Masks for use in optical lithography below 180 nm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

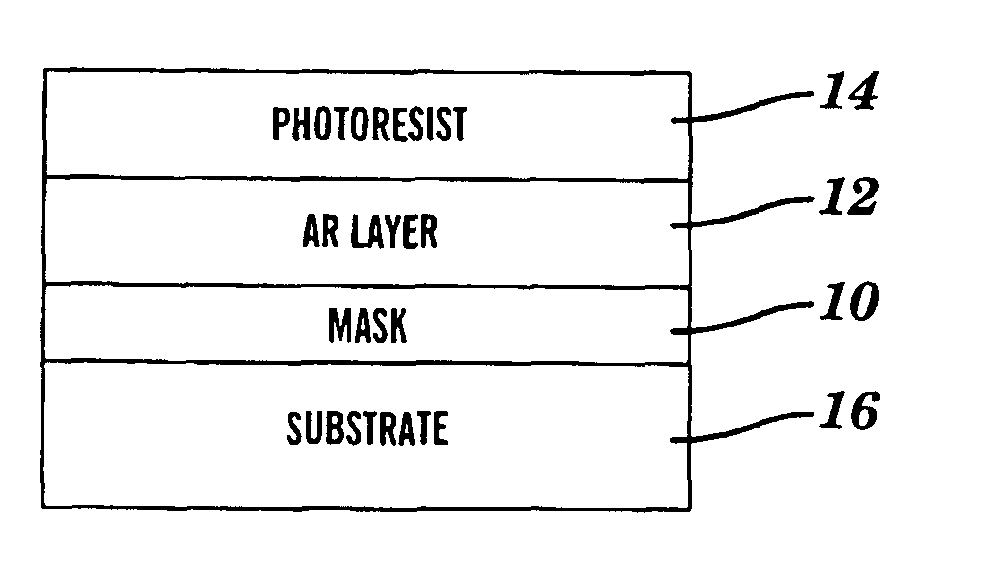

[0024]A mask film 10 for use in optical lithography at or below about 180 nm in accordance with one embodiment of the invention as illustrated in FIG. 10. The mask 10 has an optical density of at least about 4.0 for wavelengths at or below about 180 nm and a thickness of about 1000 angstroms or less. The present invention provides a number of advantages including providing a mask 10 which has suitable optical properties for lithography at or below about 180 nm and has suitable etch characteristics.

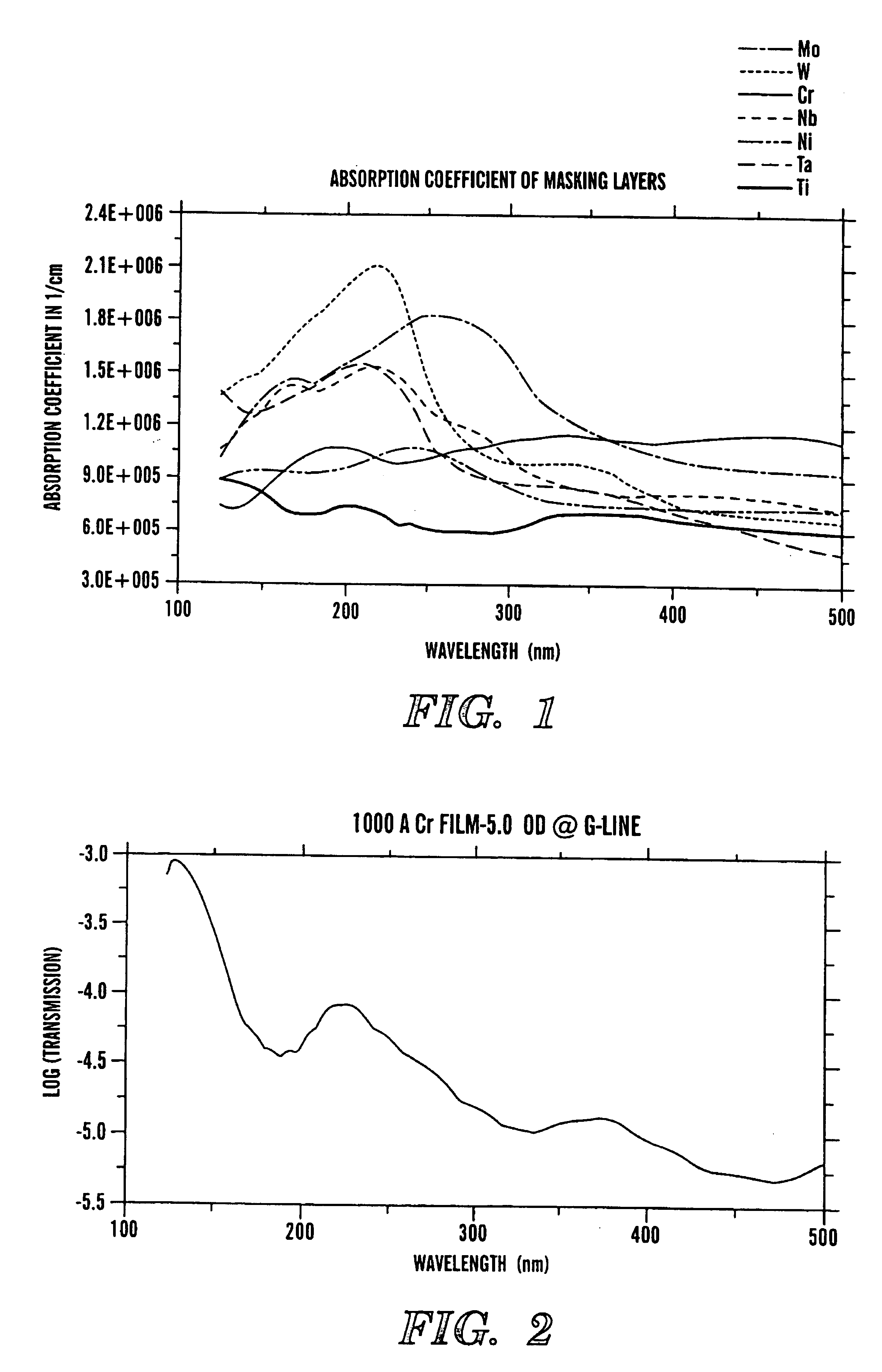

[0025]Referring to FIG. 1, the absorption coefficients (1 / cm) for molybdenum (Mo), tungsten (W), chromium (Cr), niobium (Nb), nickel (Ni), tantalum (Ta), and titanium (Ti) metals at wavelengths from 110 nm to 500 nm are illustrated. As discussed in greater detail earlier in the background with reference to FIGS. 1 and 2, chromium is a good choice for use as a mask 10 for wavelengths ranging between about 193 nm to about 436 nm, but does not possess desirable optical properties as a mask 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com