Battery charger and battery charging method

a battery charger and charging method technology, which is applied in the field of battery charger and battery charging method for charging a battery, can solve the problems of reducing affecting the service life of the battery, so as to achieve the effect of suppressing the temperature ris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

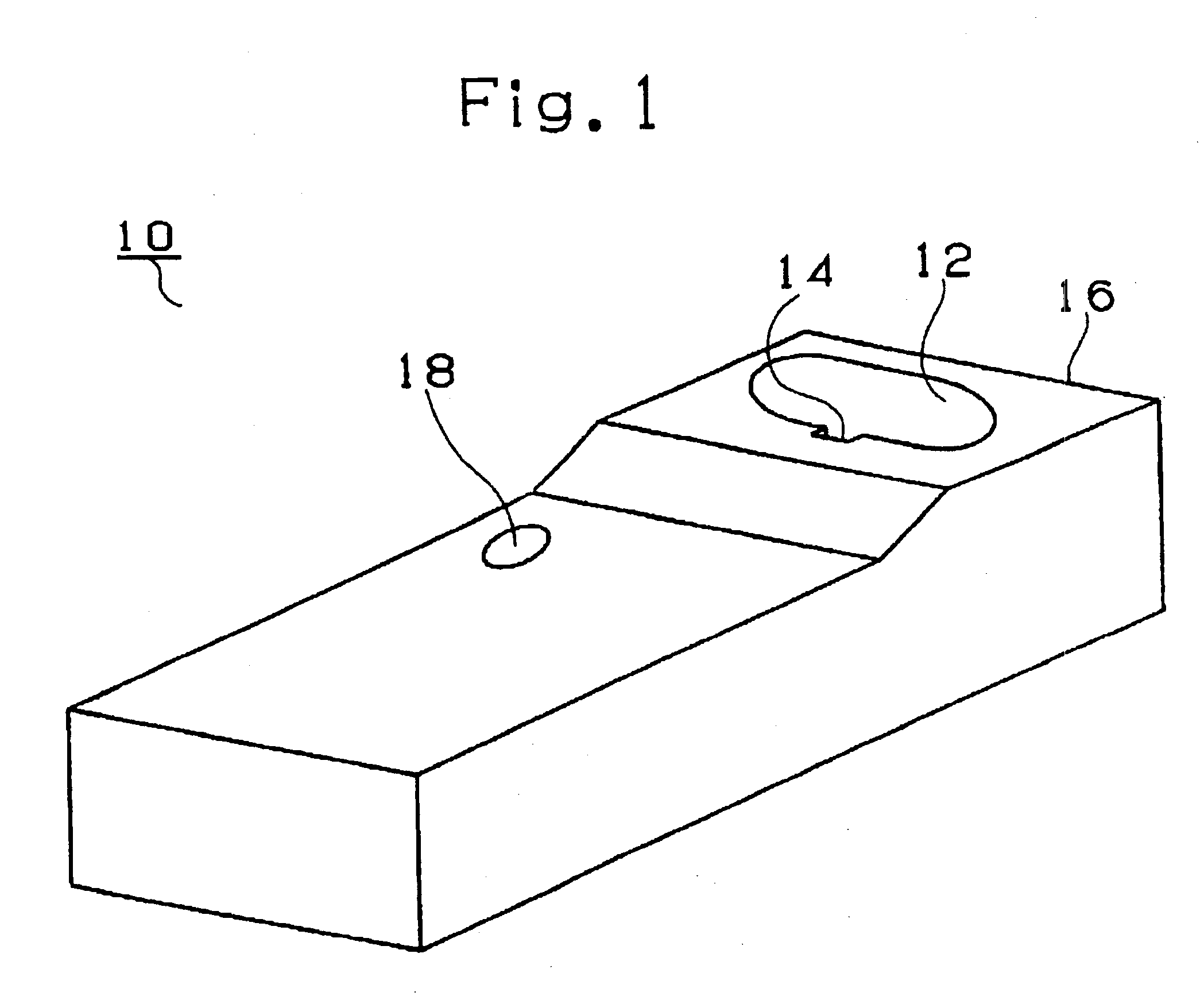

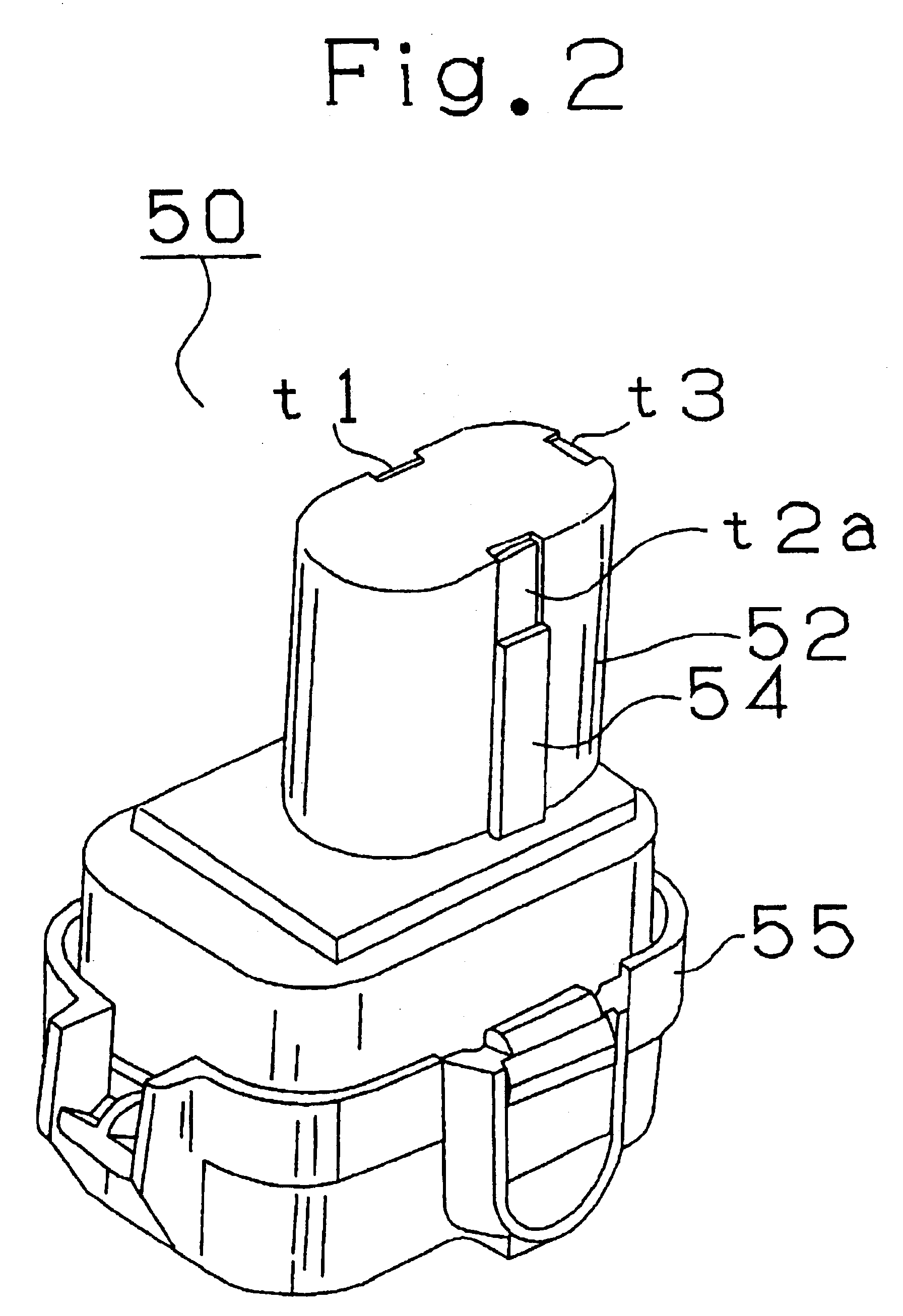

[0065]FIG. 1 shows a battery charger 10inof the present invention, FIG. 2 shows a battery pack 50 charged by the battery charger 10 and FIG. 3 shows a battery-powered drill 70 driven by the battery pack 50.

[0066]As shown in FIG. 2, the battery pack 50 containing a nickel metal hydride battery cell consists of a generally cylindrical fitted part 52 and a generally prismatic base 55. A key-shaped key part 54 is formed on the side of the fitted part 52 and the first input terminal t1 connected to the positive electrode of the battery, the second input terminal t2a connected to the negative electrode thereof and the third terminal t3 connected to a temperature sensor consisting of a thermistor are arranged on the upper portion of the fitted part 52.

[0067]As shown in FIG. 1, the battery charger 10 charging the battery packs 50 is provided with a fitting hole 12 into which the fitted part 52 of the battery pack 50 is fitted. A keyway 14 for introducing the key part 54 of the fitted part 5...

second embodiment

[0092]The specific charge control of the battery charger in the second embodiment will be described with reference to FIG. 12.

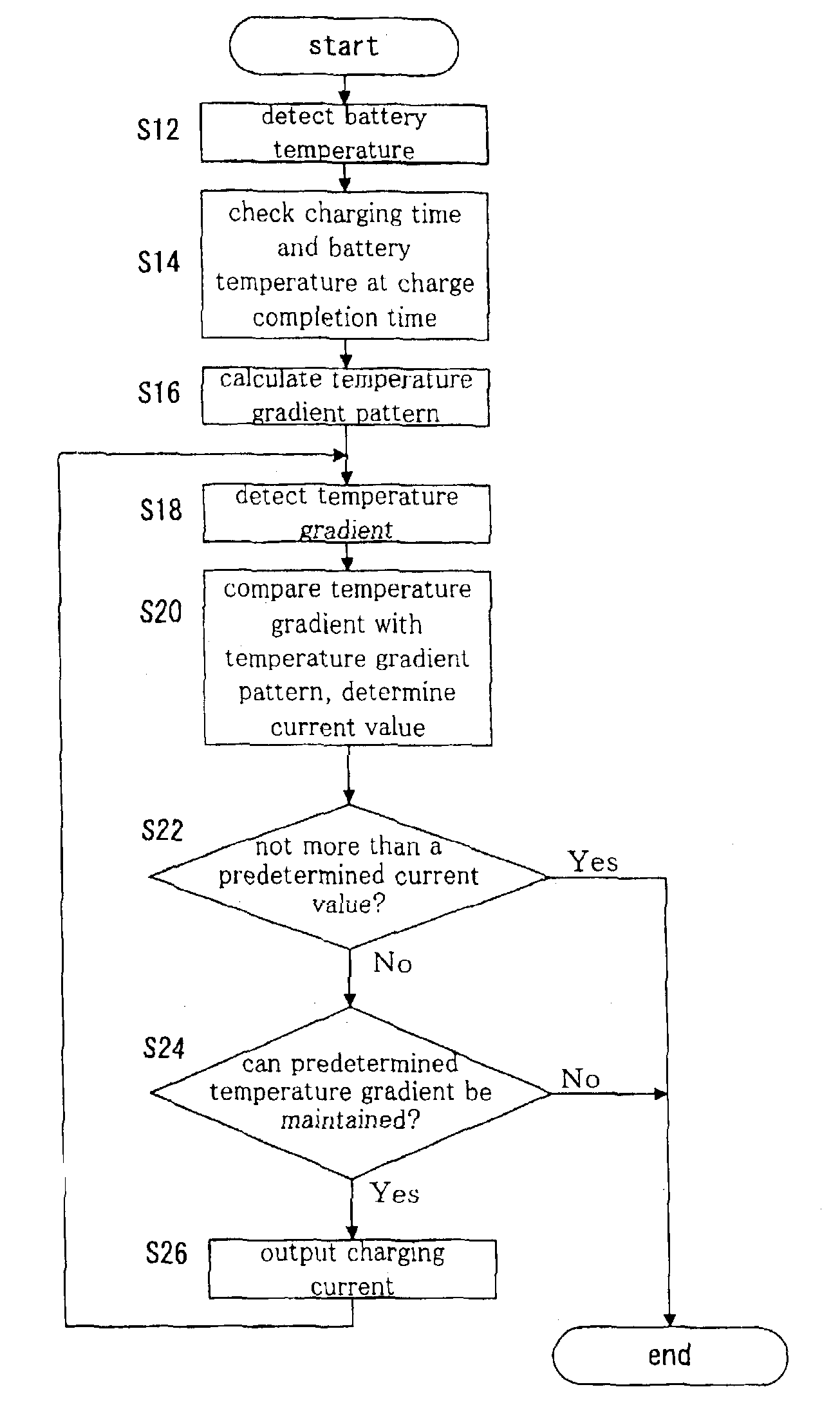

[0093]First, the control section 136 detects the temperature of the battery pack 150 from the temperature detecting section 138 (in S112). Here, it is assumed that outside air temperature is 20° C. and battery temperature is 25° C. Next, charging time and battery temperature at the time of the completion of charge are checked (in S114). In this case, when charging time is 20 minutes, the final temperature rise value of 35 degrees (30 deg+5 deg) is obtained. Thereafter, a temperature rise pattern is calculated (in S116).

[0094]The control section 136 differentiates the difference between the temperature value inputted from the previous temperature detecting section and the temperature value inputted this time and obtains a temperature rise value (in S118). The control section 136 then compares this detected temperature rise value with the temperature rise patte...

third embodiment

[0098]Next, a battery charging method in the third embodiment according to the present invention will be described with reference to FIGS. 13 to 15.

[0099]In the second embodiment stated above, the battery charger holds the charging time and final battery temperature rise values shown in FIG. 10. In the third embodiment, by contrast, a battery pack holds border lines each indicating the final temperature when battery charge is completed at the lowest temperature described above with reference to FIG. 9. Namely, the final temperature which the battery reaches when it is completed with charge differs depending on the voltage of the battery pack (the number of battery cells), the type of the battery (nickel metal hydride batteries may have different characteristics), the heat radiation characteristics of the battery pack and the like. Due to this, the battery charger in this embodiment is intended to be capable of charging any battery pack most efficiently by making the battery pack hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com