Control module for flywheel operated hand tool

a control module and hand tool technology, applied in the direction of control systems, dc motor stoppers, manufacturing tools, etc., can solve the problems of inability or not desired, on-site air compressor, and often an impediment to the user's dragging pneumatic umbilical, so as to avoid human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

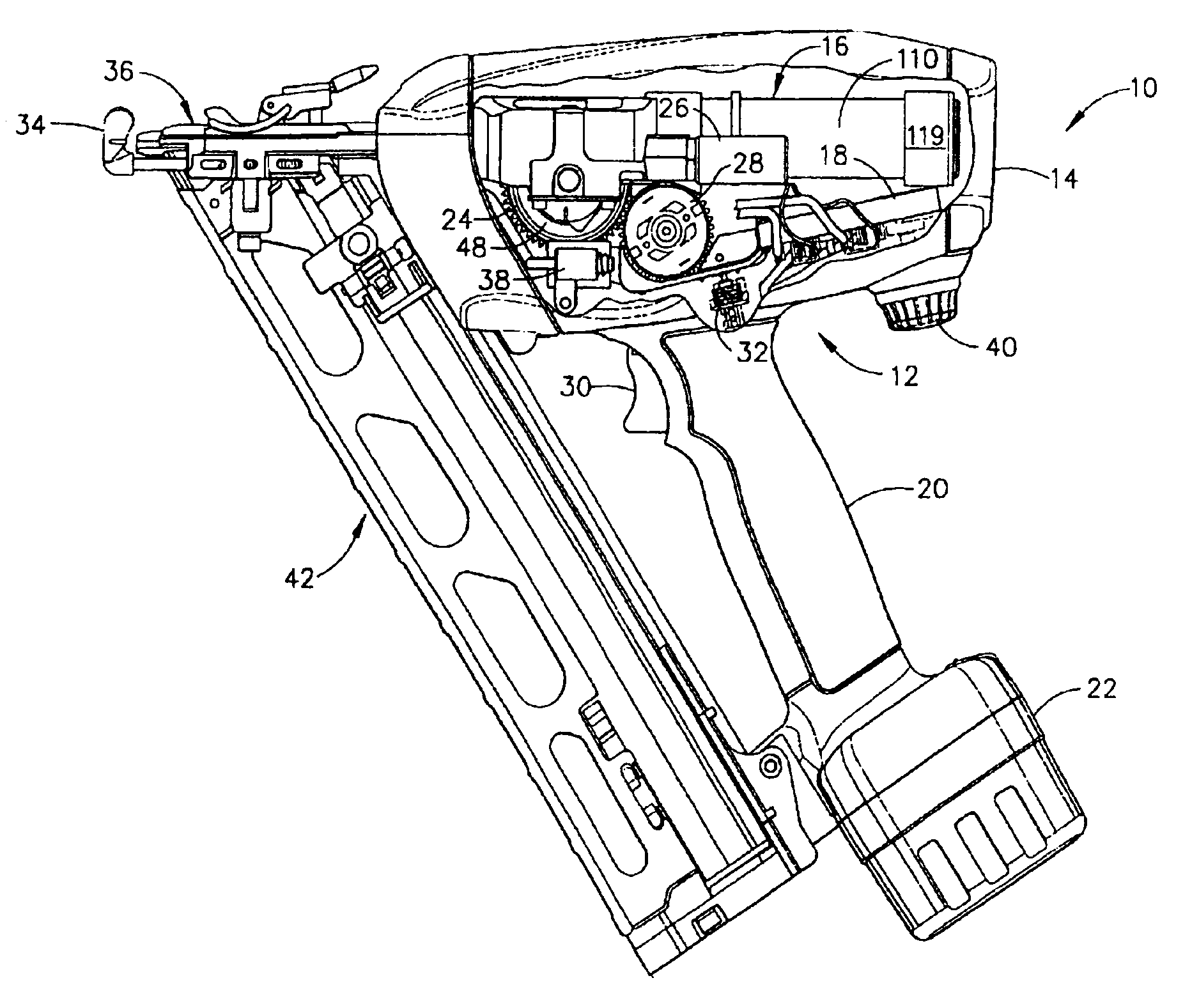

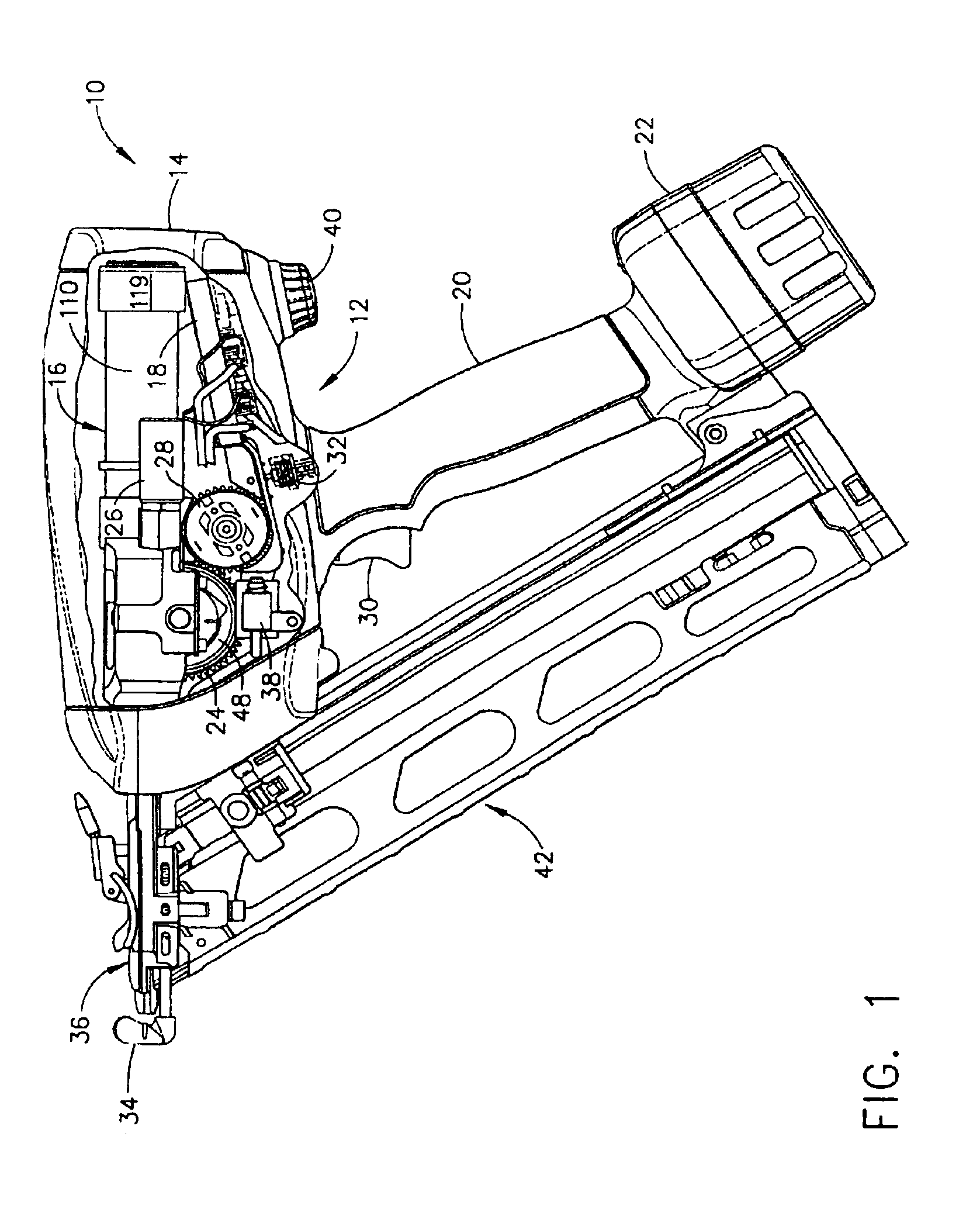

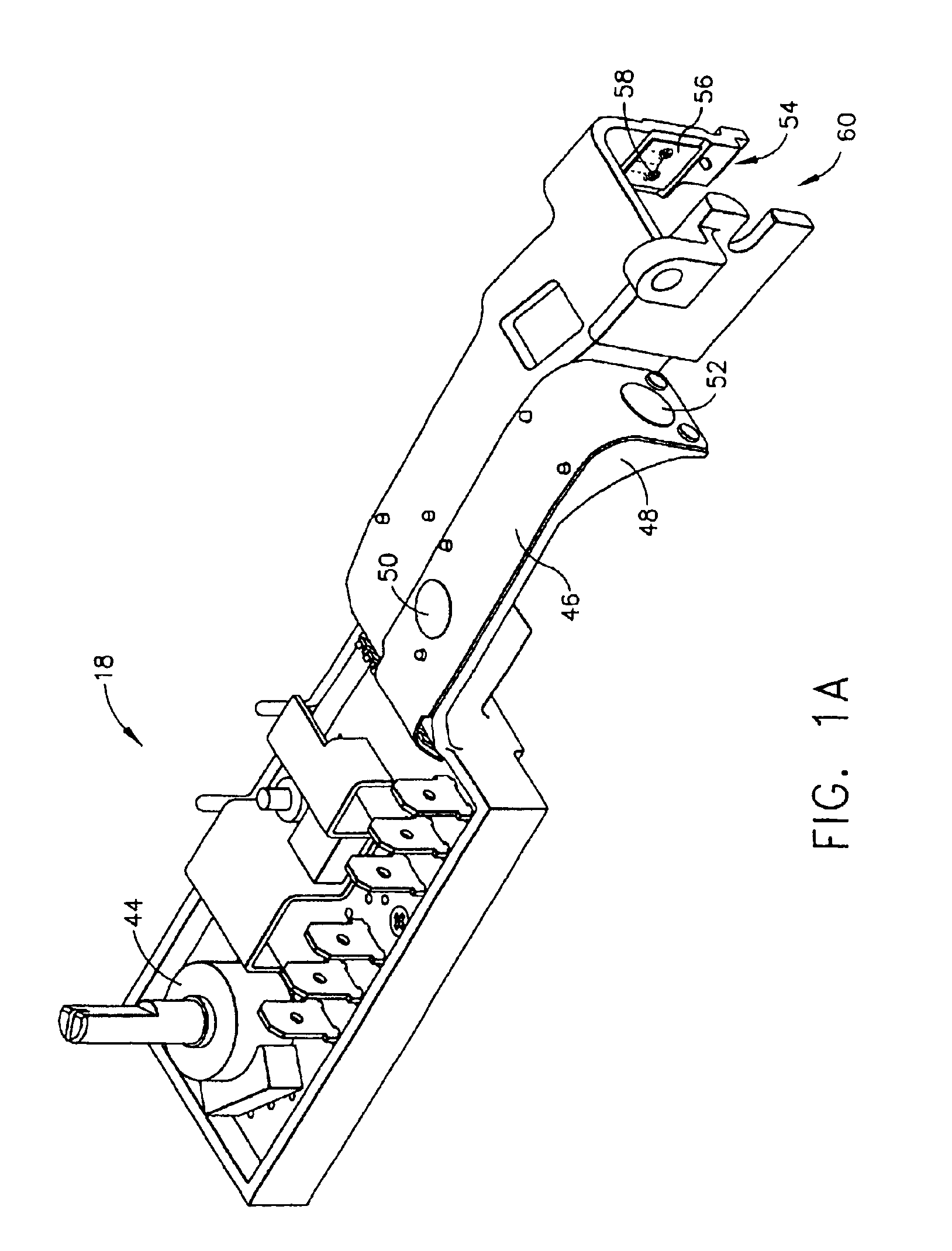

[0049]With reference to FIG. 1, wherein like numbers refer to like components throughout the several views, a portable flywheel operated hand tool, depicted as a hand-held nailing tool 10, includes a control system 12 that advantageously provides consistent speed control throughout a range of operating conditions. In particular, the nailing tool 10 generally comprises a housing or main body 14 enclosing a fastener drive assembly 16 and a control module 18, and further includes and a gripping handle 20. Attached to the end of handle 20 is a removable, rechargeable battery 22 for providing the necessary electrical energy to operate a DC motor 24 and a solenoid 26 of the fastener drive assembly 16, as well as the electrical control module 18. Unlike generally known batteries that are required to handle large current influxes (e.g., Nickel Cadmium), the present invention advantageously may utilize other types of batteries (e.g., Nickel Metal Hydride (NiMH), lithium Polymers).

[0050]The D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com