Method of on-site refueling using electronic identification tags, reading probe, and a truck on-board computer

a technology of electronic identification and onsite refueling, which is applied in the direction of liquid transfer devices, instruments, de-stacking articles, etc., can solve the problems of requiring manual recording, affecting the accuracy of onsite refueling, so as to improve accuracy, cost-effective, and simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

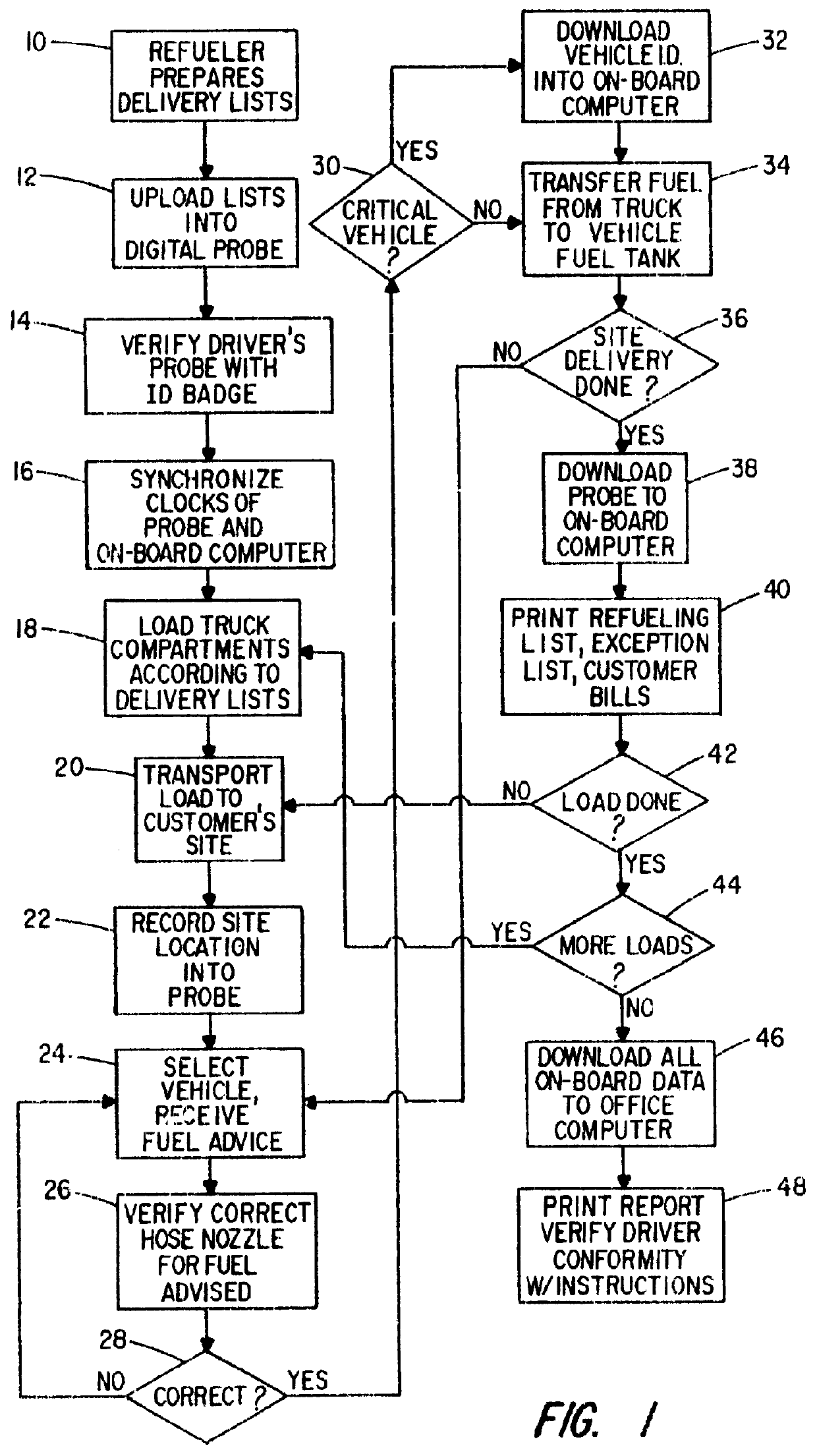

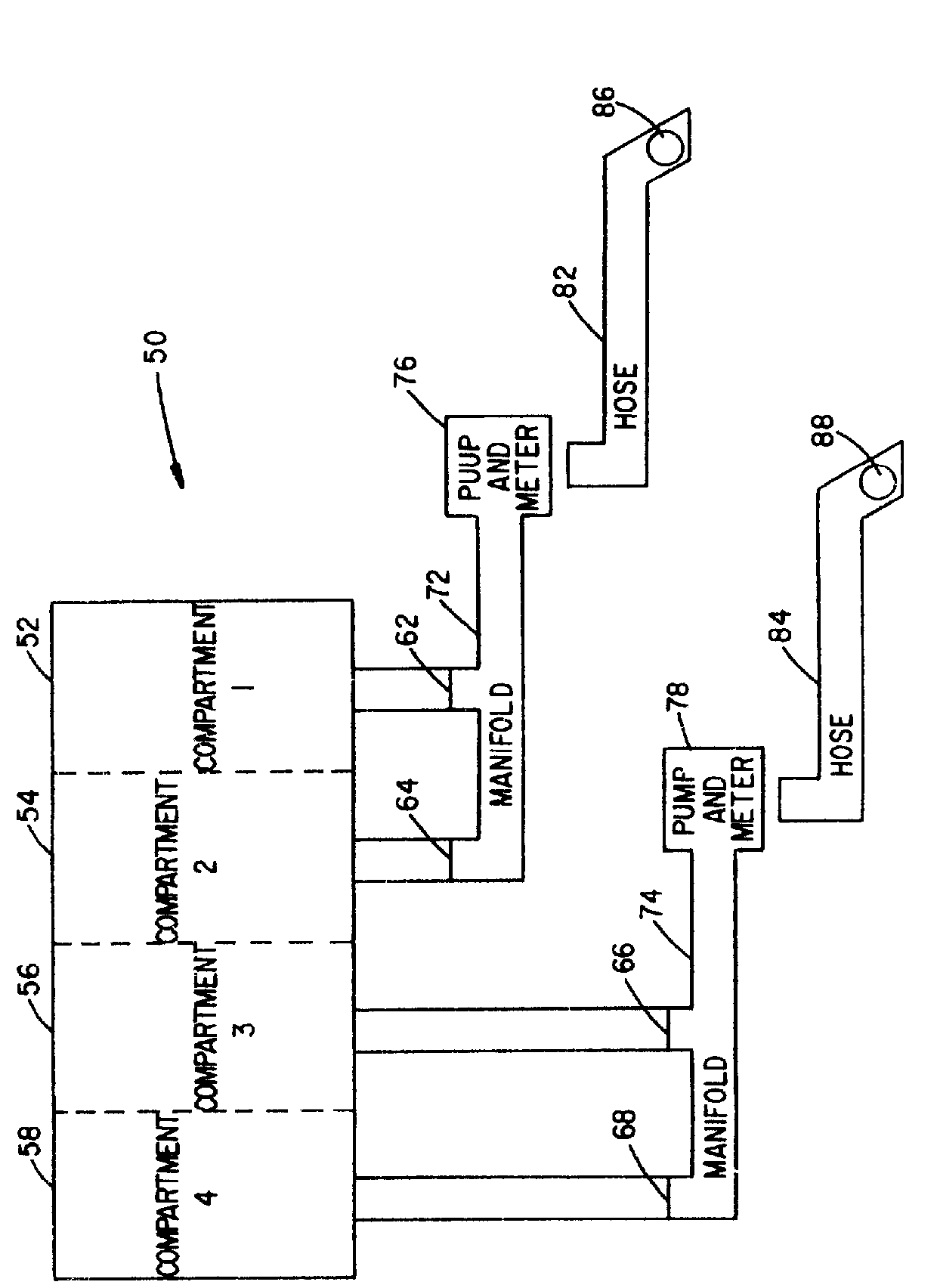

Referring first to FIG. 2 there is indicated generally by a block diagram, a delivery truck 50, having a plurality of compartments 52, 54, 56, and 58 and a corresponding outlet valve 62, 64, 66, and 68 that controls the flow of the product from each compartment to a manifold, and then through a pump and associated meter to a connected hose. Compartments 52 and 54 share manifold 72, pump 73, meter 76, and hose 82. Compartments 56 and 58 share manifold 74, pump 75, meter 78, and hose 84. The delivery hose 82 allows compartments 52 and 54, and corresponding valves 62 and 64, and corresponding pump 73 and meter 76 of the delivery truck 50 to be coupled to the plurality of customer vehicle fuel tanks 100. The delivery hose 84 allows compartments 56 and 58, and corresponding valves 66 and 68, and corresponding pump 75 and meter 78 of the delivery truck 50 to be coupled to the plurality of customer vehicle fuel tanks 100. Each delivery hose has a passive ROM device 86 and 88 affixed near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com