Lens with external aperture stop

a technology of aperture stop and lens, applied in the field of compact lenses, can solve the problems of increasing the cost of assembling and mounting the lens in the lens cell, increasing the cost of the lens, and large number of elements tending to be relatively large, so as to improve the optical performance, high reliability, and high yield in volume manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

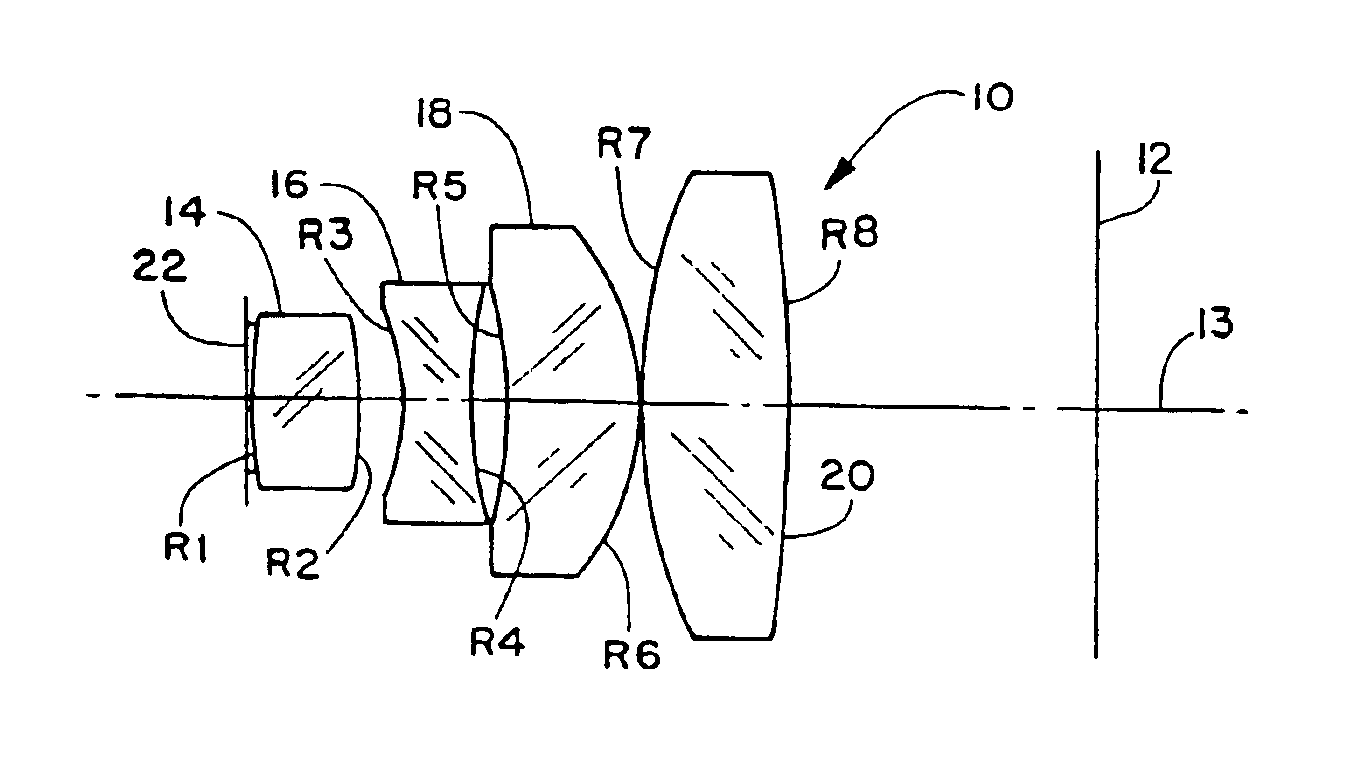

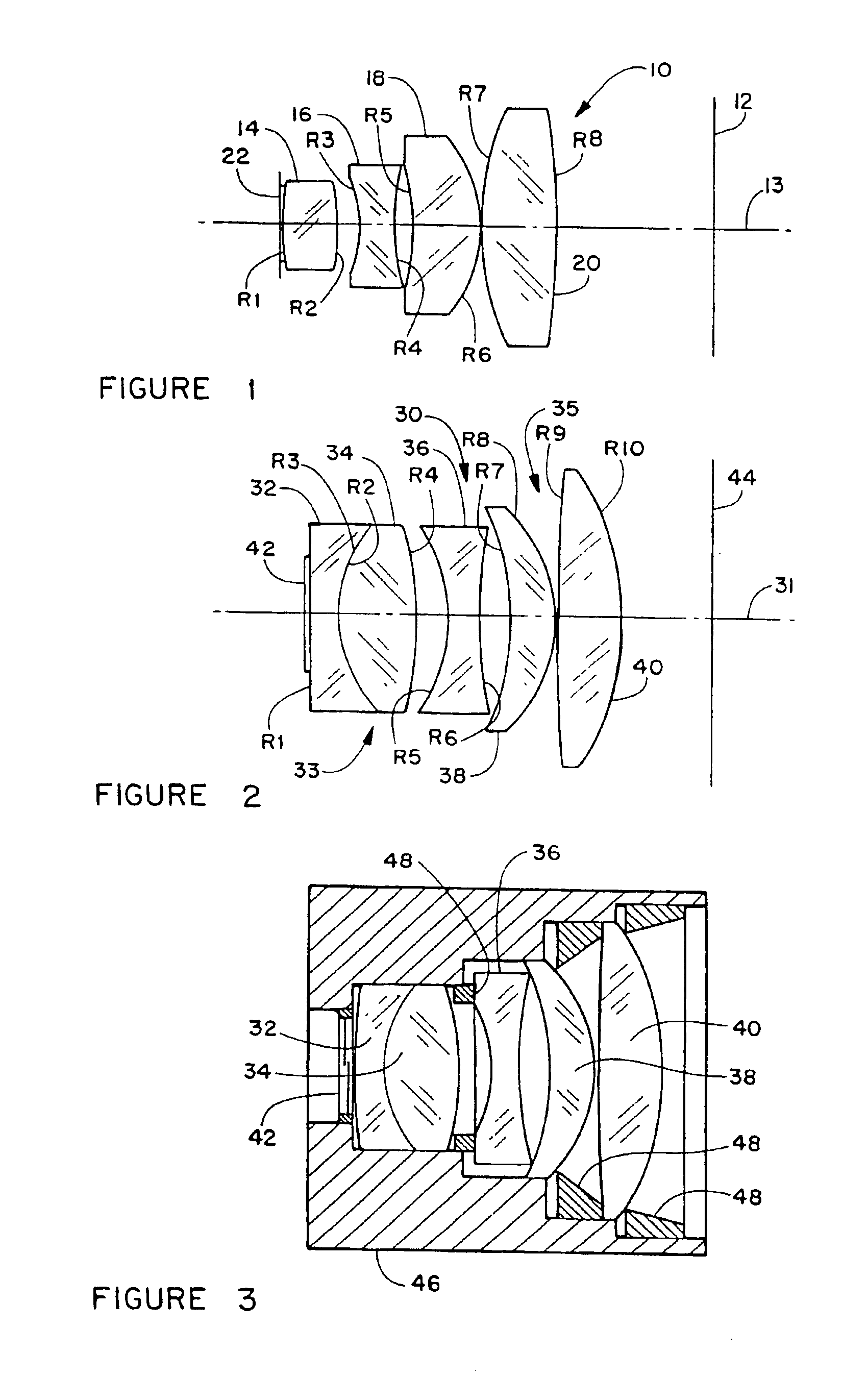

[0024]Referring to FIG. 1, there is seen a schematic axial section view of a lens assembly 10 for forming an image at a image plane 12, which in a digital cameral is the sensor plane and in a film type camera is the film plane. The front or distal end of the lens is to the left in FIG. 1. Line 13 represents the lens optical axis.

[0025]The lens assembly 10 includes a bi-cover distal lens element 14 and a proximal lens group including a first bi-concave element 16, a second meniscus element 18 and a third bi-convex element 20. The aperture stop plane is schematically indicated by line 22, closely adjacent to distal lens element 14. Distal element 14 provides most of the focussing power while the proximal group of elements 16, 18 and 20 provides aberration compensation to correct for any optical imperfections present in element 14. Any suitable spacing between lens elements may be used. Aperture stop 22 is preferably as close to distal element 14 as is practical. Overall length from ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com