Process for configuring software in a build-to-order computer system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

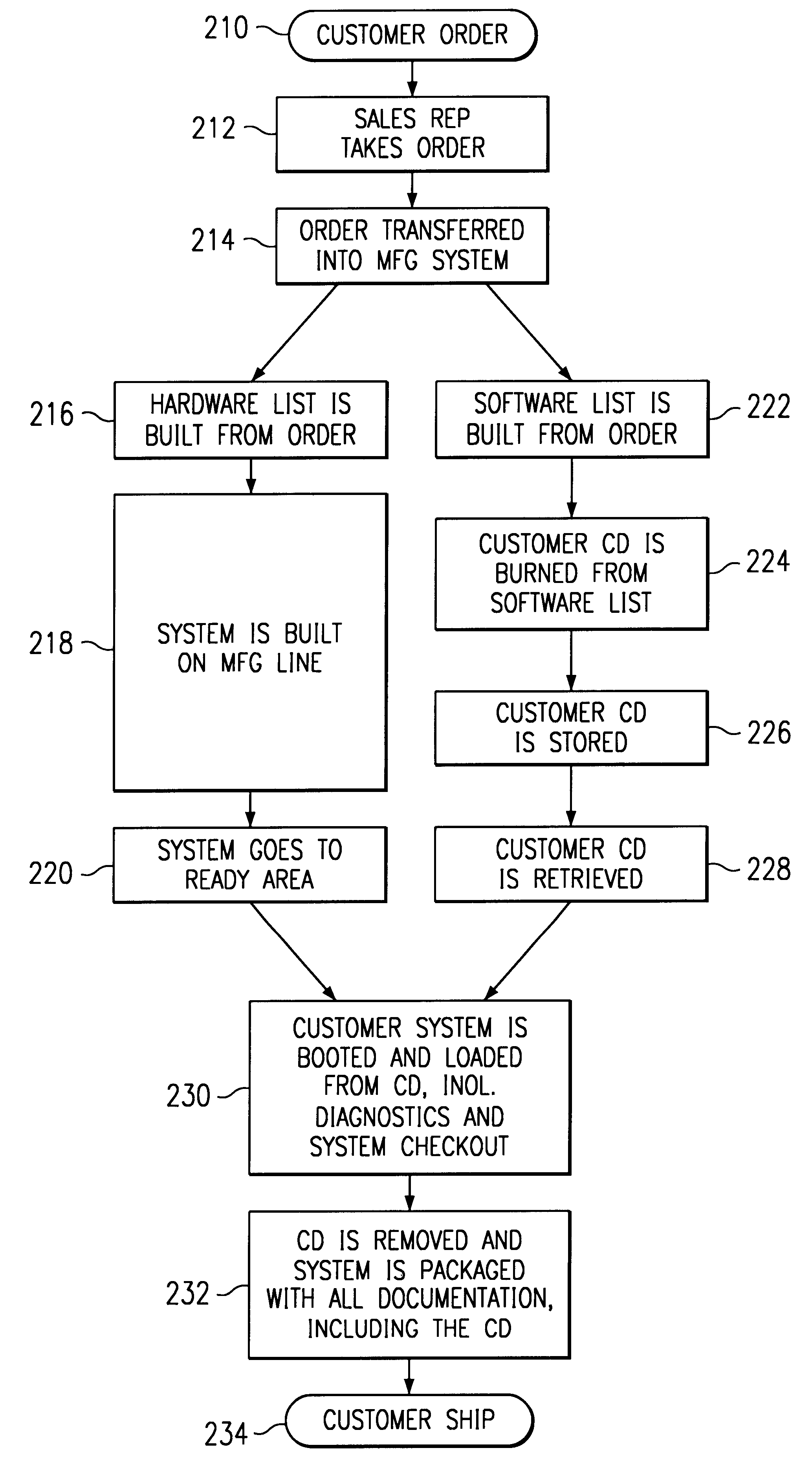

[0021]Referring to FIG. 1, a schematic block diagram shows a network for communicating information among various systems in a computer system manufacturing environment. A manufacturing system 100 includes a network 110 which is connected to various computers, computer systems, workstations and storage devices. For example, an order-entry computer system 112 is furnished to receive and process orders for computer systems. System orders specify a desired hardware configuration and a desired software configuration. Network 110 communicates with a hardware assembly line 114 via a connection to a hardware assembly line computer system 116. Also the network 110 communicates with a software assembly system 118 via a connection to a recording computer system 120. The recording computer system 120 assembles system software and writes the assembled software on a CD-ROM using a CD-ROM writer 122. To assemble the software, the recording computer system 120 accesses a library of software program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com