Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Oil Quenching Safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrosive vacuumizer pollution-discharge spraying-purification operation-observing/monitoring vacuum furnace

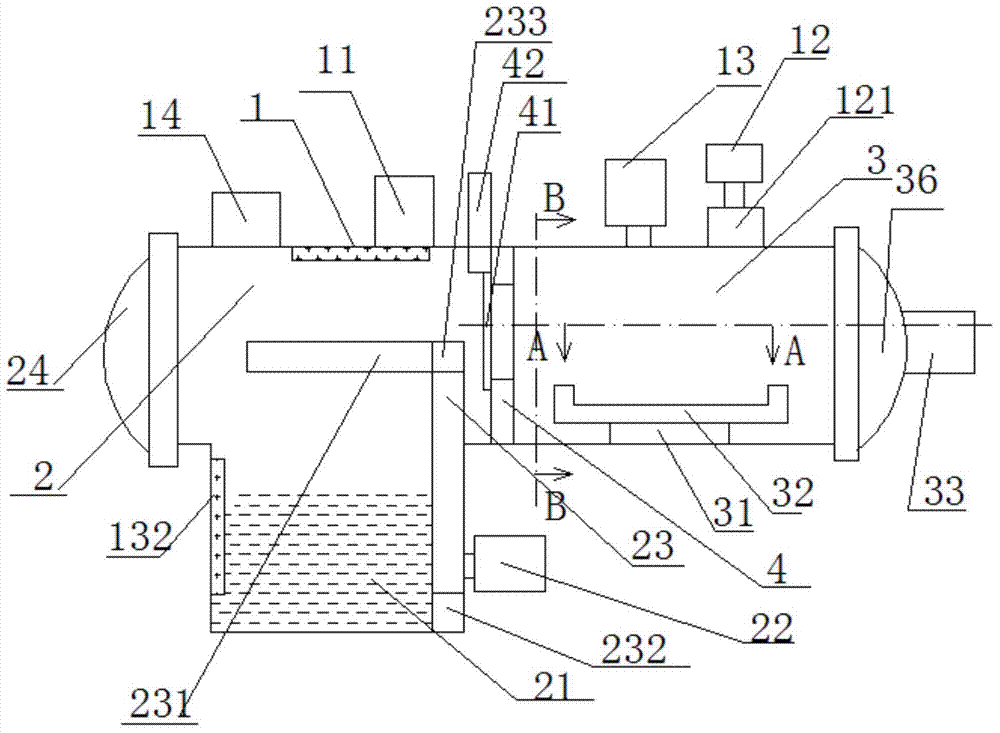

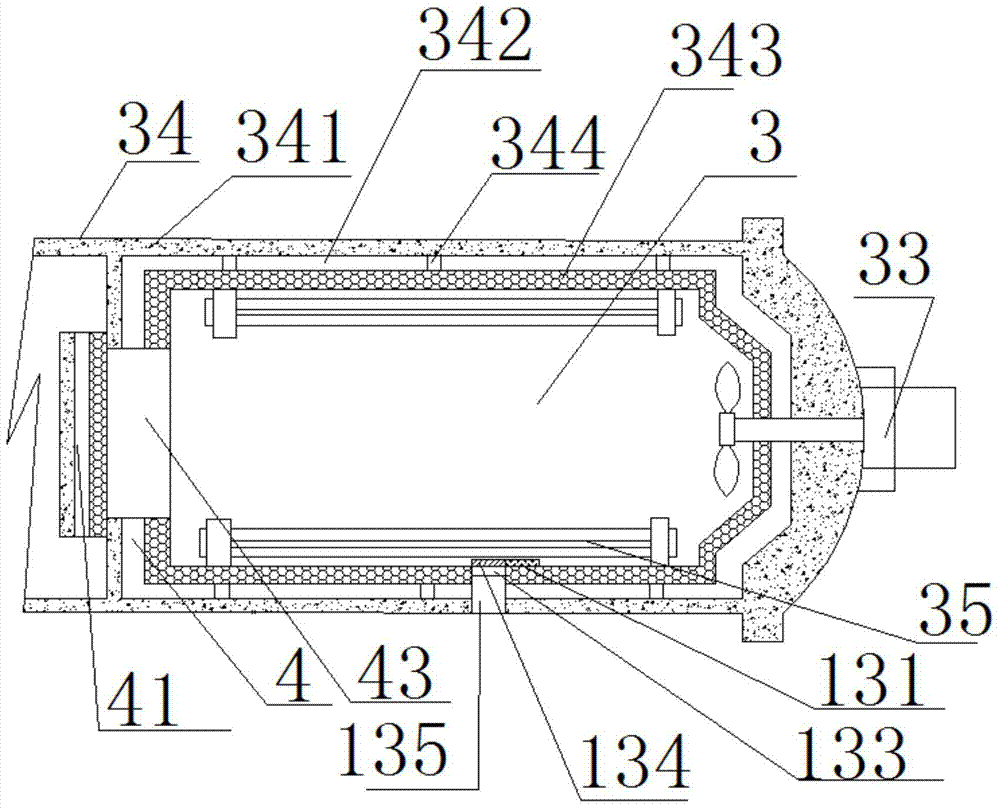

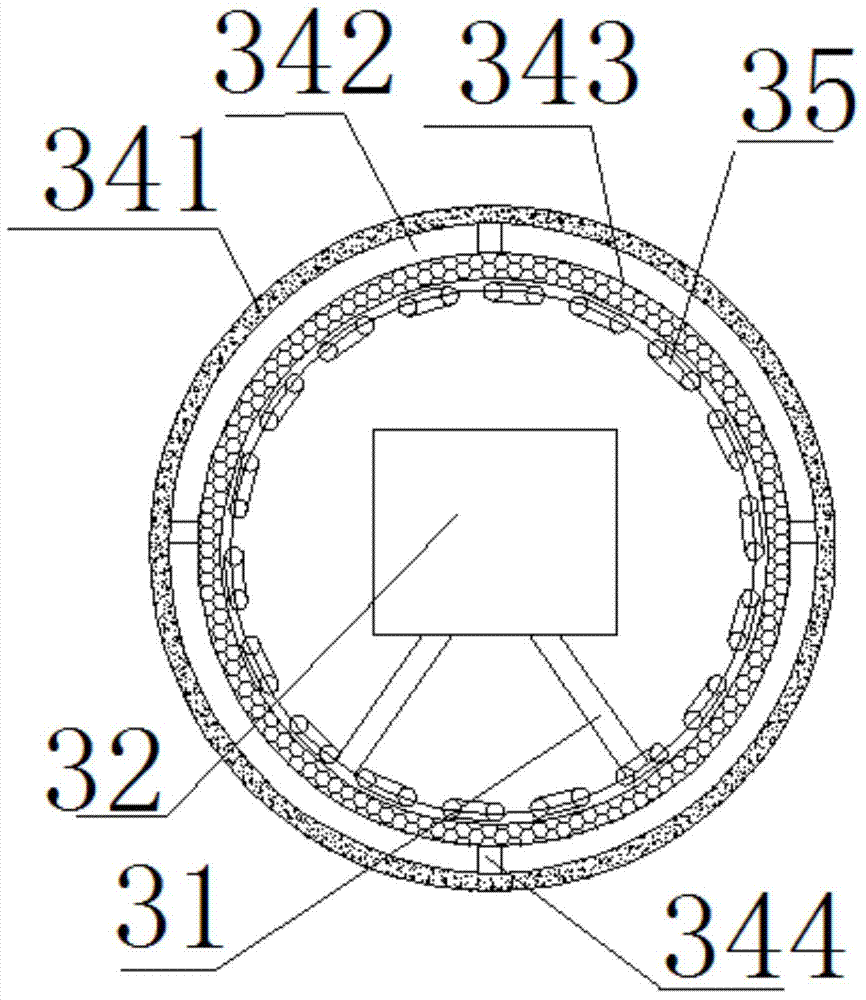

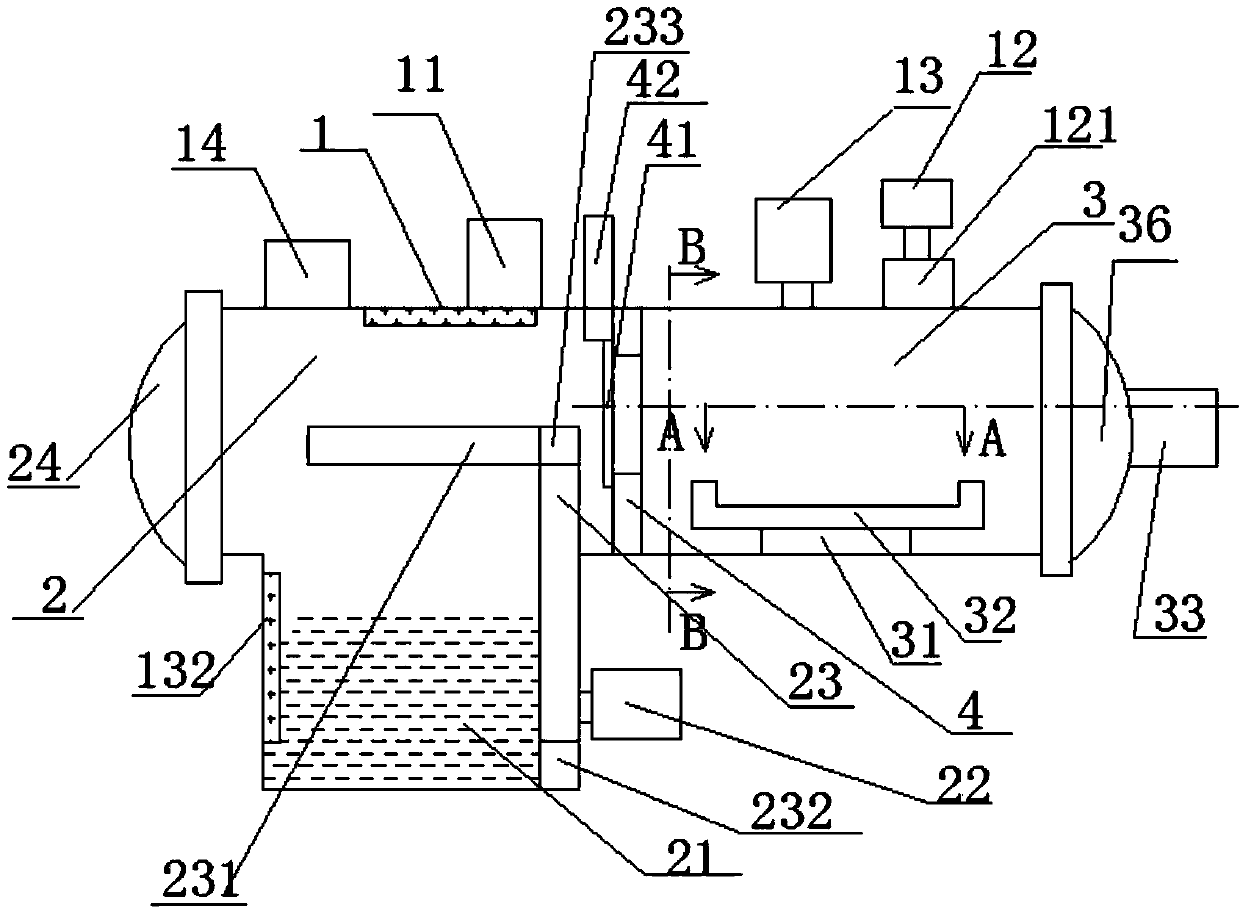

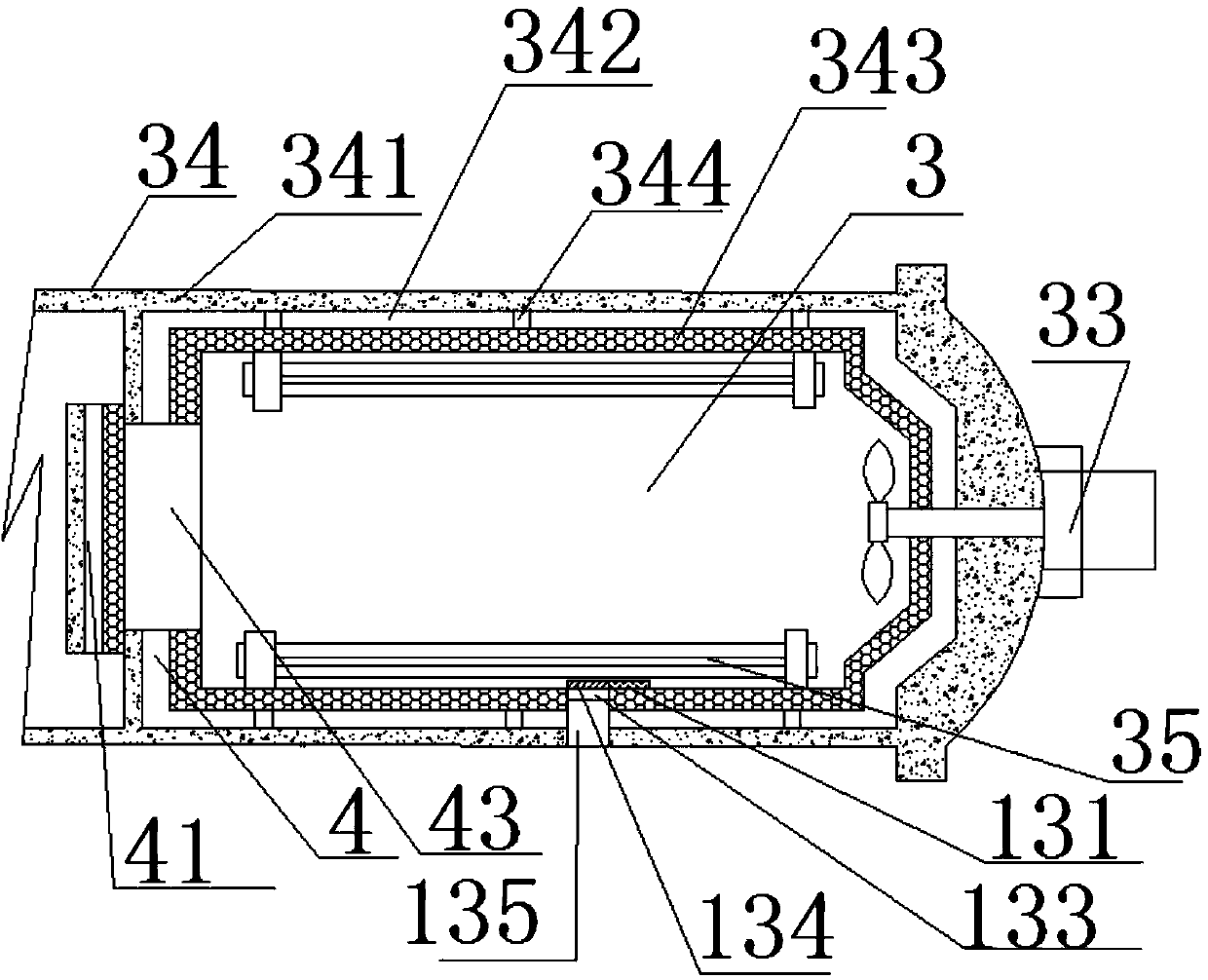

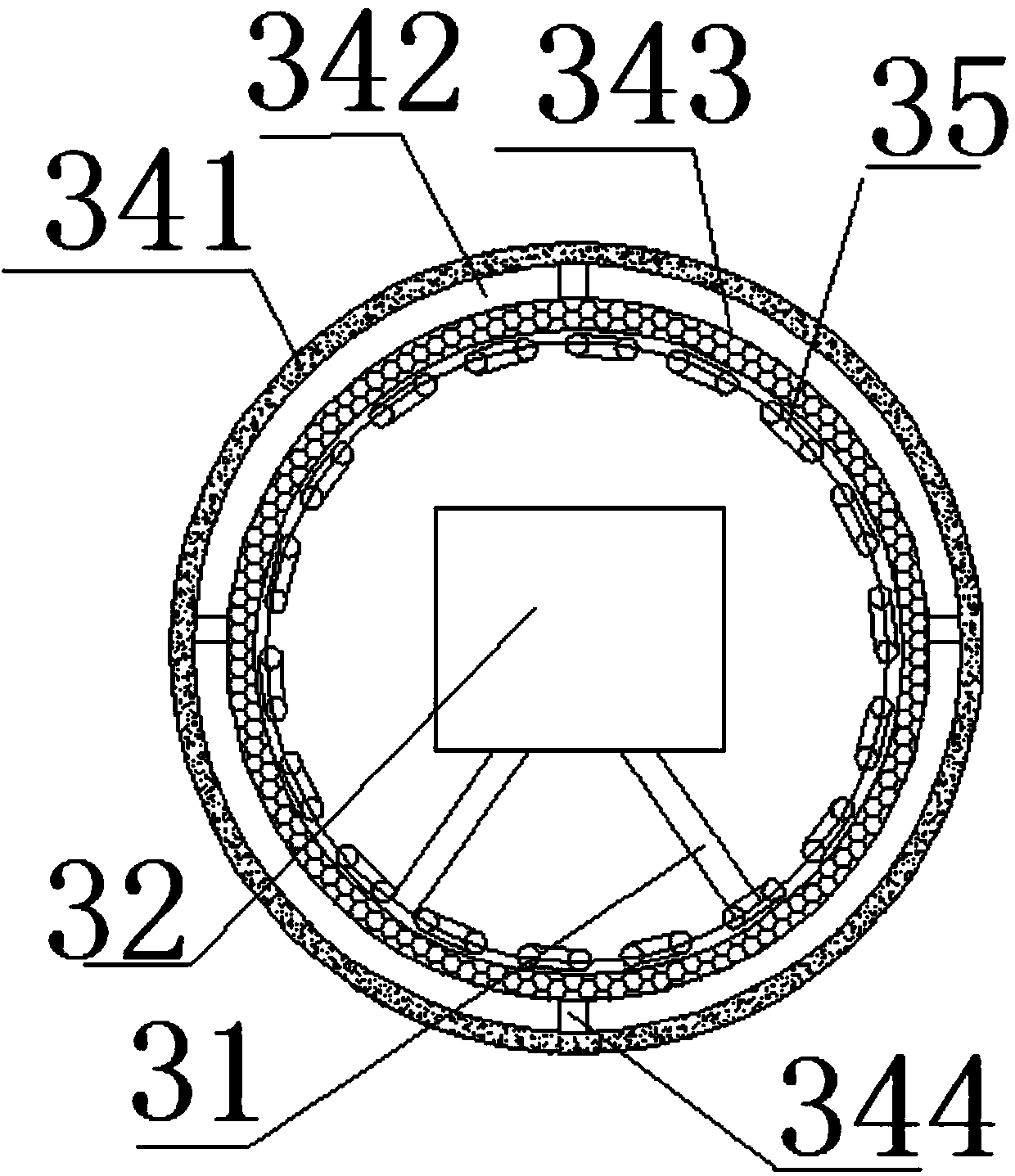

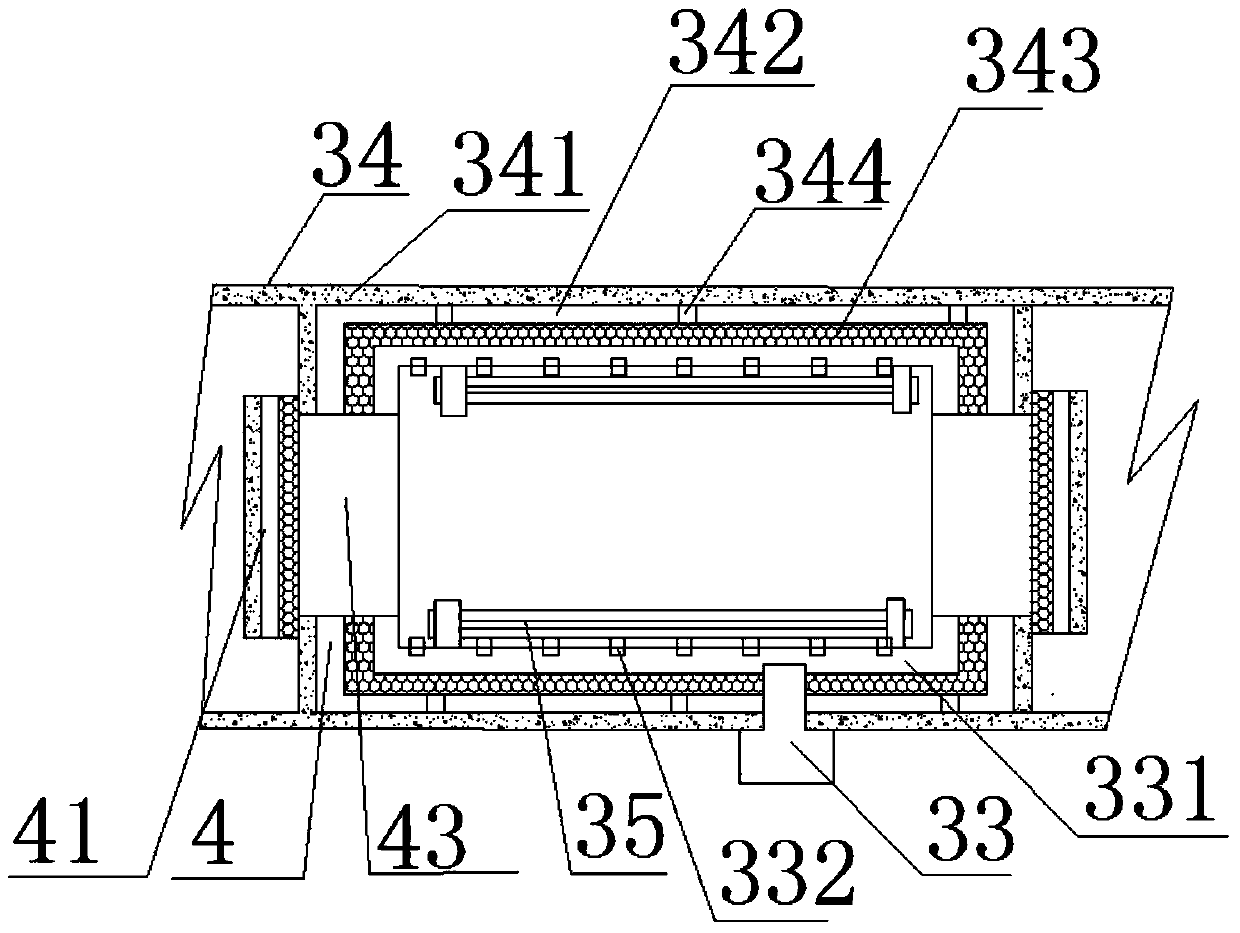

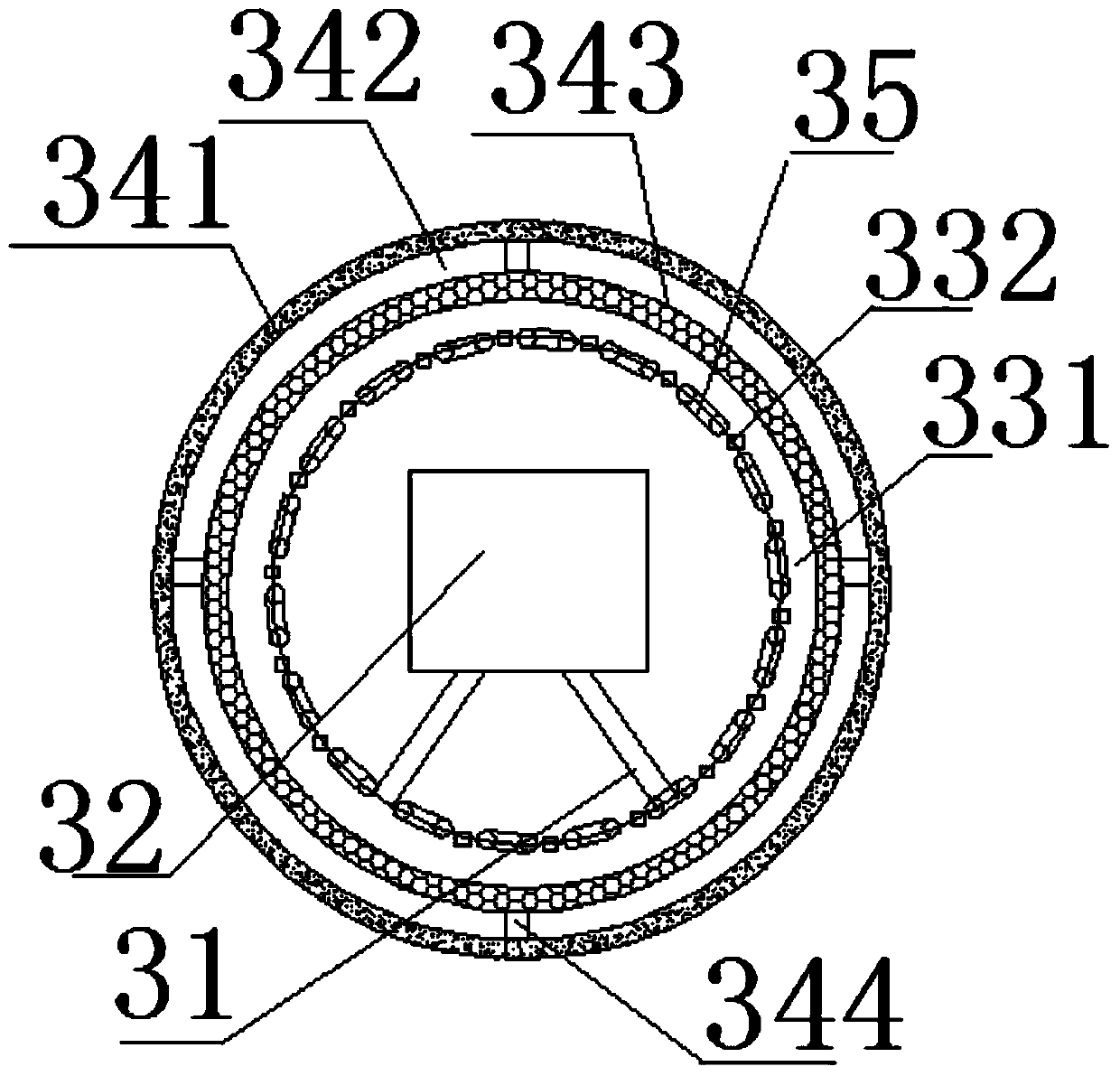

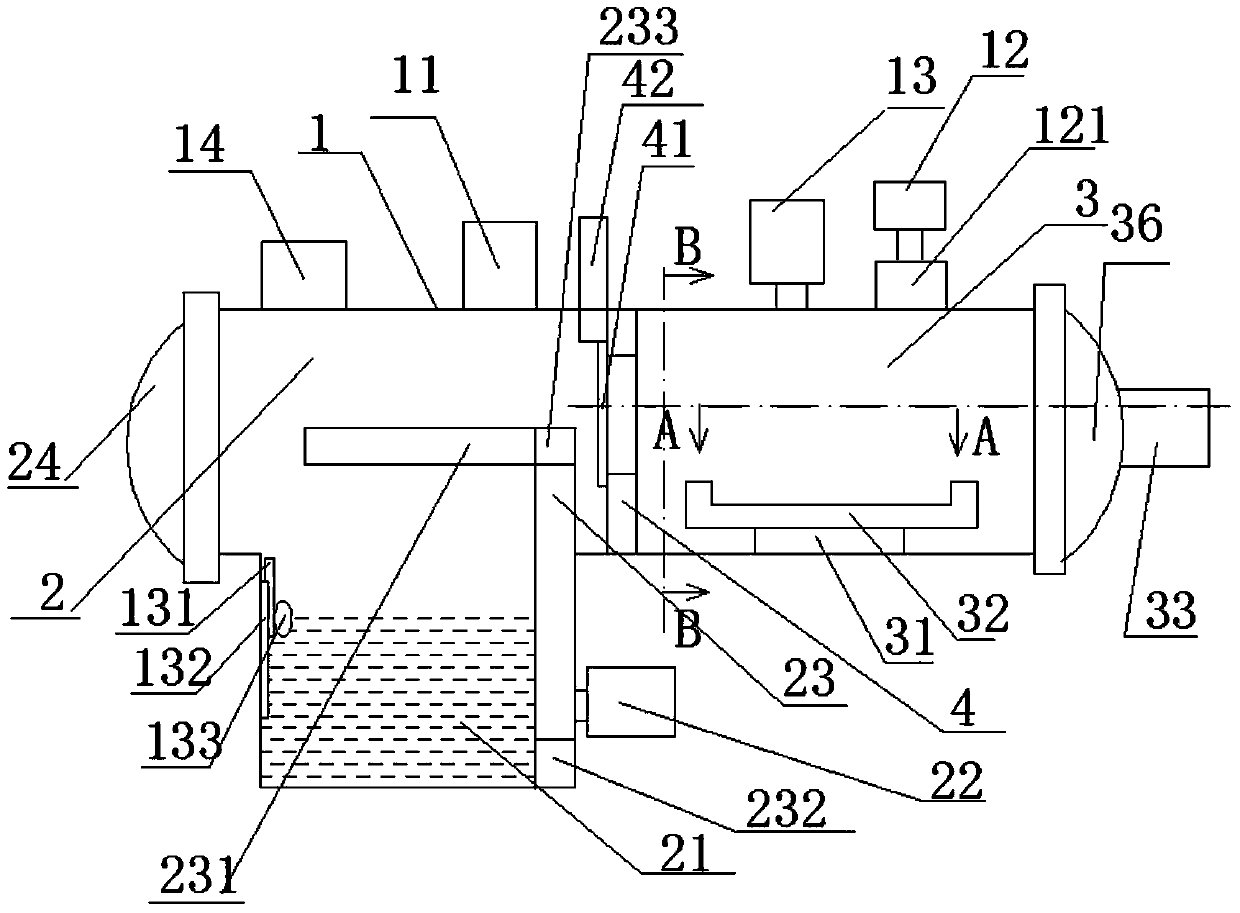

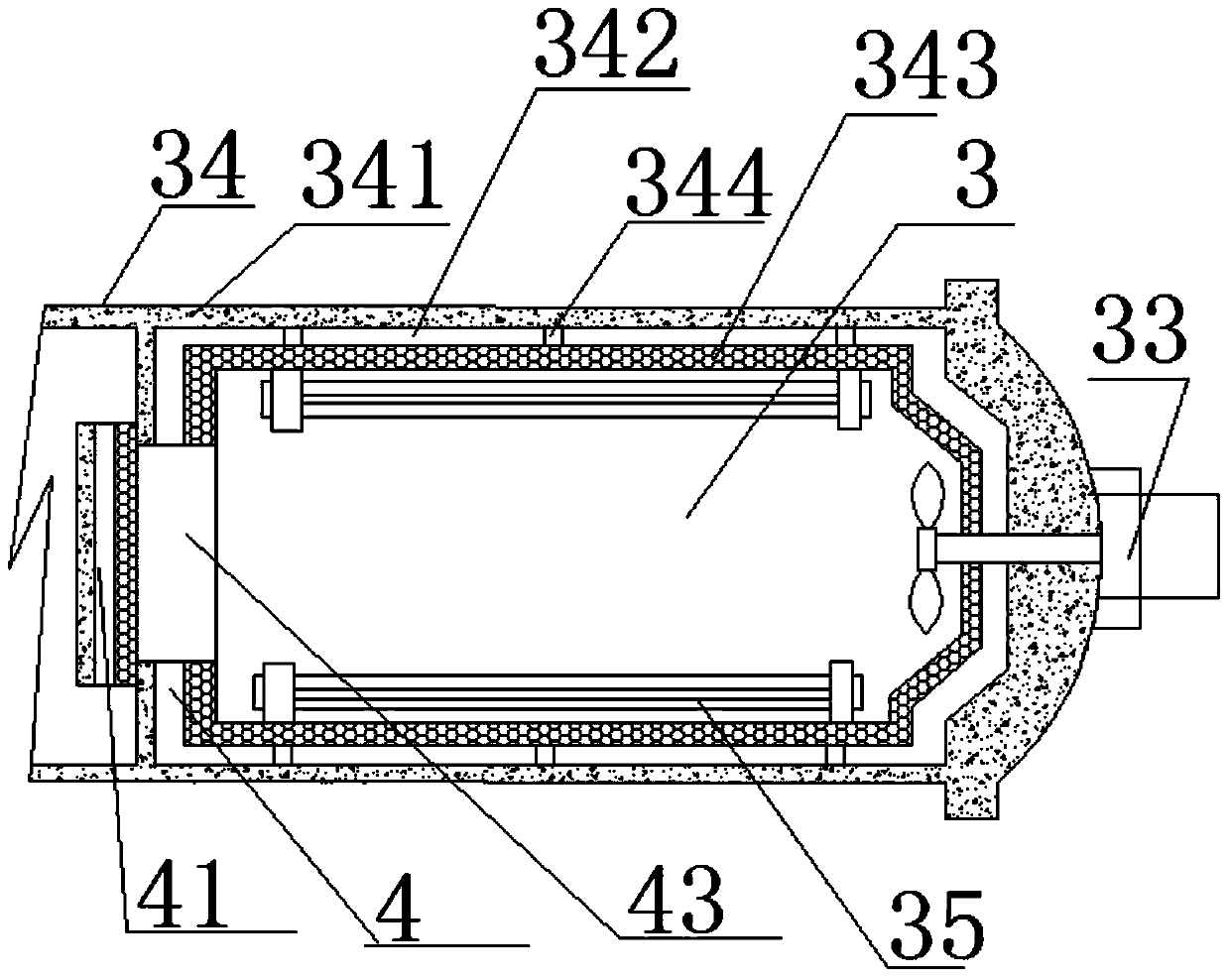

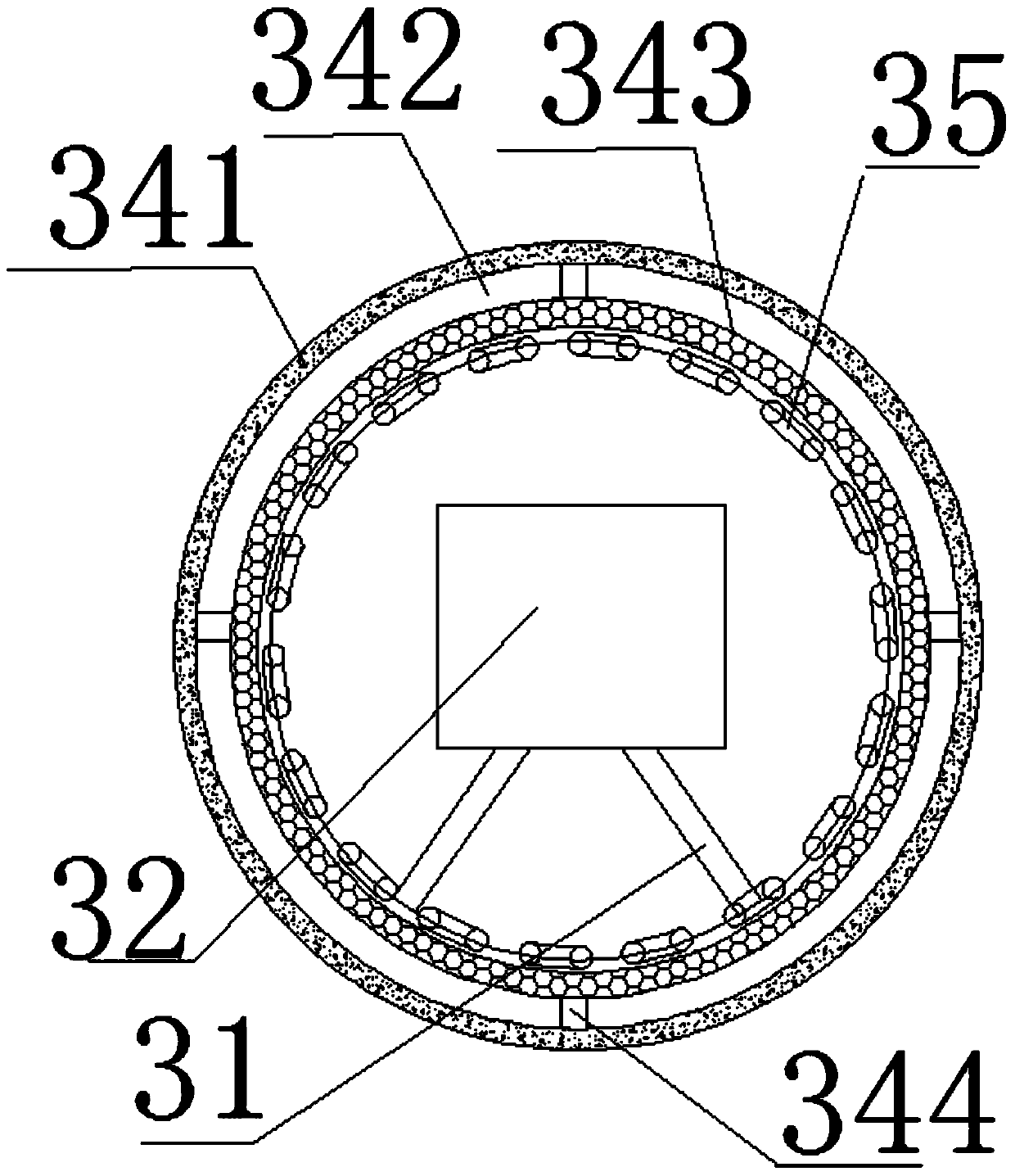

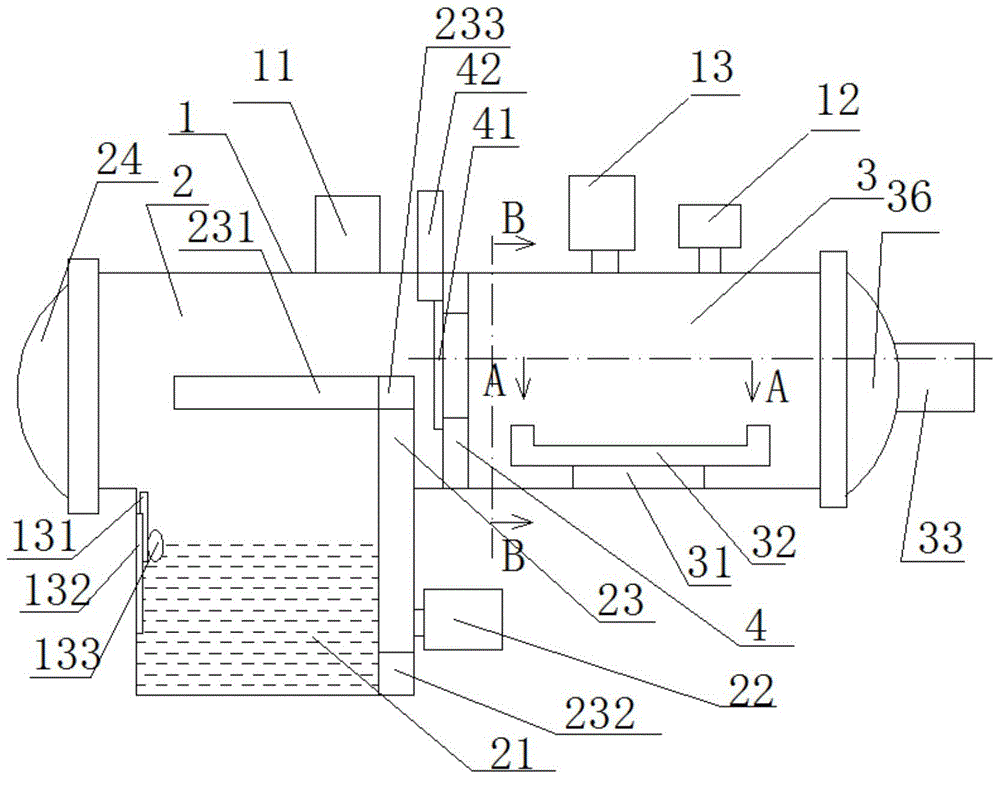

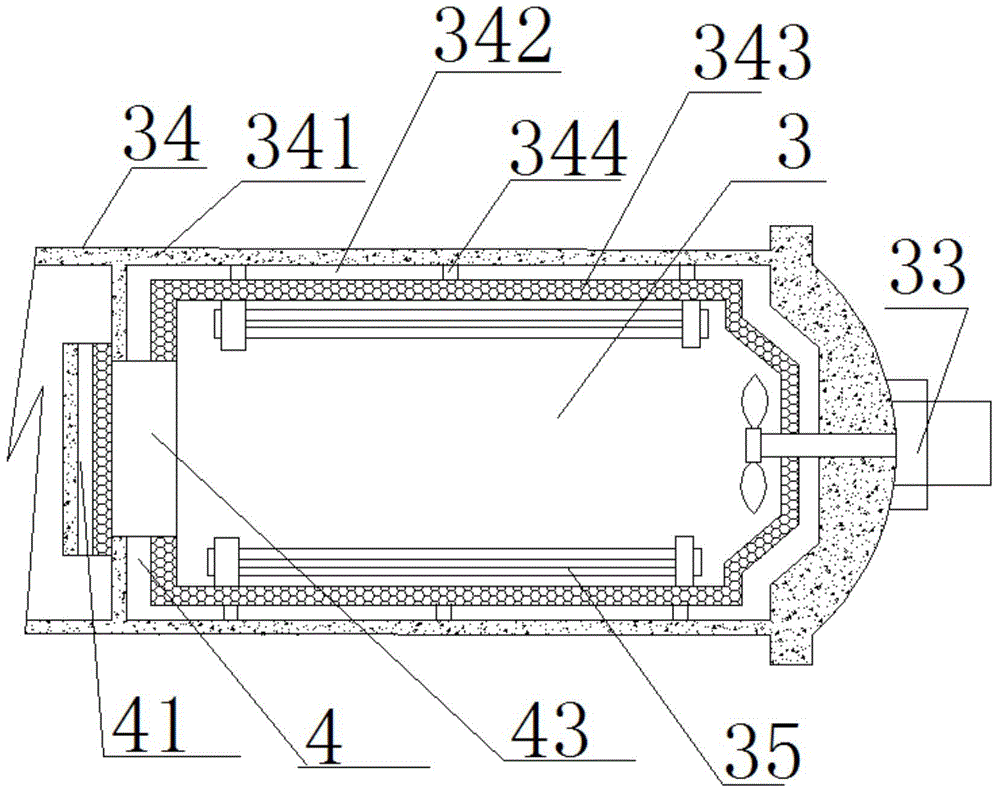

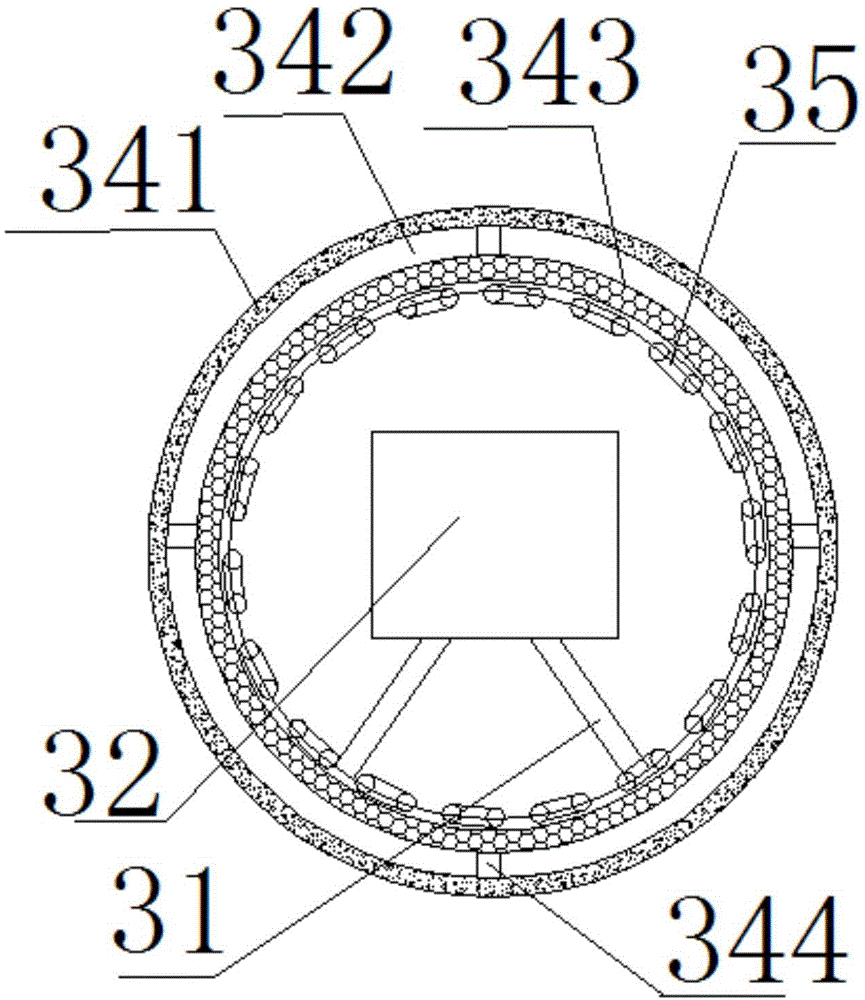

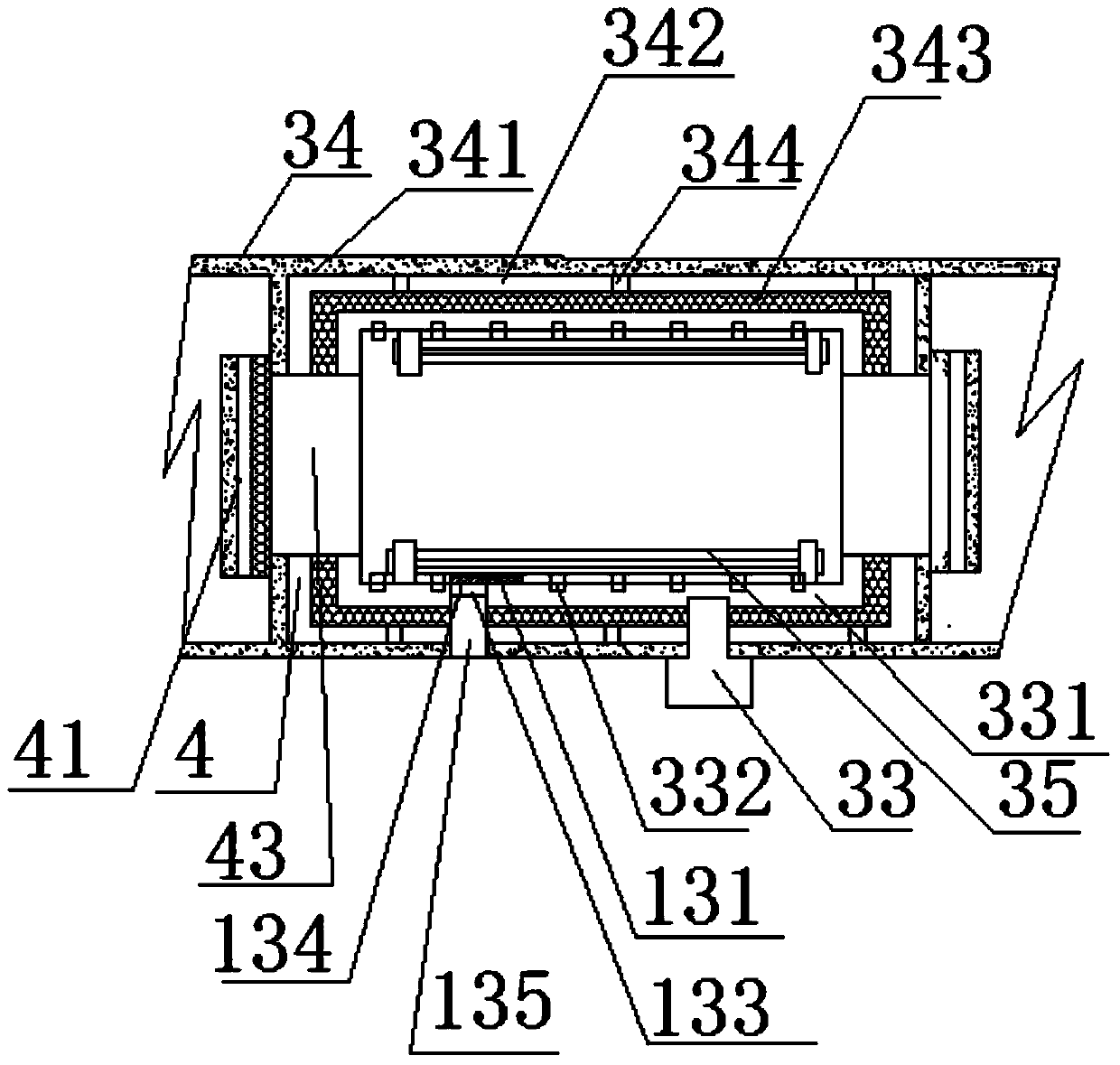

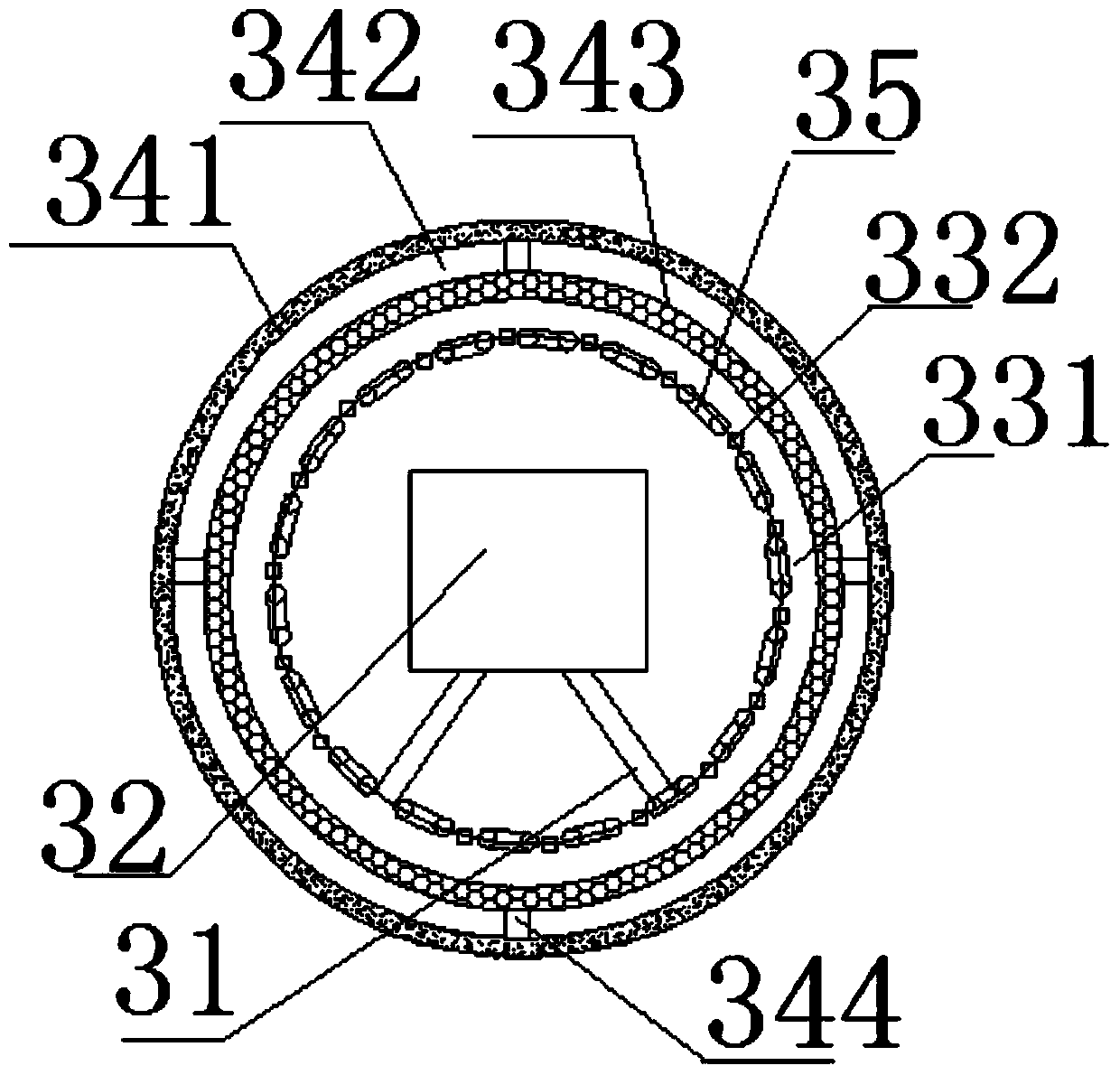

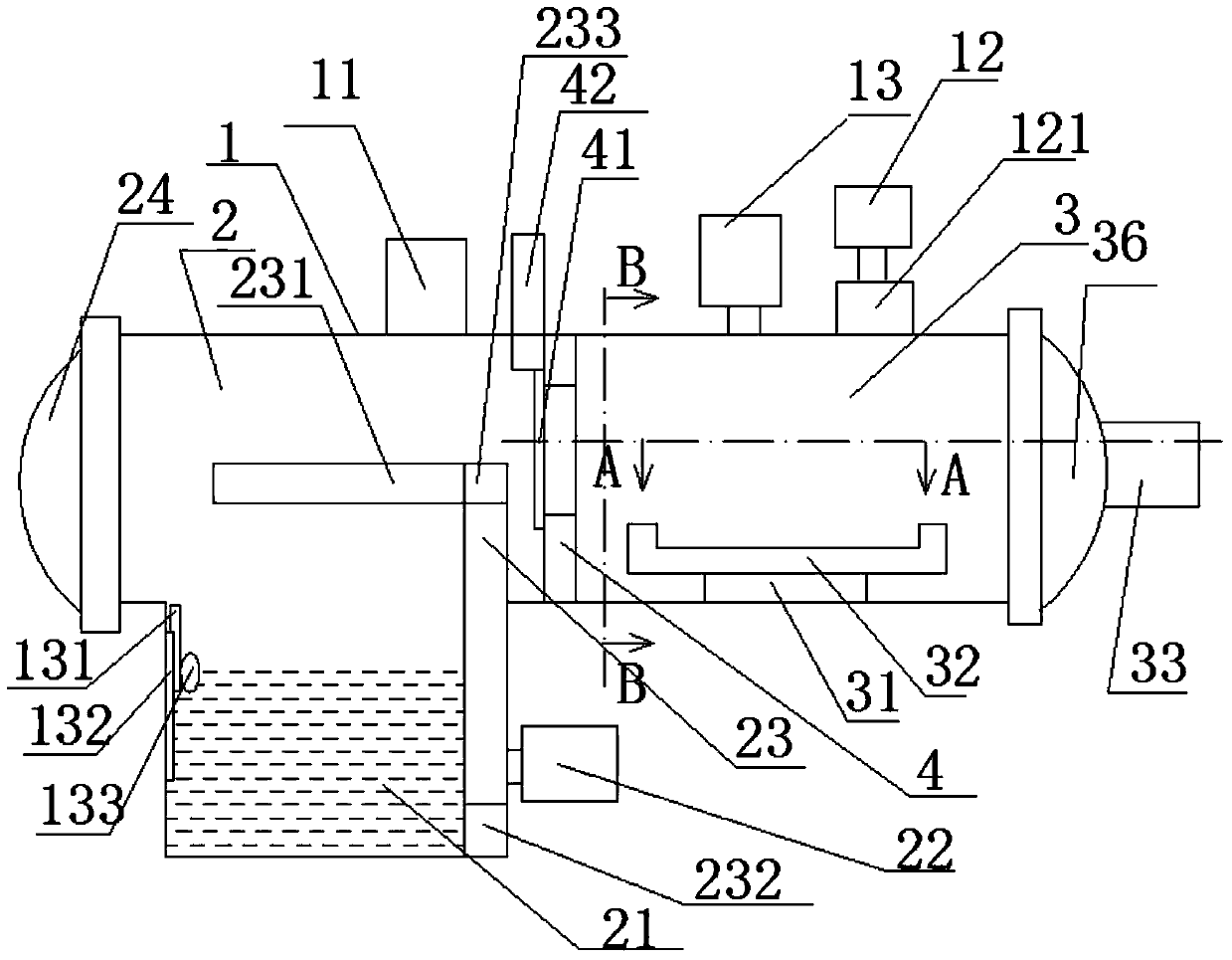

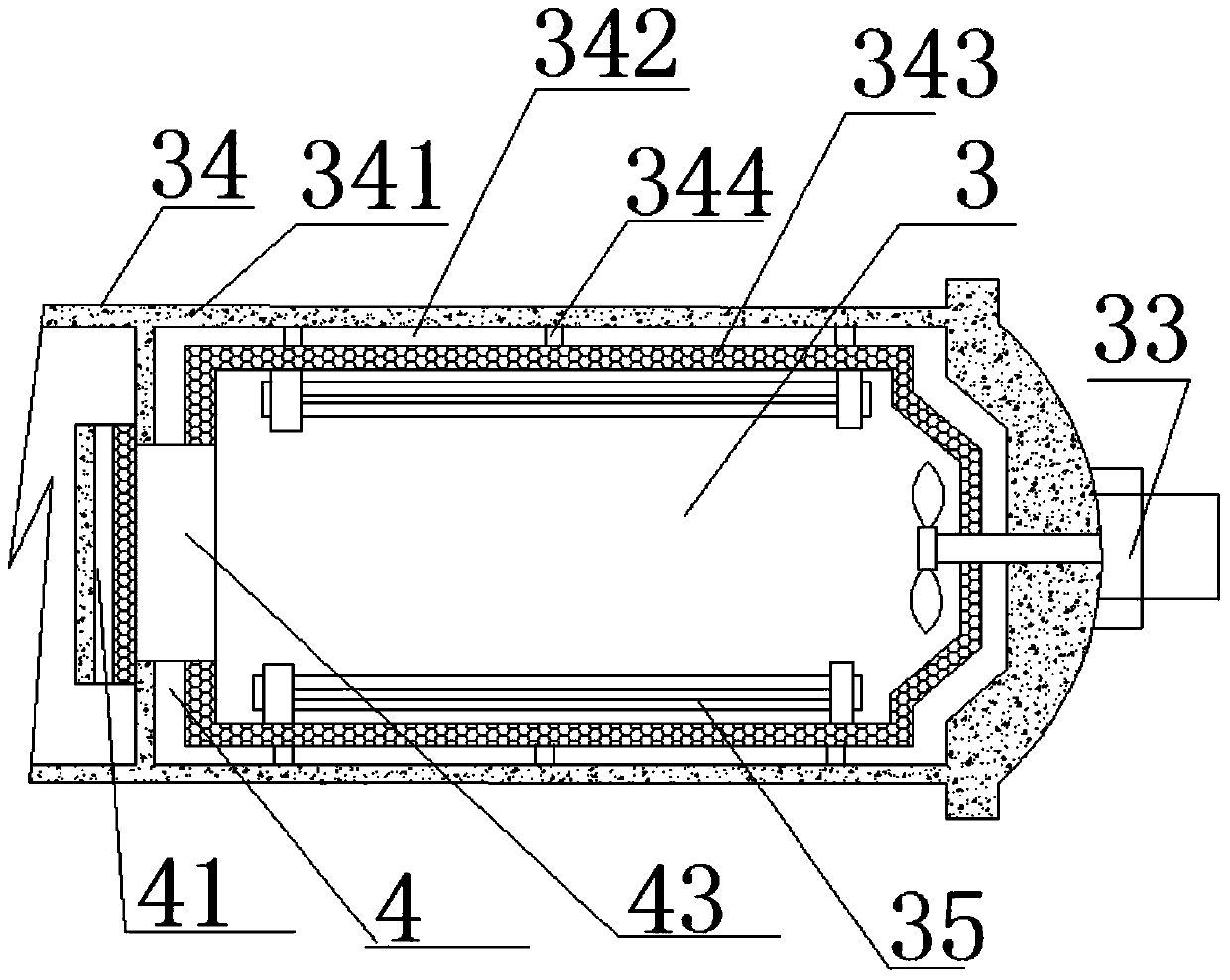

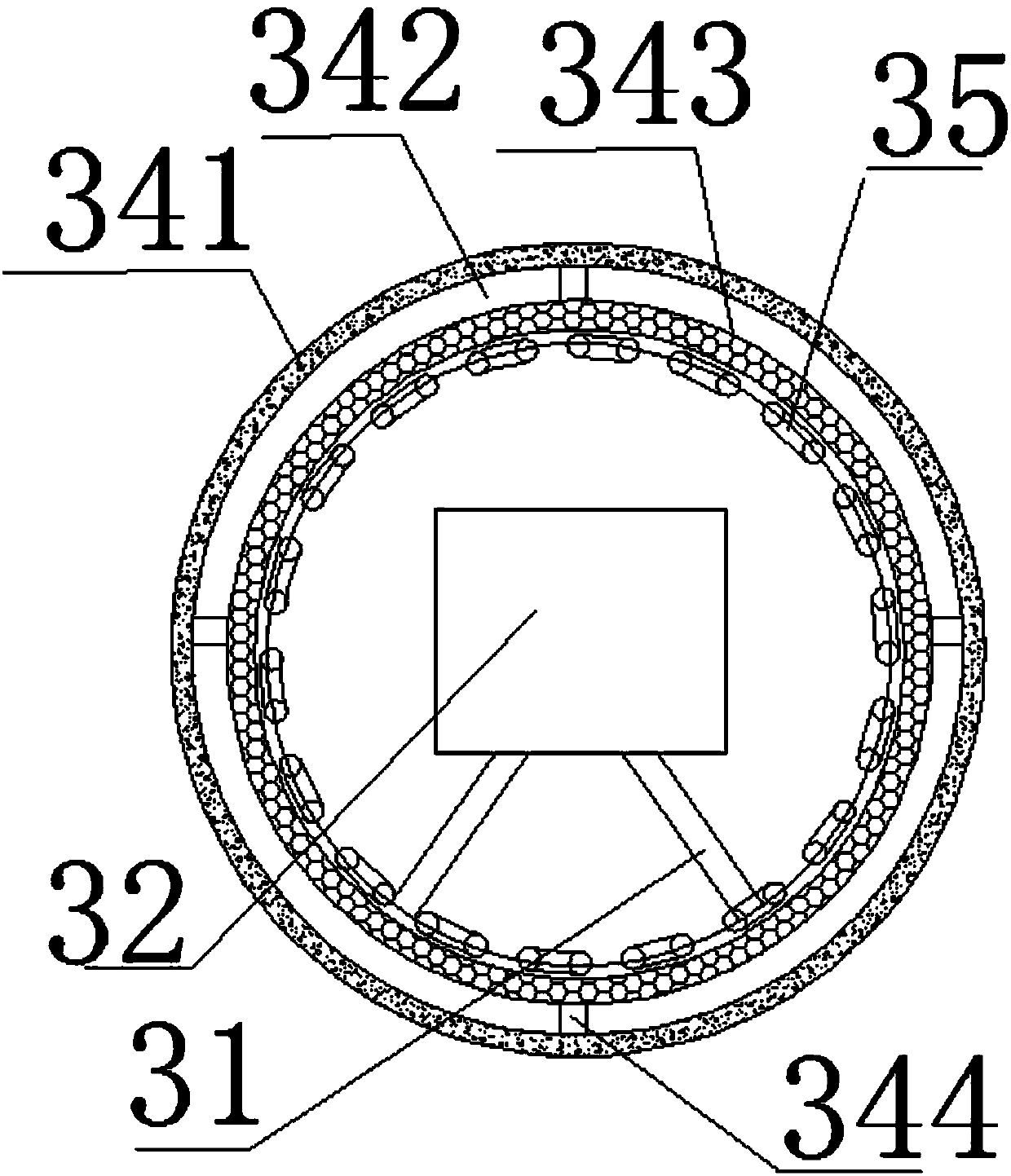

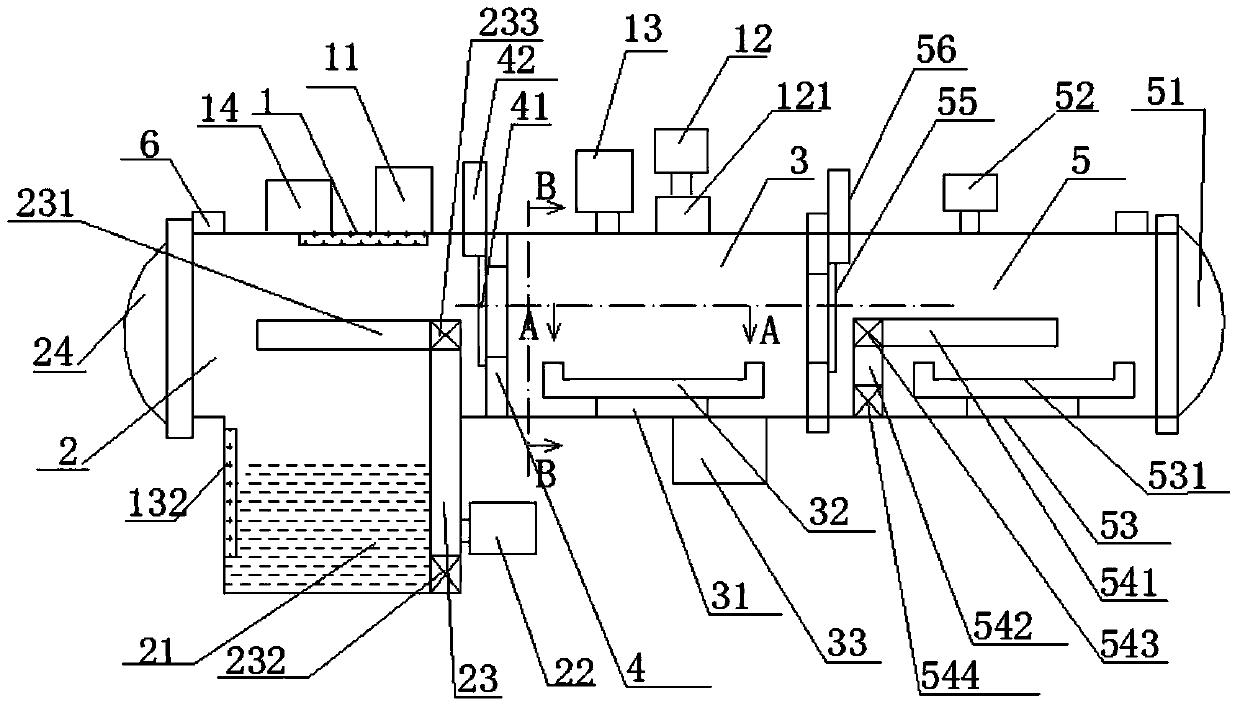

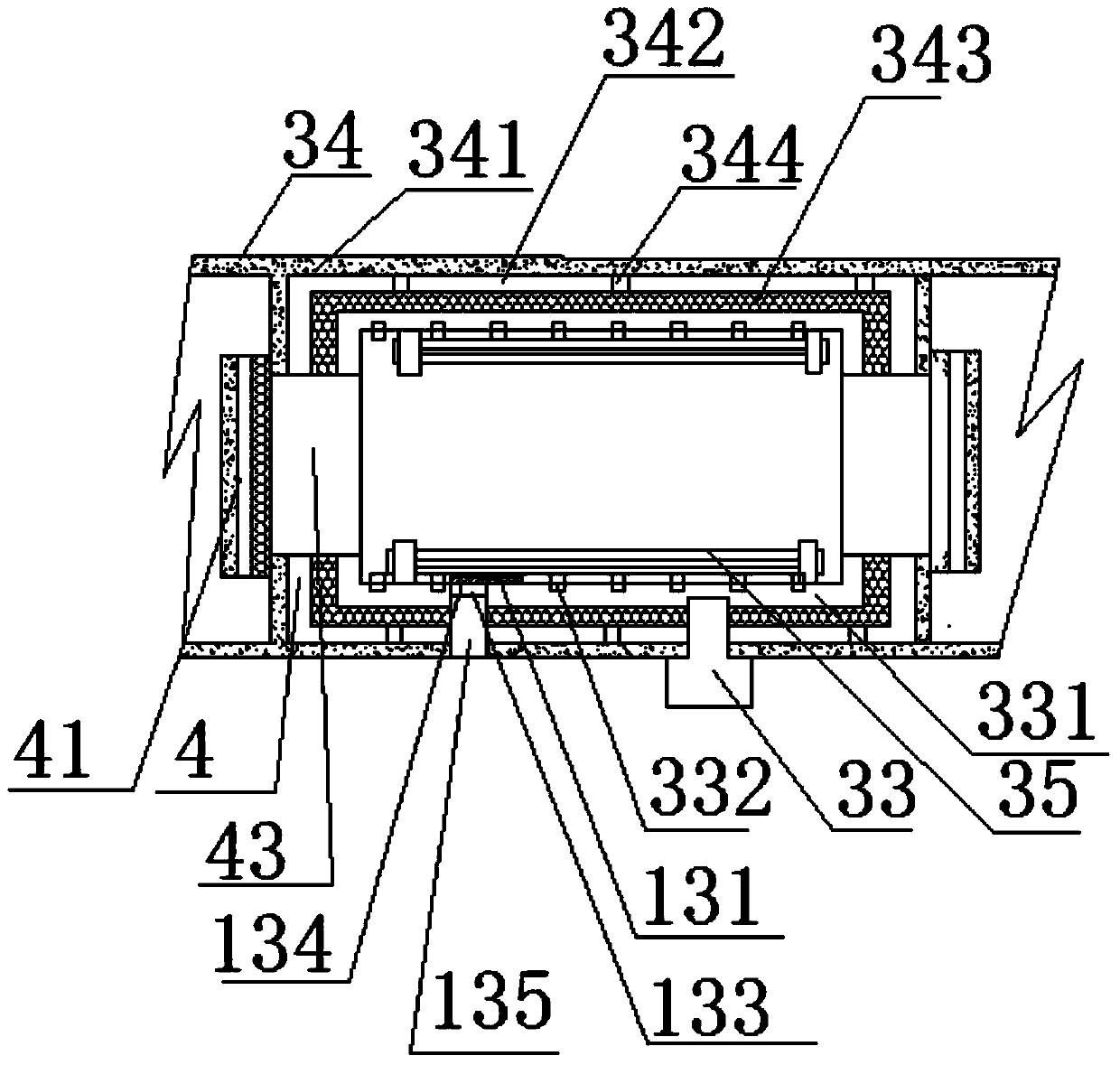

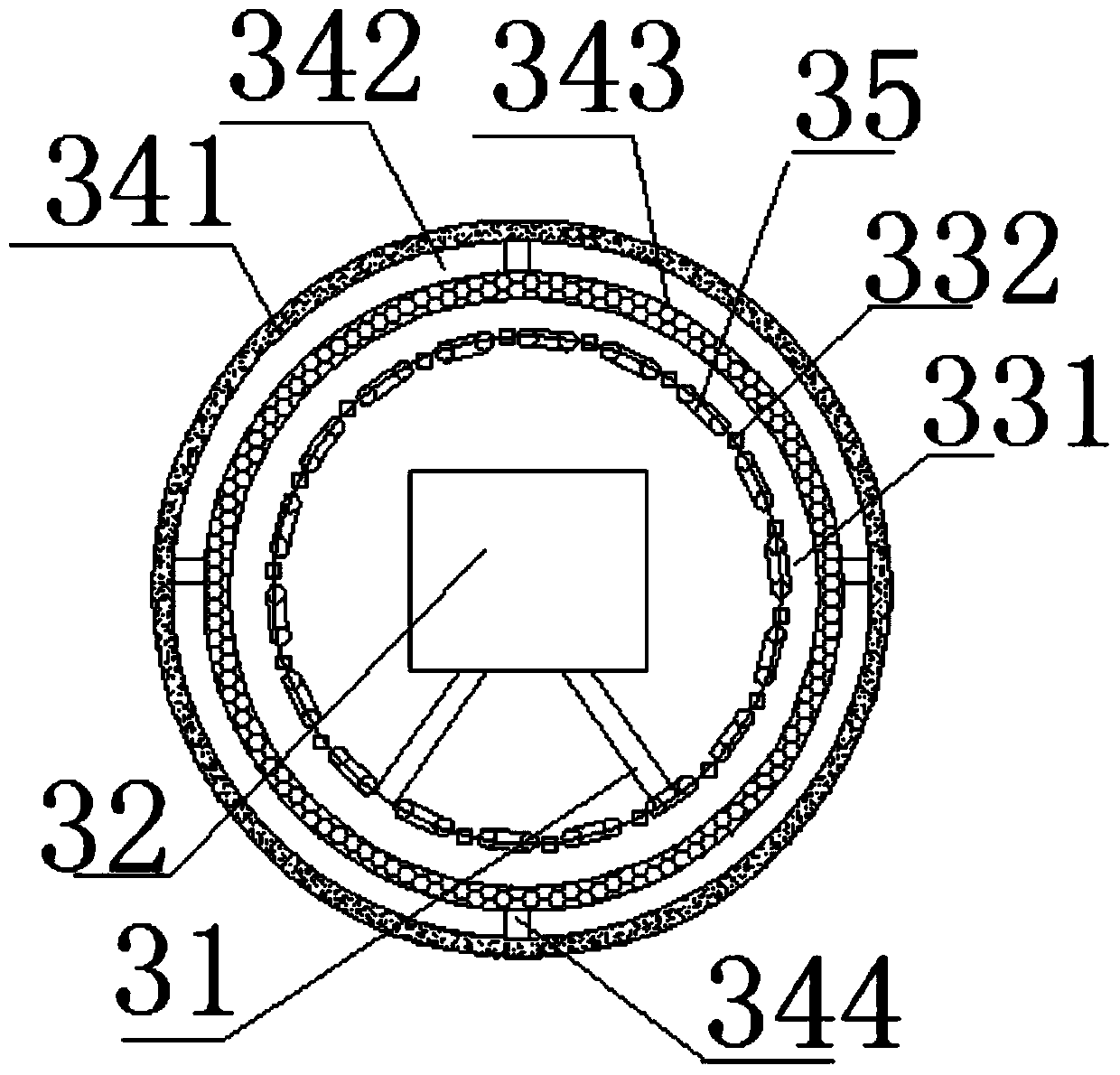

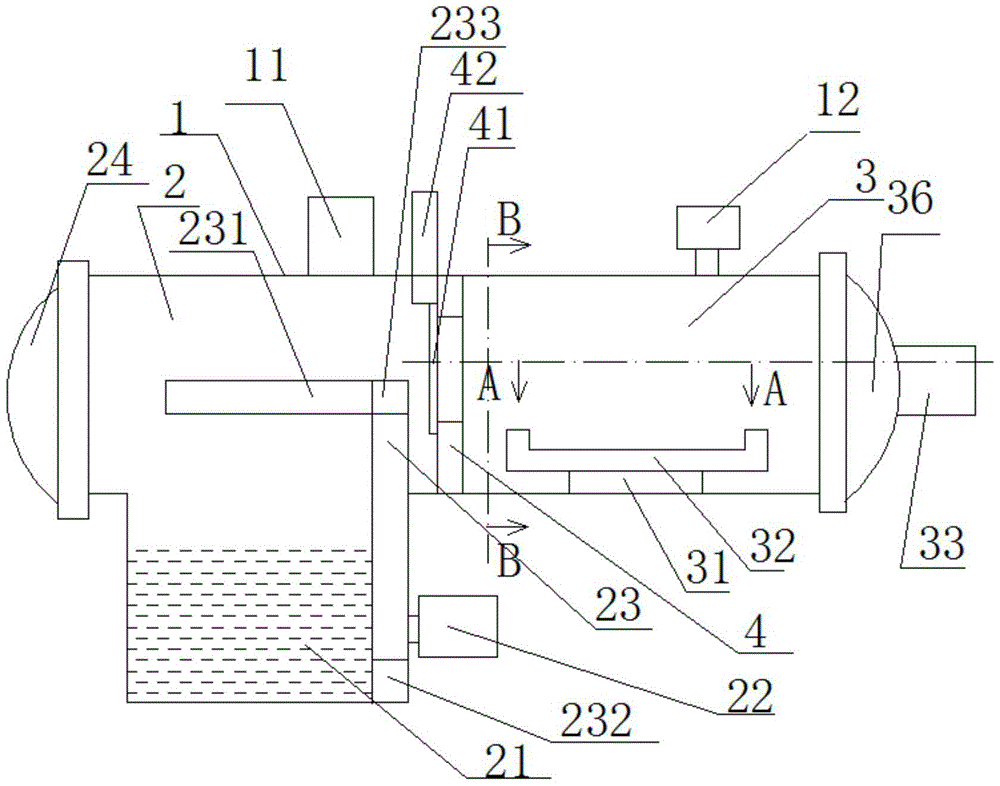

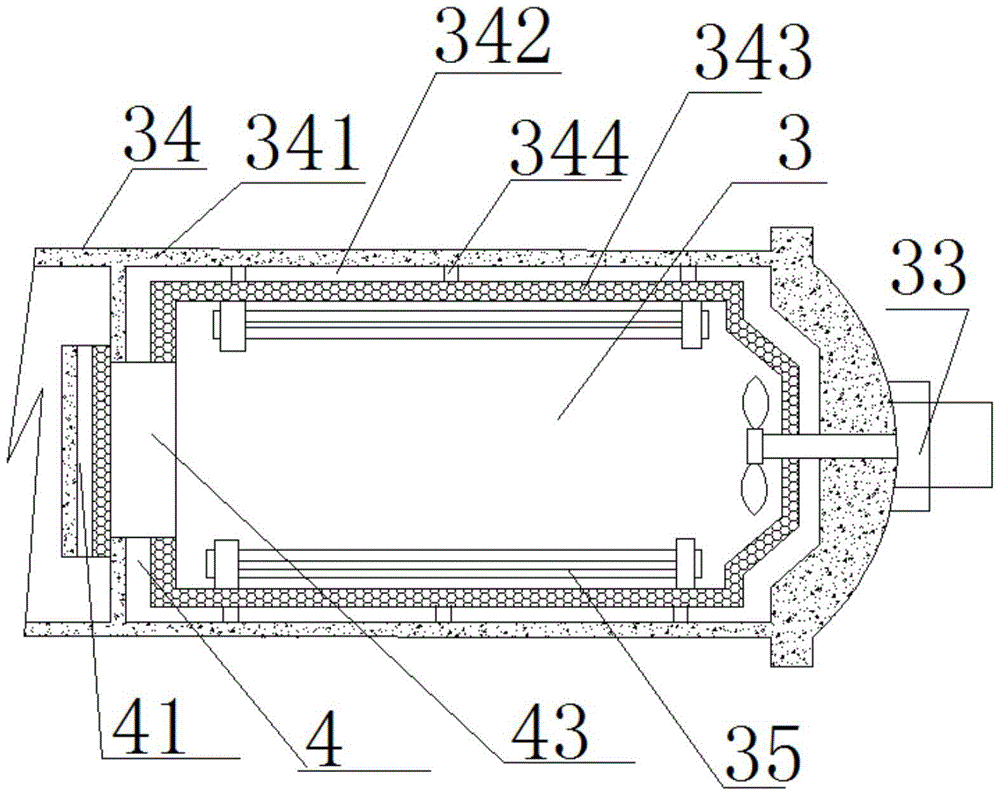

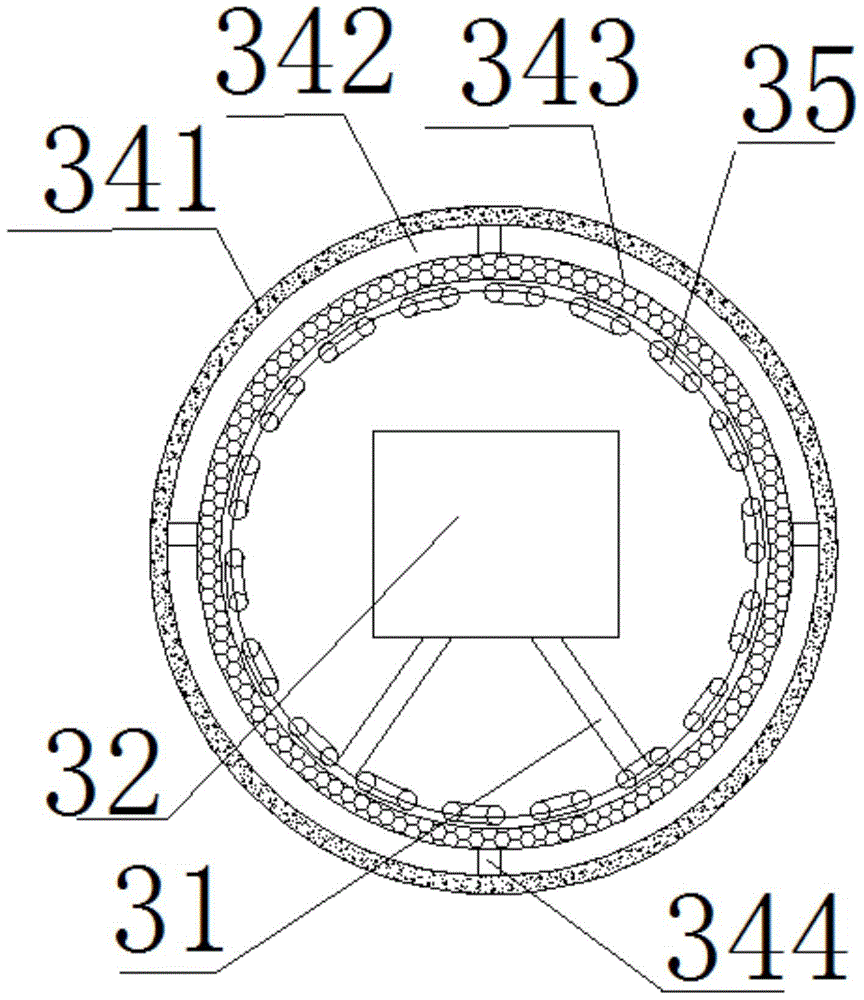

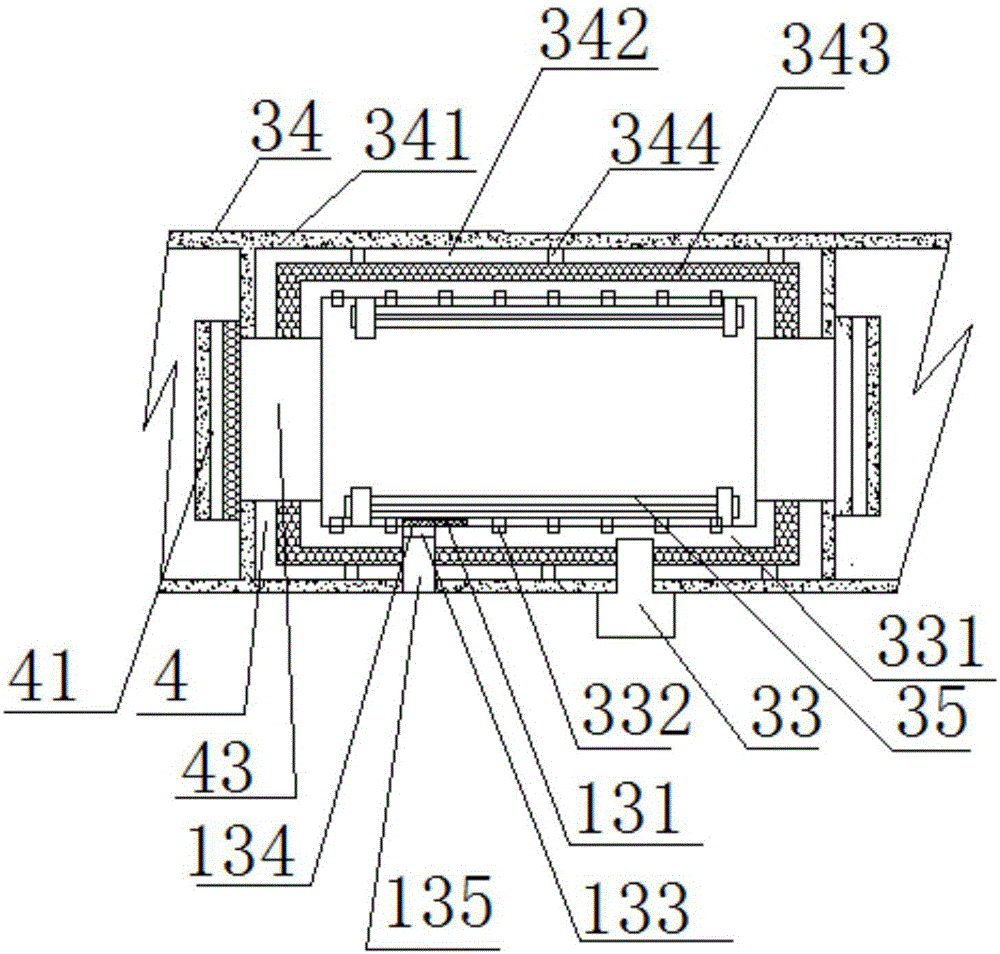

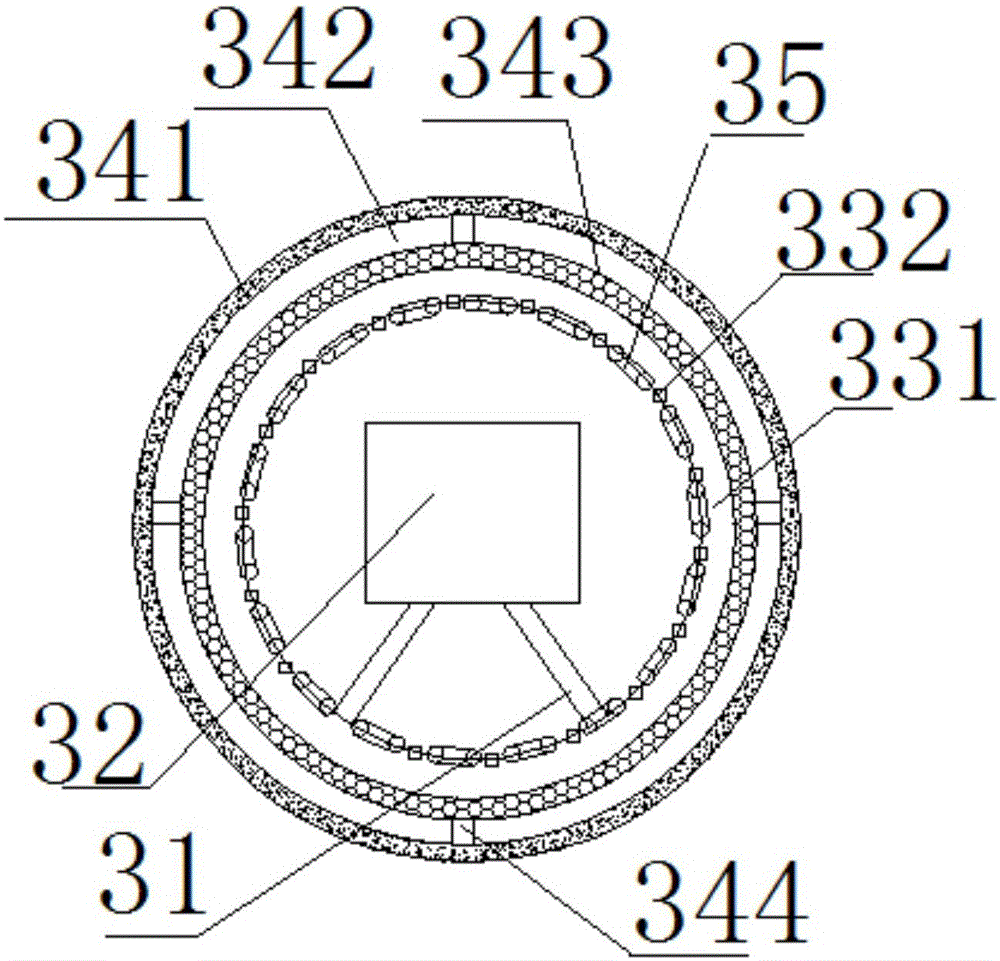

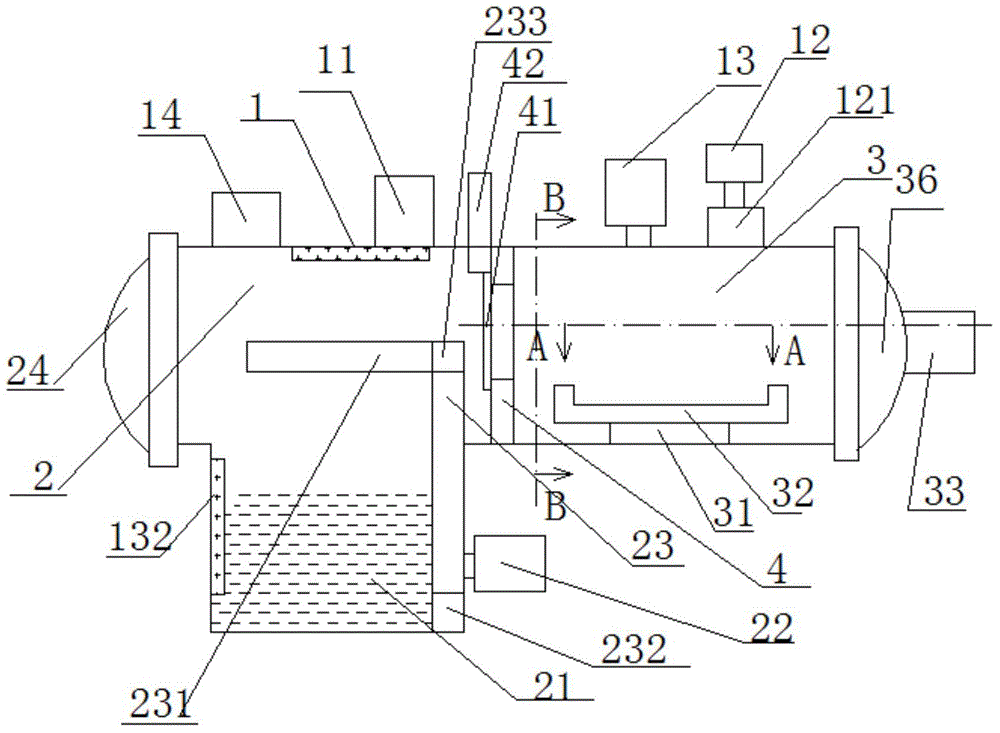

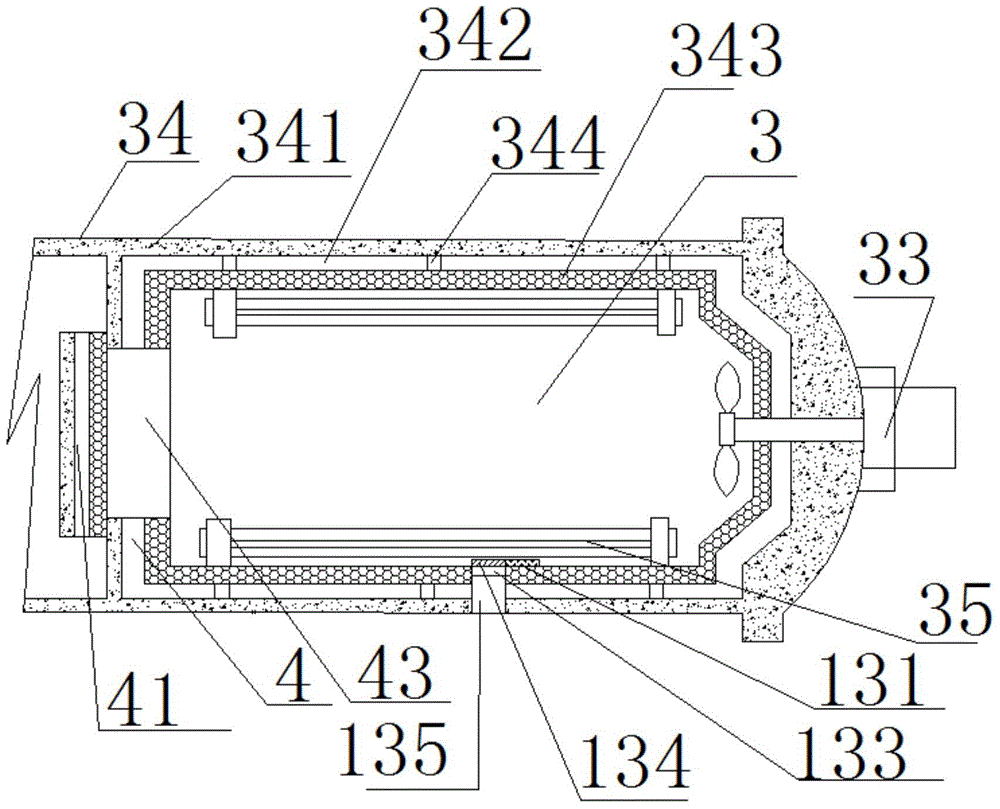

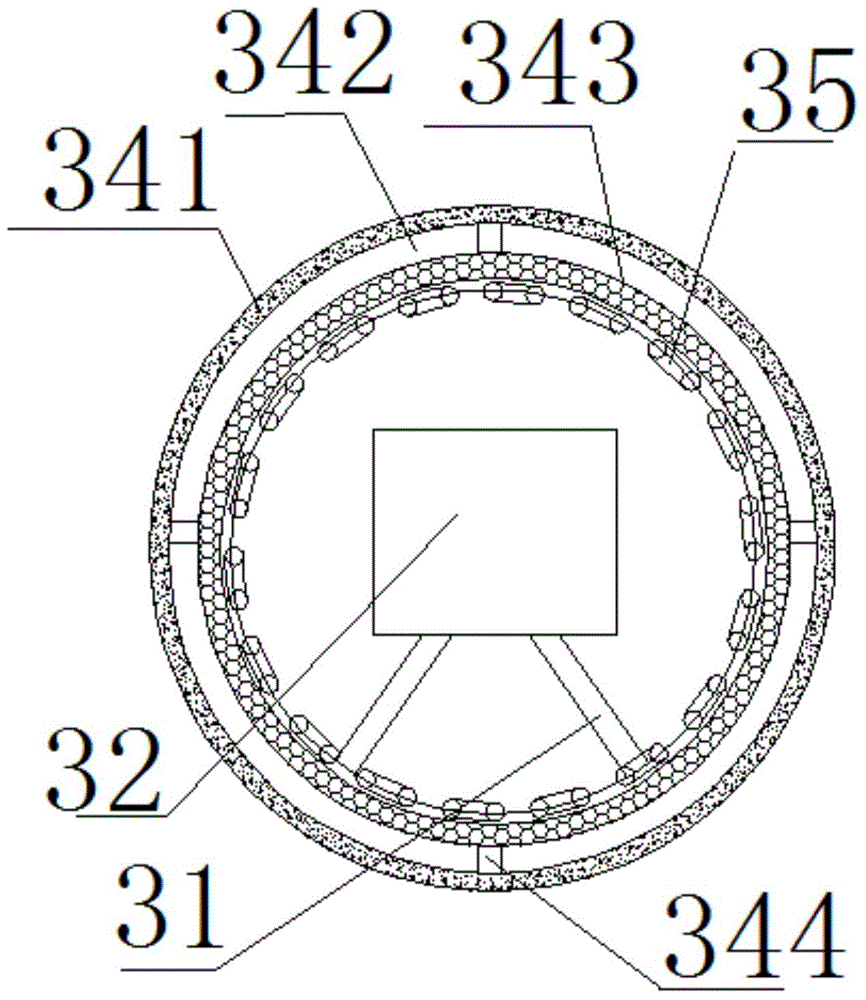

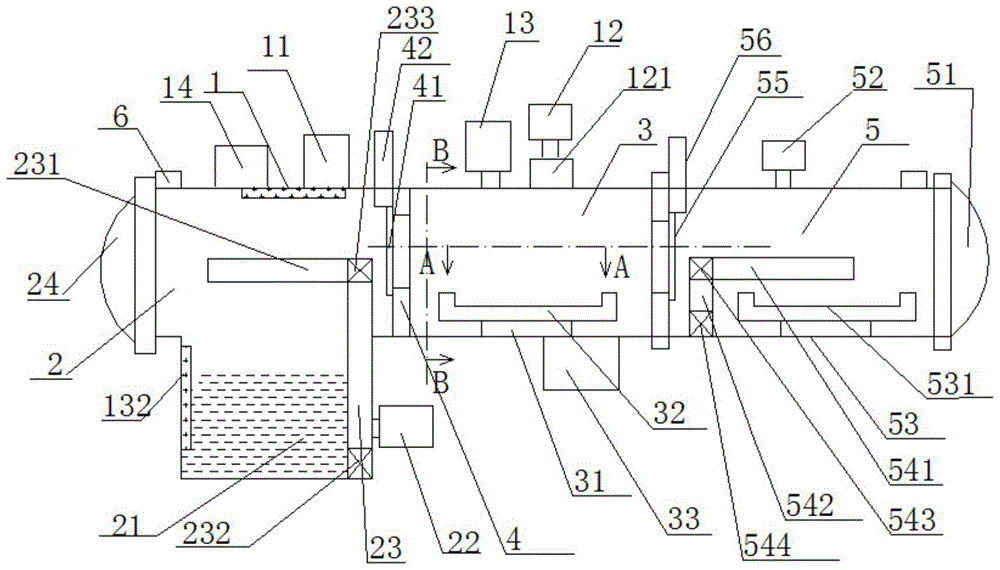

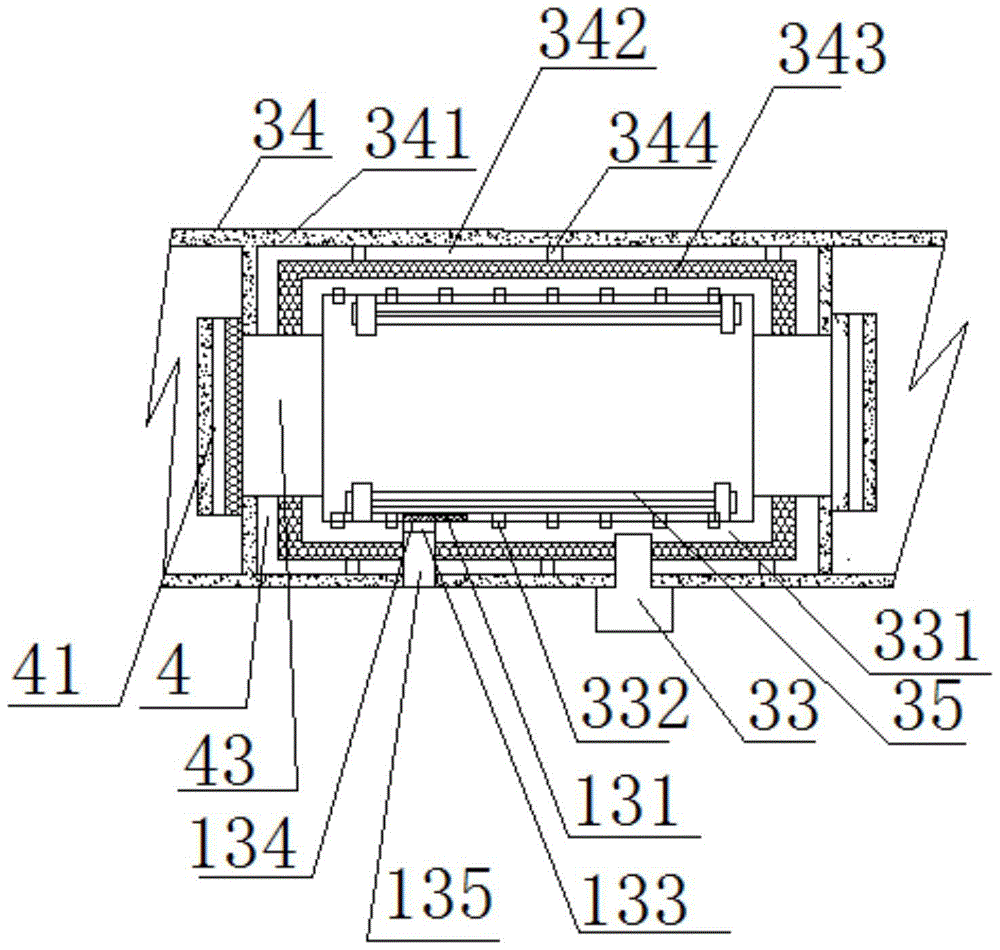

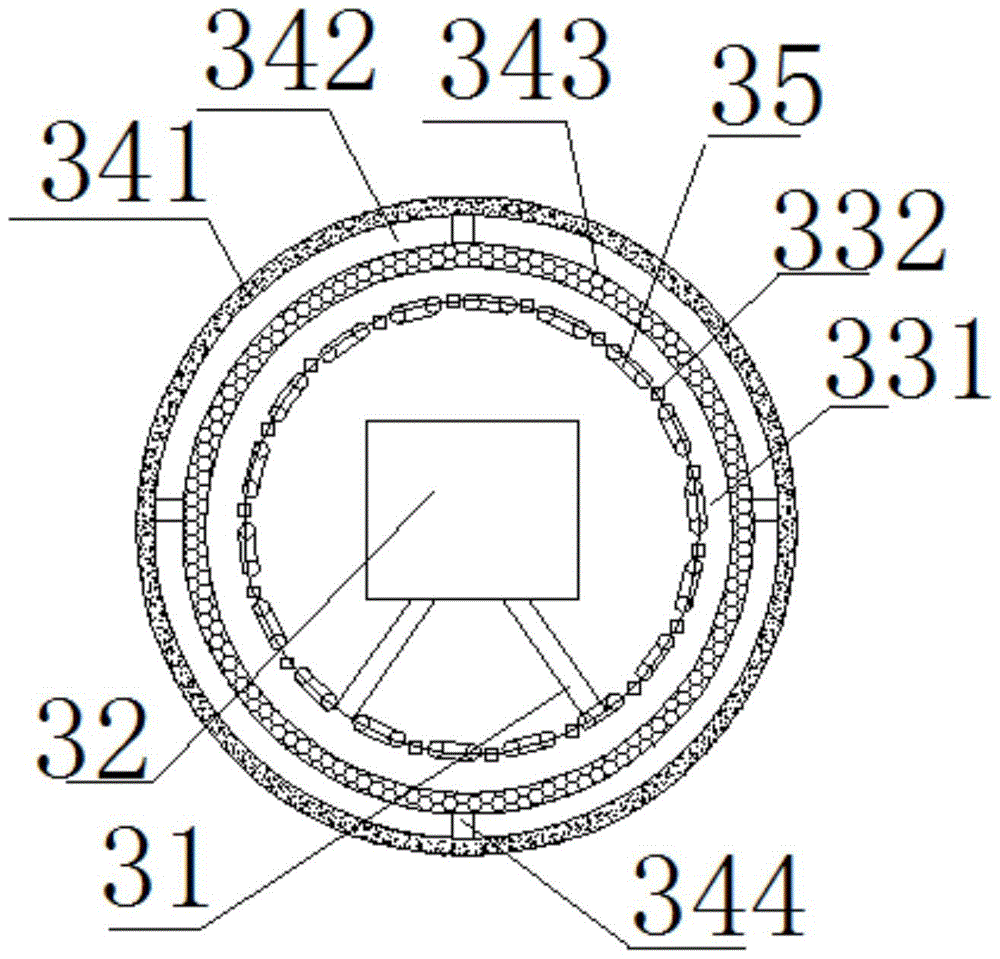

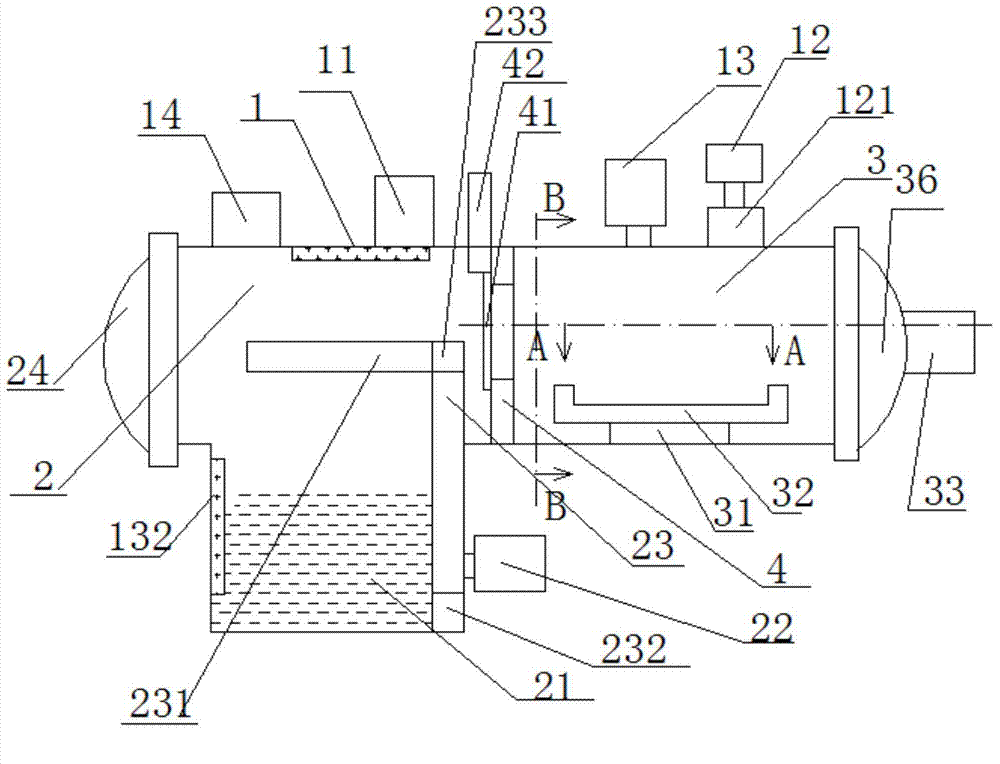

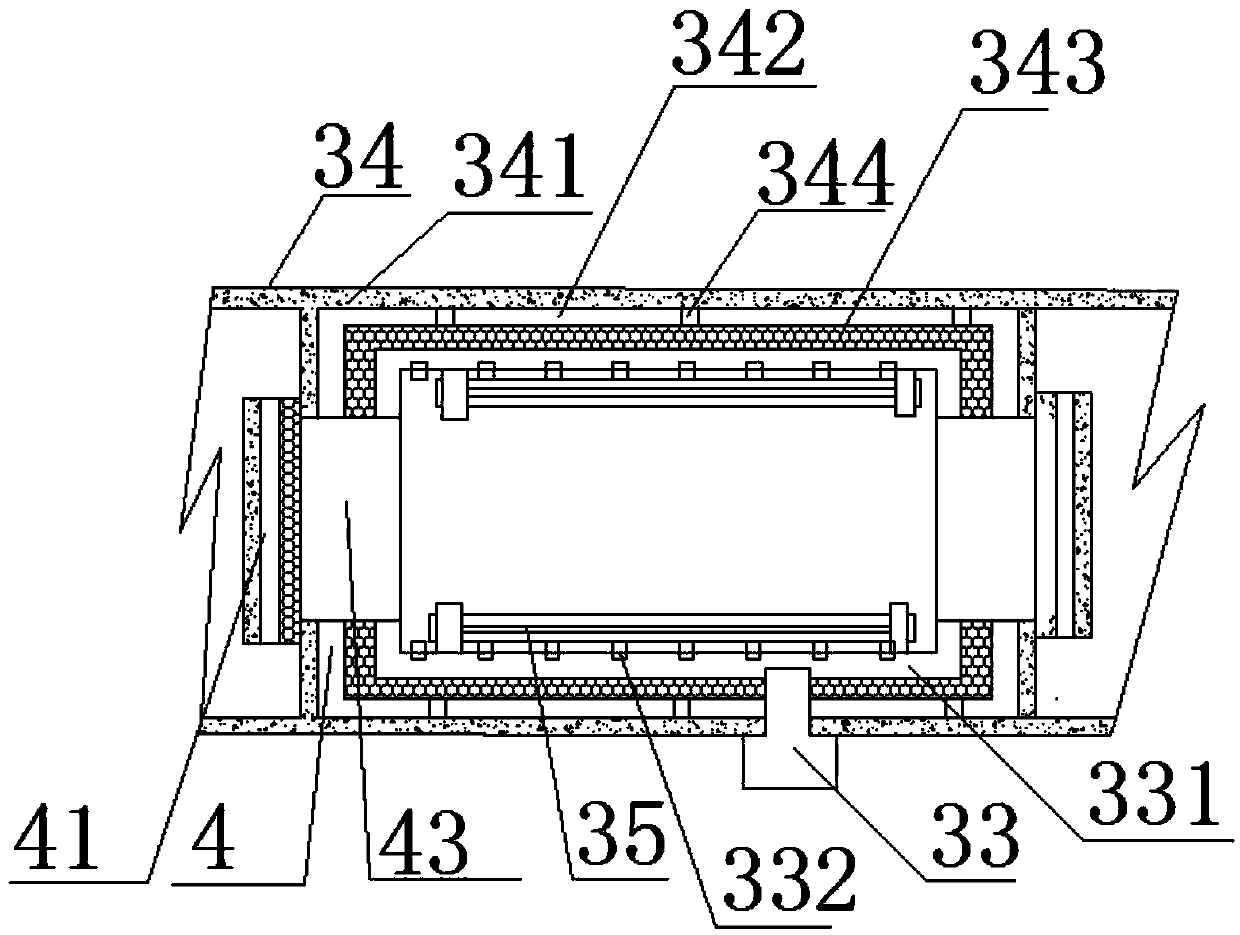

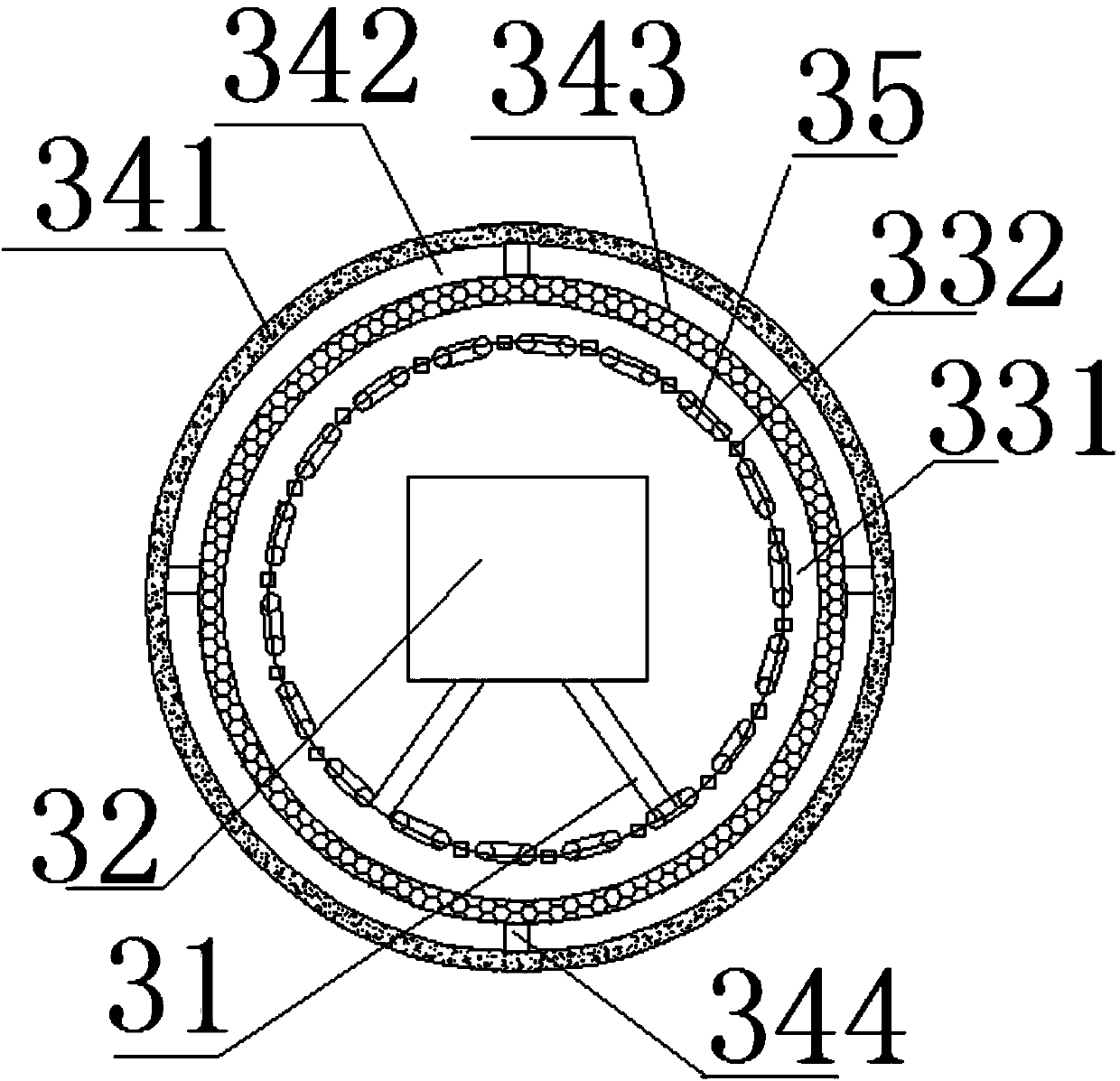

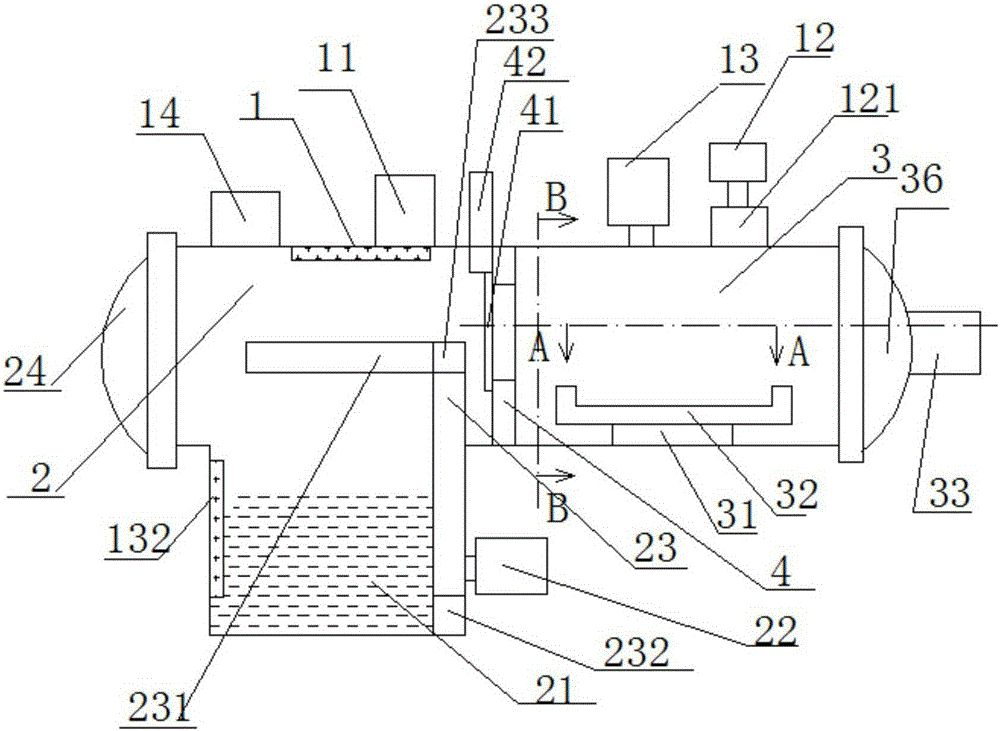

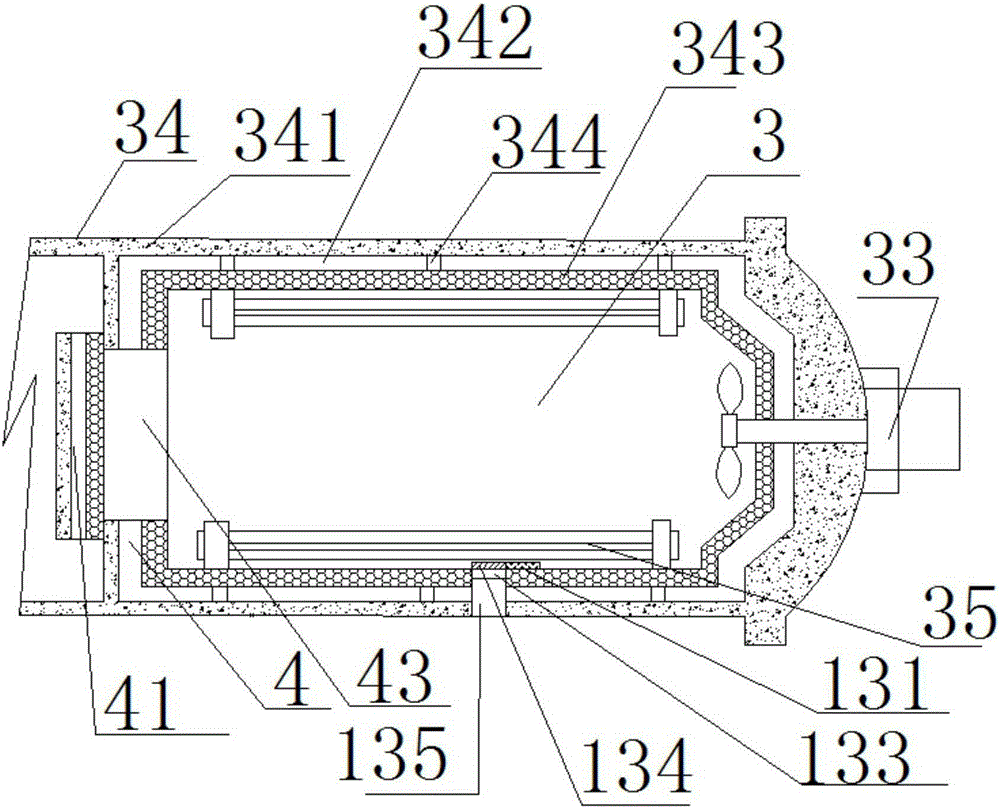

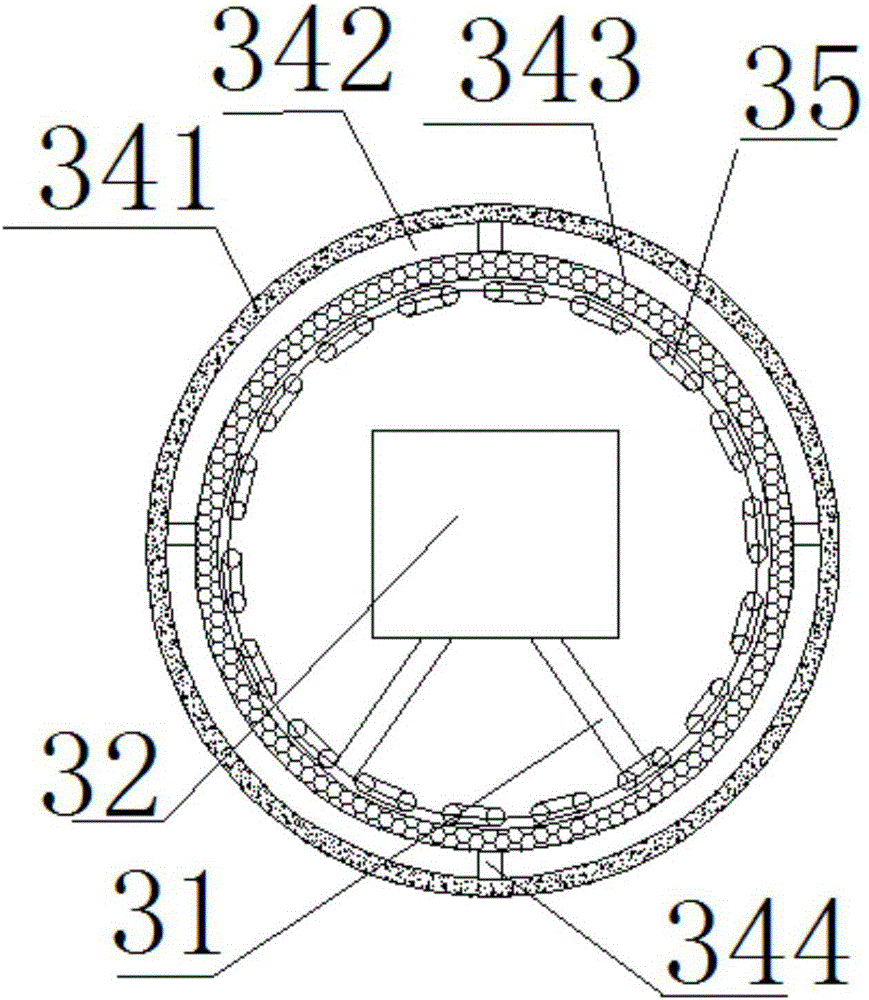

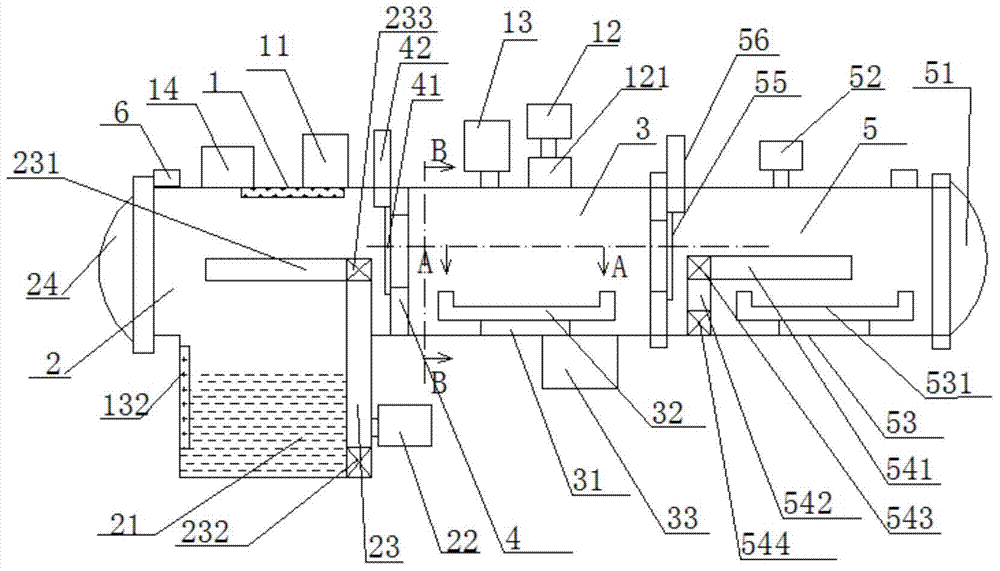

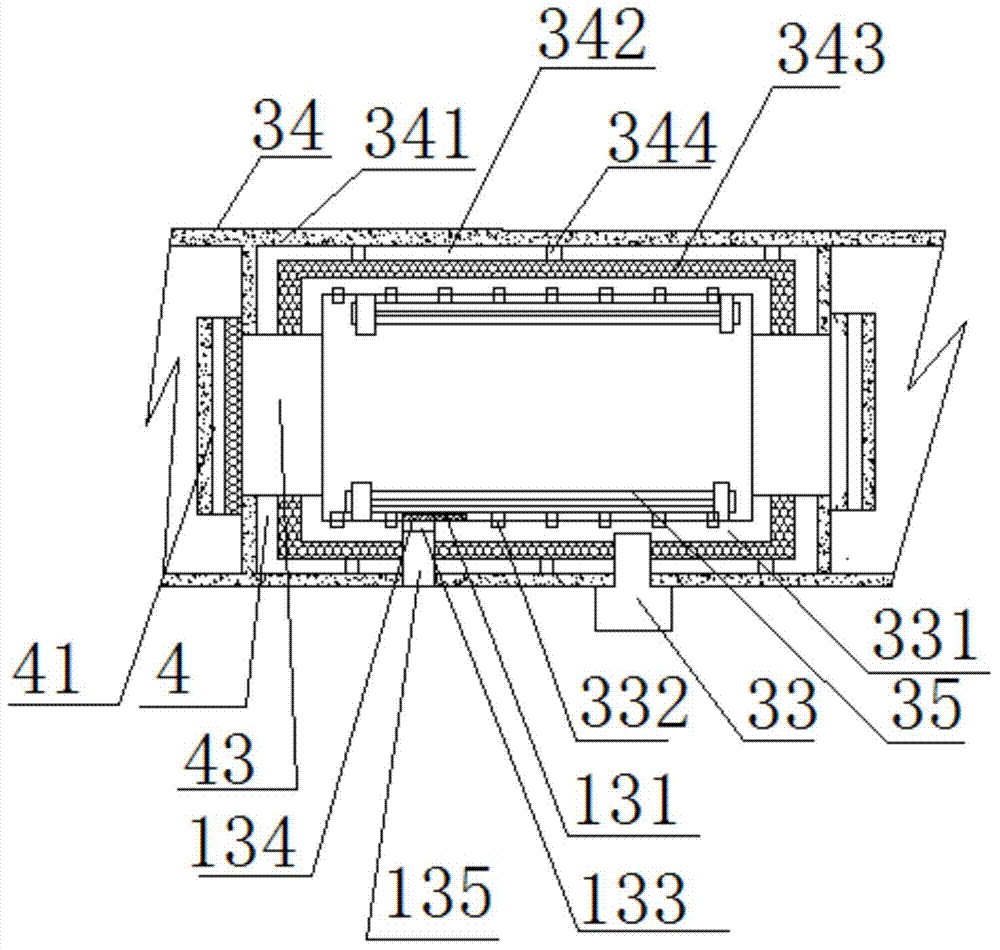

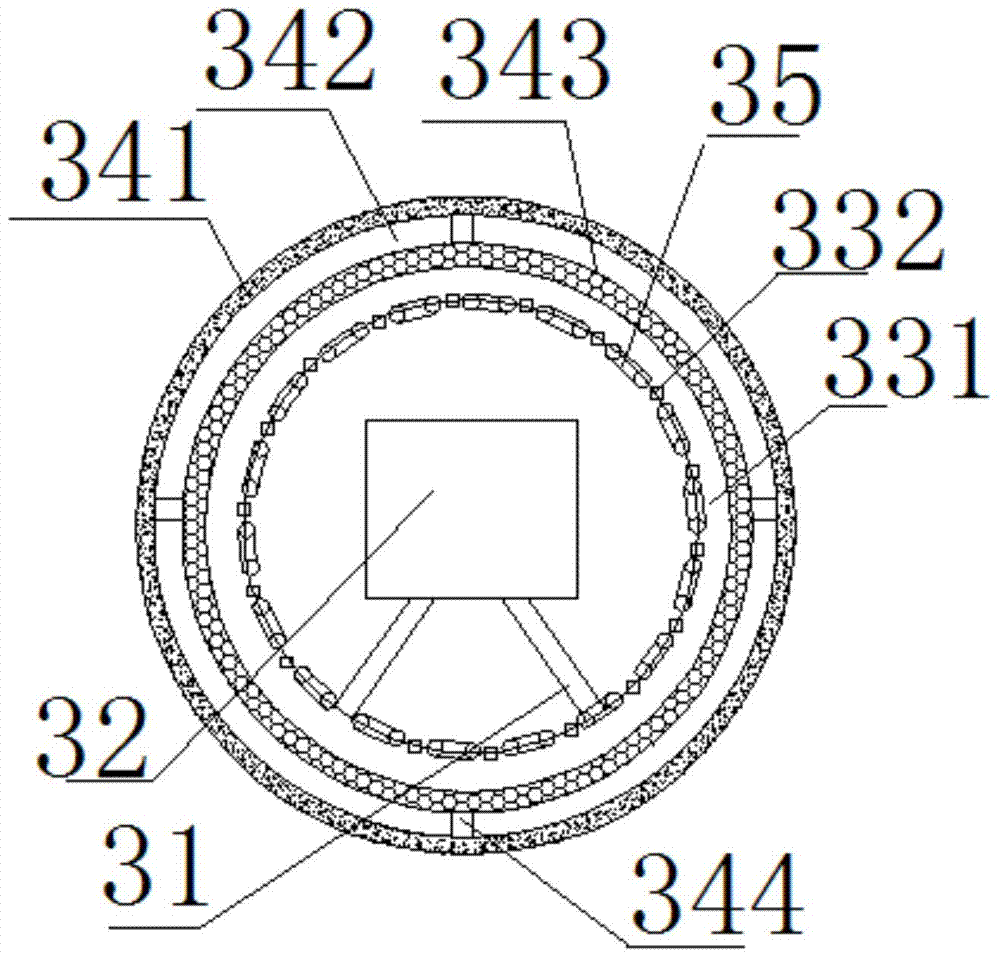

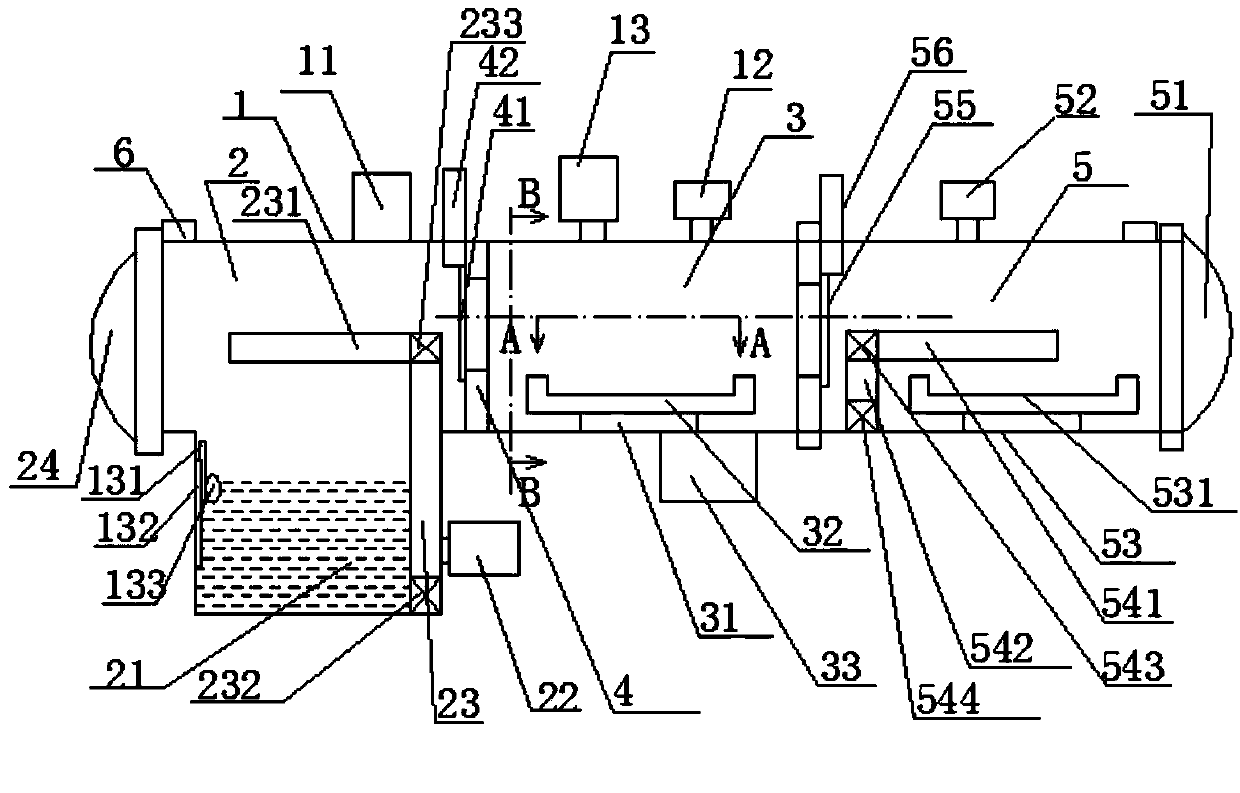

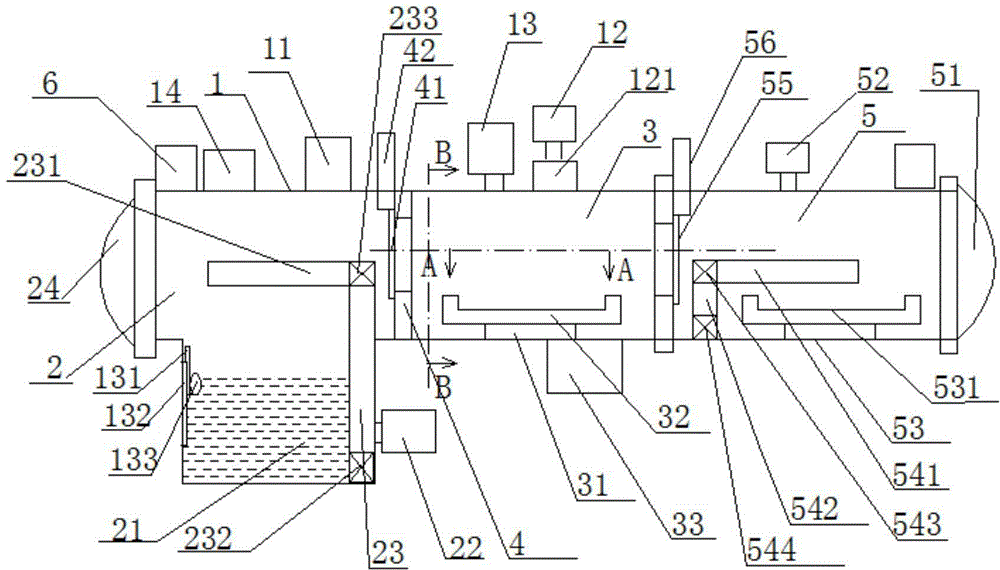

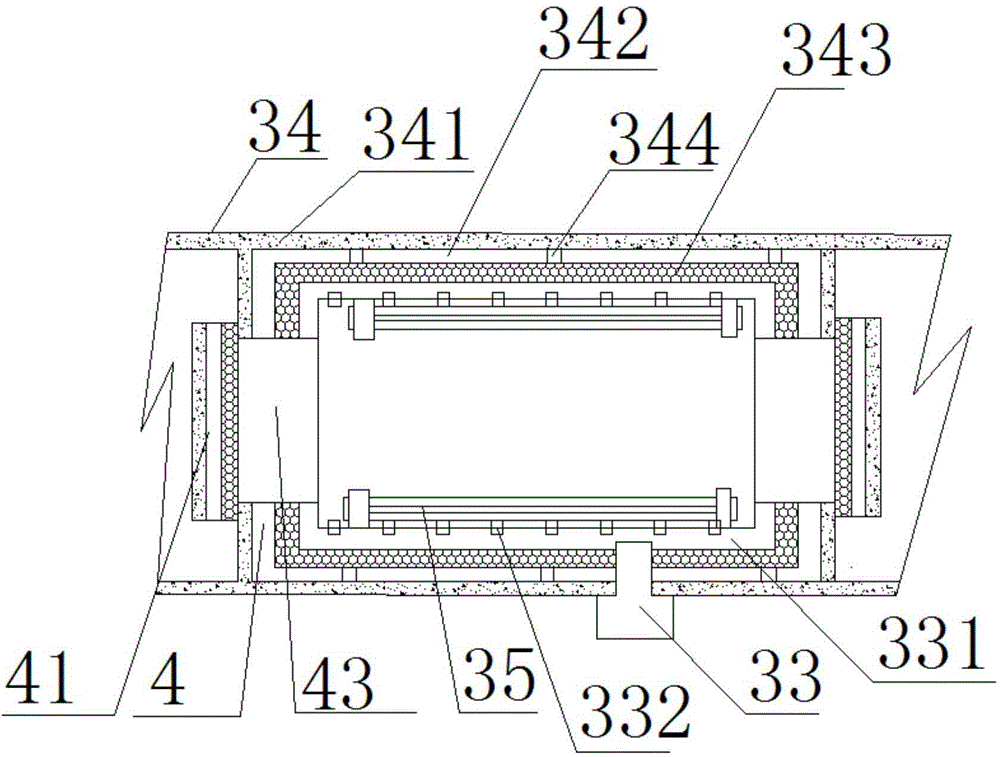

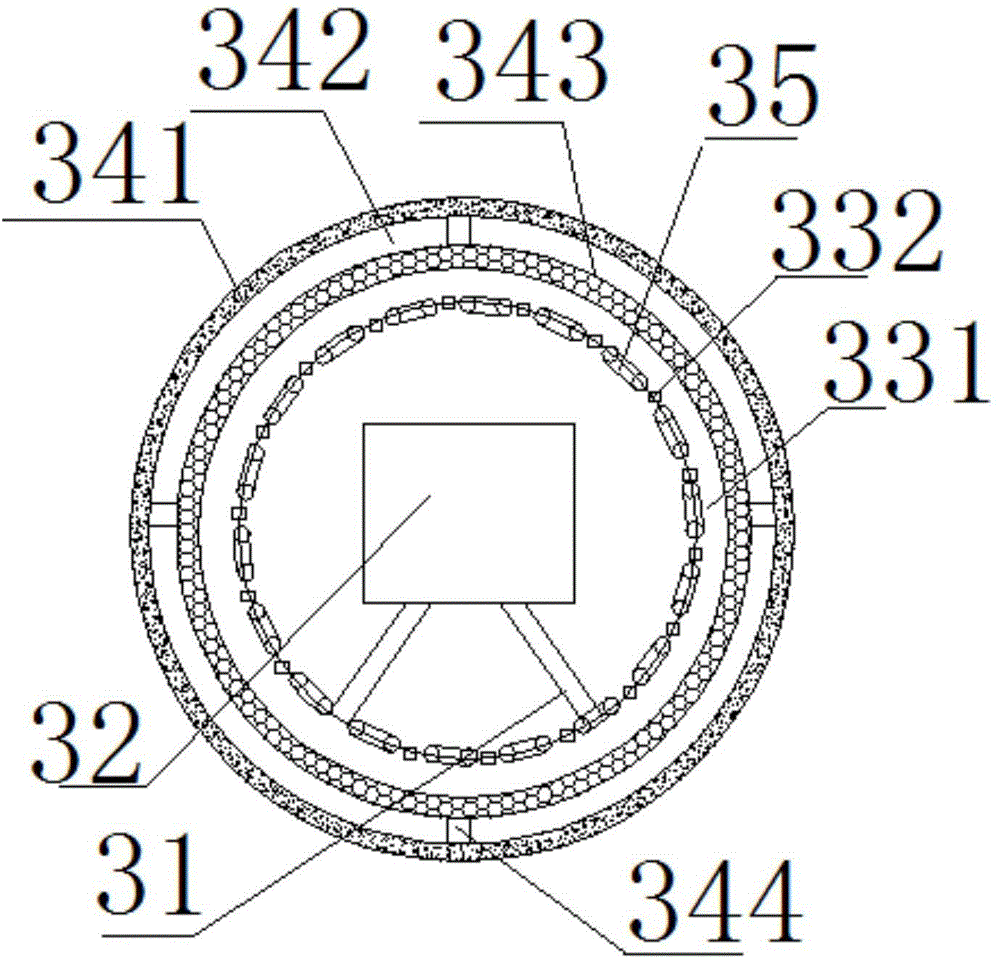

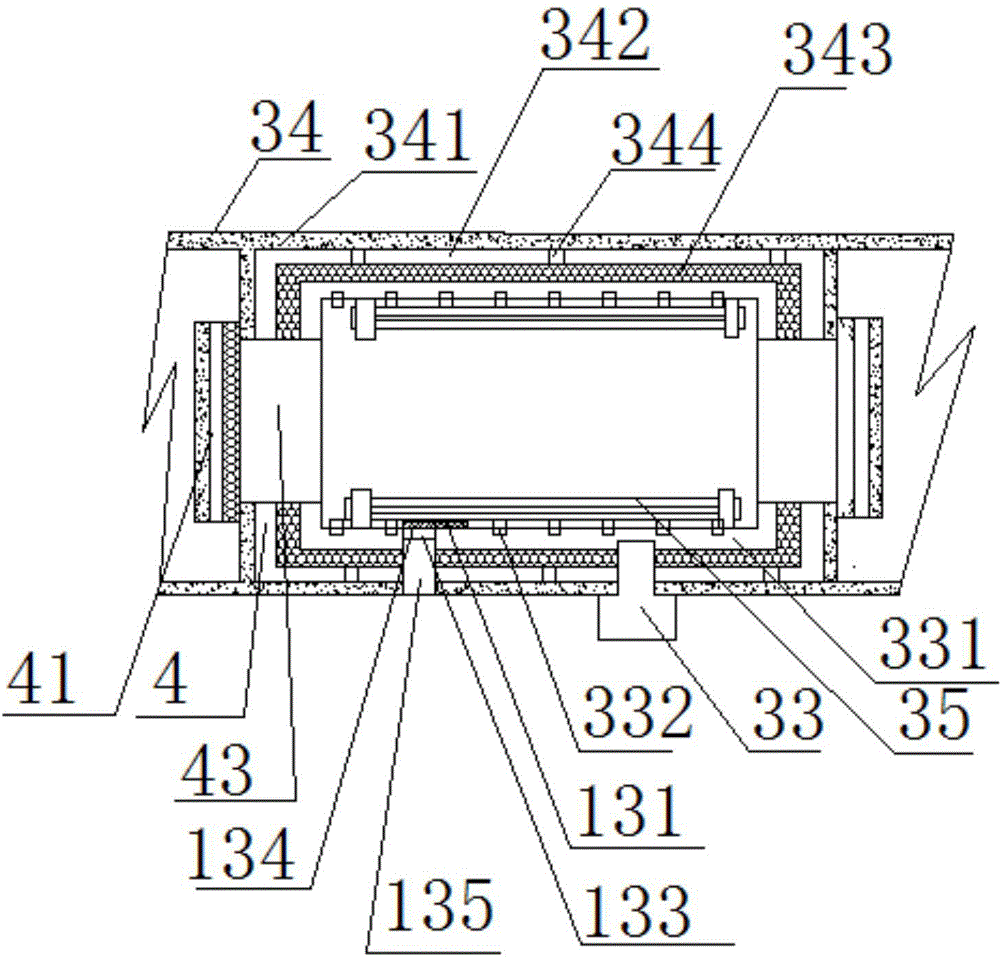

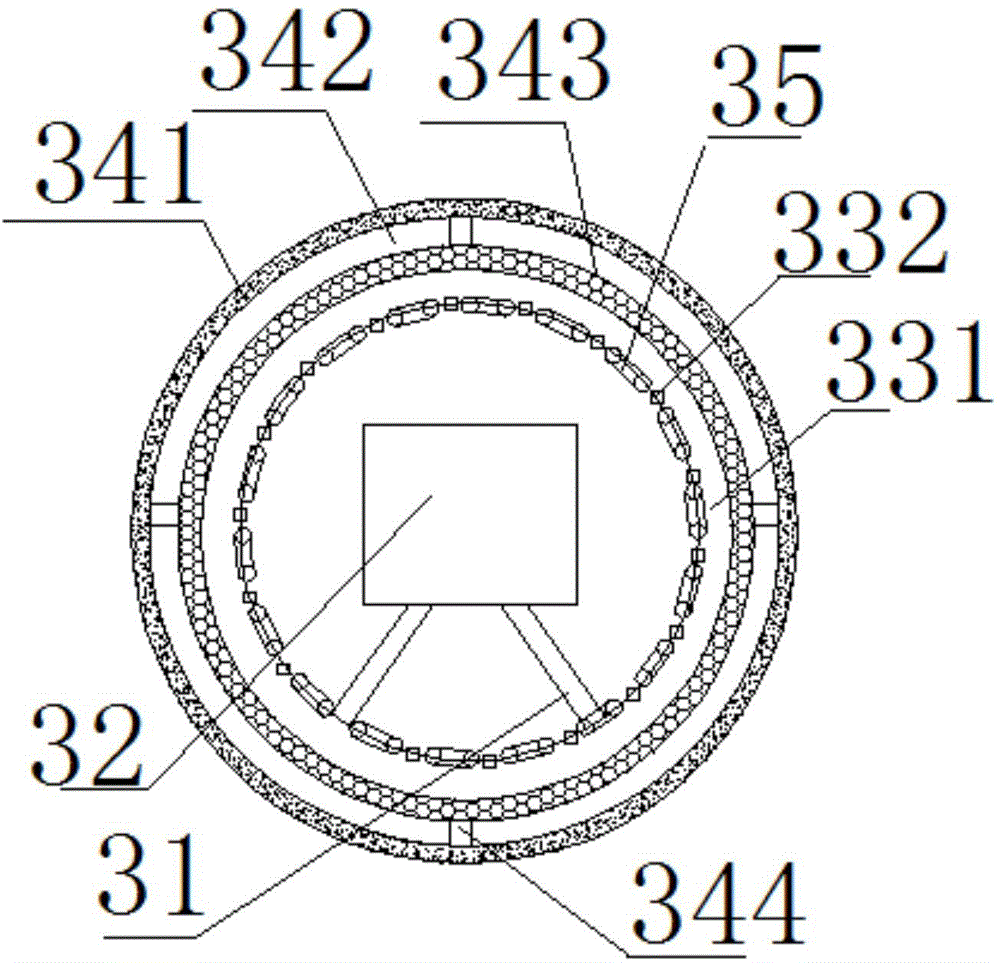

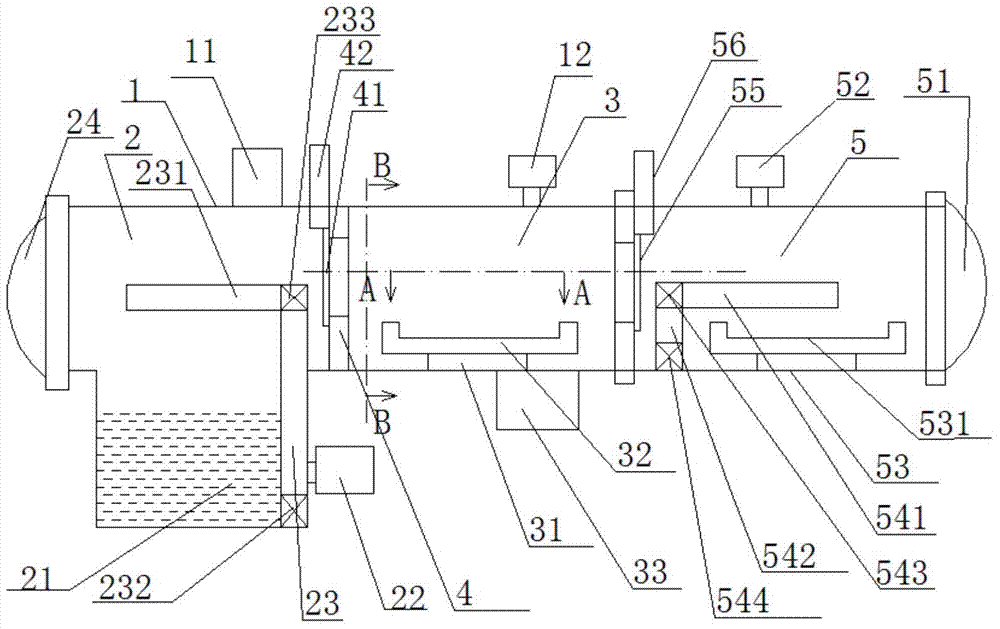

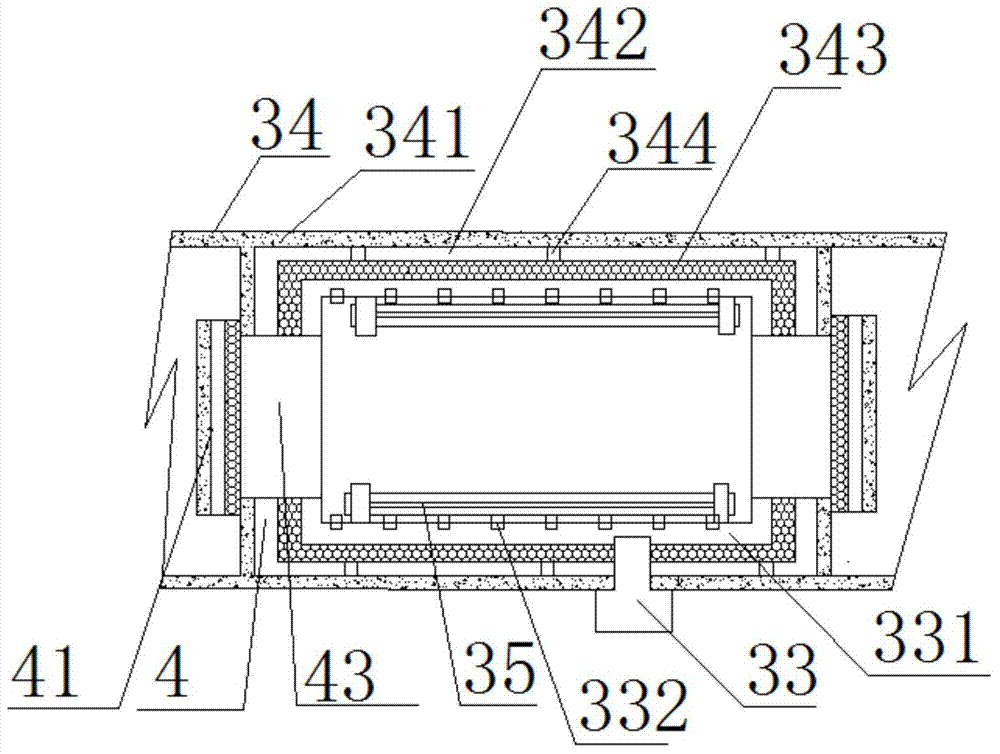

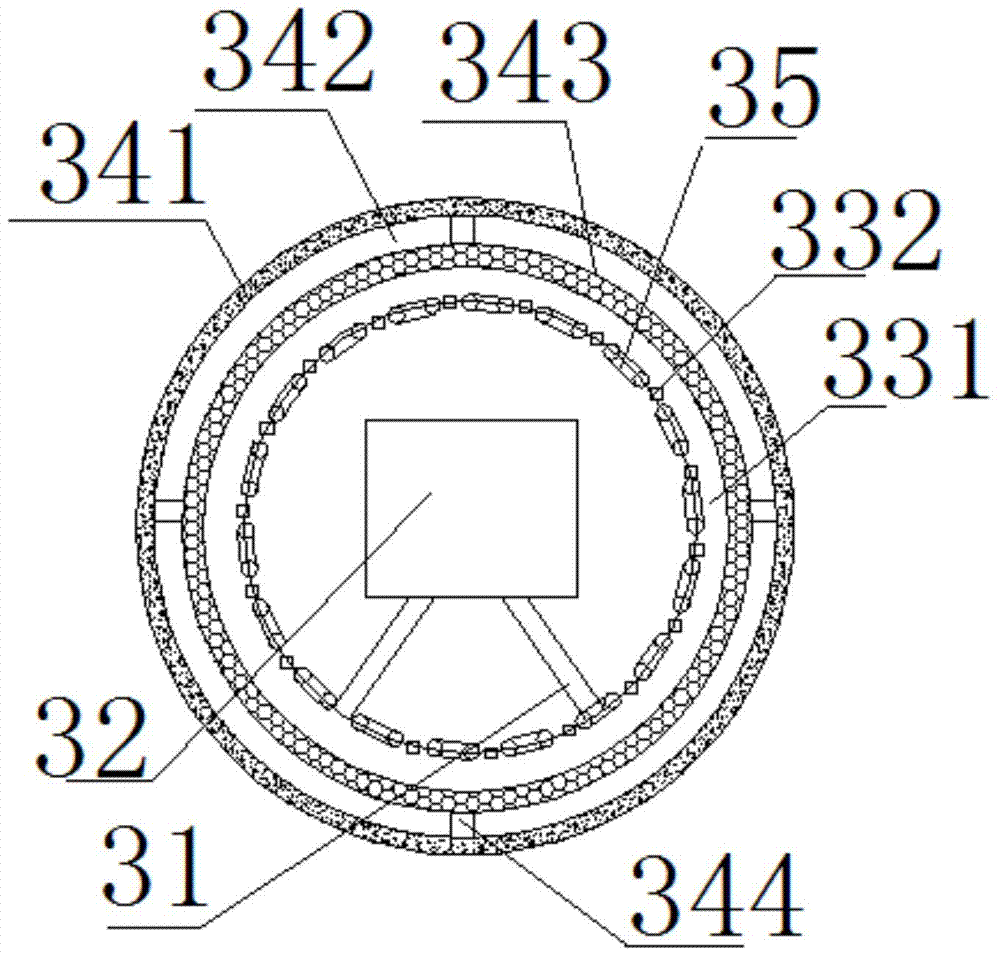

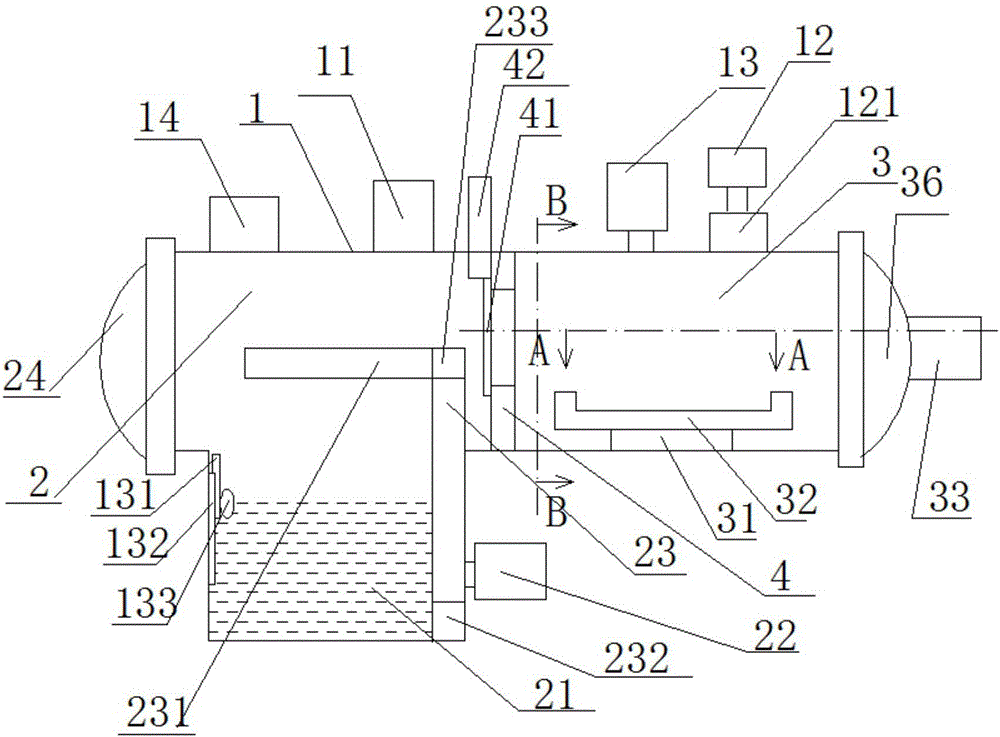

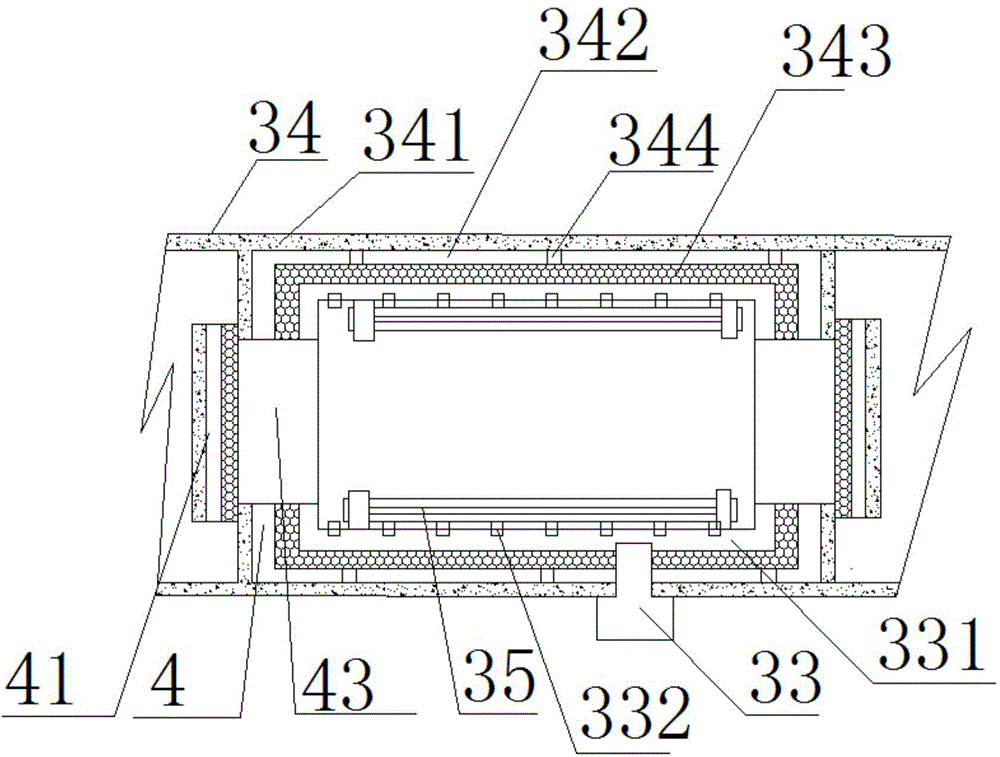

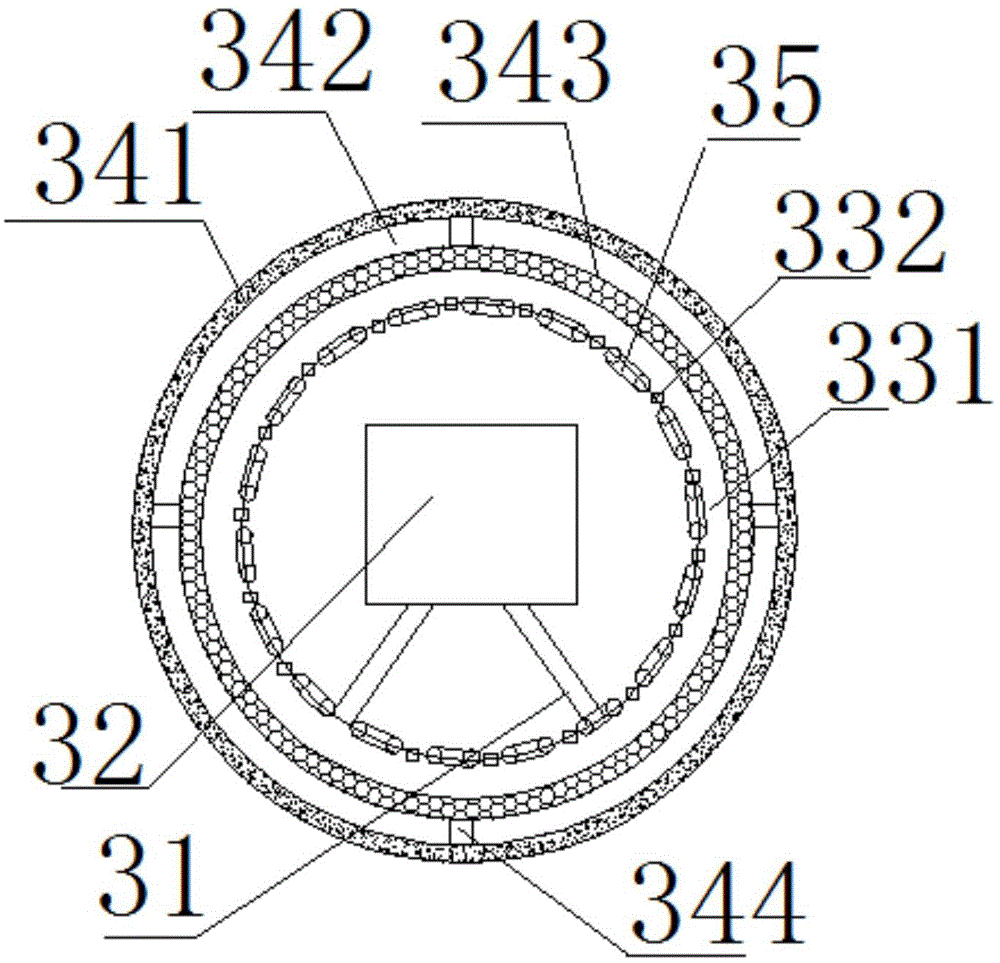

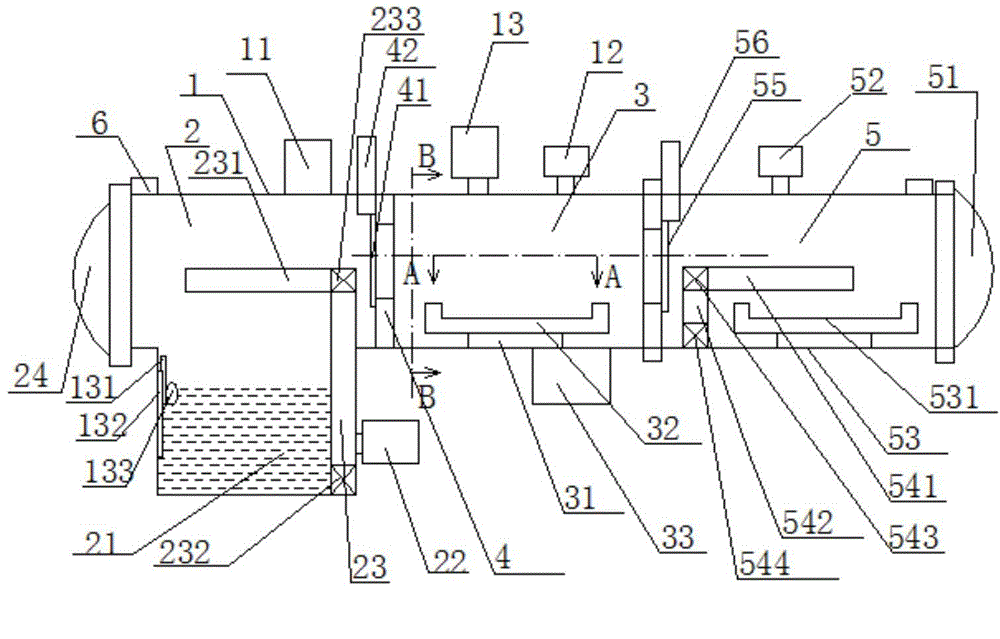

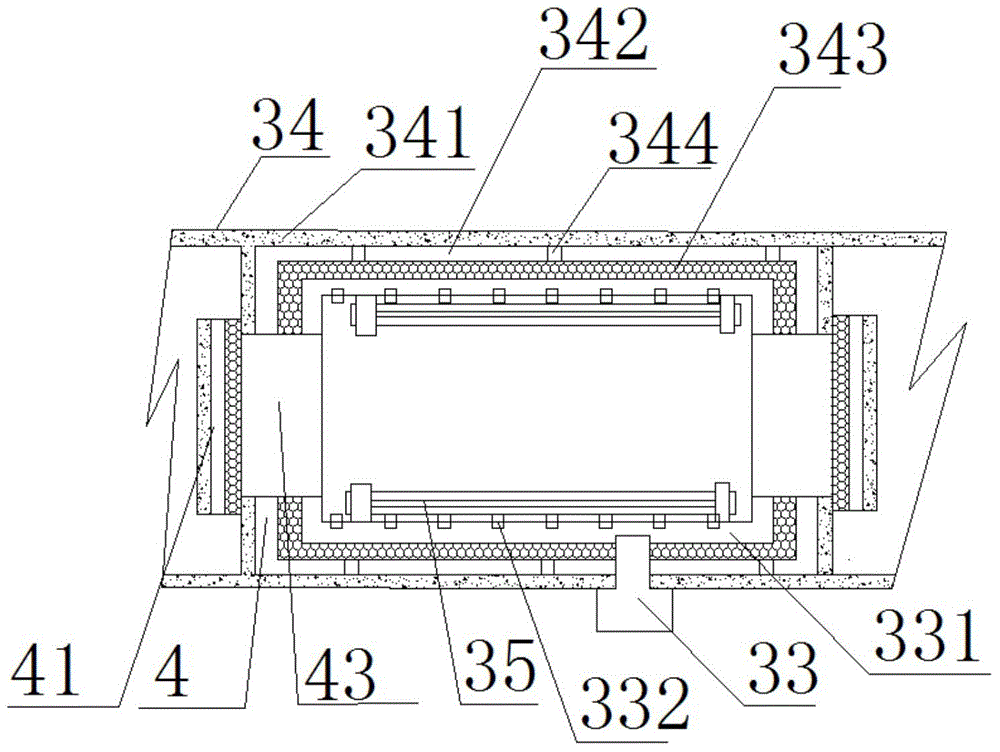

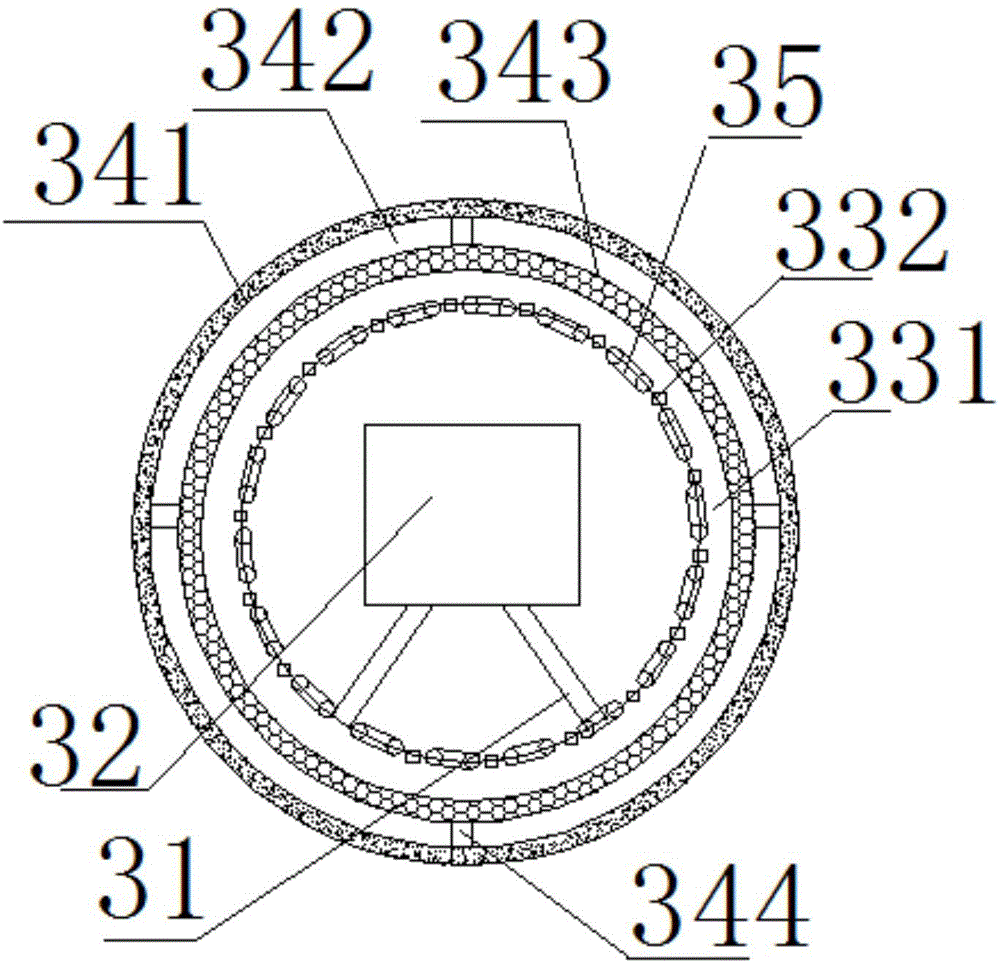

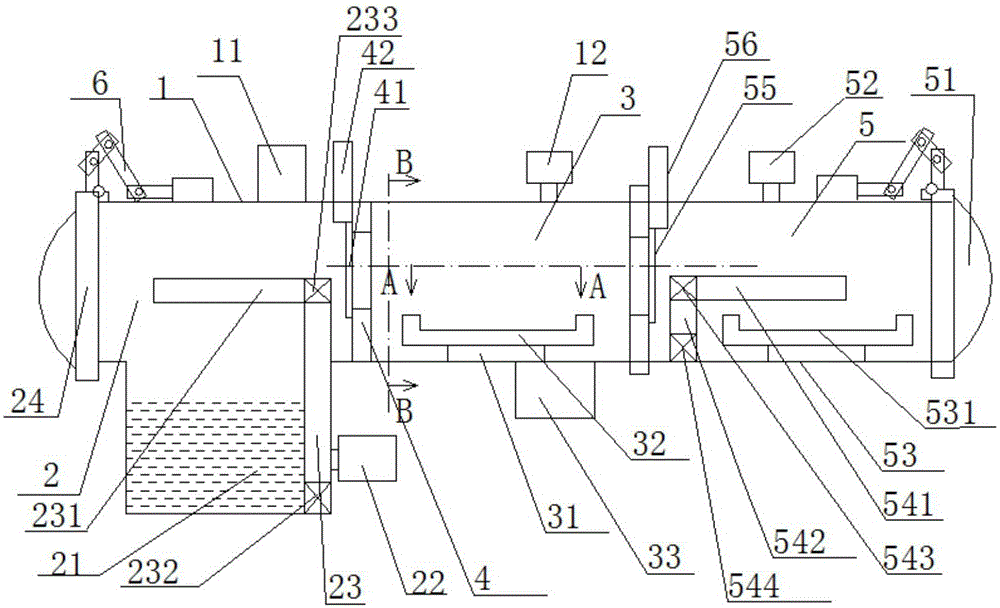

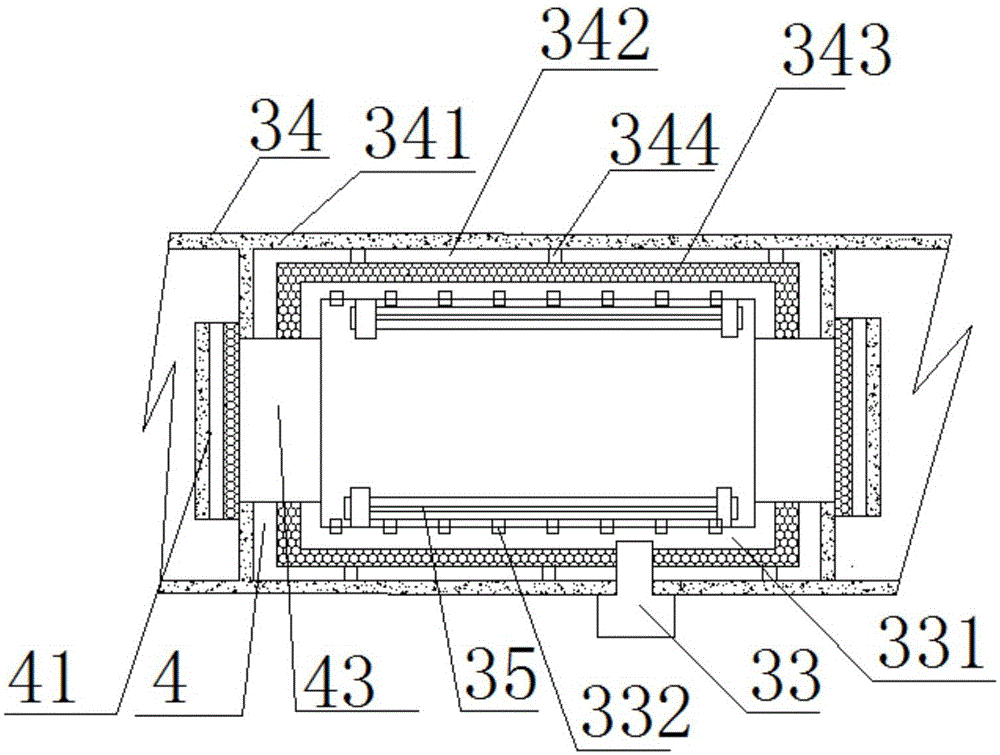

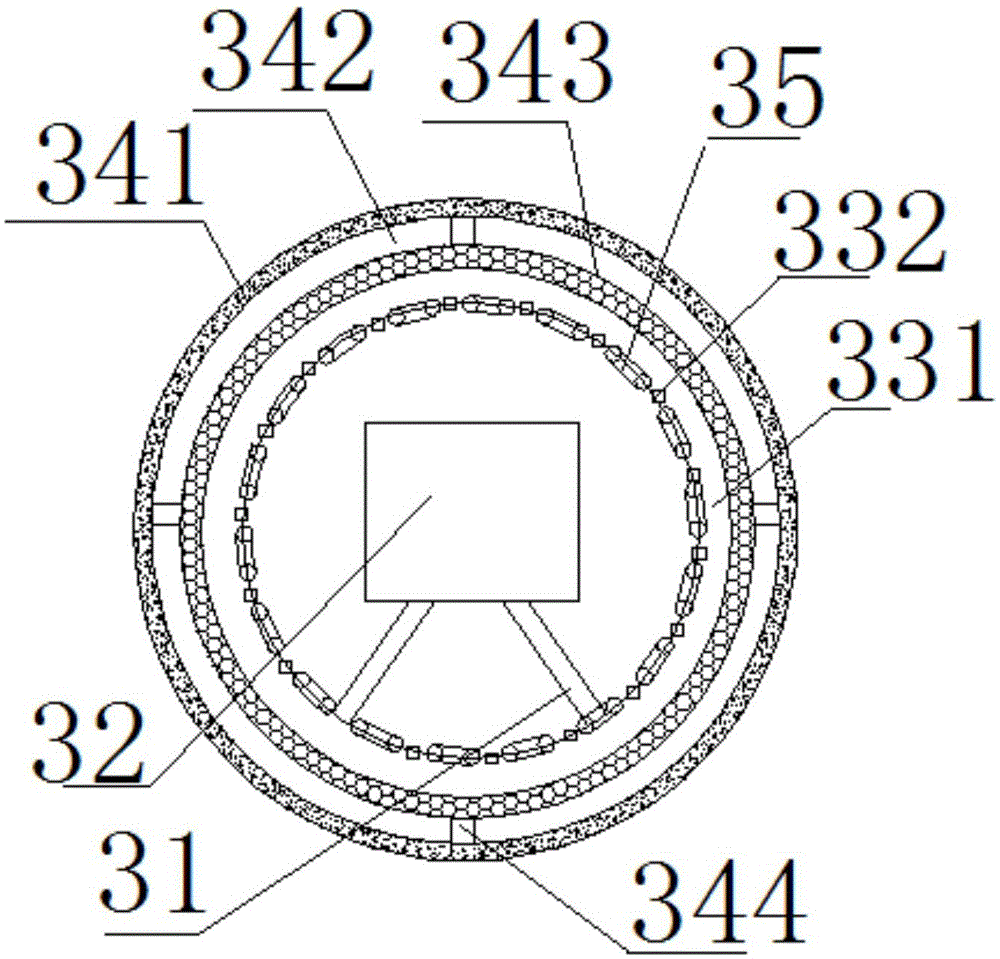

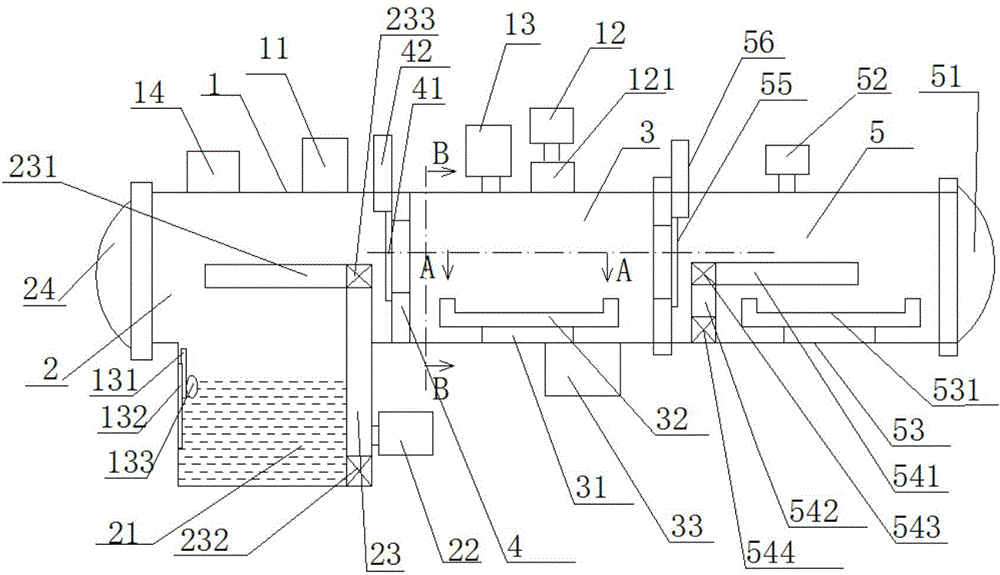

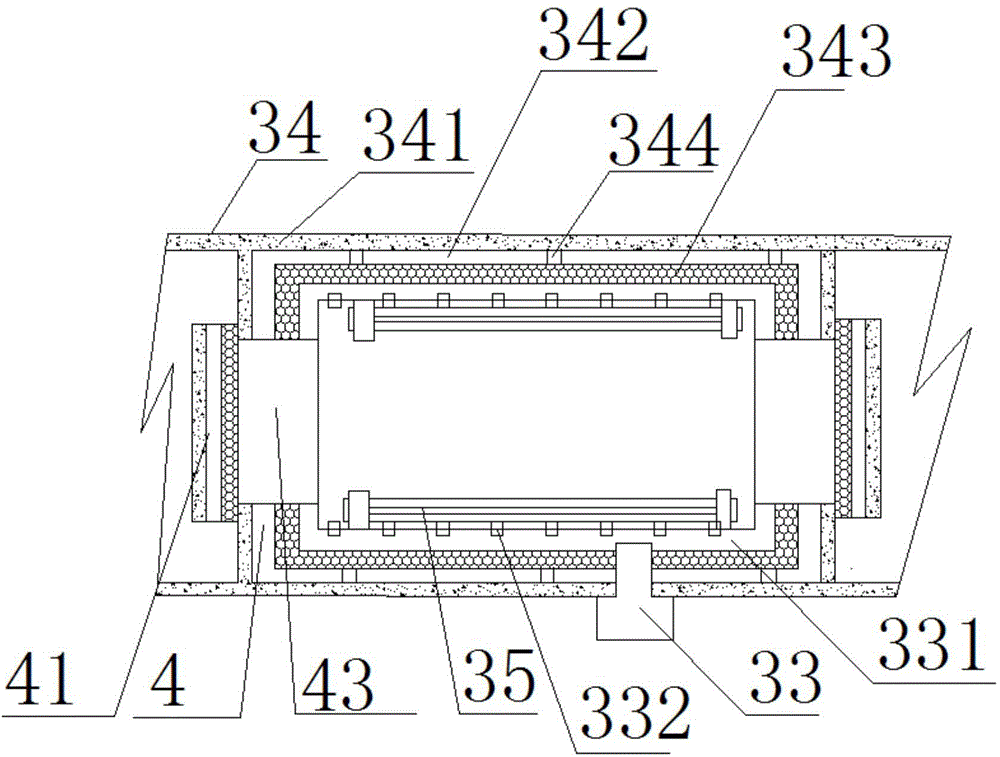

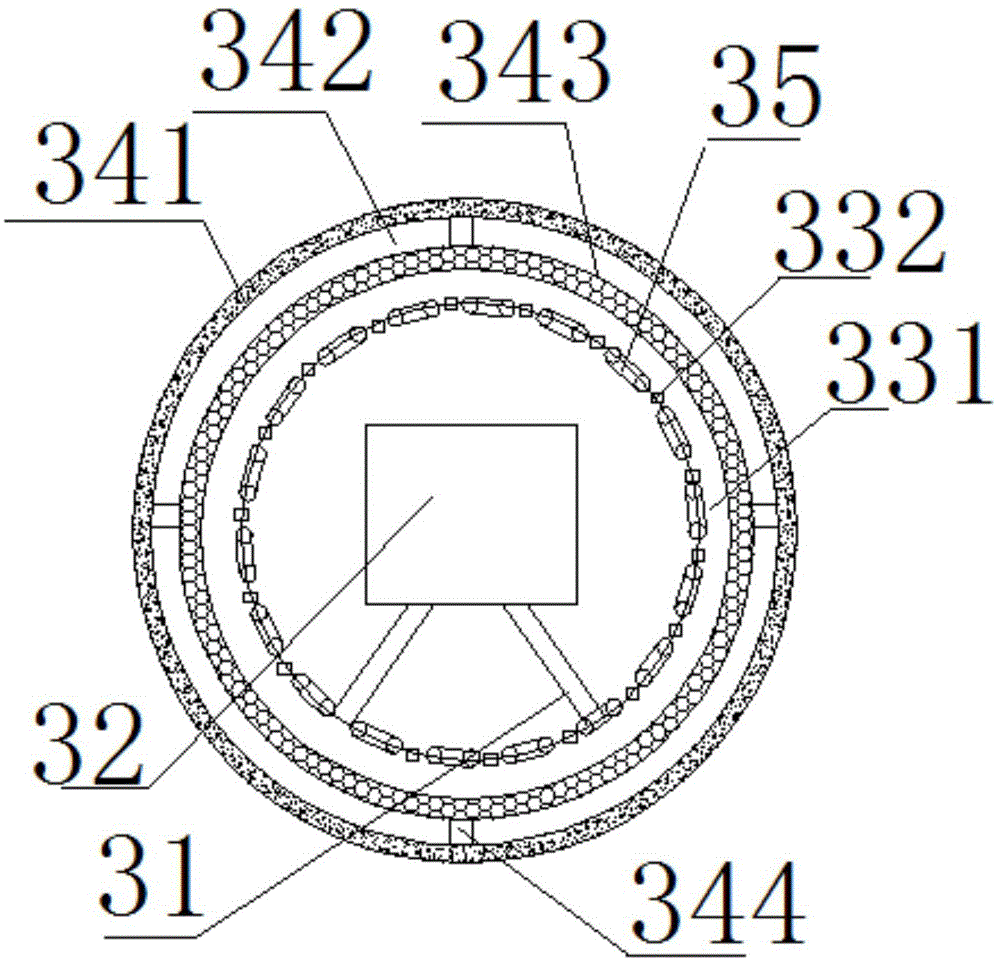

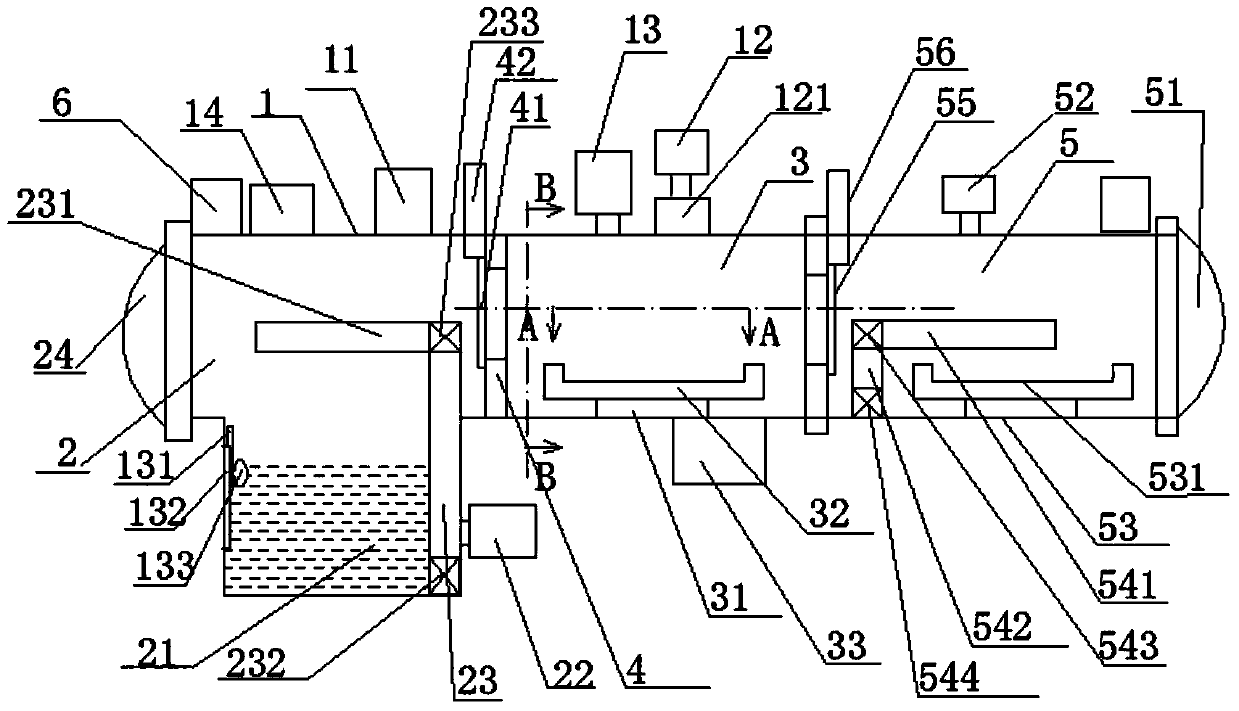

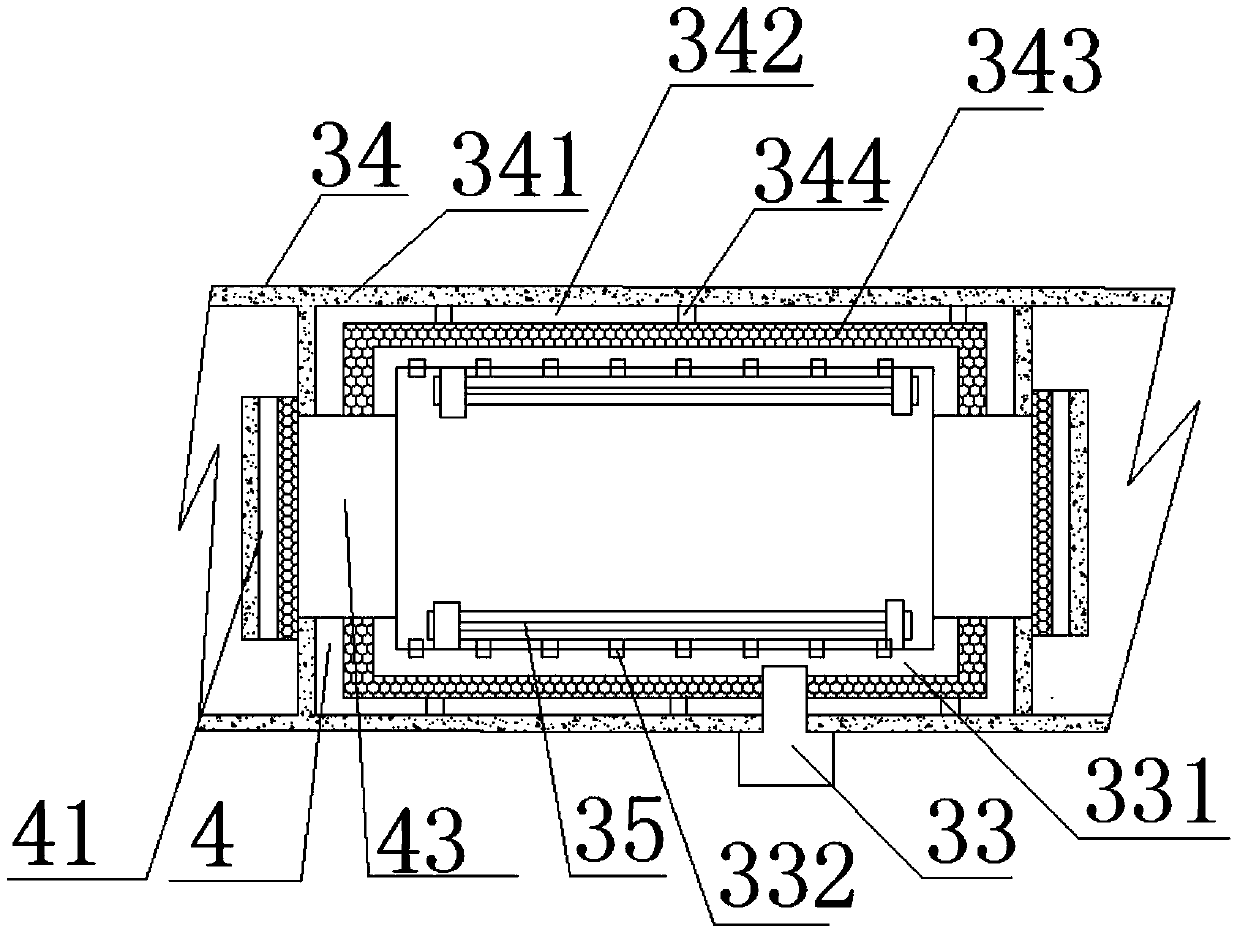

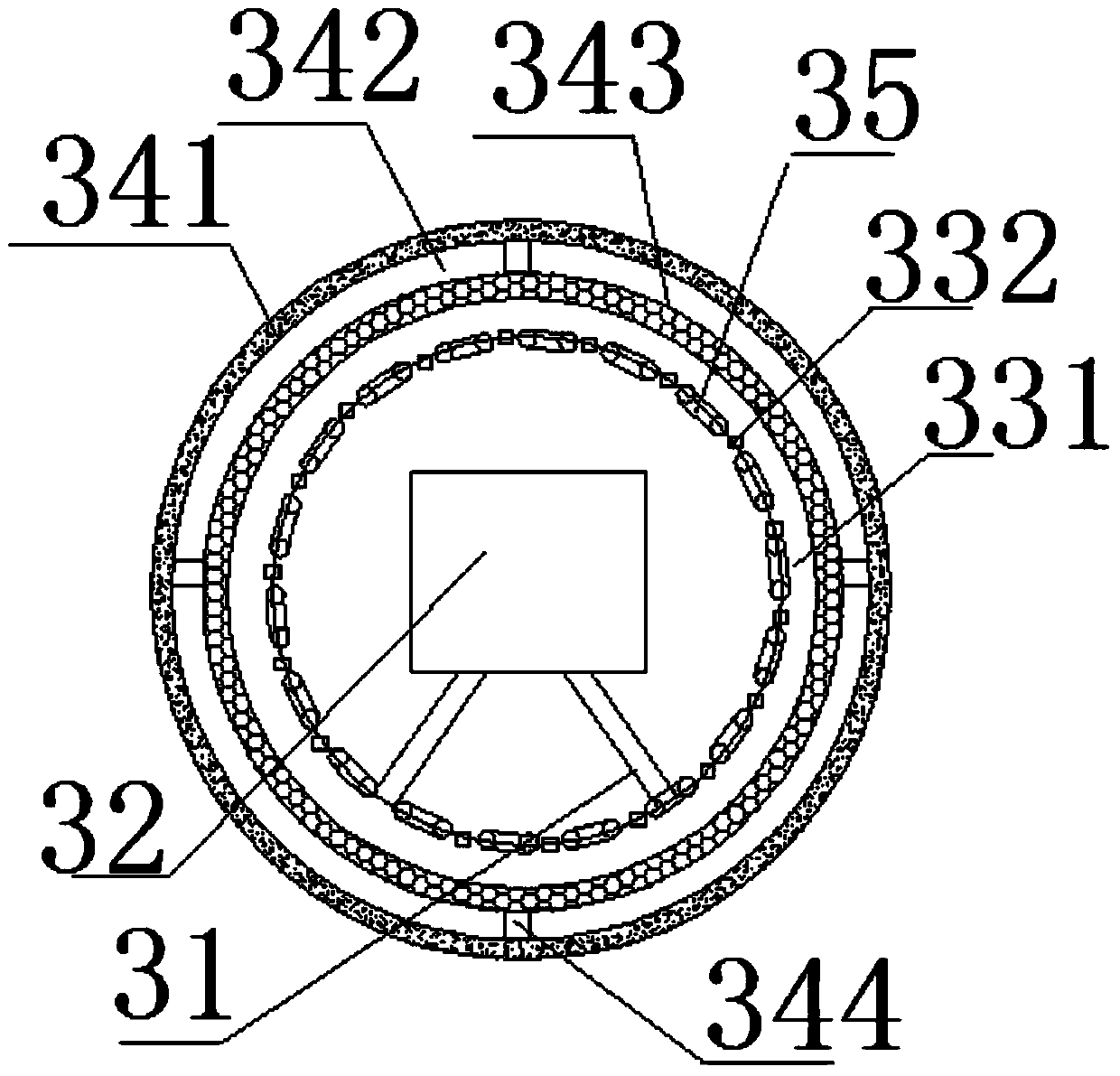

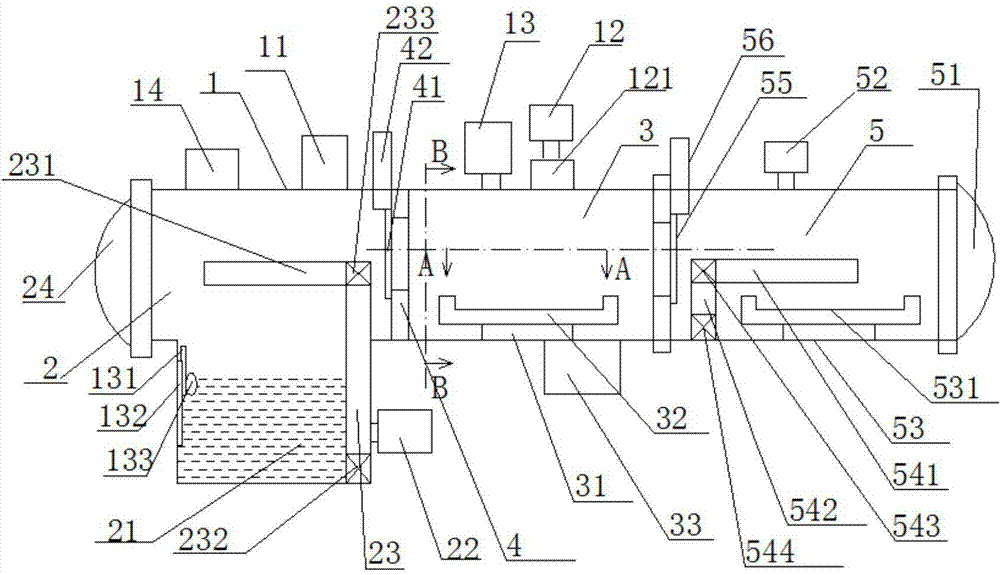

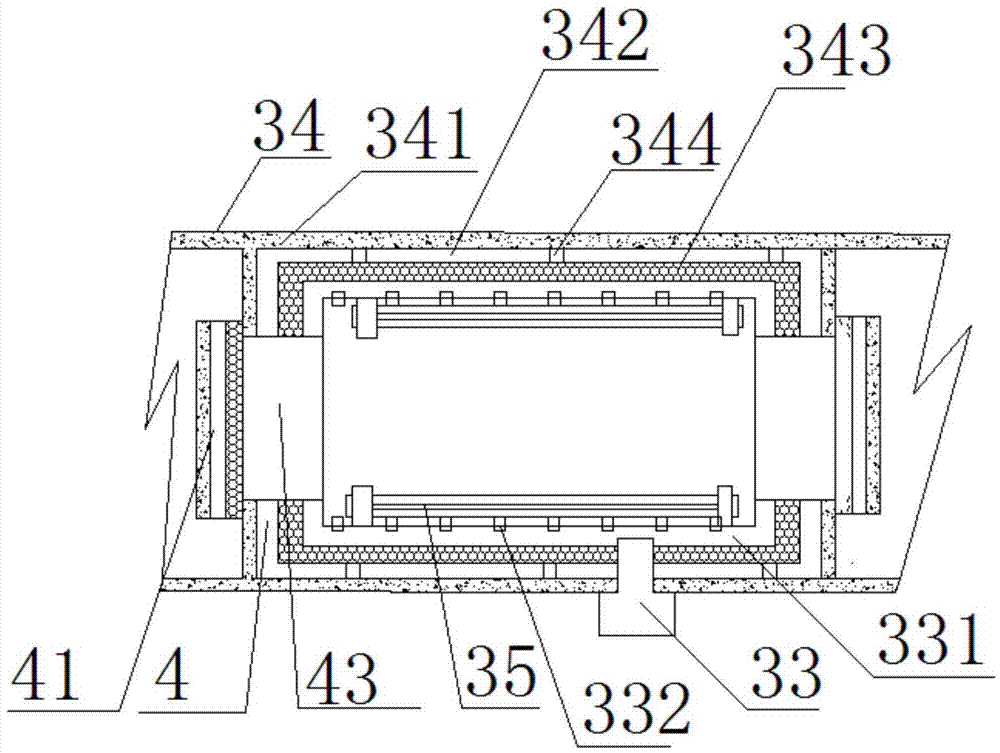

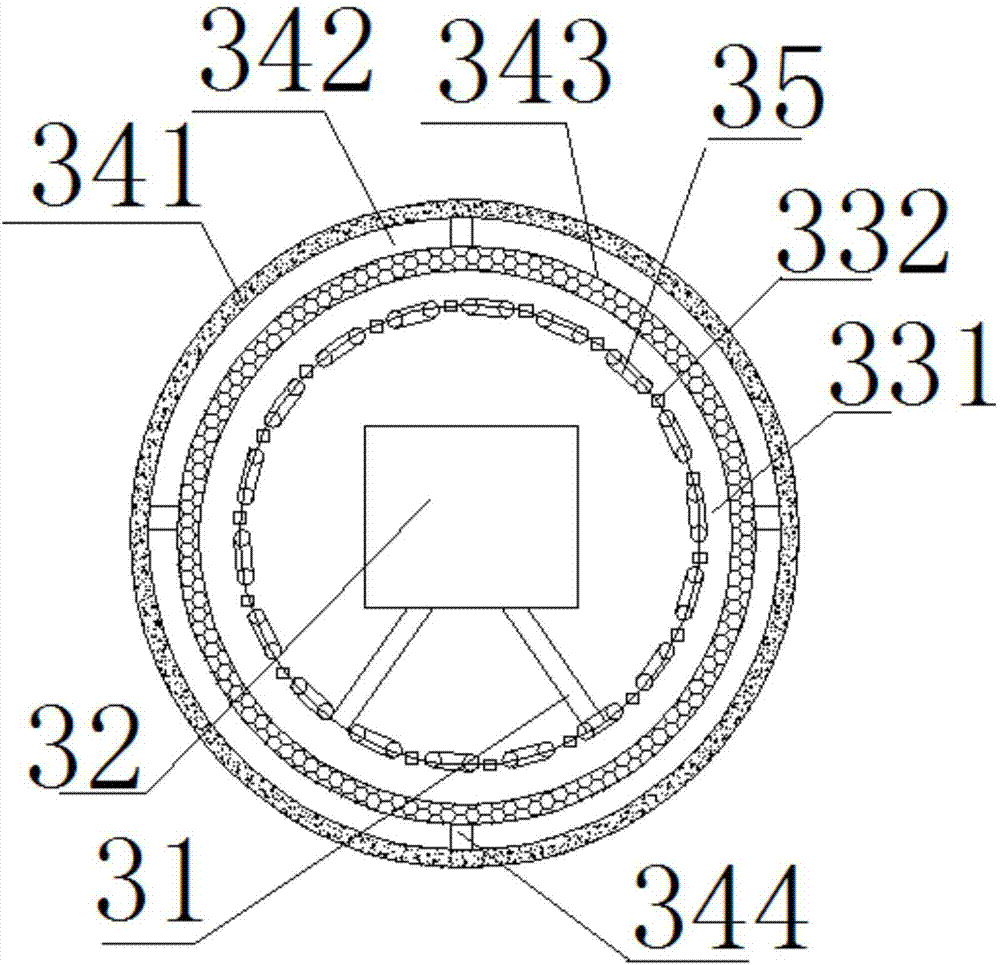

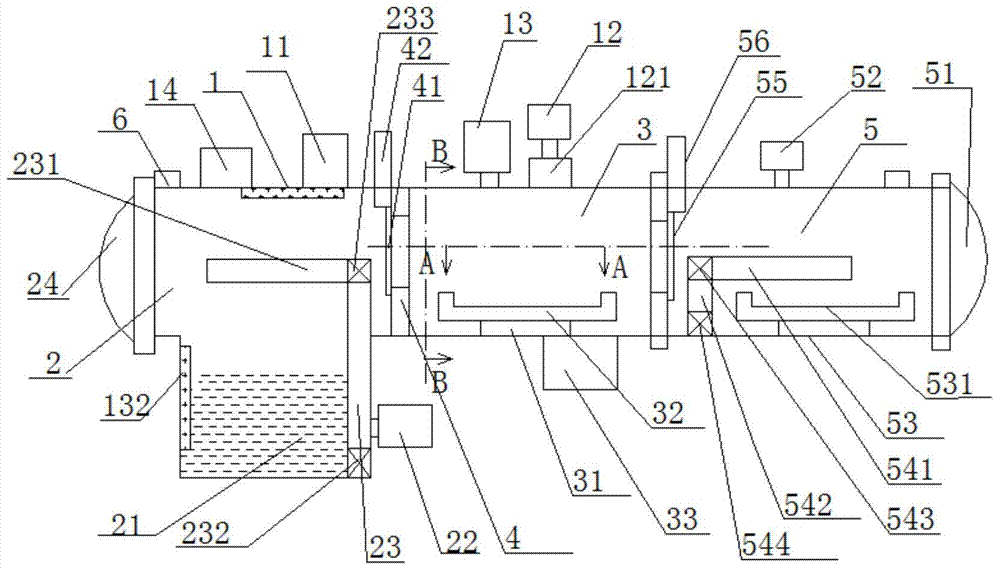

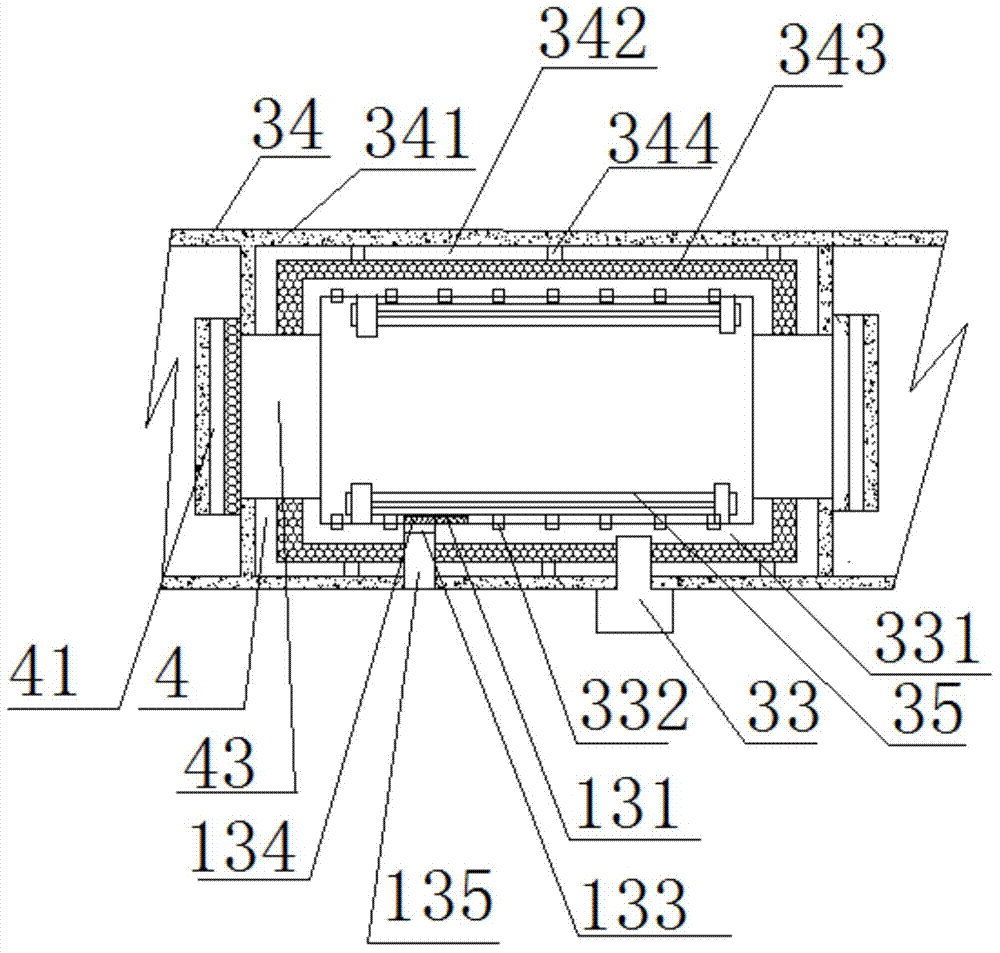

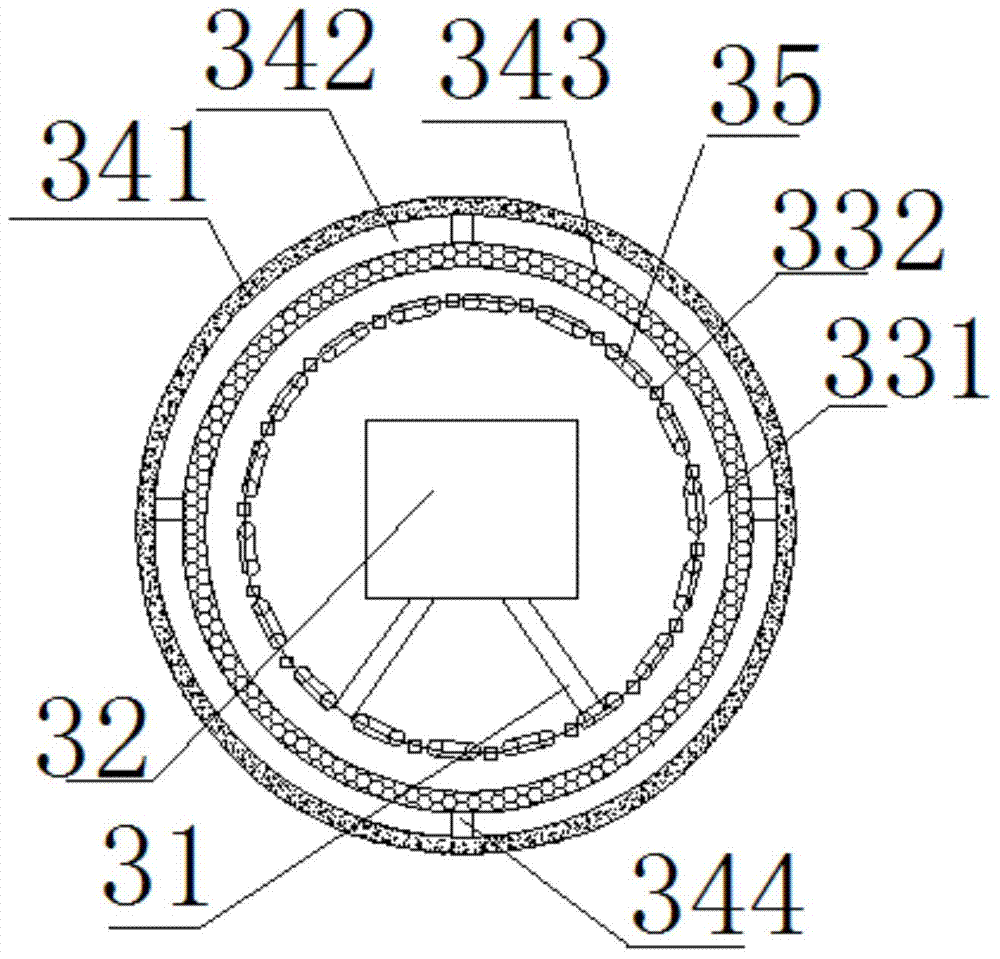

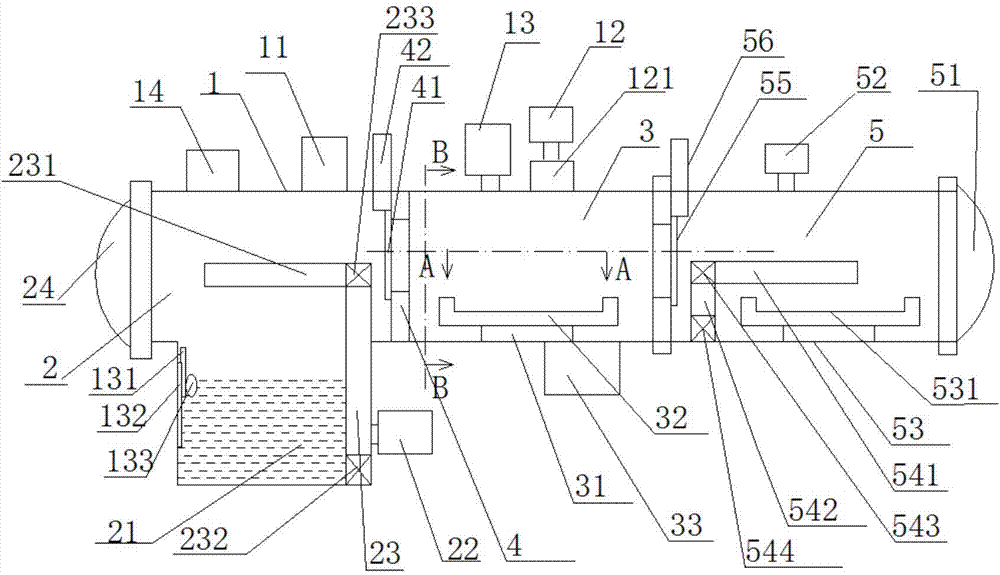

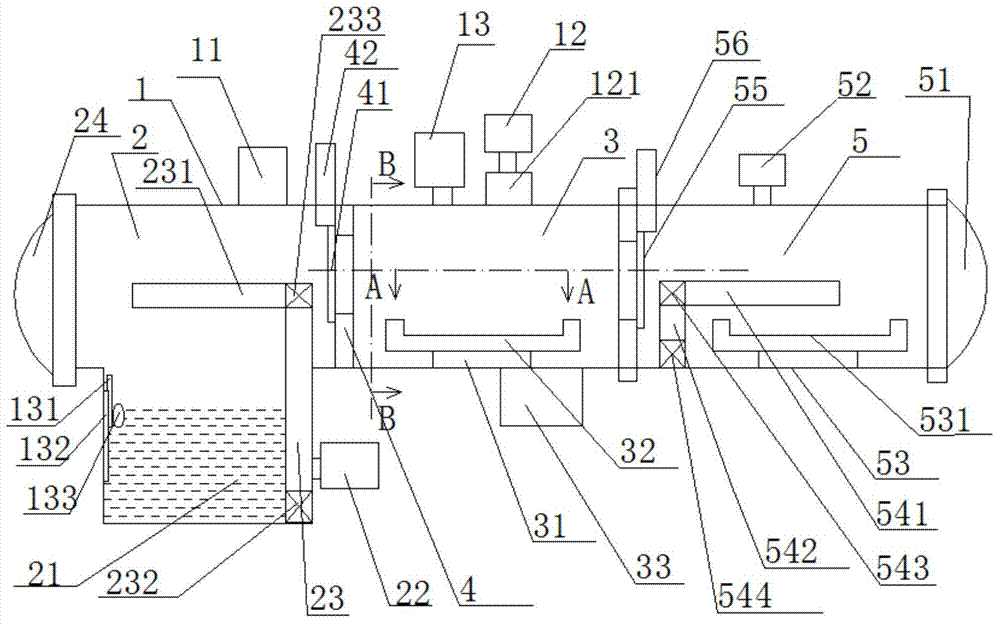

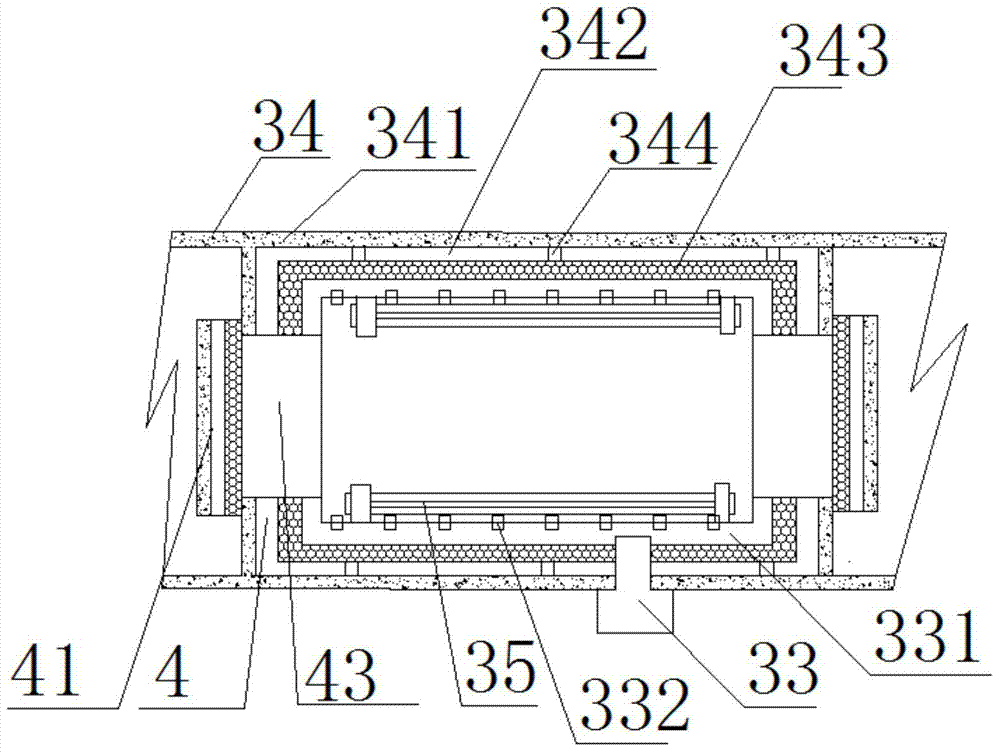

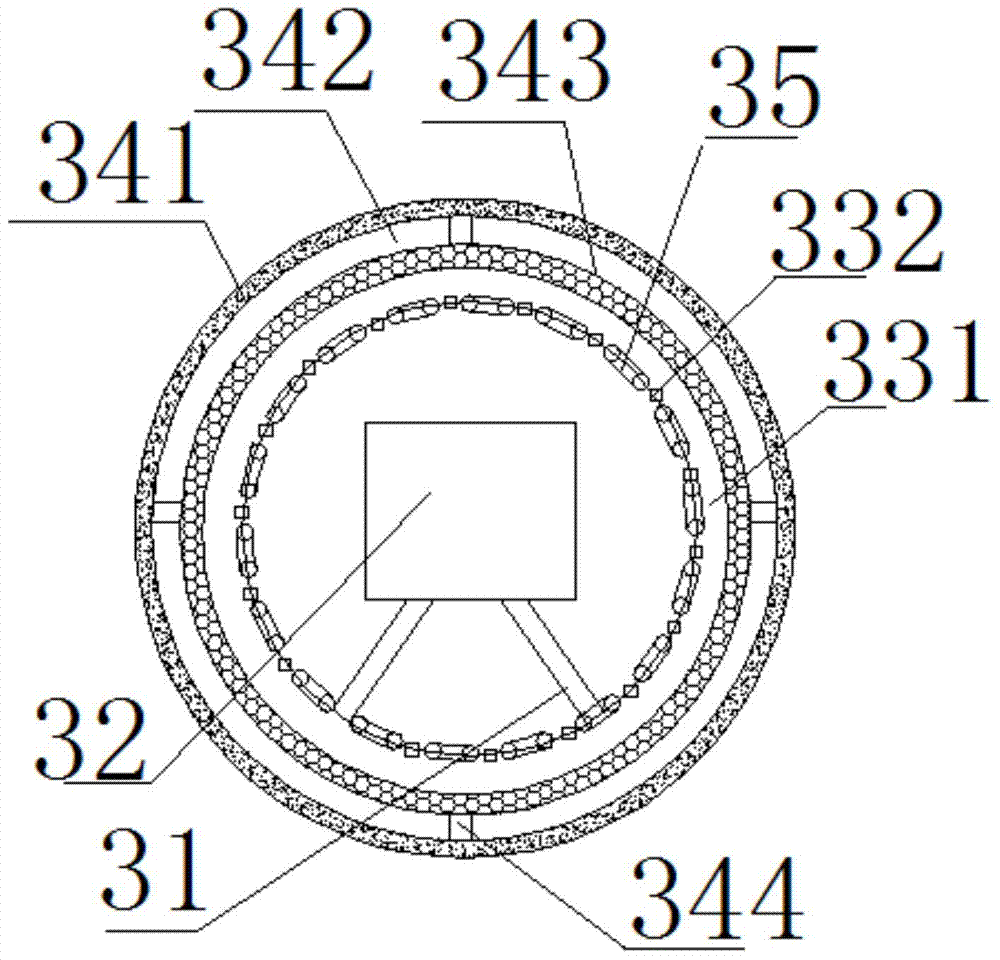

The invention relates to an anticorrosive vacuumizer pollution-discharge spraying-purification operation-observing / monitoring vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can observe the machining condition, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

Anticorrosive vacuumizer pollution-discharge liquid-purification observation-monitoring-operation vacuum furnace

InactiveCN103740908AEvenly heatedNot easy to splashFurnace typesHeat treatment process controlInsulation layerCooling chamber

The invention relates to an anticorrosive vacuumizer pollution-discharge liquid-purification observation-monitoring-operation vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can observe the machining condition, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Monitoring and operating three-chamber vacuum furnace

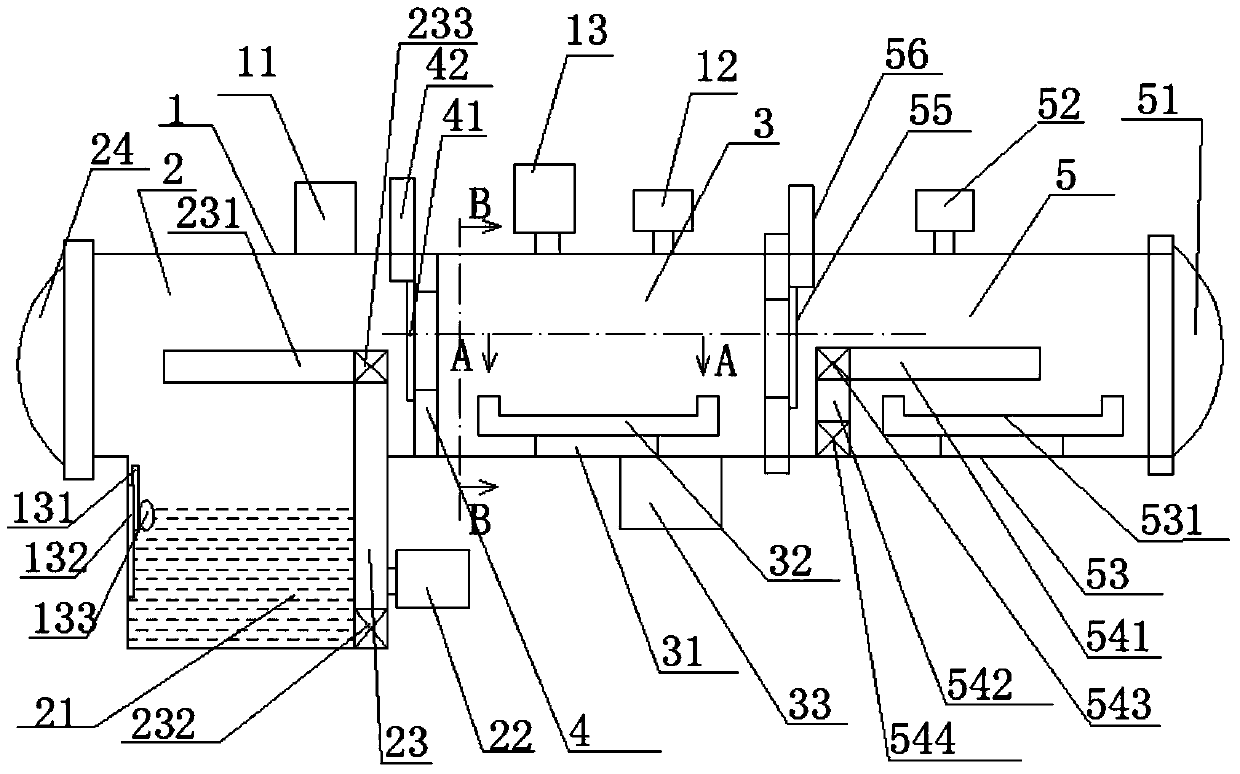

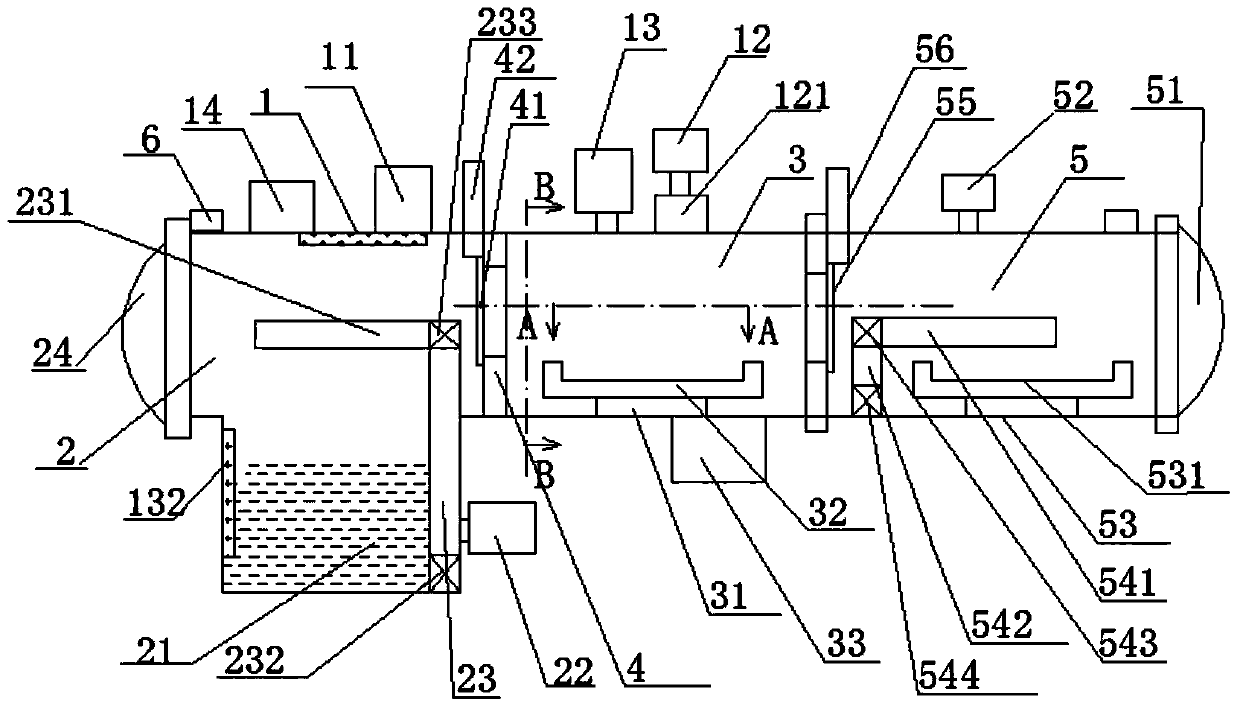

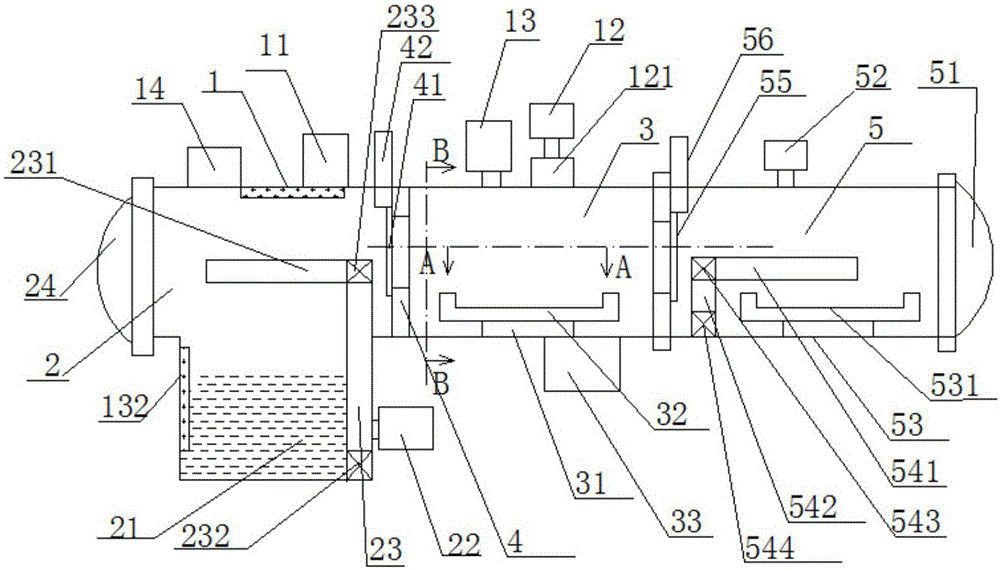

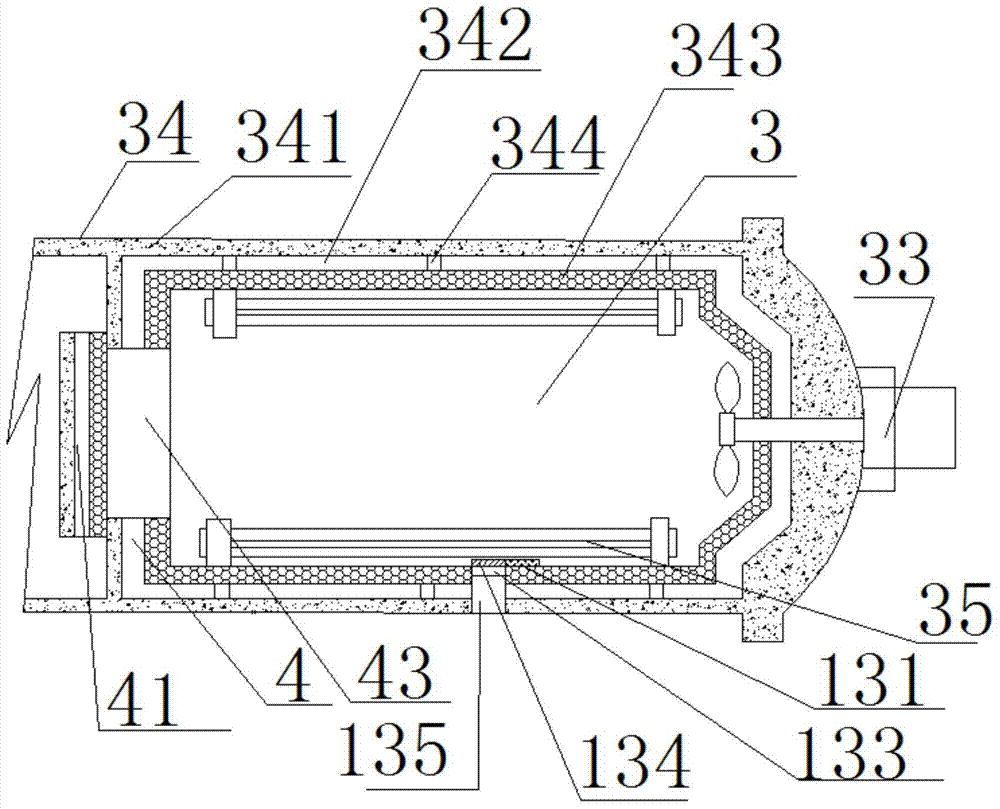

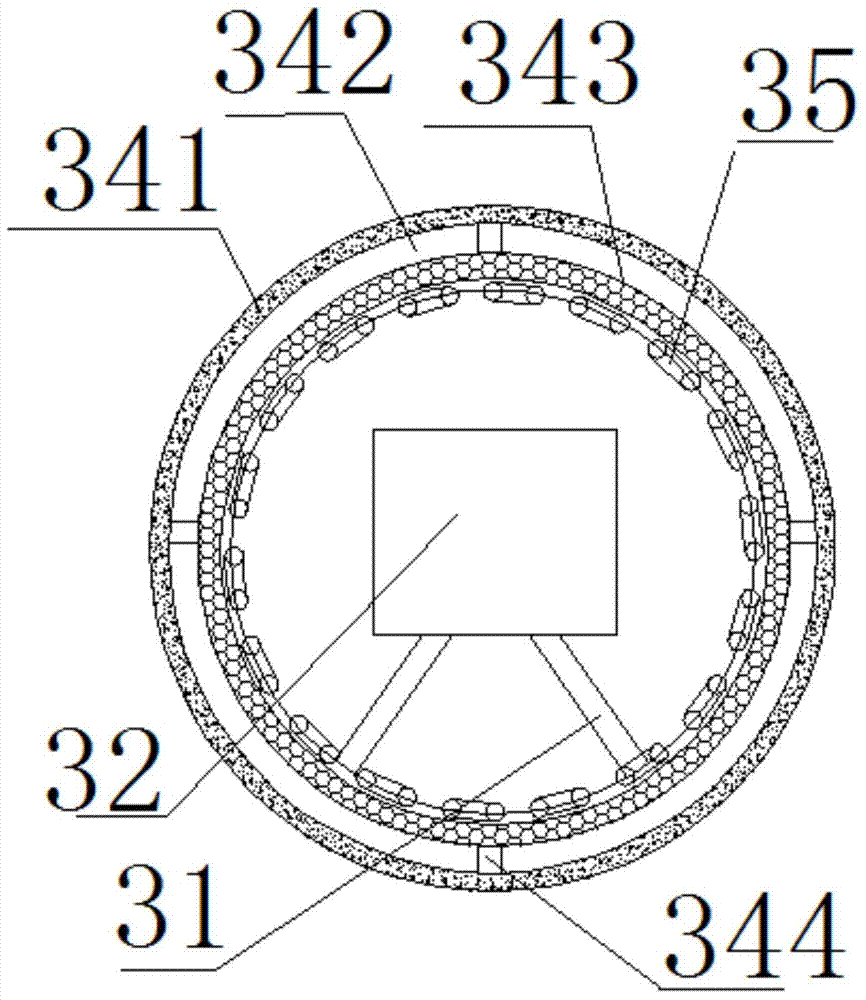

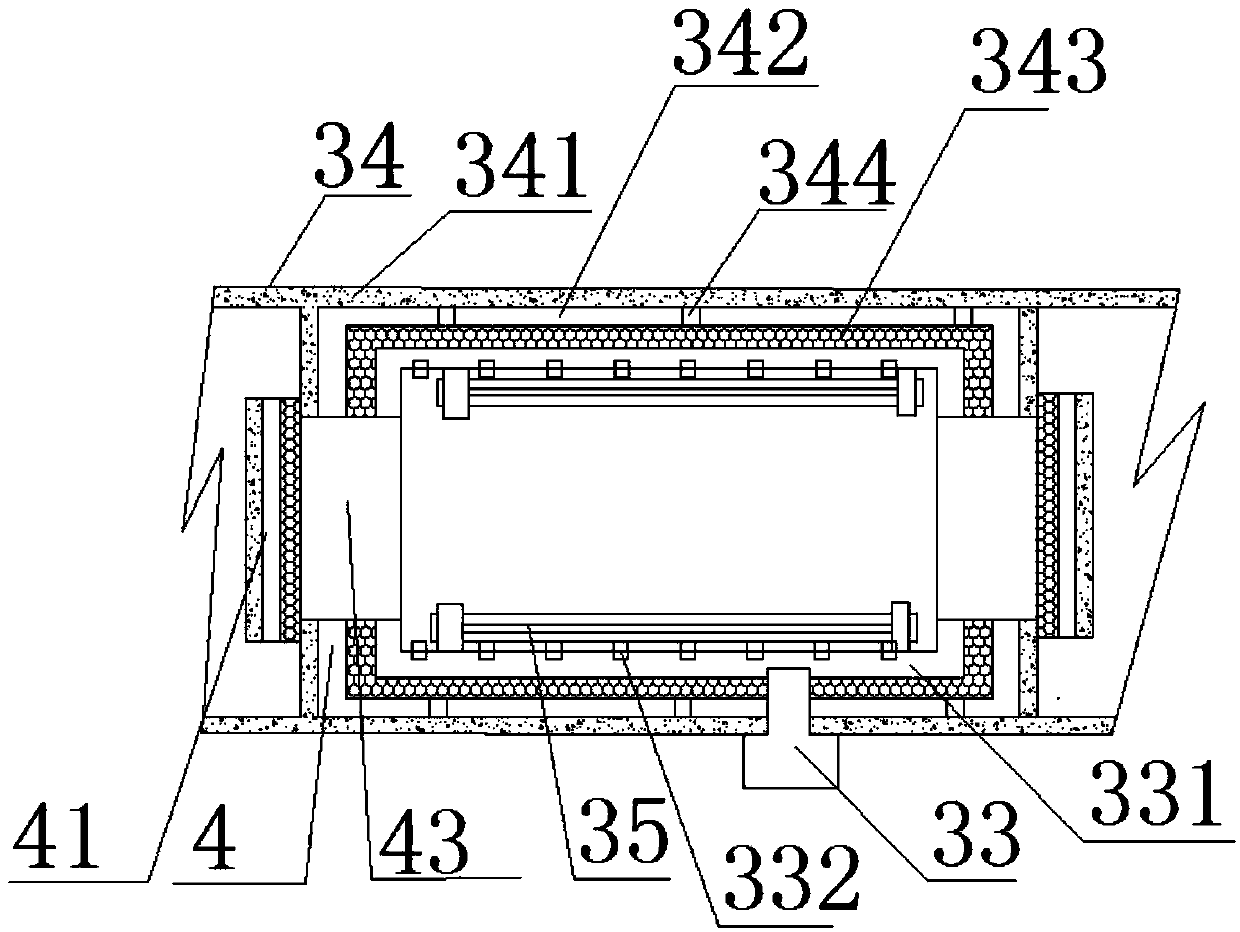

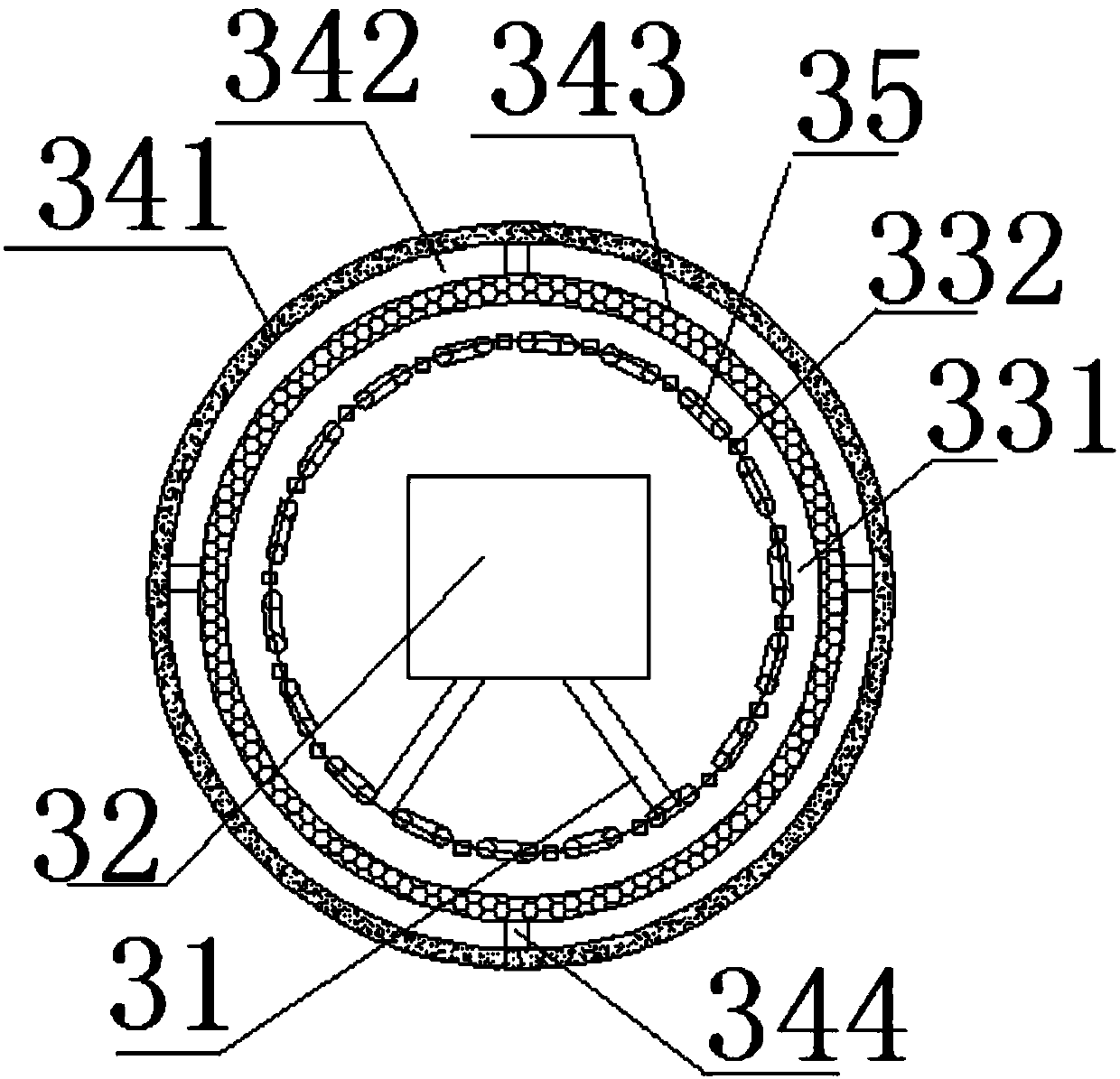

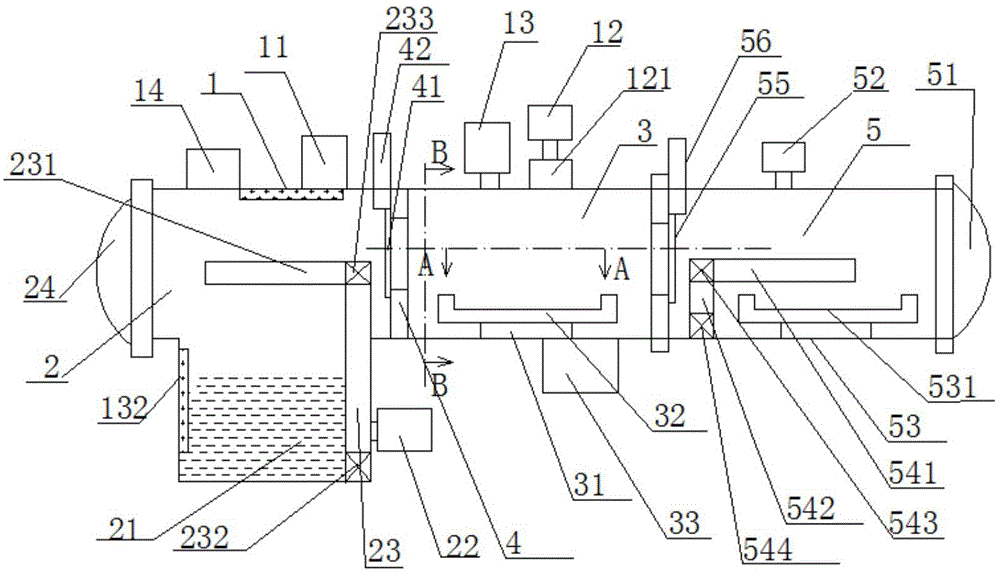

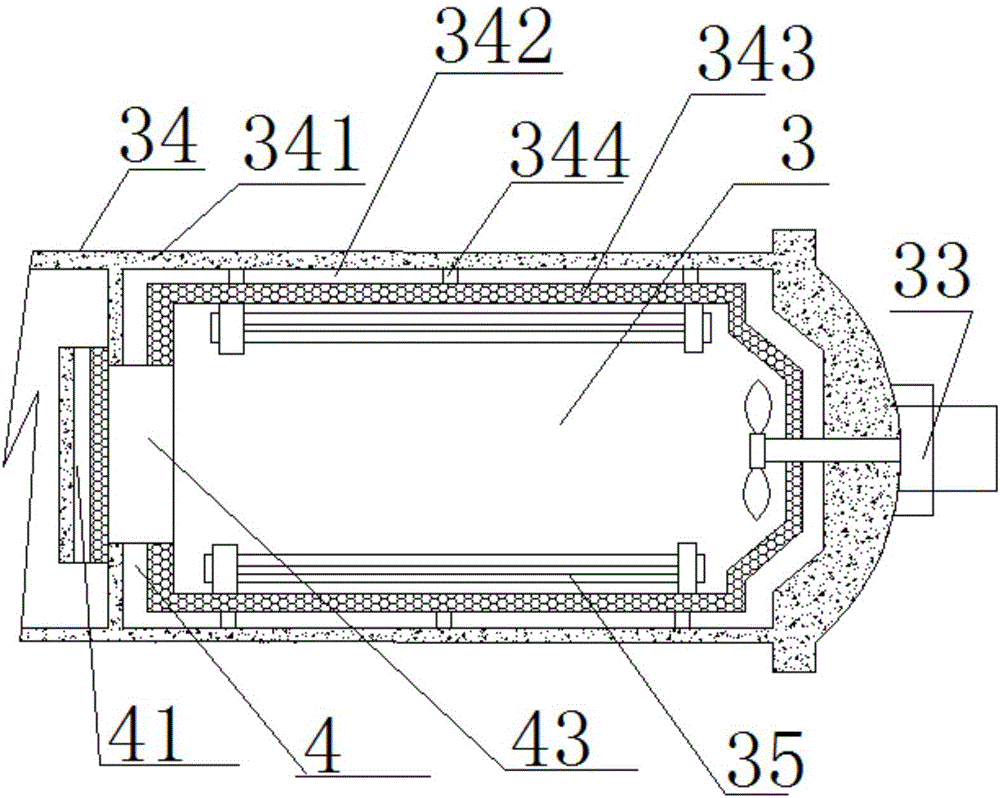

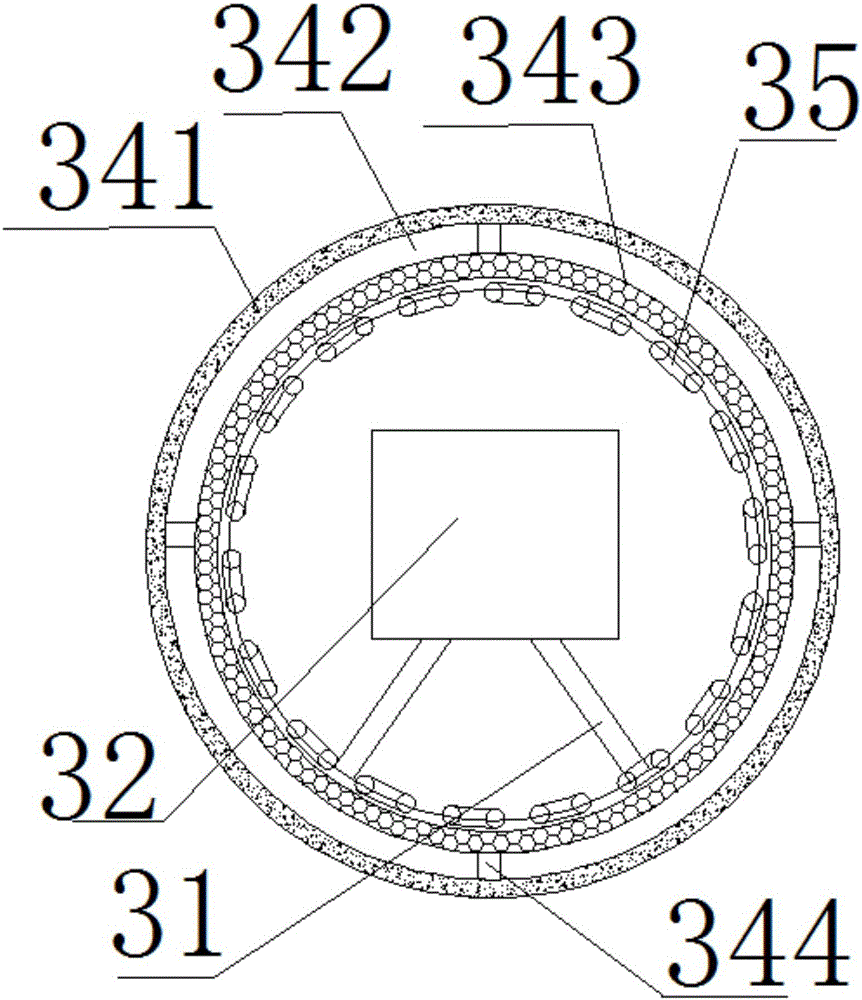

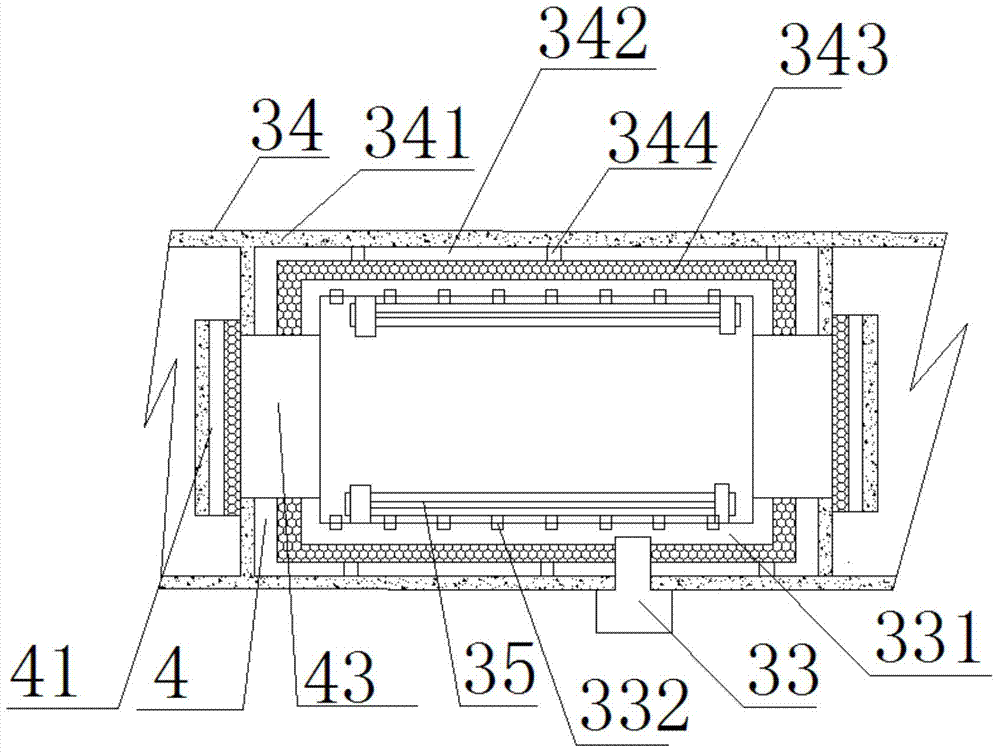

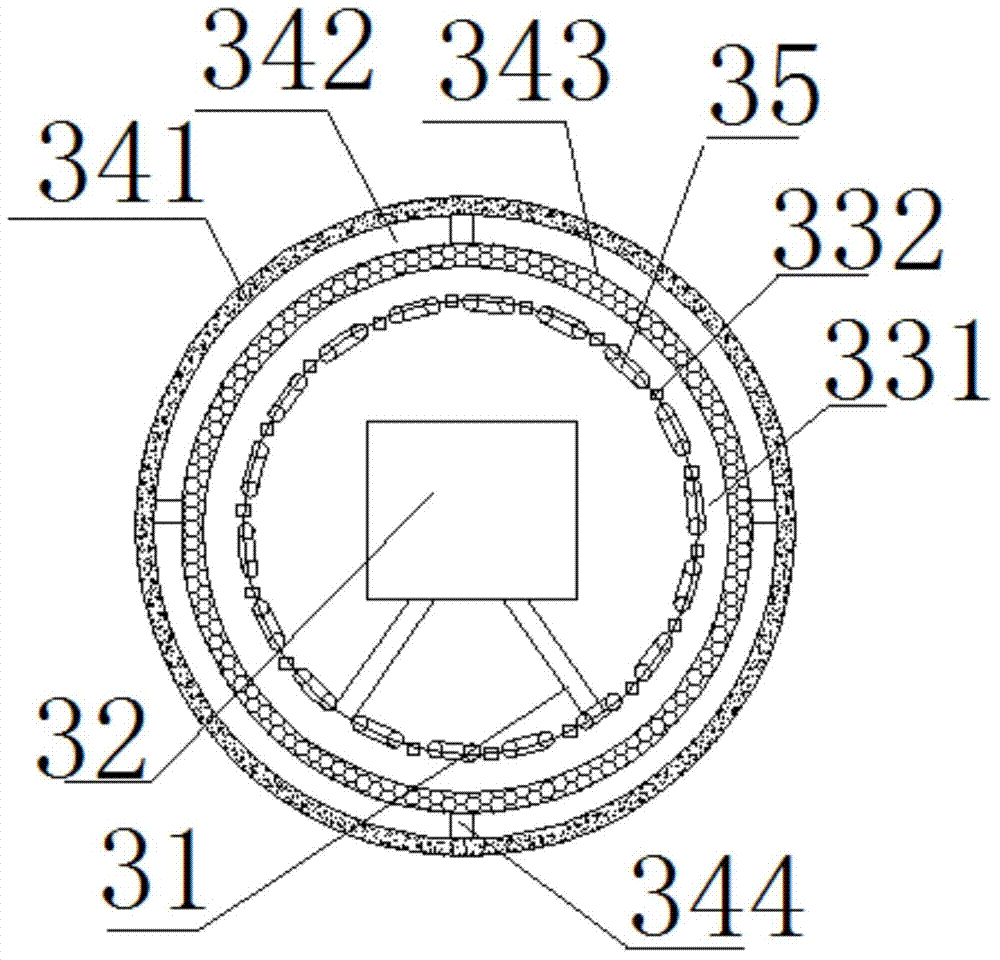

The invention relates to a monitoring and operating three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The monitoring and operating three-chamber vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism and a monitoring and operating system, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through a chamber wall which is provided with an oil isolating door; the cooling chamber comprises a gas quenching chamber and an oil quenching chamber, and an inflating quick-cooling mechanism is arranged on the upper part of the gas quenching chamber, and an oil quenching oil tank with a stirrer is arranged on the lower part of the oil quenching chamber; a gas convection circulating mechanism is arranged on the heating chamber, and a heat isolating layer, a vacuum layer and a stainless steel shell are sequentially arranged in the heating chamber and the heat isolating door from the inside to outside of the heating chamber. The monitoring and operating three-chamber vacuum furnace provided by the invention is safe in quenching oil and uniform in heating materials, and also is good in heat isolating effect and high in product quality. Energy resources can be saved, and meanwhile, the processing efficiency is high.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

Anticorrosive vacuumizer pollution-discharge liquid-purification monitoring-operation vacuum furnace

ActiveCN103740910AEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesInsulation layerCooling chamber

The invention relates to an anticorrosive vacuumizer pollution-discharge liquid-purification monitoring-operation vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:NANTONG FEIBEN MACHINERY

A monitoring operation vacuum furnace

InactiveCN103725843BEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesThermal insulationMonitoring system

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

Automatic-opening/closing anticorrosive liquid-purification observation monitoring three-chamber vacuum furnace

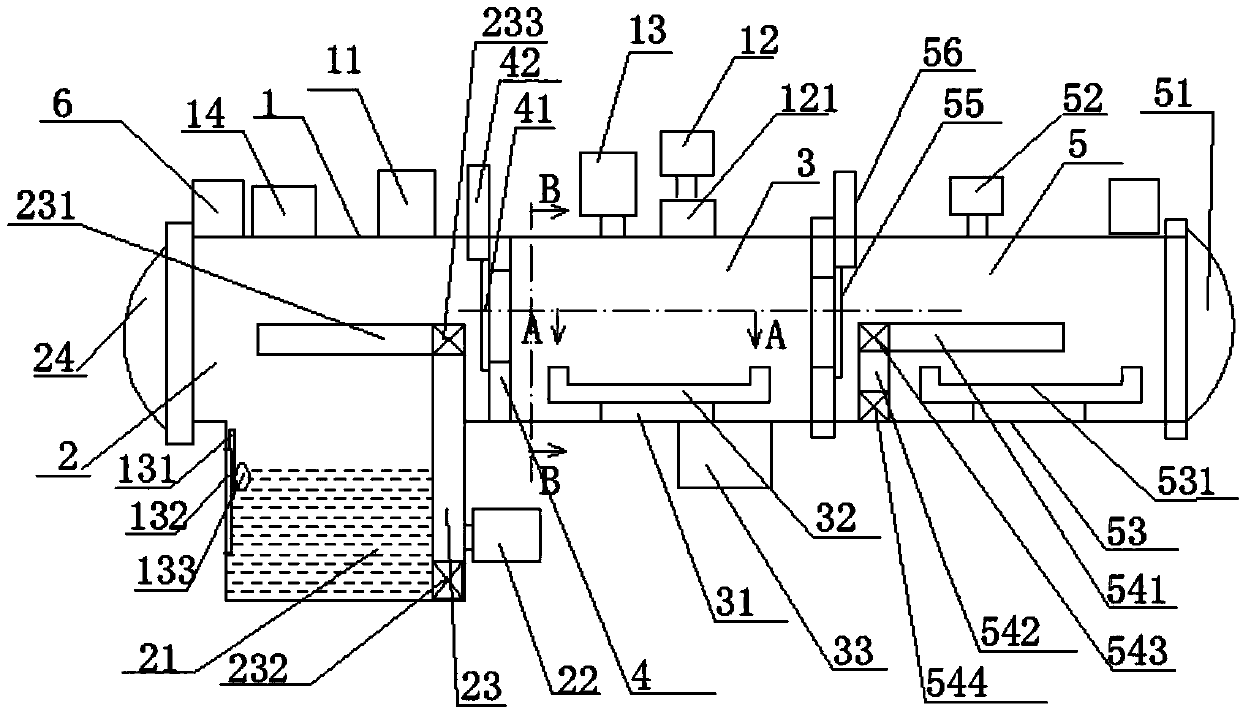

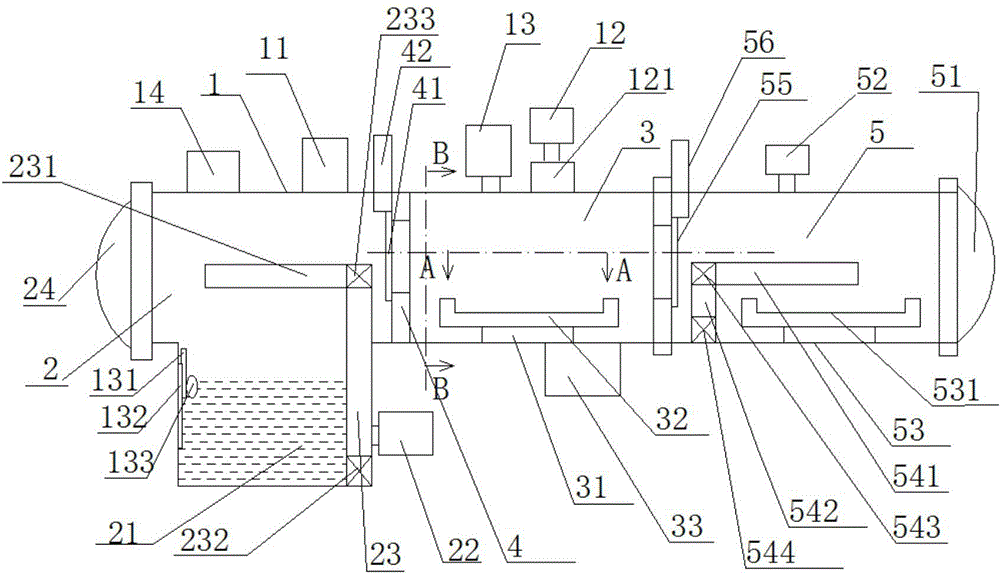

The invention relates to an automatic-opening / closing anticorrosive liquid-purification observation monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an observation device, an automatic opening and closing mechanism, an operation monitoring system and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can observe the machining condition, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

Monitoring operation vacuum furnace of corrosion-resistant vacuumizer

The invention relates to a monitoring operation vacuum furnace of a corrosion-resistant vacuumizer, belonging to the technical field of monitoring operation vacuum furnaces of corrosion-resistant vacuumizers. The monitoring operation vacuum furnace comprises a cooling chamber and a heating chamber, wherein the cooling chamber and the heating chamber are separated through a chamber separating wall; the chamber separating wall is provided with a heat insulation door; the cooling chamber comprises a gas quenching chamber and an oil quenching chamber, meanwhile, the upper part of the gas quenching chamber is provided with a rapid inflation cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching groove with a stirrer; the heating chamber is provided with a gas convective circulation mechanism, and the heating chamber and the heat insulation door are respectively and sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from the inside to outside of the heating chamber; and the monitoring operation vacuum furnace also comprises an operation monitoring system and a dust collector. The monitoring operation vacuum furnace of the corrosion-resistant vacuumizer, provided by the invention, is safe in oil quenching and uniform in material heating, and good in heat insulation effect; and meanwhile, the monitoring operation vacuum furnace is good in quality, and the vacuumizer can be prevented from being corroded.

Owner:WUJIANG YATAI VACUUM EQUIP TECH

Automatic-opening/closing anticorrosive pollution-discharge dry-purification observation operation-monitoring three-chamber vacuum furnace

InactiveCN103725842AEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesEnvironmental resistanceInsulation layer

The invention relates to an automatic-opening / closing anticorrosive pollution-discharge dry-purification observation operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an observation device, an automatic opening and closing mechanism, an operation monitoring system and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can observe the machining condition, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

a vacuum furnace

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

A three-chamber vacuum furnace for anti-corrosion sewage liquid purification observation monitoring operation

InactiveCN103725847BEvenly heatedNot easy to splashFurnace typesHeat treatment process controlEnvironmental resistanceInsulation layer

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

An observation and monitoring operation vacuum furnace for anti-corrosion vacuum machine blowdown liquid purification

InactiveCN103740908BEvenly heatedNot easy to splashFurnace typesHeat treatment process controlInsulation layerCooling chamber

The invention relates to an anticorrosive vacuumizer pollution-discharge liquid-purification observation-monitoring-operation vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can observe the machining condition, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

A three-chamber vacuum furnace for self-opening and closing anti-corrosion and sewage dry purification observation monitoring operation

InactiveCN103725842BEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesInsulation layerCooling chamber

The invention relates to an automatic-opening / closing anticorrosive pollution-discharge dry-purification observation operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an observation device, an automatic opening and closing mechanism, an operation monitoring system and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can observe the machining condition, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

Anticorrosive vacuumizer pollution-discharge dry-purification operation-observing/monitoring vacuum furnace

InactiveCN103898314AEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesInsulation layerMonitoring system

The invention relates to an anticorrosive vacuumizer pollution-discharge dry-purification operation-observing / monitoring vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The anticorrosive vacuumizer pollution-discharge dry-purification operation-observing / monitoring vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can observe the machining condition, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:WUJIANG YATAI VACUUM EQUIP TECH

Anticorrosive pollution-discharge dry-purification operation-monitoring three-chamber vacuum furnace

InactiveCN103725853AEvenly heatedNot easy to splashFurnace typesHeat treatment process controlInsulation layerCooling chamber

The invention relates to an anticorrosive pollution-discharge dry-purification operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an operation monitoring system, an automatic opening and closing mechanism and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

An anti-corrosion vacuum machine blowdown shower type purification observation monitoring operation vacuum furnace

The invention relates to an anticorrosive vacuumizer pollution-discharge spraying-purification operation-observing / monitoring vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can observe the machining condition, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

A self-opening and closing anti-corrosion liquid purification observation monitoring three-chamber vacuum furnace

The invention relates to an automatic-opening / closing anticorrosive liquid-purification observation monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an observation device, an automatic opening and closing mechanism, an operation monitoring system and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can observe the machining condition, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

Automatic opening and closing three-chamber vacuum furnace capable of monitoring operation

The invention relates to an automatic opening and closing three-chamber vacuum furnace capable of monitoring operation, belonging to the technical field of vacuum furnaces. The three-chamber vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, vacuumizing mechanisms, an operation monitoring system and an automatic opening and closing mechanism, wherein the two sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber via chamber separation walls; insulation doors are arranged on the chamber separation walls; the cooling chamber comprises a gas quenching chamber and an oil quenching chamber; meanwhile, a filled gas quick cooling mechanism is arranged at the upper part of the gas quenching chamber; an oil quenching tank with a stirrer is arranged at the lower part of the oil quenching chamber; a gas convective circulation mechanism is arranged on the heating chamber; both the heating chamber and the insulation doors are provided with insulation layers, vacuum layers and stainless steel shells from the interior of the heating chamber to the exterior in sequence. The three-chamber vacuum furnace not only is safe in oil quenching and uniform in material heating but also has good insulation effects and high product quality, can save energy and automatically open the furnace door, and simultaneously has high processing efficiency.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

A three-chamber vacuum furnace for anti-corrosion sewage discharge liquid purification monitoring operation

InactiveCN103725851BEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesEnvironmental resistanceInsulation layer

The invention relates to an anticorrosive pollution-discharge liquid-purification operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an operation monitoring system, an automatic opening and closing mechanism and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

A three-chamber vacuum furnace for anti-corrosion, sewage, shower, purification, observation, monitoring and operation

InactiveCN103725839BEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesEnvironmental resistanceInsulation layer

The invention relates to an anticorrosive pollution-discharge spray-purification observation operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an observation device, an operation monitoring system and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can observe the machining conditions, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

A three-chamber vacuum furnace

The invention relates to a three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber and a vacuumizing mechanism, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, energy saving and high machining efficiency.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

A monitoring operation vacuum furnace for anti-corrosion vacuum pump sewage liquid purification

ActiveCN103740910BEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesInsulation layerCooling chamber

The invention relates to an anticorrosive vacuumizer pollution-discharge liquid-purification monitoring-operation vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber and separation walls, wherein each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside; and the vacuum furnace also comprises an operation-monitoring system, a dust collector and an exhaust purifier. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect and high product quality, can prevent the vacuumizer from being corroded, and is environment-friendly in evacuation.

Owner:NANTONG FEIBEN MACHINERY

Anti-corrosion and soiling solution-discharging type purifying, monitoring and operating three-chamber vacuum oven

InactiveCN103911497AEvenly heatedNot easy to splashFurnace typesHeat treatment furnacesThermal insulationCooling chamber

The invention relates to an anti-corrosion and soiling solution-discharging type purifying, monitoring and operating three-chamber vacuum oven, and belongs to the technical field of vacuum ovens. The anti-corrosion and soiling solution-discharging type purifying, monitoring and operating three-chamber vacuum oven comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuum pumping mechanism, an operation monitoring system and an exhaust purifier. Two sides of the heating chamber are connected to the preparation chamber and the cooling chamber through chamber-separating walls; the chamber-separating walls are provided with thermal insulation doors; the cooling chamber comprises a gas quenching chamber and an oil quenching chamber; the upper part of the gas quenching chamber is provided with an air charging quick cooling mechanism; the lower part of the oil gas quenching chamber is provided with an oil quenching oil tank with a stirrer; the heating chamber is provided with a gas convective circulation mechanism; and the heating chamber and the thermal insulation doors are provided with a thermal insulation layer, a vacuum layer and a stainless steel shell successively from the internal part of the heating chamber outward. The anti-corrosion and soiling solution-discharging type purifying, monitoring and operating three-chamber vacuum oven is safe in oil quenching and uniform in material heating, has a good thermal insulation effect and high product quality, and can save energy. Meanwhile, a processing efficiency is high; the vacuum pumping machine can be prevented from corrosion; and the exhaust gas is environment-friendly.

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

A self-opening and closing monitoring operation three-chamber vacuum furnace

The invention relates to an automatic opening and closing three-chamber vacuum furnace capable of monitoring operation, belonging to the technical field of vacuum furnaces. The three-chamber vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, vacuumizing mechanisms, an operation monitoring system and an automatic opening and closing mechanism, wherein the two sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber via chamber separation walls; insulation doors are arranged on the chamber separation walls; the cooling chamber comprises a gas quenching chamber and an oil quenching chamber; meanwhile, a filled gas quick cooling mechanism is arranged at the upper part of the gas quenching chamber; an oil quenching tank with a stirrer is arranged at the lower part of the oil quenching chamber; a gas convective circulation mechanism is arranged on the heating chamber; both the heating chamber and the insulation doors are provided with insulation layers, vacuum layers and stainless steel shells from the interior of the heating chamber to the exterior in sequence. The three-chamber vacuum furnace not only is safe in oil quenching and uniform in material heating but also has good insulation effects and high product quality, can save energy and automatically open the furnace door, and simultaneously has high processing efficiency.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

A self-opening and closing three-chamber vacuum furnace

InactiveCN103725838BEvenly heatedNot easy to splashFurnace typesHeat treatment furnacesInsulation layerCooling chamber

The invention relates to an automatic-opening / closing three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism and an automatic opening and closing mechanism, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, energy saving and high machining efficiency, and can automatically open and close the furnace door.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

A three-chamber vacuum furnace for anti-corrosion sewage discharge liquid purification monitoring operation

InactiveCN103911497BEvenly heatedNot easy to splashFurnace typesHeat treatment furnacesEnvironmental resistanceThermal insulation

The invention relates to an anti-corrosion and soiling solution-discharging type purifying, monitoring and operating three-chamber vacuum oven, and belongs to the technical field of vacuum ovens. The anti-corrosion and soiling solution-discharging type purifying, monitoring and operating three-chamber vacuum oven comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuum pumping mechanism, an operation monitoring system and an exhaust purifier. Two sides of the heating chamber are connected to the preparation chamber and the cooling chamber through chamber-separating walls; the chamber-separating walls are provided with thermal insulation doors; the cooling chamber comprises a gas quenching chamber and an oil quenching chamber; the upper part of the gas quenching chamber is provided with an air charging quick cooling mechanism; the lower part of the oil gas quenching chamber is provided with an oil quenching oil tank with a stirrer; the heating chamber is provided with a gas convective circulation mechanism; and the heating chamber and the thermal insulation doors are provided with a thermal insulation layer, a vacuum layer and a stainless steel shell successively from the internal part of the heating chamber outward. The anti-corrosion and soiling solution-discharging type purifying, monitoring and operating three-chamber vacuum oven is safe in oil quenching and uniform in material heating, has a good thermal insulation effect and high product quality, and can save energy. Meanwhile, a processing efficiency is high; the vacuum pumping machine can be prevented from corrosion; and the exhaust gas is environment-friendly.

Owner:SUZHOU PULINGDA AUTOMATION TECH CO LTD

Anticorrosive pollution-discharge liquid-purification operation-monitoring three-chamber vacuum furnace

InactiveCN103725851AEvenly heatedNot easy to splashHeat treatment process controlQuenching devicesEnvironmental resistanceInsulation layer

The invention relates to an anticorrosive pollution-discharge liquid-purification operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an operation monitoring system, an automatic opening and closing mechanism and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

A three-chamber vacuum furnace for anti-corrosion and sewage discharge dry purification monitoring operation

The invention relates to an anticorrosive pollution-discharge dry-purification operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an operation monitoring system and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

A self-opening and closing anti-corrosion shower purification observation monitoring three-chamber vacuum furnace

The invention relates to an automatic-opening / closing anticorrosive spray-purification observation monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an observation device, an operation monitoring system, an automatic opening and closing mechanism and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can observe the machining condition, can automatically open the furnace door, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

A three-chamber vacuum furnace for anti-corrosion and sewage shower purification monitoring operation

InactiveCN103725844BEvenly heatedNot easy to splashFurnace typesHeat treatment process controlInsulation layerCooling chamber

The invention relates to an anticorrosive pollution-discharge spray-purification operation-monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism, an operation monitoring system and an exhaust purifier, wherein both sides of the heating chamber are respectively connected with the preparation chamber and the cooling chamber through separation walls; each separation wall is provided with a heat insulation door; the cooling chamber comprises an air quenching chamber and an oil quenching chamber, the upper part of the air quenching chamber is provided with an air charging quick-cooling mechanism, and the lower part of the oil quenching chamber is provided with an oil quenching oil tank provided with a stirrer; the heating chamber is provided with a gas convection circulation mechanism; and the heating chamber and each heat insulation door are respectively sequentially provided with a heat insulation layer, a vacuum layer and a stainless steel shell from inside to outside. The vacuum furnace has the advantages of safe oil quenching, uniform material heating, favorable heat insulation effect, high product quality, energy saving and high machining efficiency, can prevent the vacuumizing mechanism from being corroded, and is environment-friendly in evacuation.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

An anti-corrosion monitoring operation three-chamber vacuum furnace

The invention relates to an anti-corrosion operation monitoring three-chamber vacuum furnace, belonging to the technical field of vacuum furnaces. The anti-corrosion operation monitoring three-chamber vacuum furnace comprises a cooling chamber, a heating chamber, a preparation chamber, a vacuumizing mechanism and an operation monitoring system, wherein the two sides of the heating chamber are connected with the preparation chamber and the cooling chamber through a partition wall respectively; a heat insulation door is arranged on the partition wall; the cooling chamber comprises a gas quenching chamber, an oil quenching chamber, a gas filling quick-cooling mechanism and an oil quenching oil tank; a gas convection circulation mechanism is arranged on the heating chamber; the heating chamber and the heat insulation door are provided with a heat insulation layer, a vacuum layer and a stainless steel shell sequentially from the inside of the heating chamber to the outside; a dust collector is arranged on the exhaust pipes between the vacuumizing mechanism and the cooling chamber and the heating chamber respectively. The anti-corrosion operation monitoring three-chamber vacuum furnace provided by the invention has the advantages of safe oil quenching, uniform material heating, good heat insulation effect and high product quality and can save energy; meanwhile, the processing efficiency is high, and the corrosion of the vacuumizing mechanism can be avoided.

Owner:SUZHOU WANTAI VACUUM FIRING FURNACE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com