Methods for growing semiconductors and devices thereof from the alloy semiconductor GaInNAs

a technology of alloy semiconductors and gainnas, which is applied in the direction of crystal growth process, semiconductor laser, polycrystalline material growth, etc., can solve the problems of inability to achieve previously conceived not feasible by devices, and difficulty in obtaining nitrogen-containing iii-v alloy semiconductors with a large concentration of nitrogen, etc., to achieve excellent crystalline quality, low dissociation temperature, and high nitrogen conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

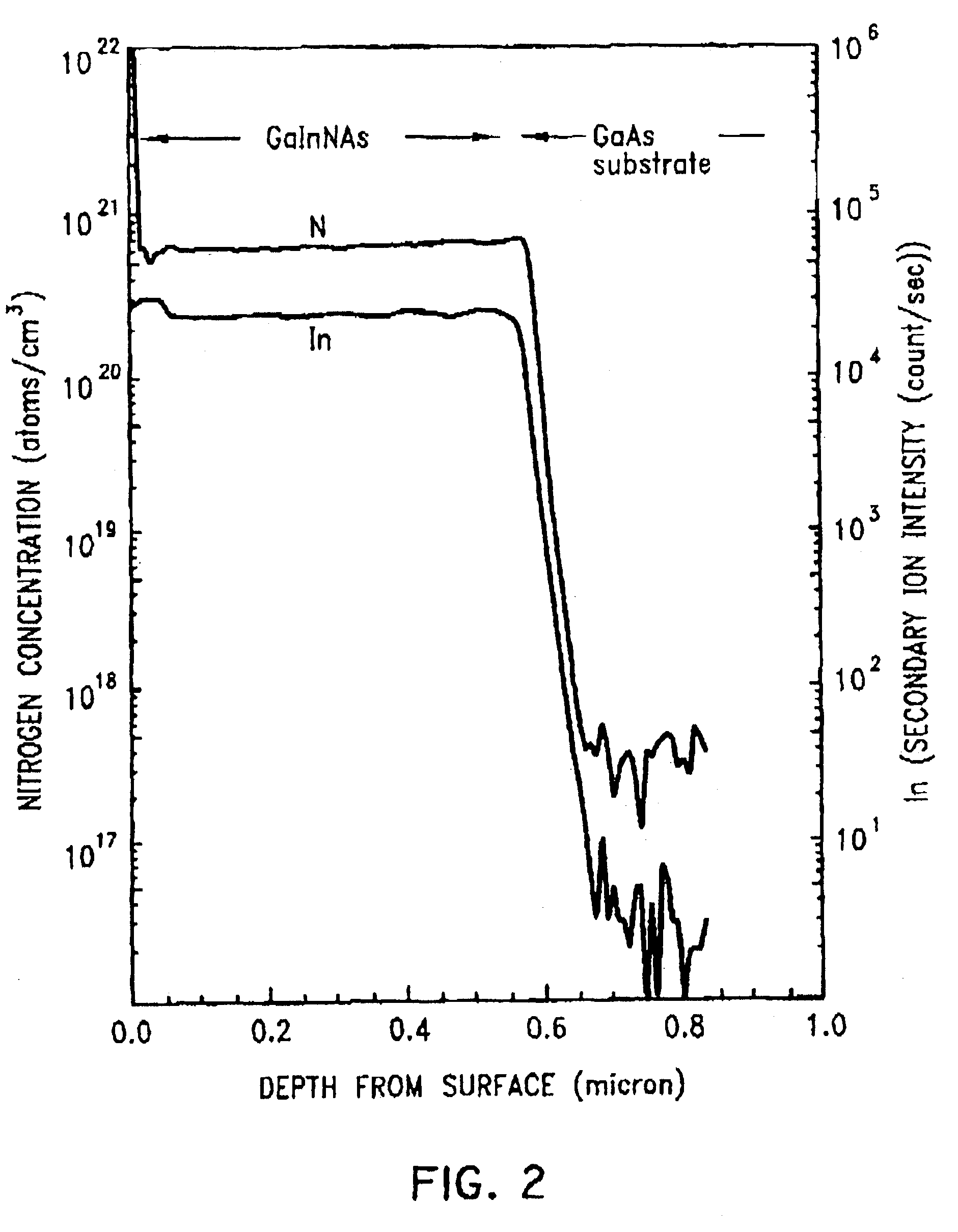

[0047]Layers of a GaInNAs alloy semiconductor of the present invention were grown on a GaAs substrate in accordance with steps which follow.

[0048]As source materials for group III element, trimethylgallium (TMG), triethylgallium (TEG), trimethylindium (TMI), or triethylindium (TEI) was used. Also used as source materials were AsH3 for arsenic, and dimethylhydrazine (DMHy), monomethylhydrazine (MMHy), or tertiary butyl amine (TBA) for nitrogen.

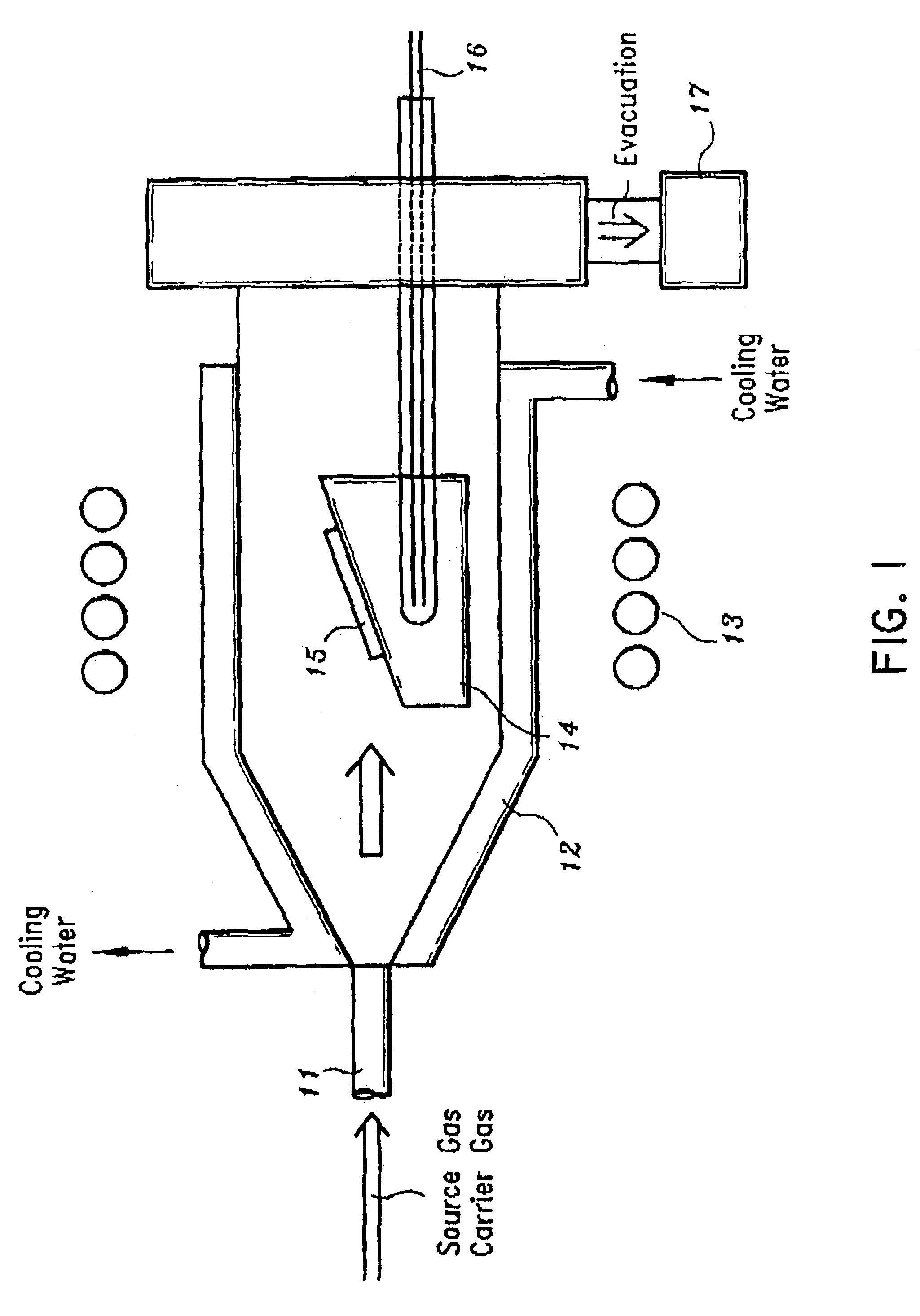

[0049]As illustrated in FIG. 1, gaseous components from these materials were introduced to a water-cooled quartz reactor 12 through a gas inlet 11. Prior to the introduction of the gaseous species, the reactor was evacuated to a pressure of 1.3×104 Pa. A carbon susceptor 14 was heated to an appropriate temperatures by a heating coil 13 fed with high frequency power and a GaAs substrate 15 was subsequently heated by the heat transfer from the susceptor 14. Source materials were dissociated by heating and resultant gaseous species from the source...

example 2

[0073]A light emitting device was fabricated using GaInNAs alloy layers for light emitting layers. FIG. 7 represents a sectional view of the device of the present embodiment.

[0074]The light emitting device comprises on an n-type (or n-) GaAs substrate 41, an n-Al0.4 Ga0.6 As cladding layer 42, a GaInNAs active layer 43, a p-Al0.4 Ga0.6 As cladding layer 44, and a p-GaAs contact layer 45, each formed by MOCVD method from the bottom in the order stated. Additionally provided for the device were a positive electrode 46 on the p-GaAs contact electrode 45 and a negative electrode 47 on the rear side of the n-GaAs substrate 41, whereby constituting a light emitting device of the broad stripe type construction.

[0075]The GaInNAs active layers were grown so as to be lattice-matched to GaAs lattice under the same conditions as those adopted in embodiment 1. As aforementioned, the GaInNAs layers do not have to be completely lattice-matched and may be in the strained lattice structure as long a...

example 3

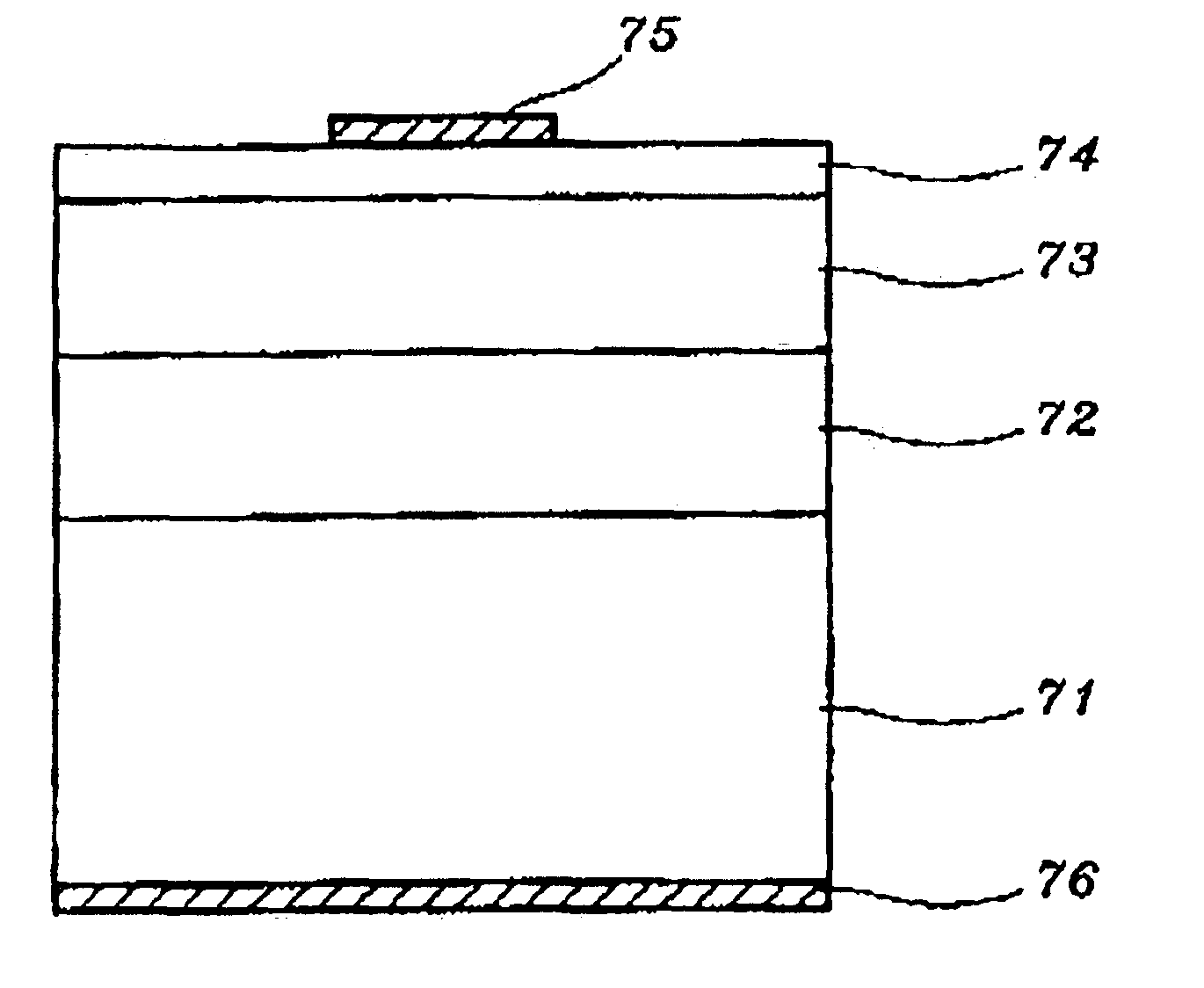

[0079]Although, there was described in embodiment 2, a light emitting device which was constituted of GaInNAs active layer and had a double heterostructure, a light emitting device comprising also a GaInNAs active layer and having the homo-junction or single heterostructure, may also be fabricated. FIG. 8 represents a sectional view of a light emitting device having a homo-junction structure of embodiment 3.

[0080]The light emitting device comprises, an n-GaInNAs layer 72, a p-GaInNAs layer 73, and a p-GaAs contact layer 74, disposed by MOCVD method on an n-GaAs substrate 71 in the order stated. Additionally provided for the device were a positive electrode 75 on the p-GaAs contact layer 74 and a negative electrode 76 on the rear side of the n-GaAs substrate 71.

[0081]The present GaInNAs layer was grown so as to be lattice-matched to the GaAs lattice under the same conditions as those adopted in embodiment 1. Also in the present growth, an AsH3 partial pressure was 50 Pa which was hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| partial pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com