Modular SMIF pod breather, adsorbent, and purge cartridges

a module and smif pod technology, applied in the field of smif pods, can solve the problems of ineffective filtering cartridges, substantially interfering with 1 m geometry semiconductor devices, and particle sizes with these sizes can be very damaging in semiconductor processing, etc., to achieve the effect of convenient and quick insertion and removal, economical, time and space efficient, and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

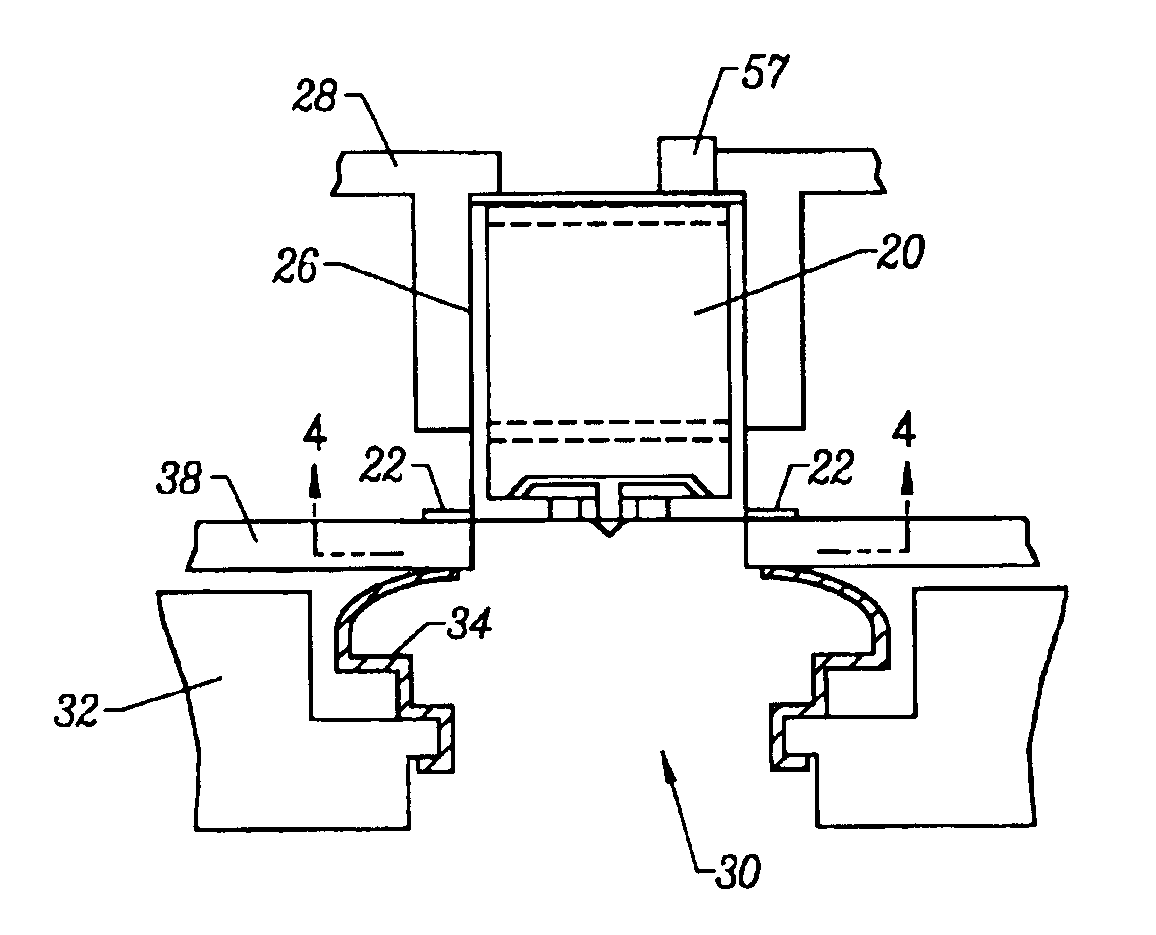

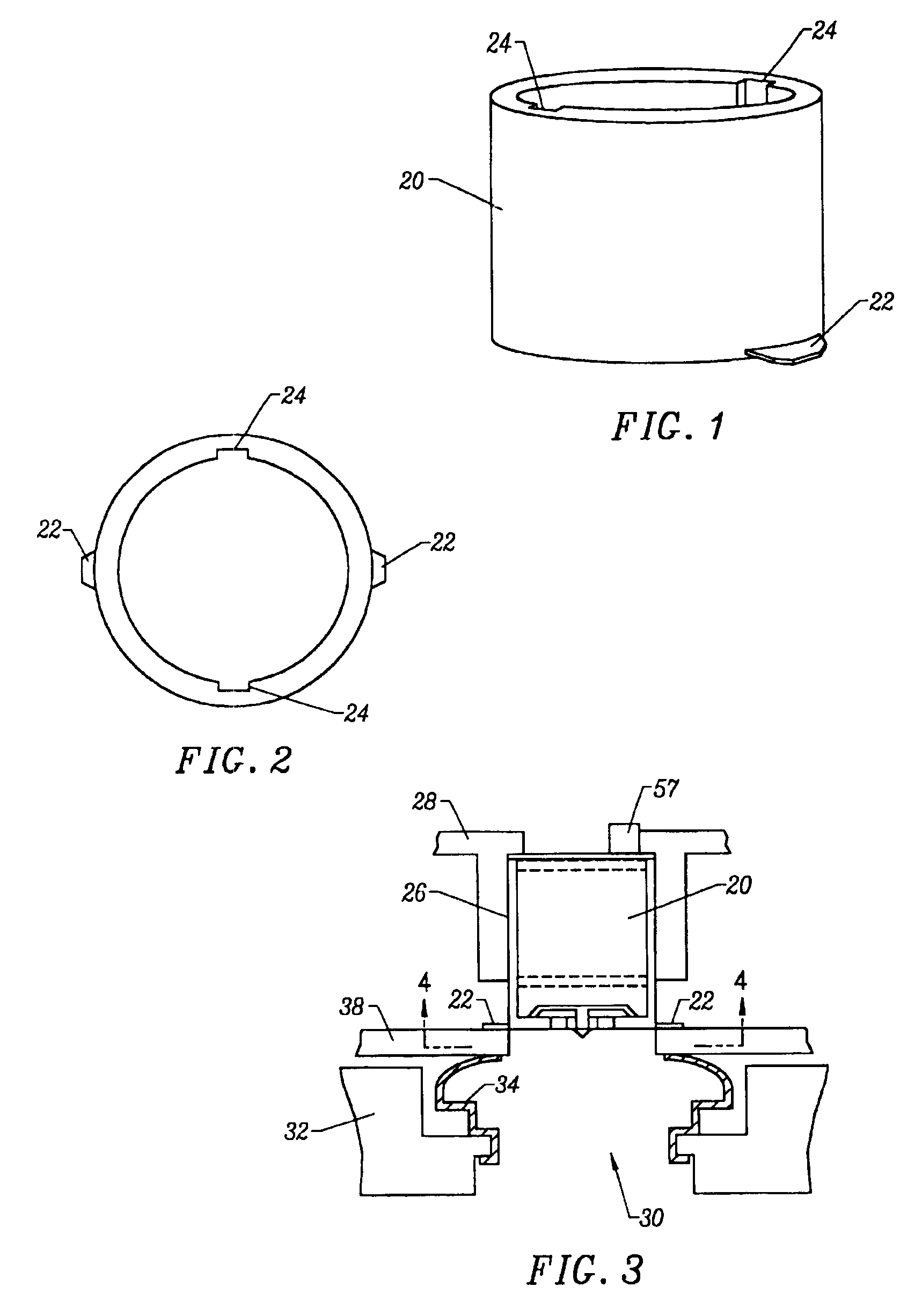

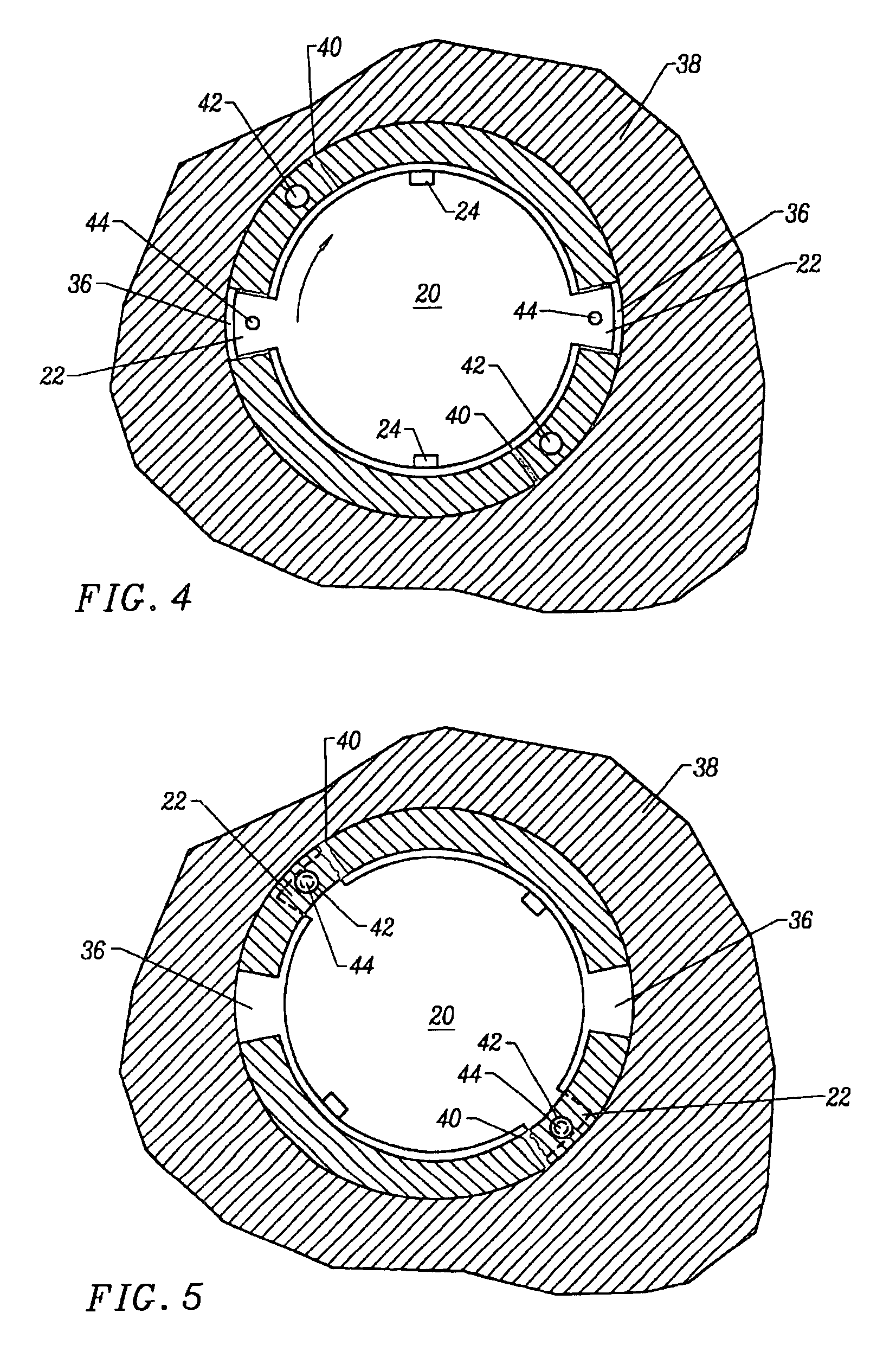

[0034]The present invention will now be described with reference to FIGS. 1-8 which in general relate to a cartridge including various configurations of valves, filters, and / or conditioning agents, which cartridge may be inserted into and removed from a receptacle on a bottom portion of a SMIF pod. It is understood that the cartridges according to the present invention may be utilized with pods of various sizes including 200 mm and 300 mm pods. Moreover, it is understood that the contents of the pods are not critical to the present invention and may include such substrates as semiconductor wafers, reticles, and flat panel displays. It is further understood that the present invention complies with and allows compliance with all applicable SEMI standards.

[0035]Referring now to FIGS. 1 and 2, there is shown external perspective and top views, respectively, of a cartridge 20 according to the present invention. The outer housing of the cartridge 20 is preferably formed of a stable, rigid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle sizes | aaaaa | aaaaa |

| particle sizes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com