Compensation method and device for tracking operation of optical storage system

a technology of optical storage system and compensation method, which is applied in the direction of digital signal error detection/correction, instruments, recording signal processing, etc., can solve problems such as runout associated, and achieve the effect of speeding up tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

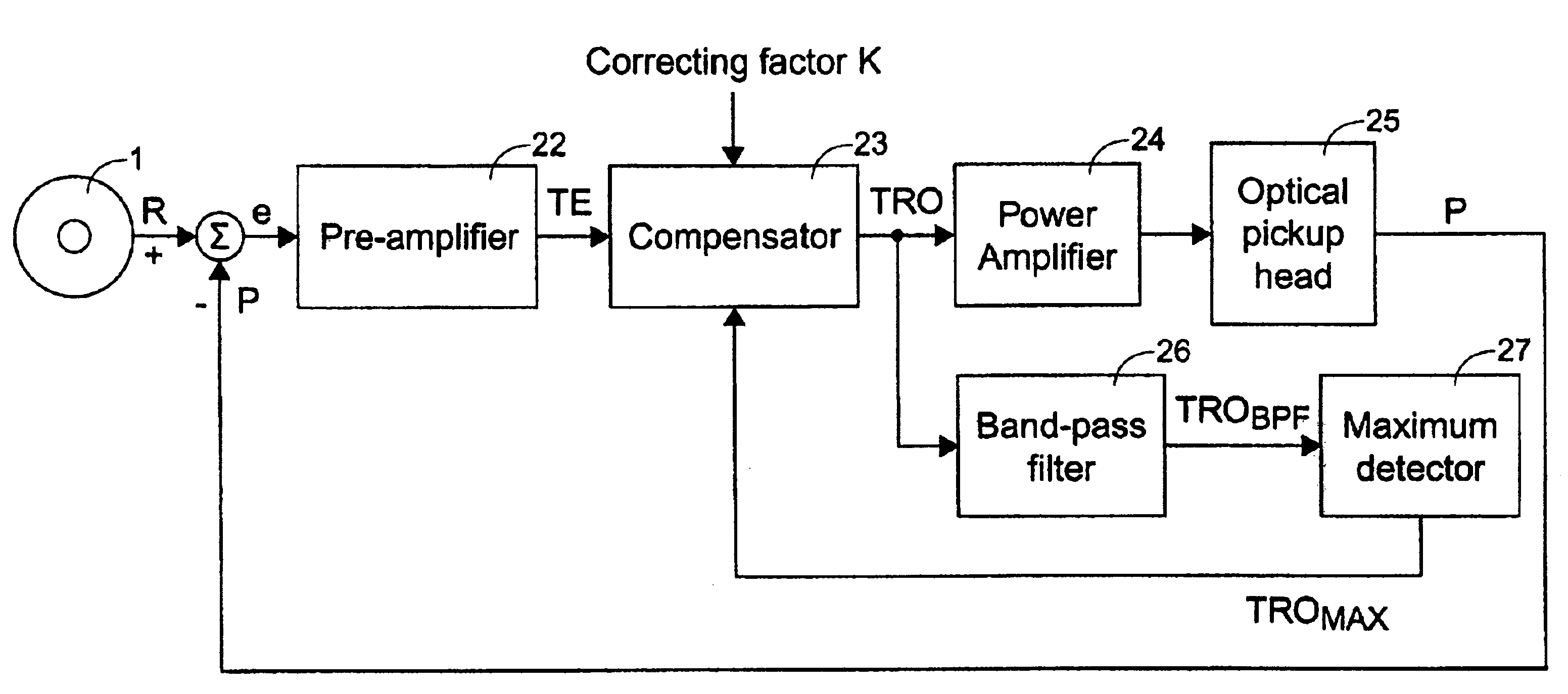

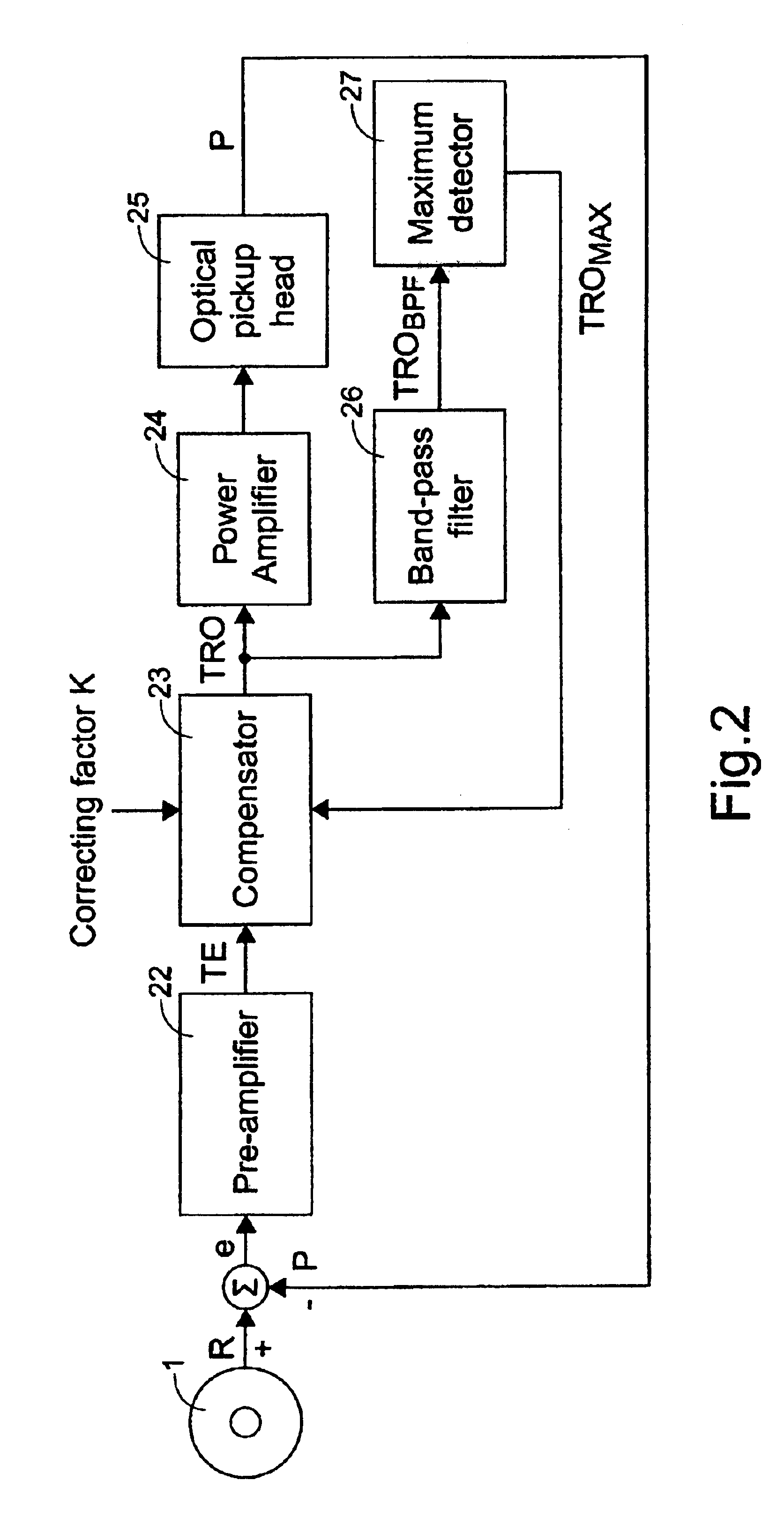

[0030]Please refer to FIG. 2, which illustrates an optical storage system according to a preferred embodiment of the present invention. The optical storage system of FIG. 2 is a control device of an optical disc drive, which includes a pre-amplifier 22, a compensator 23, a power amplifier 24, an optical pickup head 25, a band-pass filter 26, and a maximum detector 27. The optical pickup head 25 picks up data from an optical disc 1. During operation, an error signal e between the position P of the optical pickup head 25 relative to the disc and the runout R is processed by the pre-amplifier 22 to generate a tracking error TE. The tracking error TE is transmitted to the compensator 23, e.g. a digital signal processor (DSP), to be processed into a tracking output signal TRO, which is next delivered into two separate paths for further processing. In a normal operation procedure, the pre-amplifier 22, compensator 23, power amplifier 24 and the optical pickup head 25 form a close loop, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| structures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com