Interlocking segmented coil array

a coil array and segmented coil technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/form/construction, magnetic bodies, etc., can solve the problems of reducing the efficiency of motors and reducing the magnetic flux density, so as to maximize the total length of working conductors, minimize the thickness of coils and magnet flux gaps, and provide electromotive interaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

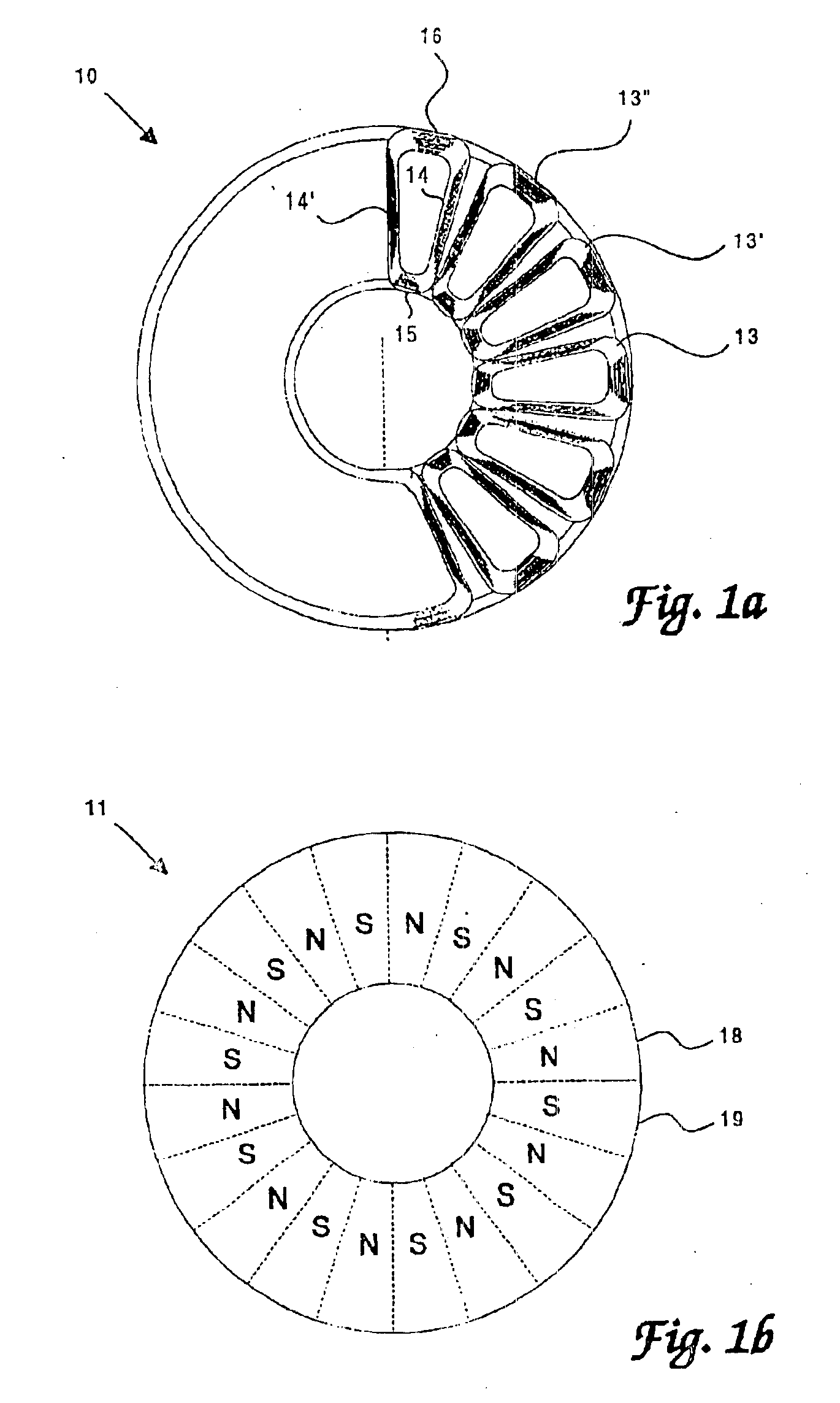

[0018]Referring now to the drawings and particularly to FIG. 1, there is shown a prior art planer coil assembly 10 and a magnet rotor 11 which may be used to make a typical prior art disc-type motor. This coil assembly 10 consists of several individual coils 13, 13′, 13″ arranged in a circular pattern, each coil 13 having two radially extending conductor portions or legs 14, 14′, an inner circumferentially extending leg 15 and an outer circumferentially extending leg 16, all lying in a single plane. In a motor utilizing such a coil assembly, the magnet rotor 11, having alternating North / South poles 18, 19 arranged in a corresponding circular pattern and affixed to a central shaft (not shown), rotates in a plane closely adjacent to, but spaced slightly above and / or below, the plane containing the coils 13, 13′, 13″. While two magnet rotors 11 may be used, one on either side of the coil assembly 10, only one may be used if a magnetic flux return, such as a soft iron disc (not shown), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com