Fasteners engageable with loops of nonwoven fabrics and with other open structures, and methods and machines for making fasteners

a non-woven fabric and loop technology, applied in the field of touch fasteners, can solve the problems of flexing and progressively peeling from the other, the effective loop height does not permit loading transition, and the effect of good peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

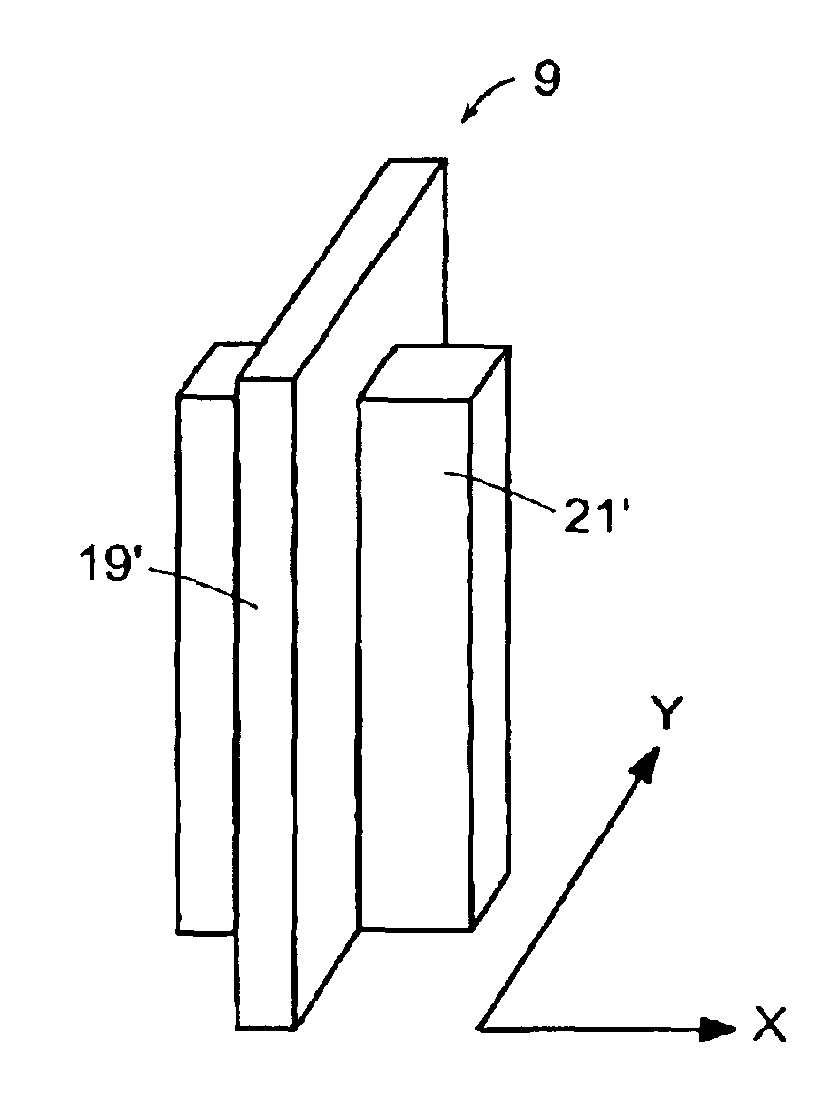

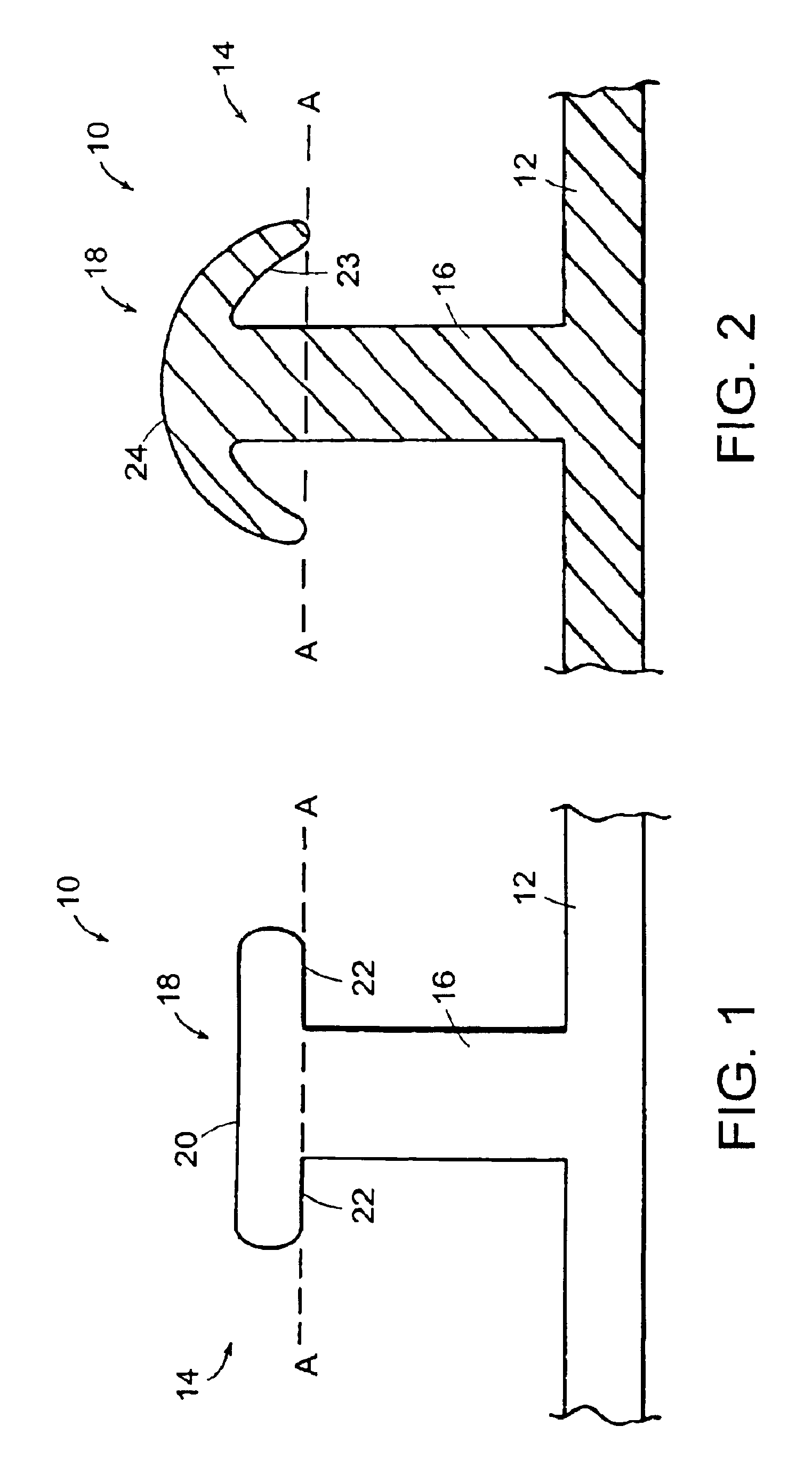

[0127]Referring to FIG. 1, fastener 10 includes a base 12 and a fastener element 14 extending from the base. (Fastener 10 generally includes an array of fastener elements; a single fastener element is shown for clarity.) Fastener element 14 includes a stem 16 and, at the terminal end of stem 16, a head 18. Head 18 is shaped for engagement with another fastener component, for example a female fastener component having a plurality of loops, a mesh such as an insect screen, or another fastener component similar to fastener 10.

[0128]As shown in FIG. 1, head 18 is substantially disc shaped, including a substantially planar top surface 20, and a substantially planar bottom surface 22 that faces and overhangs base 12. It is desirable that the disc be relatively thin, allowing a cooperating fastener element, e.g., a loop or the wire mesh of a window screen, to penetrate into the disc by flexing the disc material. Preferably, the thickness of the disc is from about 5 to 15% of the equivalent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| aspect ratio OAR | aaaaa | aaaaa |

| aspect ratio OAR | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com