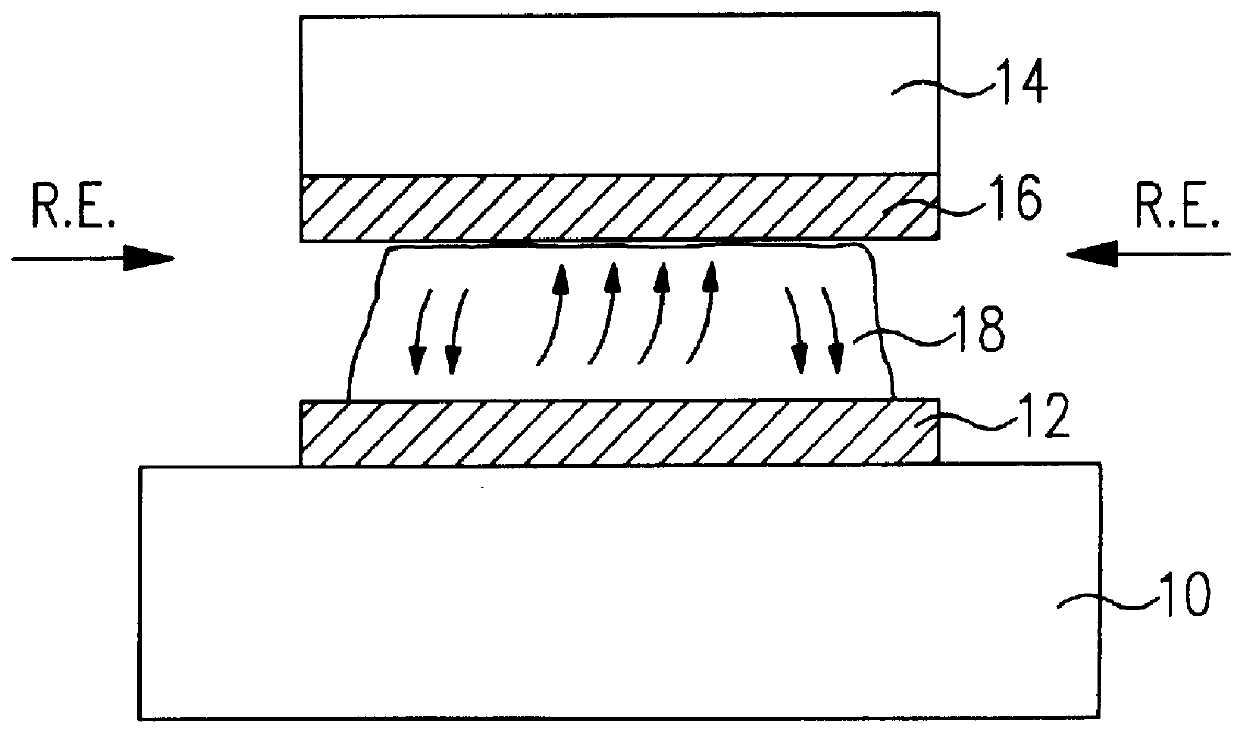

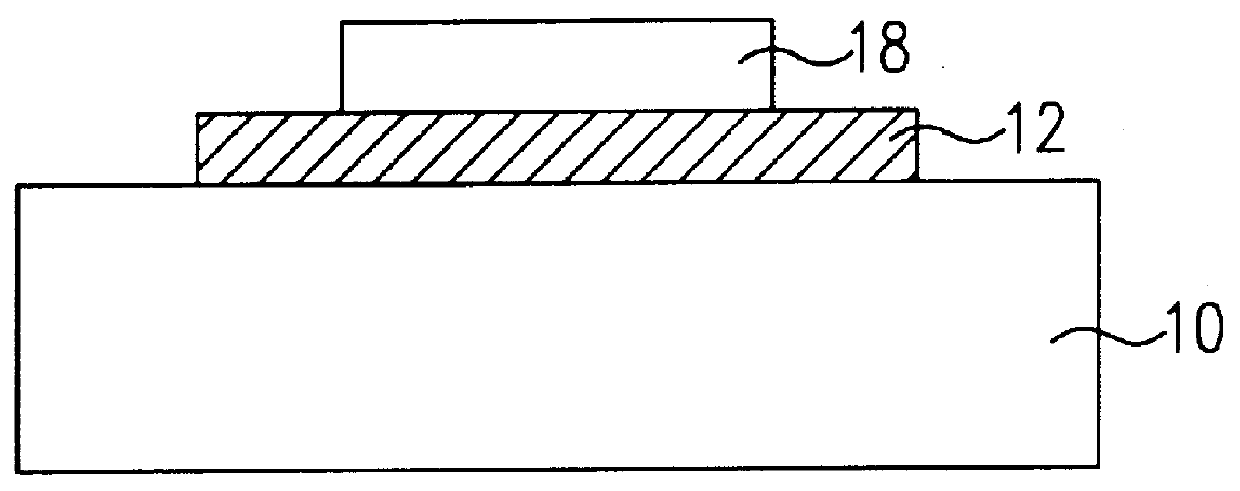

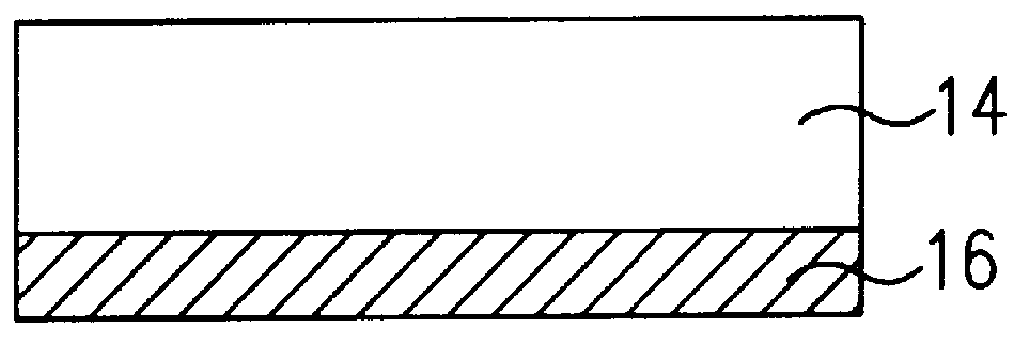

An exemplary process for providing self-aligned solder attachment of a pair of components is illustrated in FIGS. 1-3. The inventive bonding process will be particularly described in association with the self-aligned attachment of an LED to a bond pad. However, it is to be understood that the tin-rich solder of the present invention is ubiquitous in nature and can be utilized within virtually any desired soldering process. Referring back to FIG. 1, a device submount 10, which may be formed of silicon, is illustrated as including a bond pad 12. Conventionally, bond pad 12 is formed of a highly conductive material and, in particular, may comprise a tri-layer structure of titanium, platinum and gold. Gold, in general, is often used for bond pads due to its inert nature and relatively high conductivity. A device 14, such as an LED, is illustrated in FIG. 1 as positioned above bond pad 12. Device 14 also includes a conductive layer 16 (which may also comprise a tri-level, or gold plated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com