Full traction differential with hybrid gearing

a hybrid gearing and full traction technology, applied in the direction of gearing details, gearing, mechanical equipment, etc., can solve the problems of improper alignment of improperly positioned balance gears, and achieve the effect of improving the tooth contact pattern, increasing the effectiveness of torque transfer, and increasing the traction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

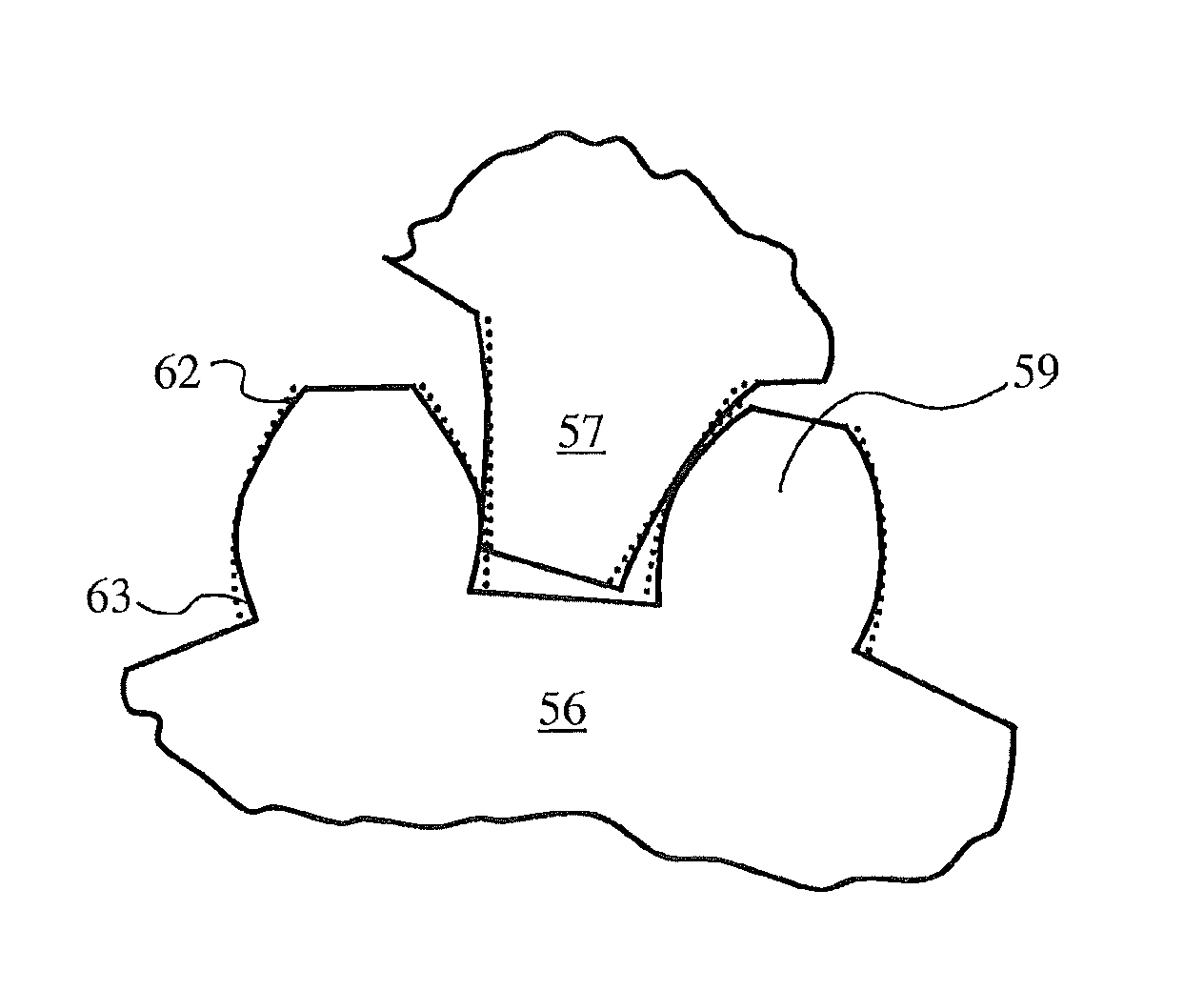

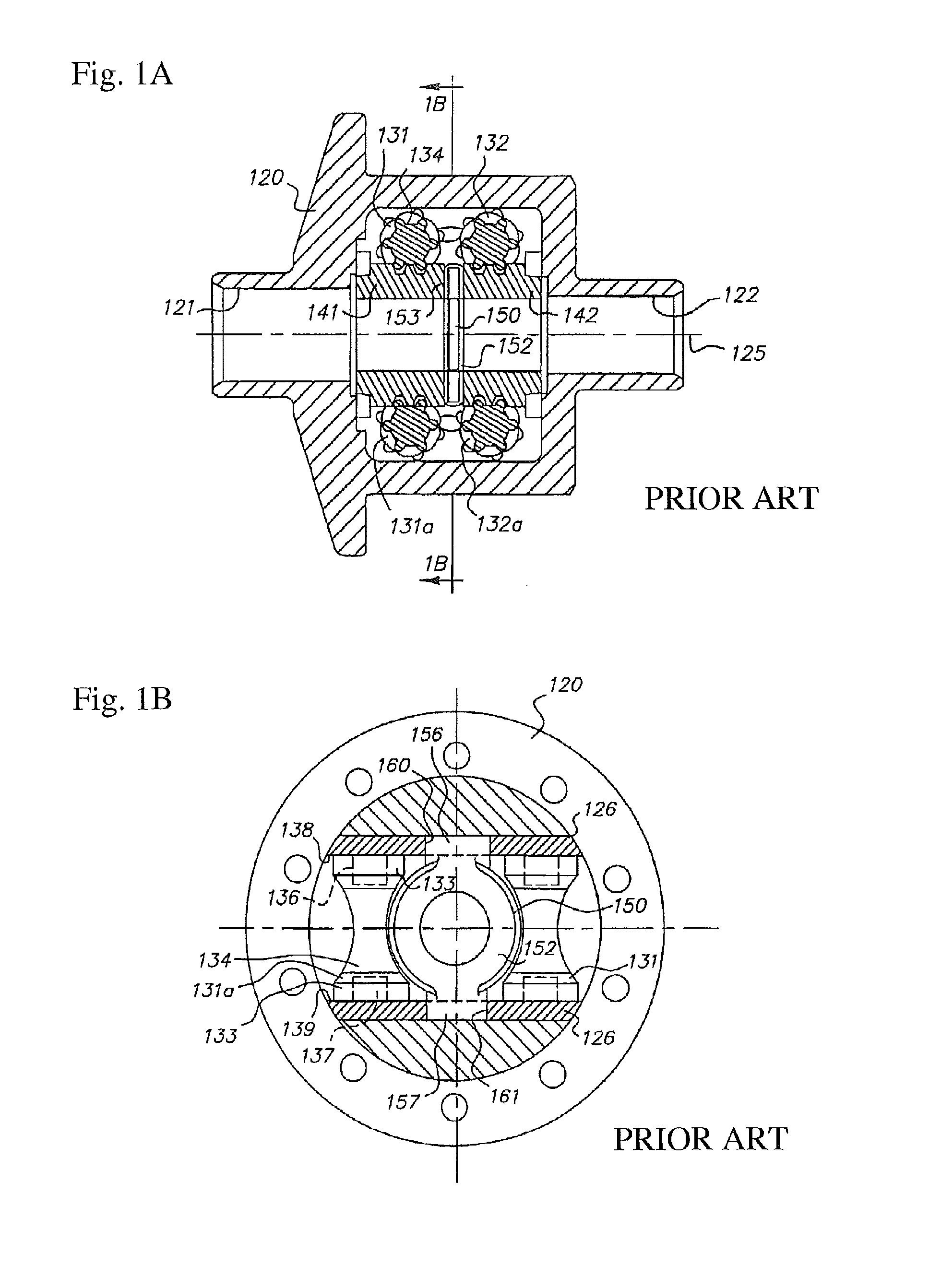

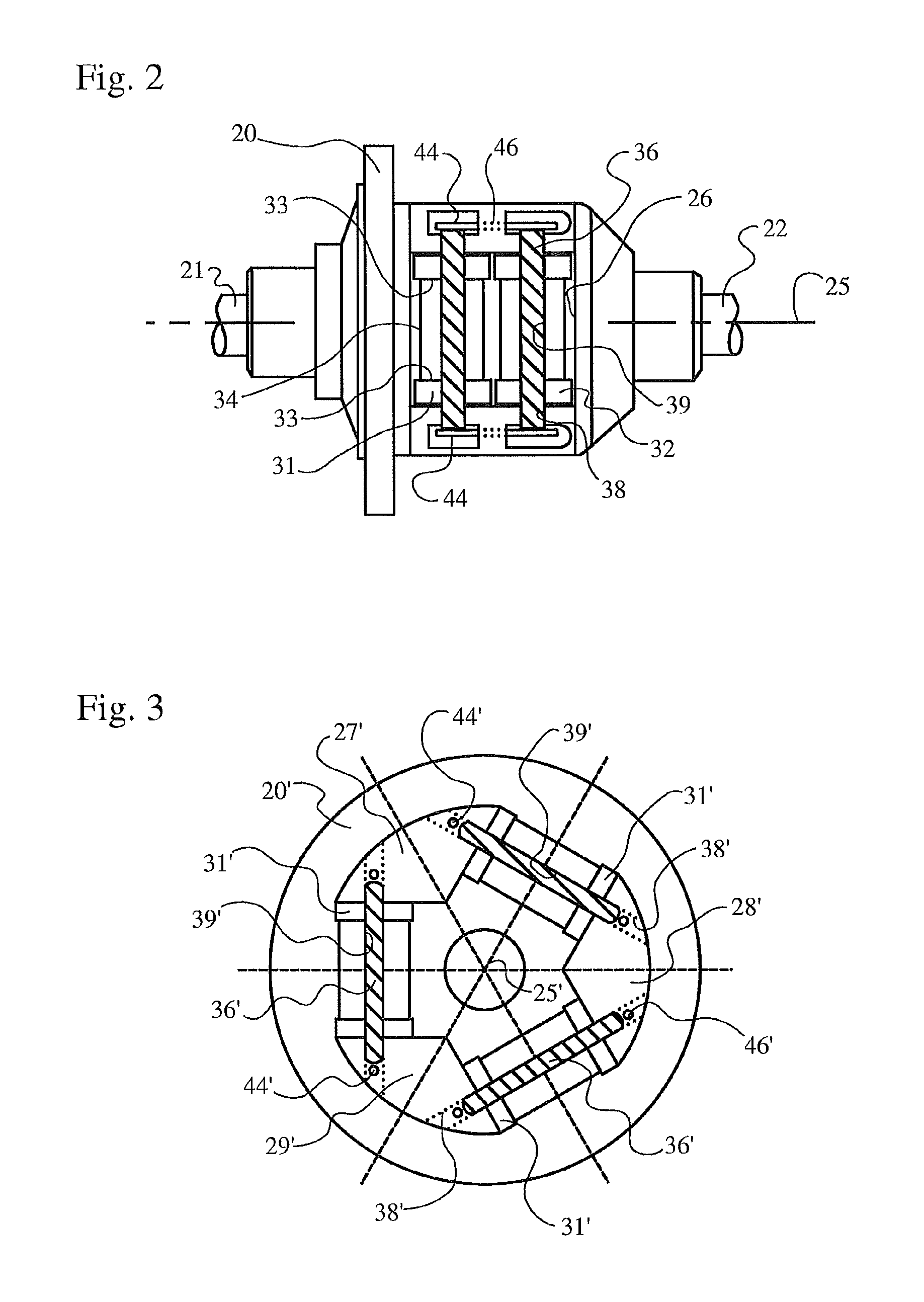

[0024]Preferably, the teeth of each side-gear worm have an involute profile but are cut with only plunge feed, while the teeth of the worm-wheel portions of the balance gears are helicoid worms having tip and root modifications made by a concave-shaped cutter. The side-gear worm teeth have a helix angle equal to or greater than 45° and significantly chamfered ends, and the gears are designed to provide a gear ratio between 1.5:1 and 2.5:1. The numbers of teeth in the (a) spur-gear portion and (b) worm-wheel portion of each balance gear, and (c) in each side-gear worm are all divisible by 2 or by 3, preferably by both 2 and 3. Further, any improperly positioned balance gear does not align properly with its respective mounting hole in the housing and, by merely rotating such a misaligned balance gear by one tooth in either direction, correct alignment and gear timing is achieved.

[0025]The new tooth design disclosed herein is best described as a “hybrid” between standard worm / worm-whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com