Patents

Literature

40results about How to "Play a role in metamorphism and toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

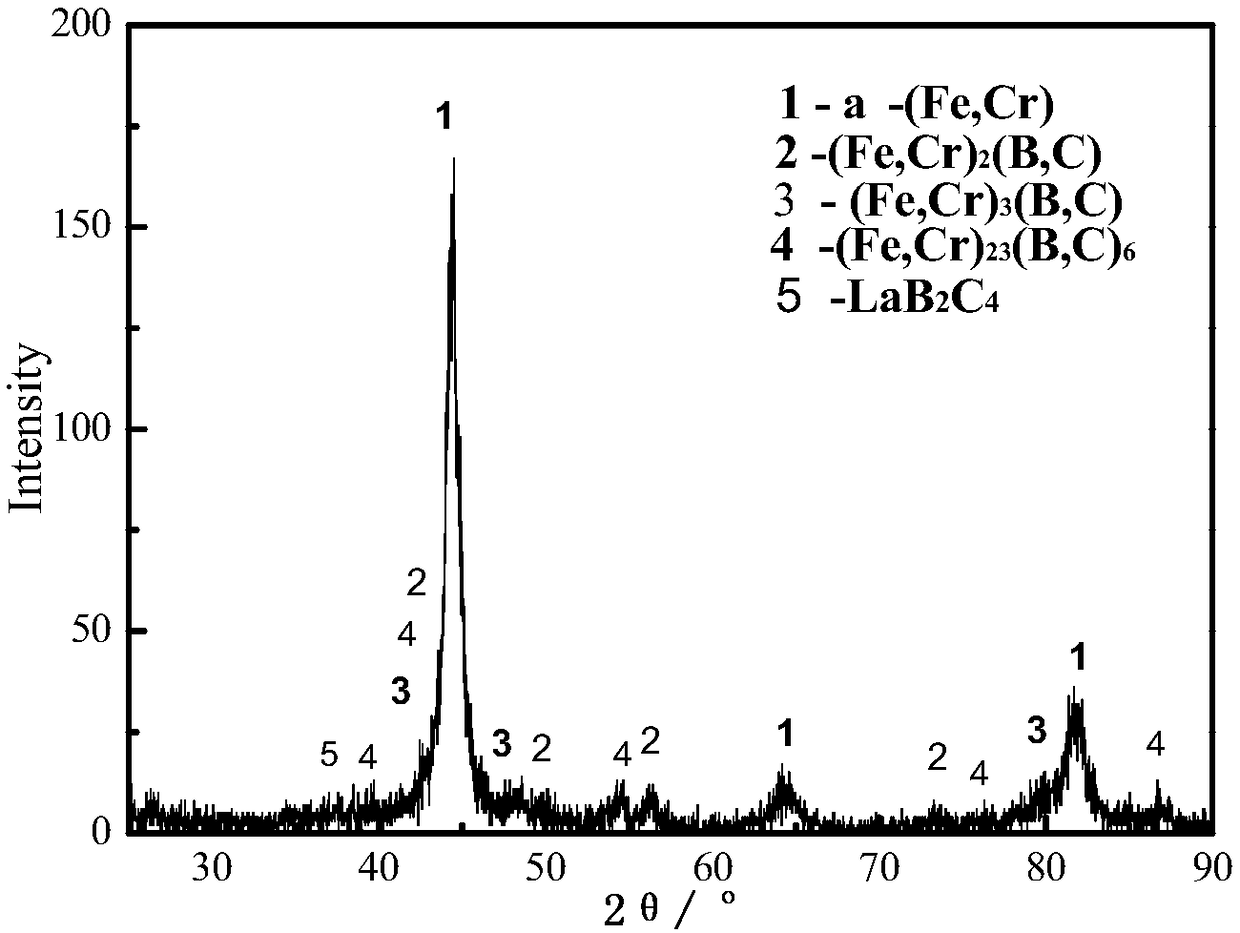

Lanthanum carbonate toughened high-hardness alloy and casting and heat treatment method thereof

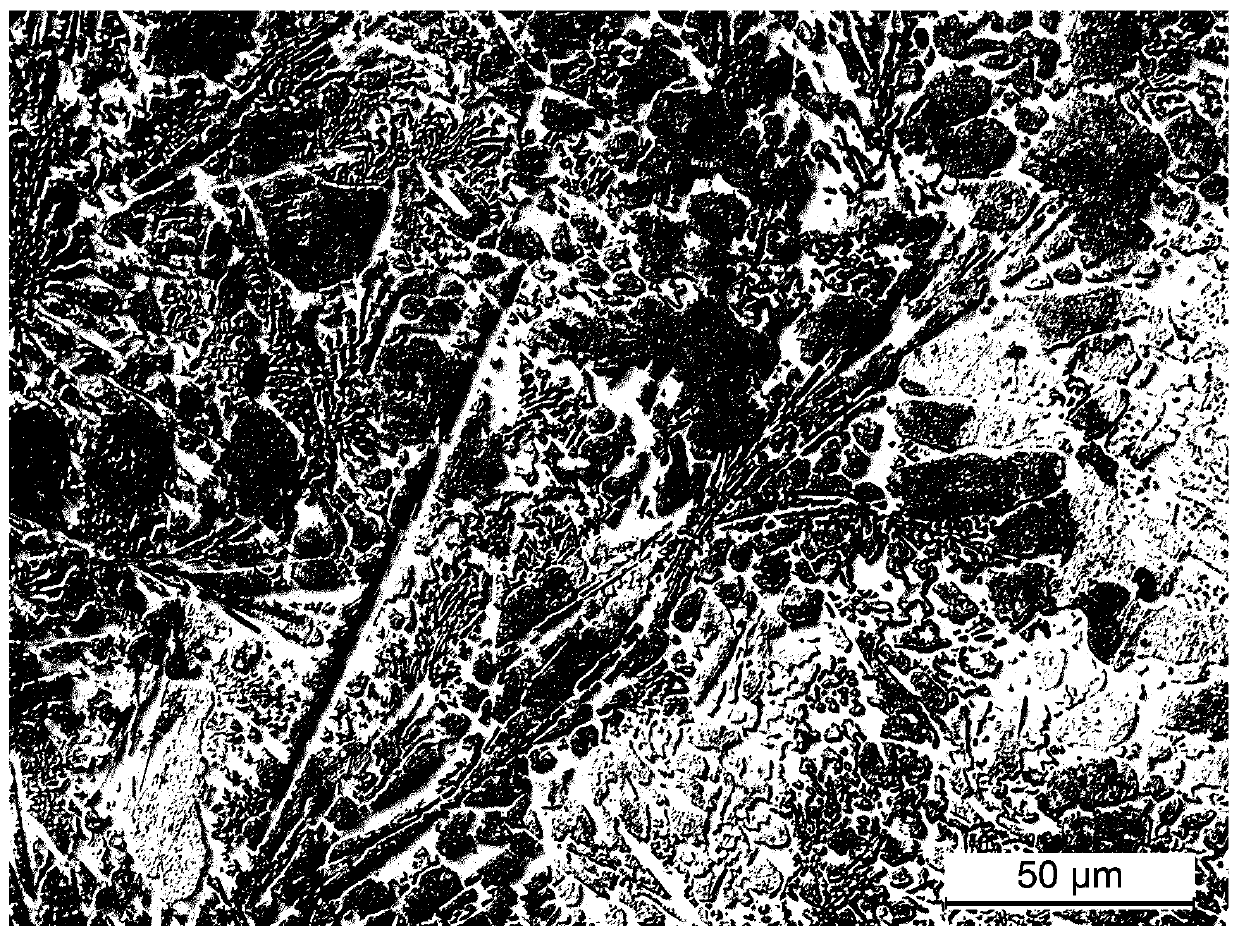

Disclosed are lanthanum carbonate toughened high-hardness alloy and a casting and heat treatment method thereof. The elements of the alloy comprise, by mass percentage, 9.0-13.0% of Cr, 2.6-2.9% of B,0.7-0.9% of C, 0.4-0.8% of Nb, 0.4-0.8% of V, less than 0.3% of Mn, 0.03-0.7% of La, 0.01% or less of S and P, and the balance Fe, wherein the total mass percentage of C and B is 3.3-3.6%, the content ratio of C to Cr is 0.06-0.08, and the total mass percentage of Nb and V is 0.5-1.0%. Fe-carbonic acid bait powder briquettes are prepared at first, alloy burdening, smelting and modification treatment are carried out, and smelting, casting and heat treatment are carried out. According to overall prepared cast ingots, the hardness reaches HRC 65.1-68.9, the impact toughness reaches 12.5-16.4 J / cm<2>, and the bending strength reaches 1195-1540 MPa.

Owner:CENT SOUTH UNIV

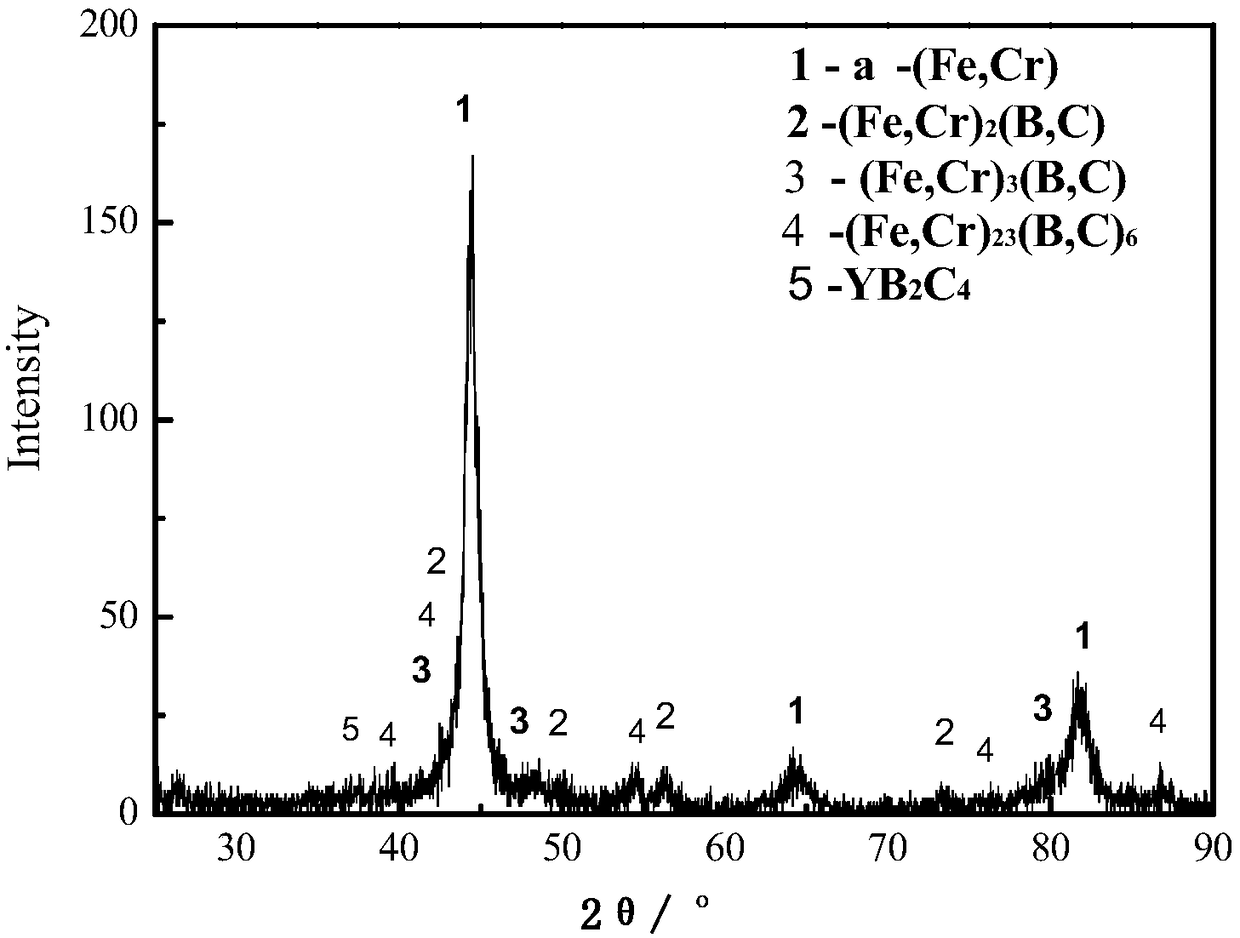

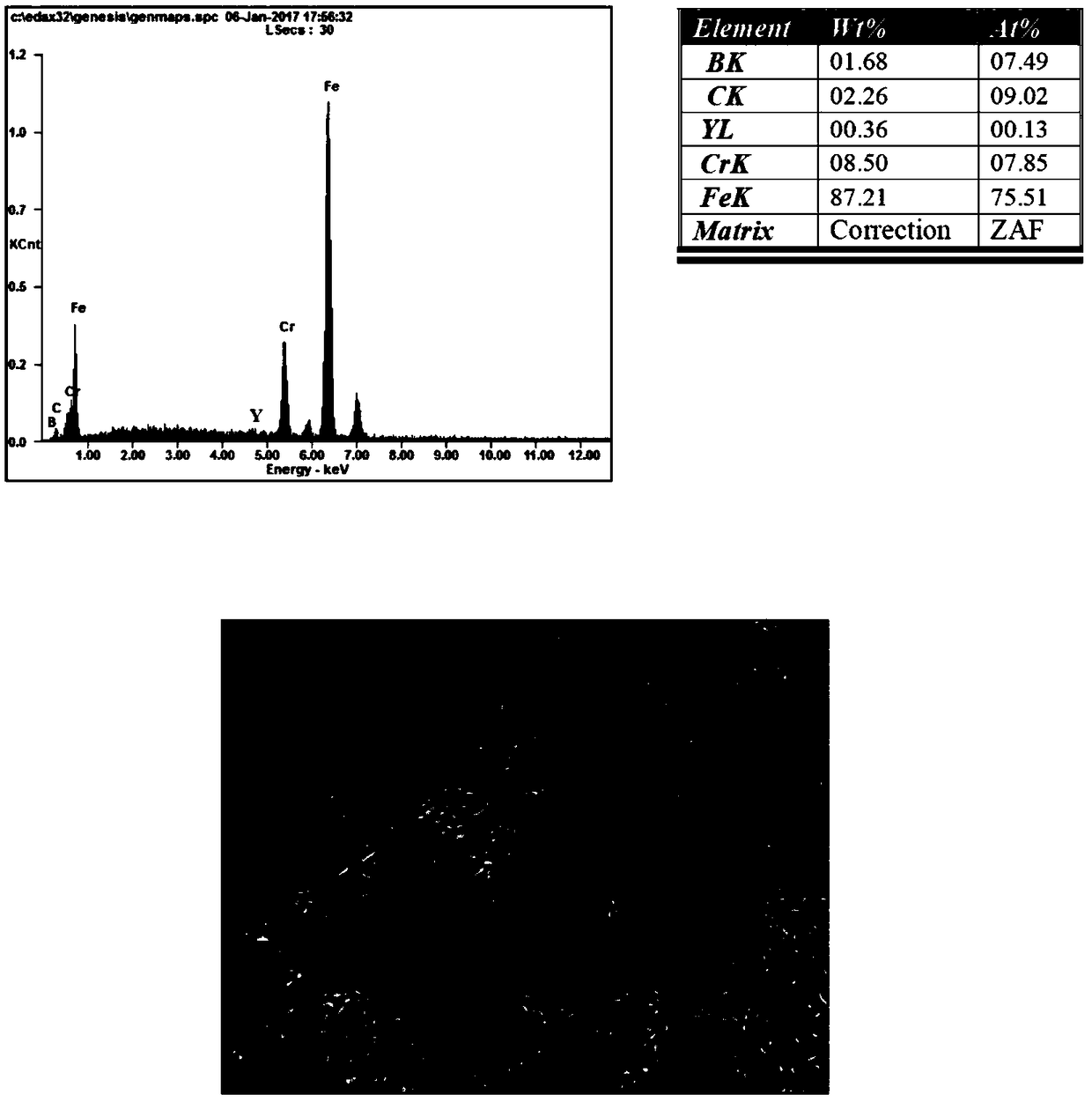

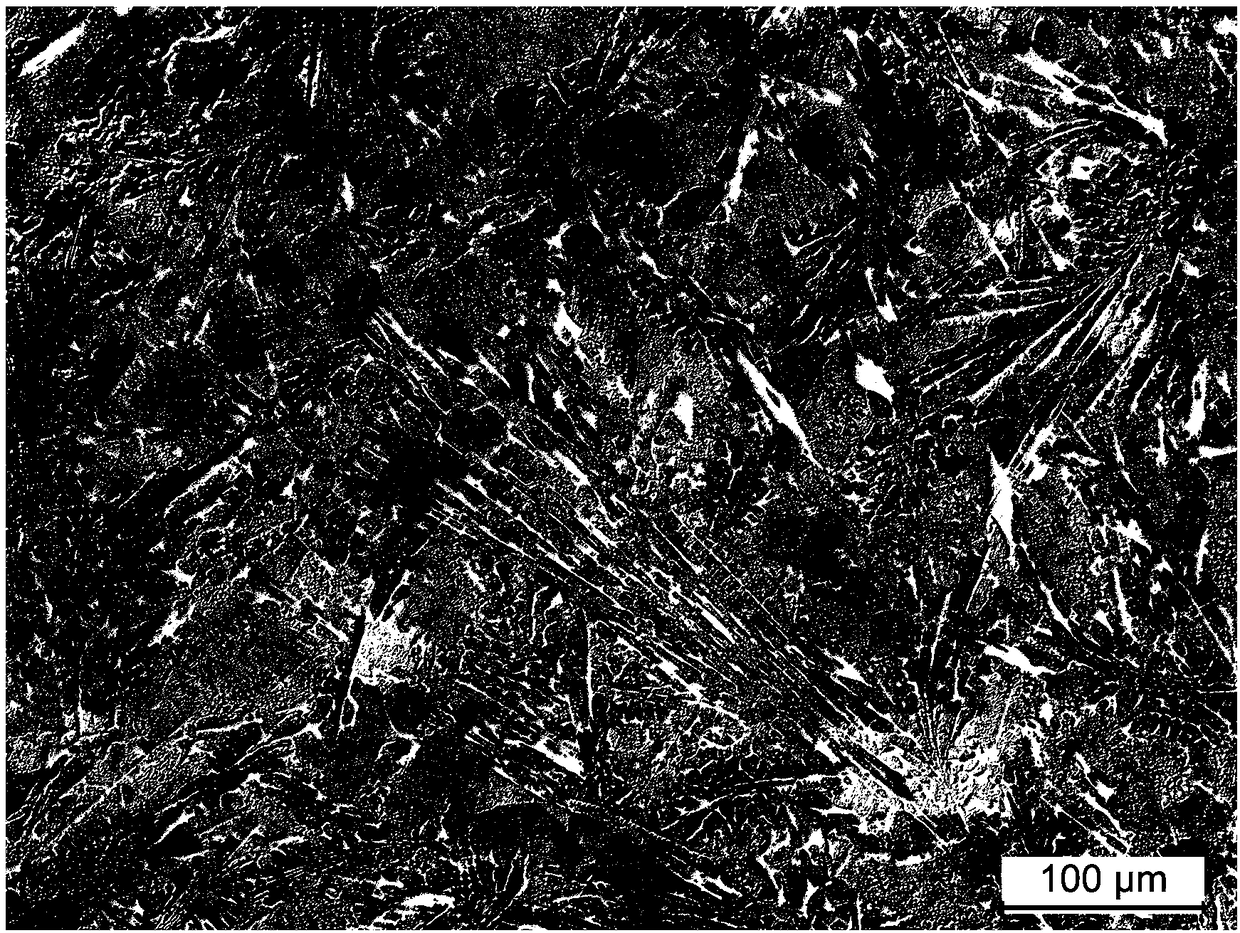

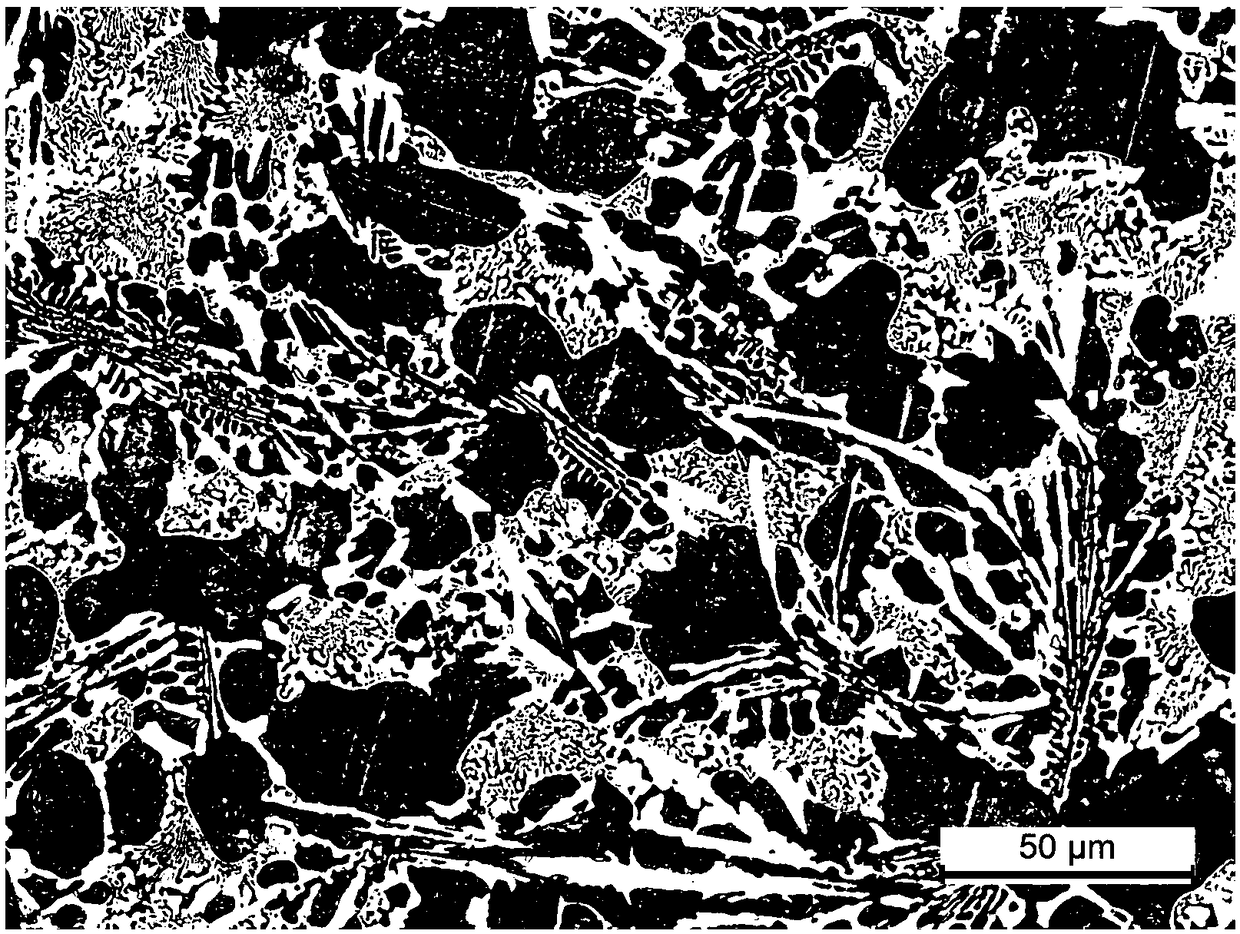

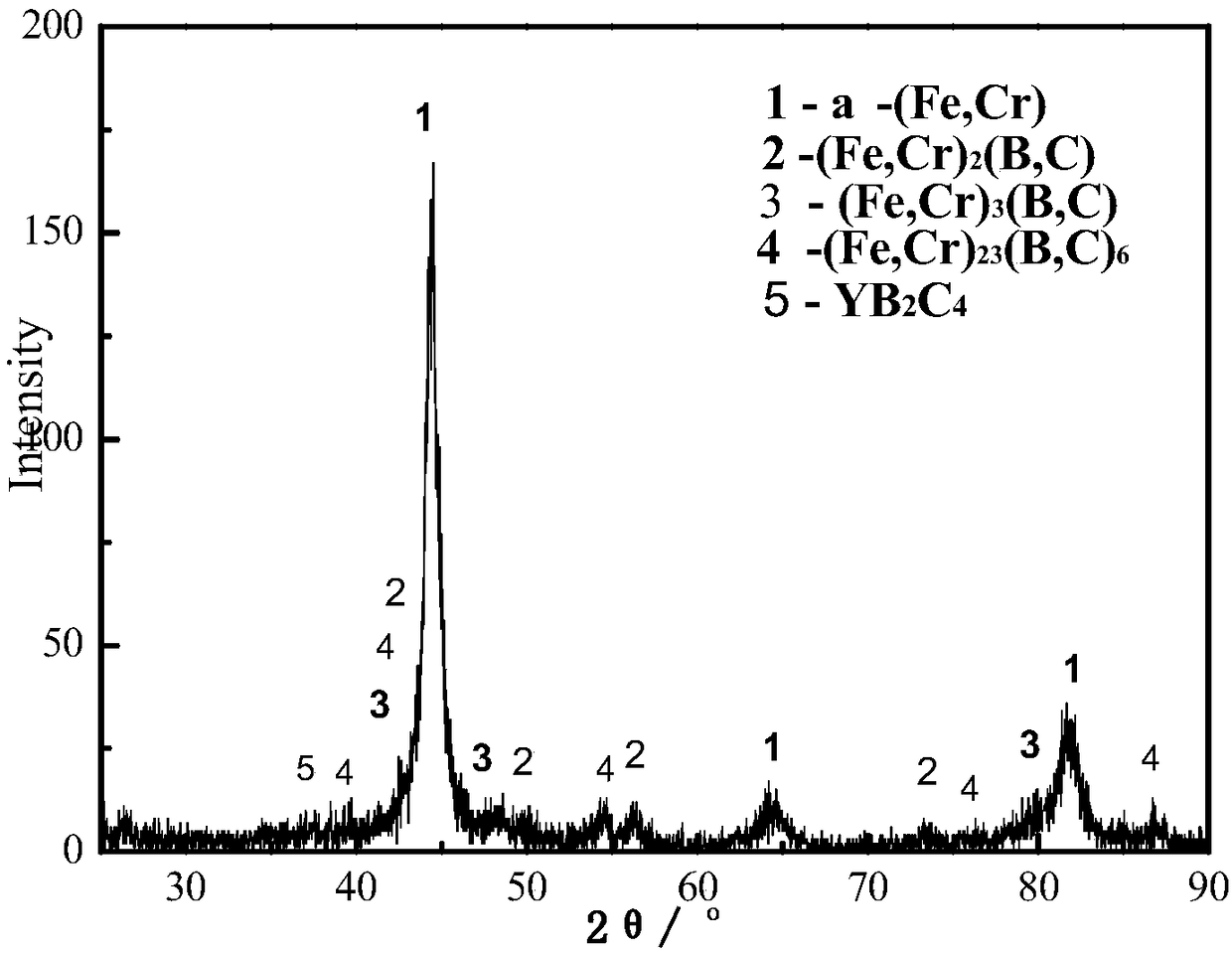

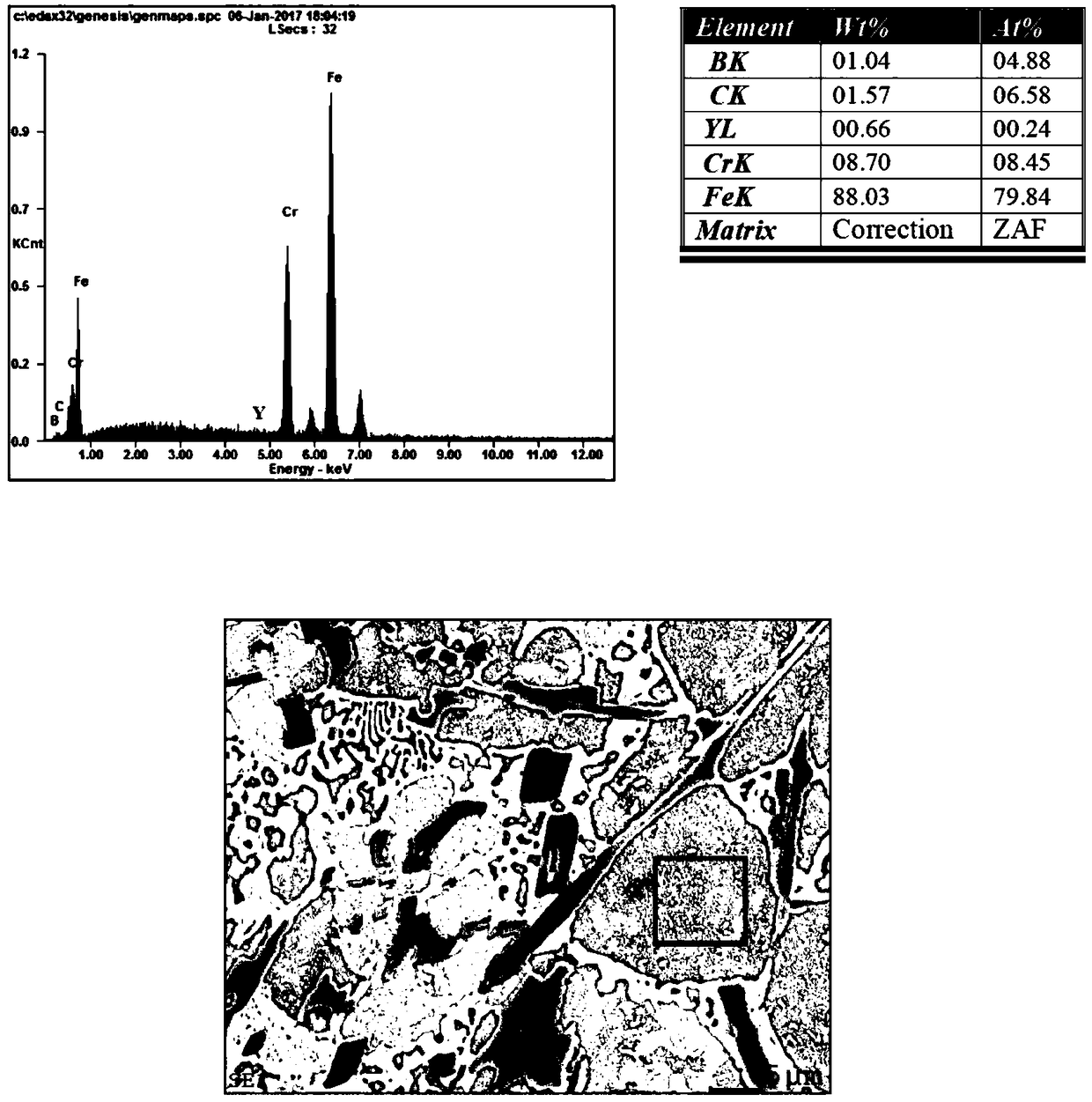

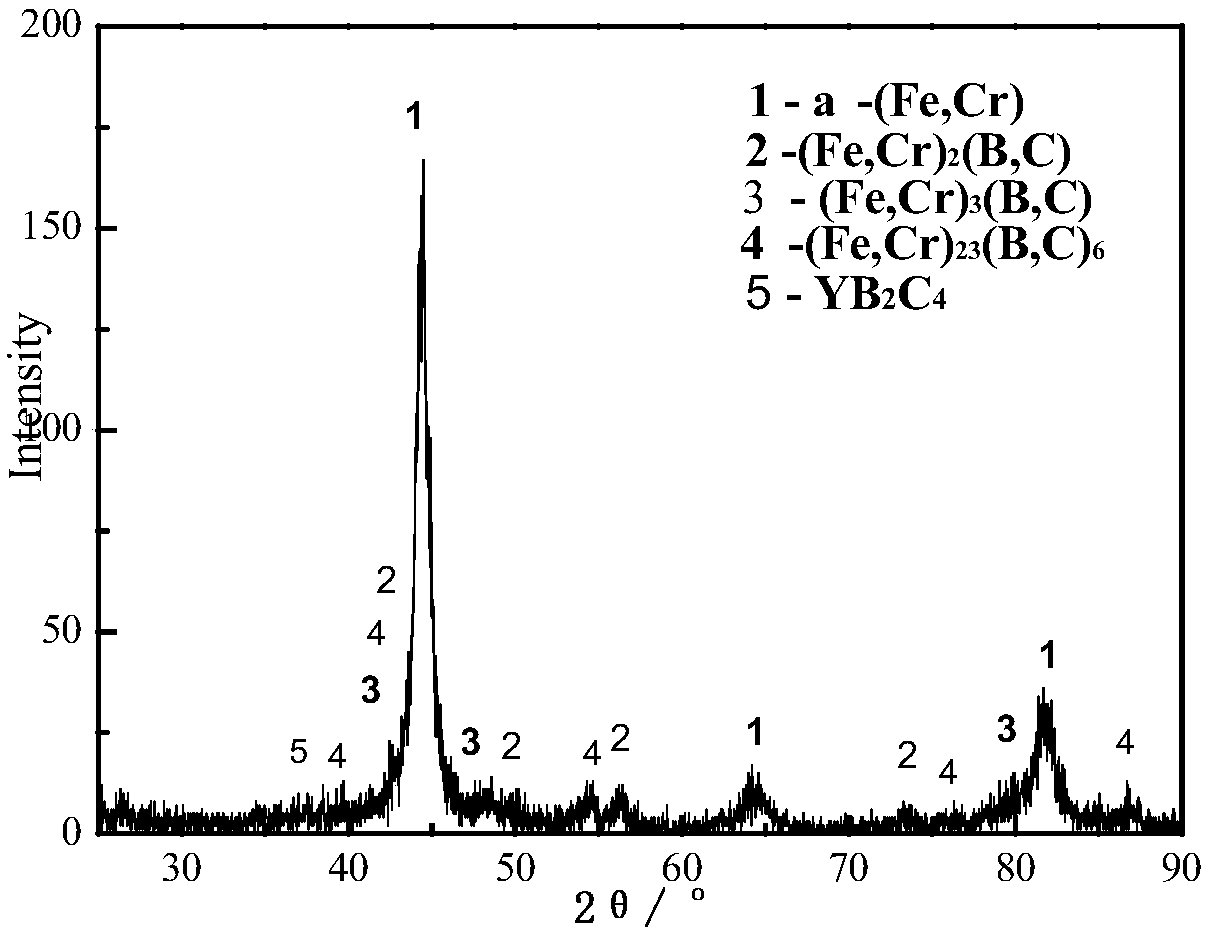

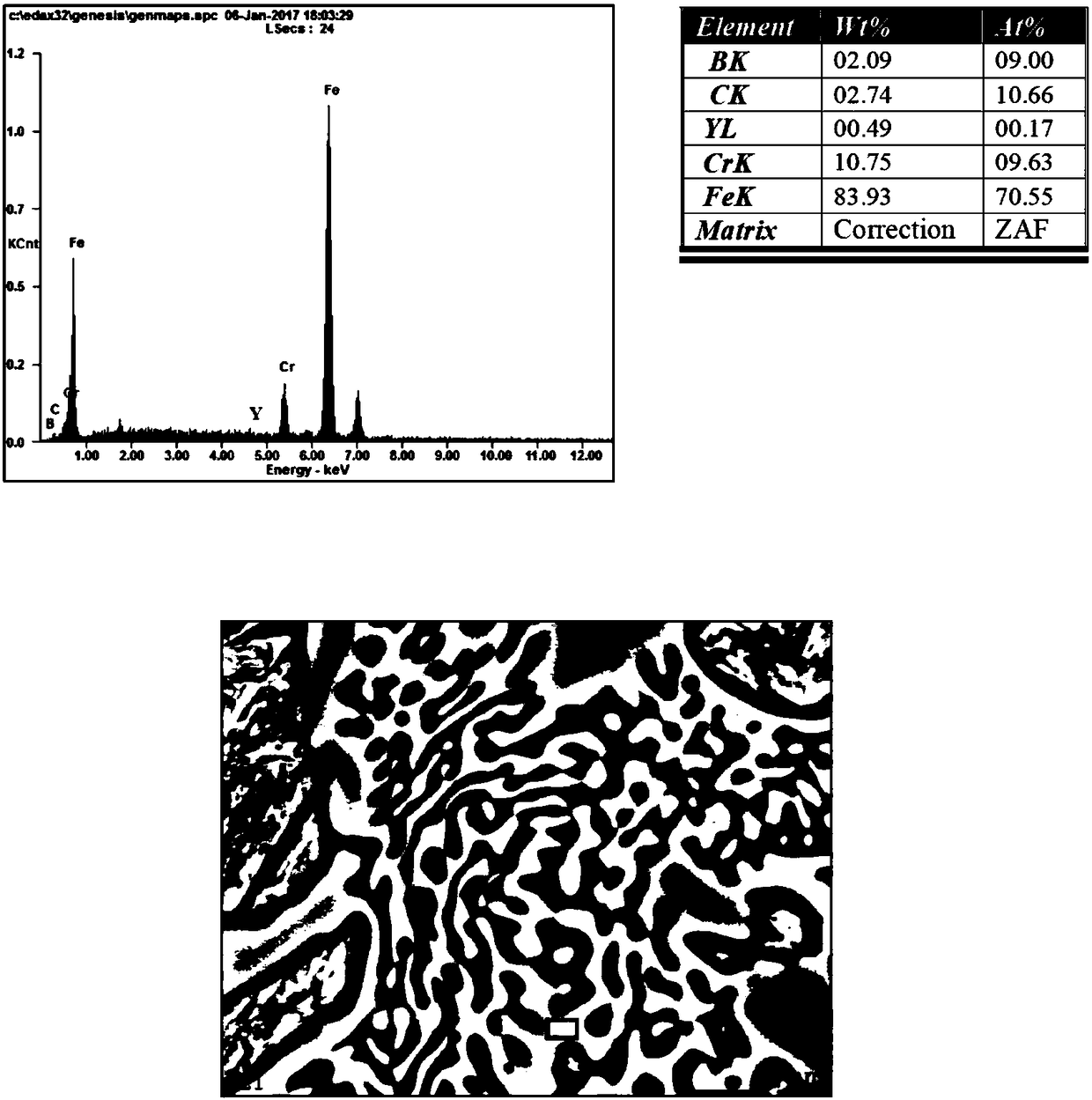

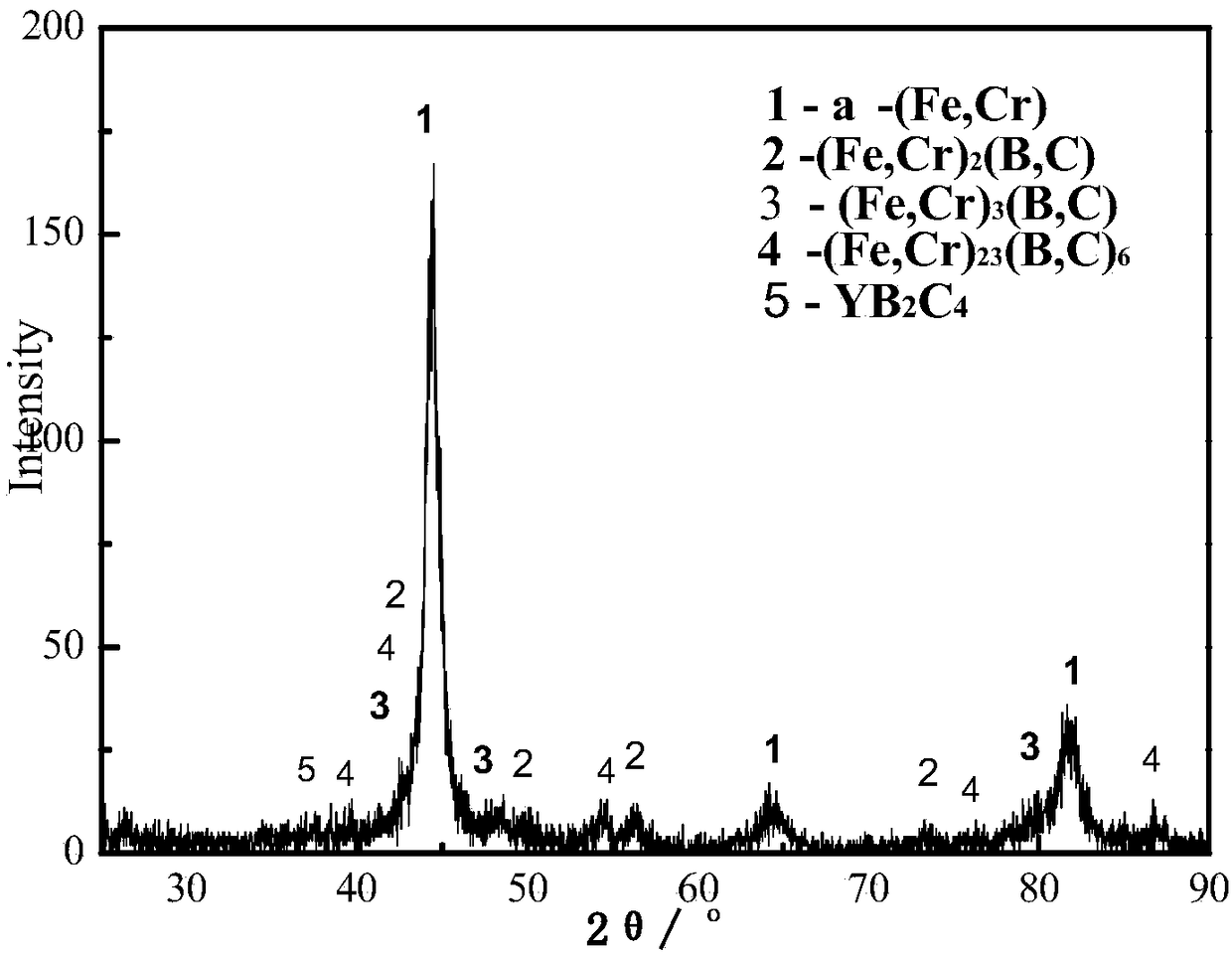

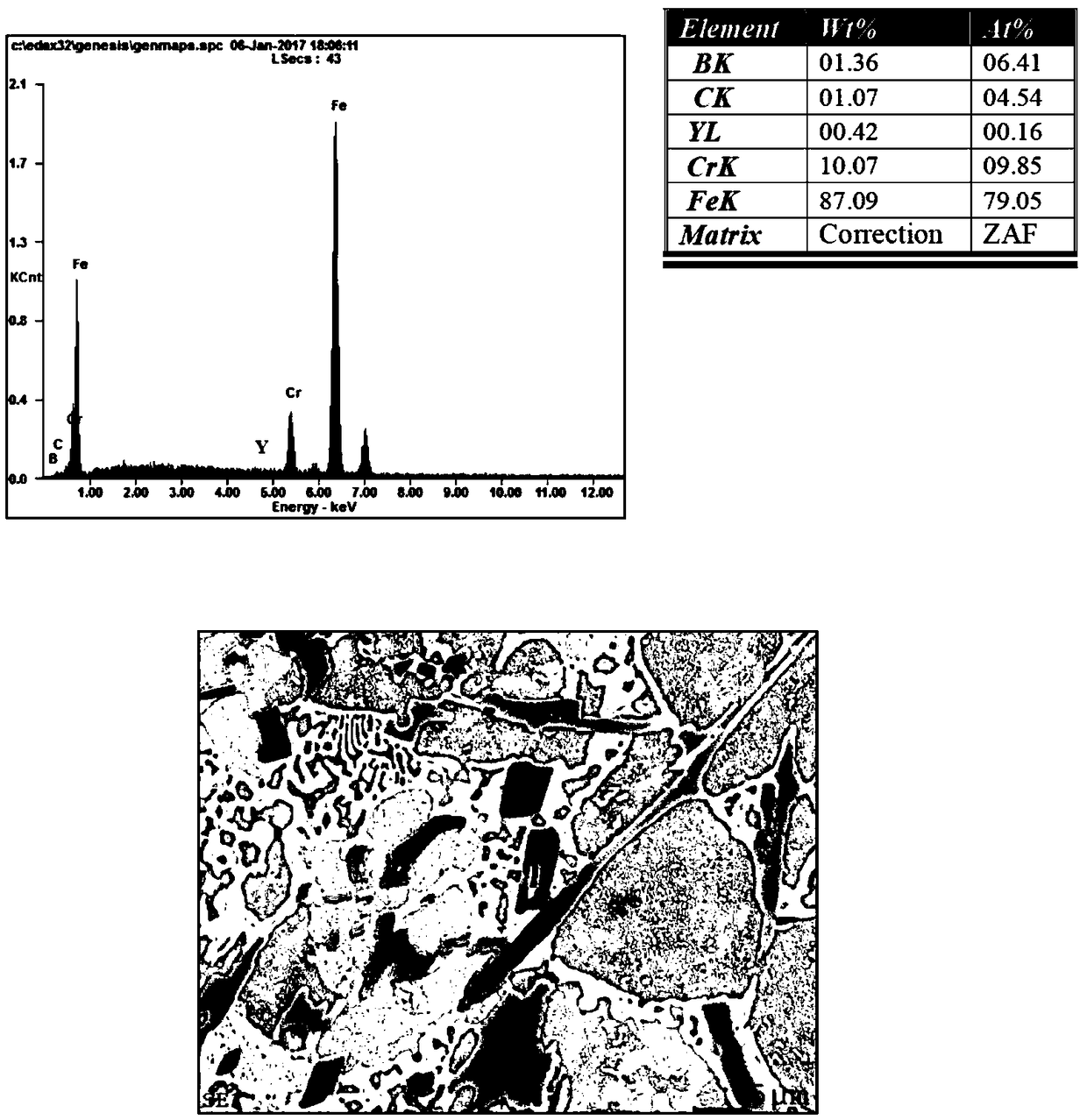

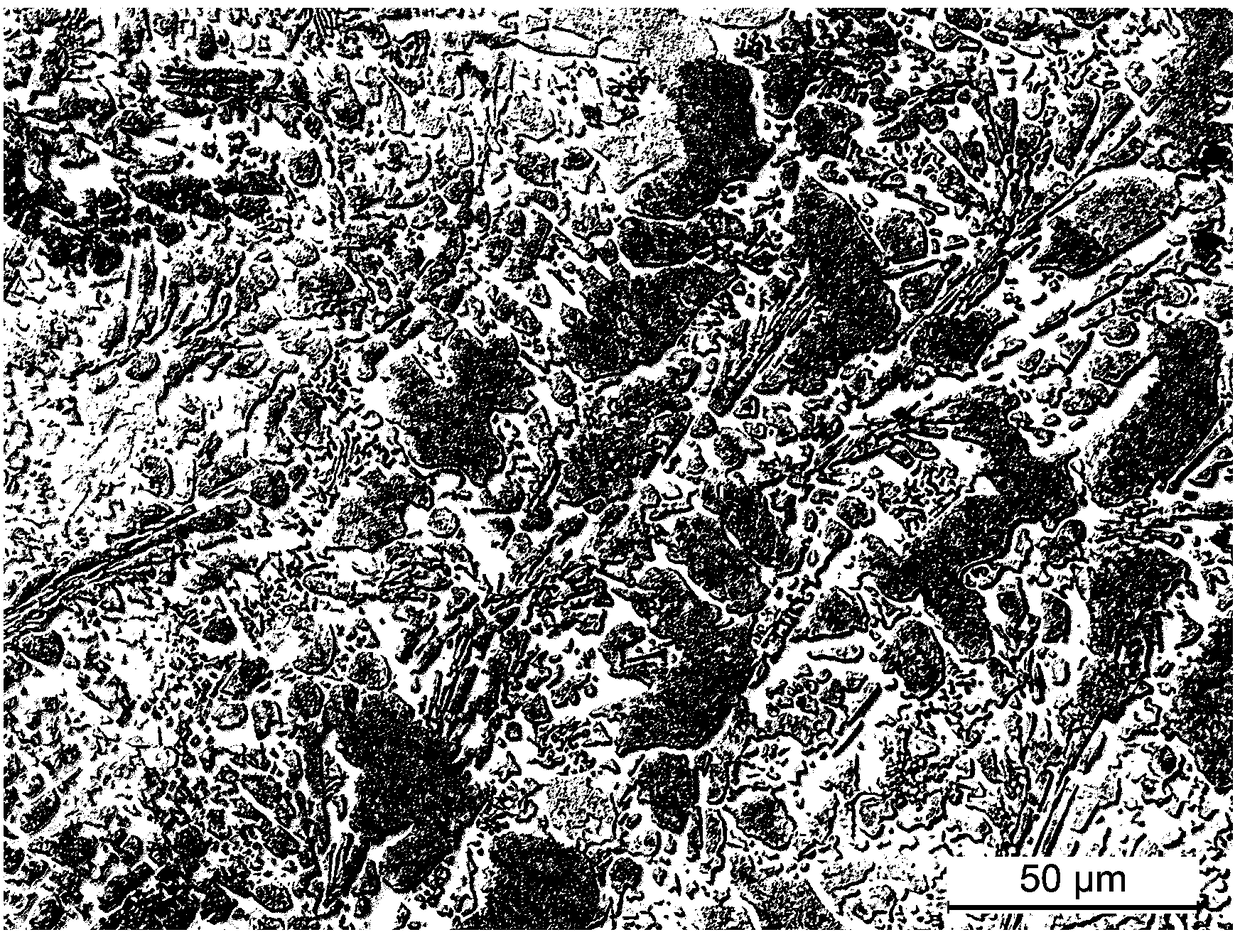

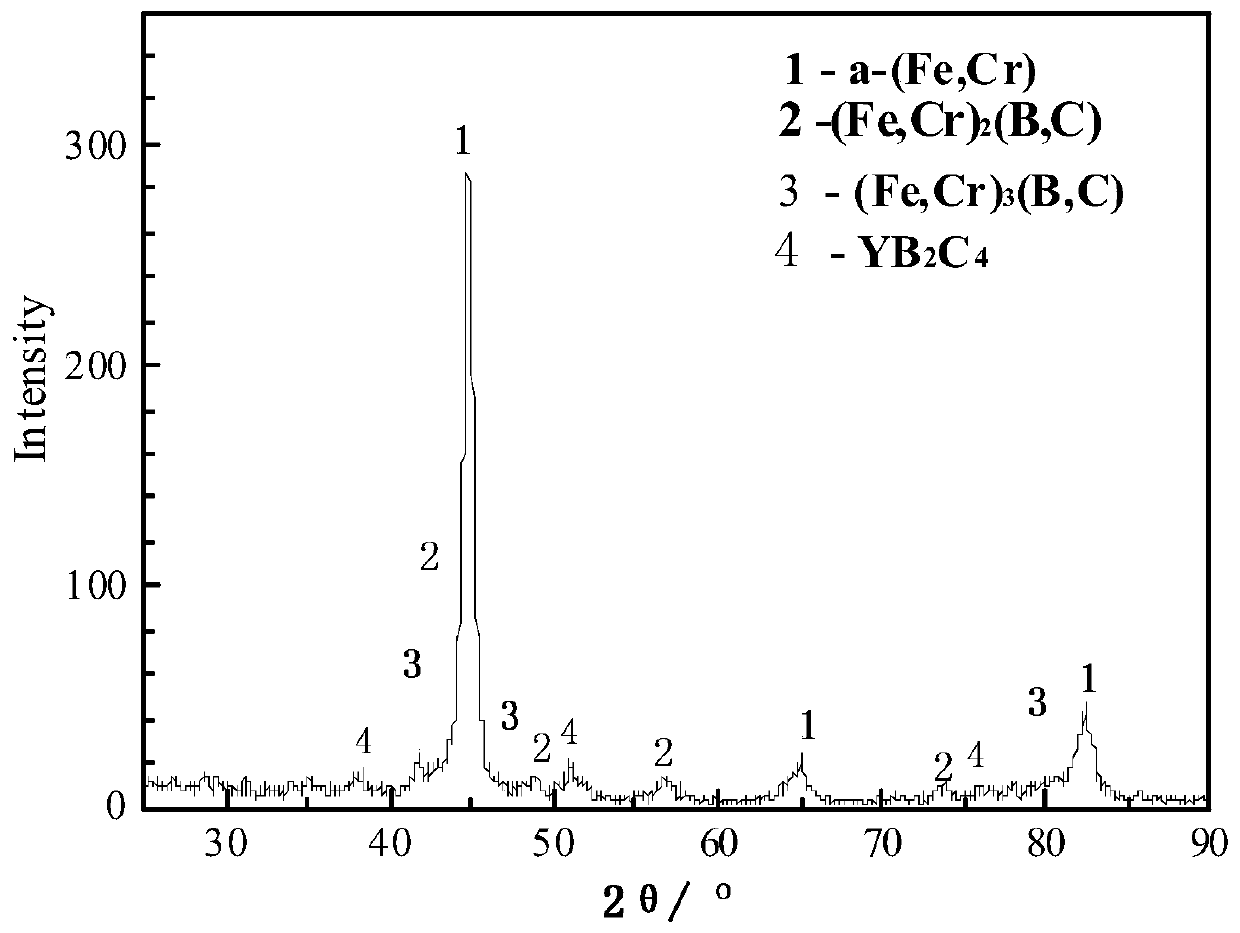

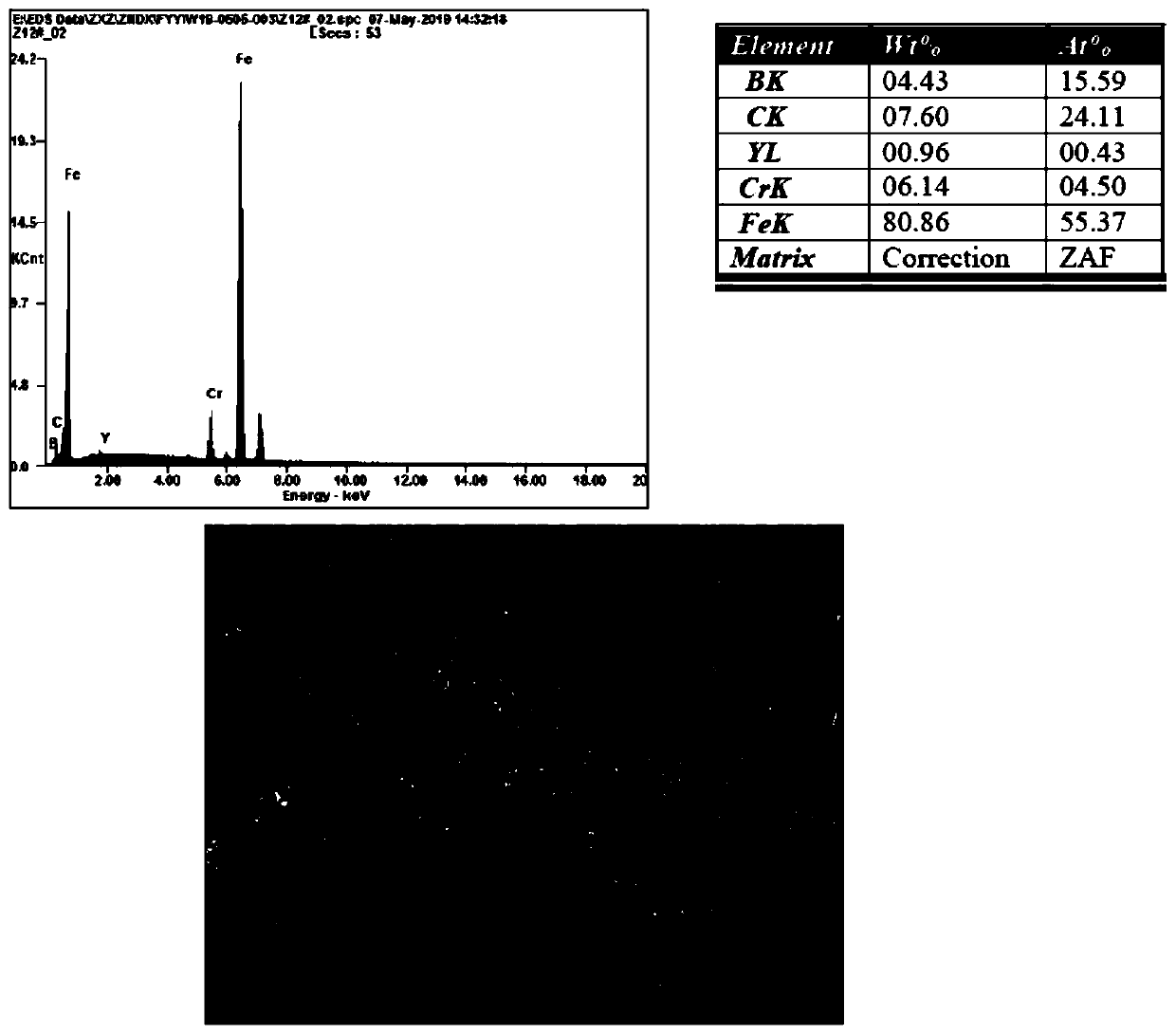

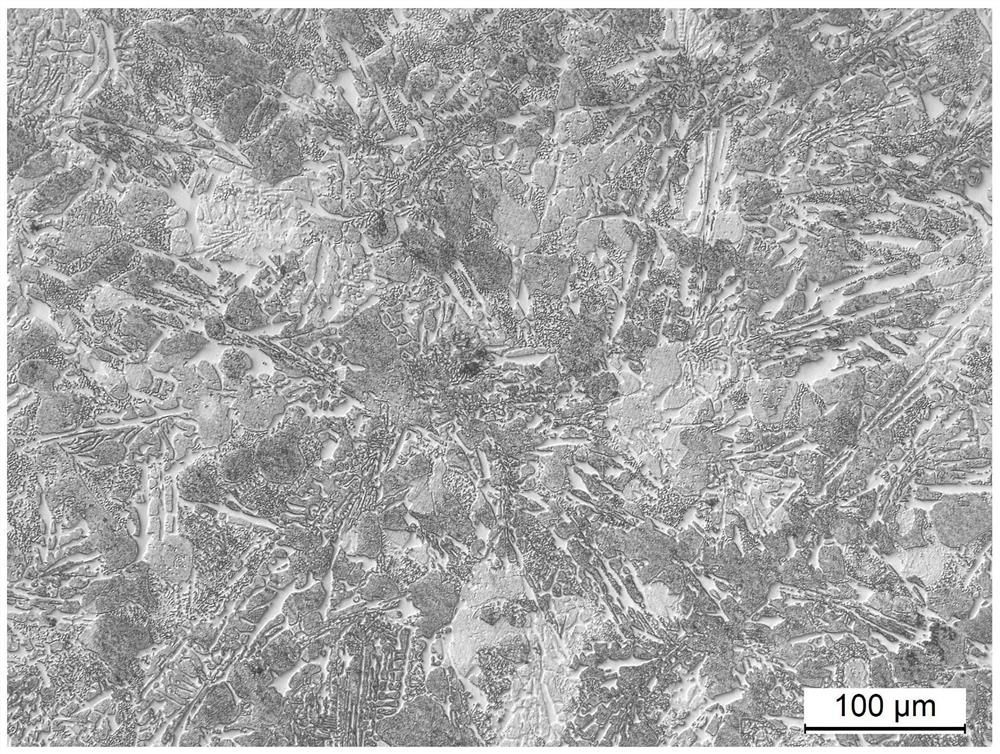

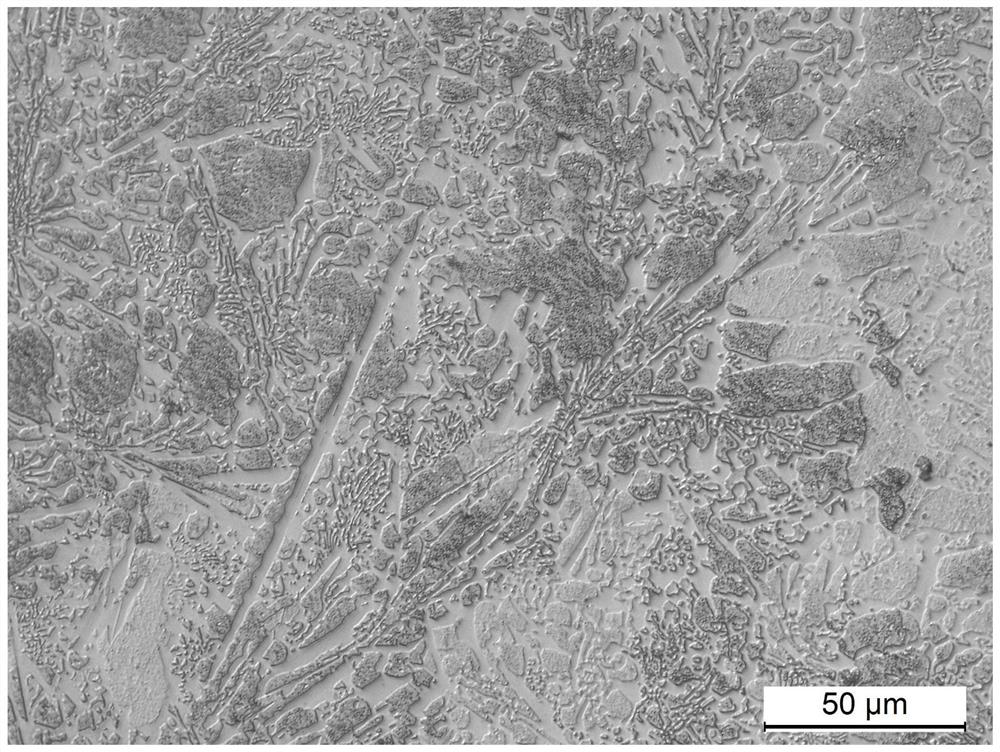

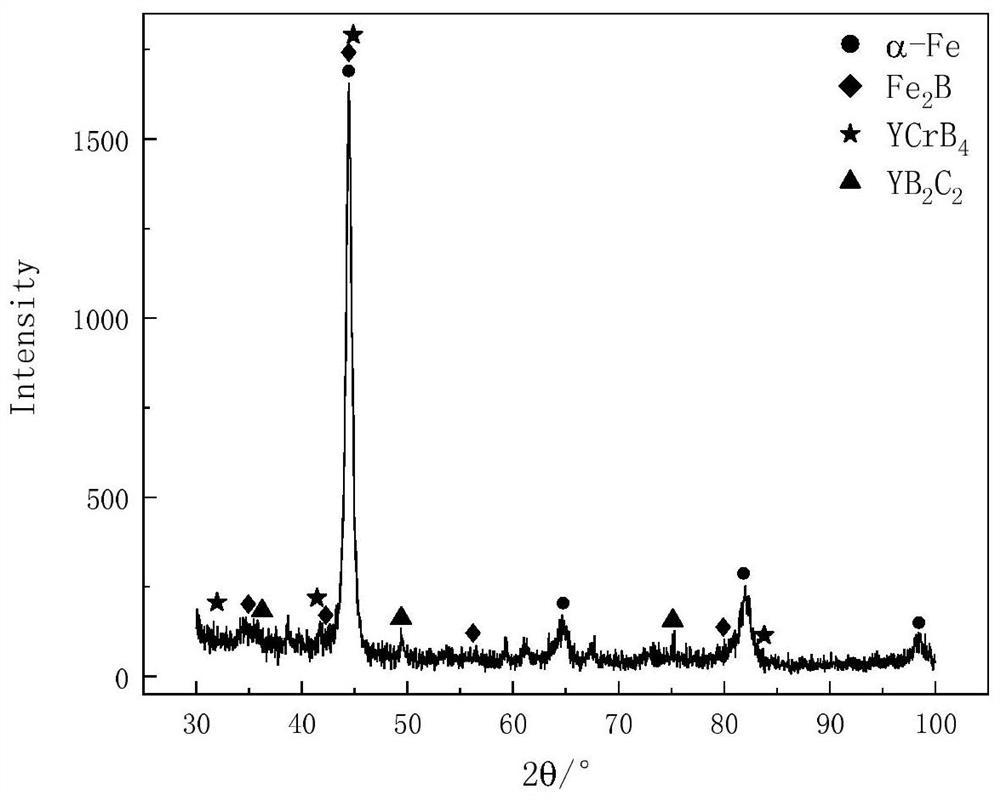

Rare-earth yttrium toughened high-hardness alloy and casting and heat treatment method thereof

The invention discloses a rare-earth yttrium toughened high-hardness alloy and a casting and heat treatment method thereof. The alloy comprises the following elements of, by mass, 9.0-13.0% of Cr, 2.6-2.9% of B, 0.7-0.9% of C, 0.4-0.8% of Nb, 0.4-0.8% of V, less than 0.3 of Mn, 0.02-0.6% of Y, less than or equal to 0.01 of S, less than or equal to 0.01 of P and the balance Fe; and the sum of C andB is 3.3-3.6, the mass ratio of C to Cr is 0.06-0.08, and the sum of Nb and V is 0.5-1.0. The method comprises steps that firstly, Fe-Y2O3 powder pressing blocks are prepared, the alloy is subjectedto dosing, smelting and modification treatment, then the alloy is subjected to casting, and then quenching-tempering treatment is adopted. According to a cast ingot of the rare-earth yttrium toughenedhigh-hardness alloy and the casting and heat treatment method thereof, the overall hardness is HRC 65.4-HRC 68.5, the impact toughness reaches 13.3-17.1 J per cm<2>, and the bending strength reaches1340-1742 MPa.

Owner:CENT SOUTH UNIV

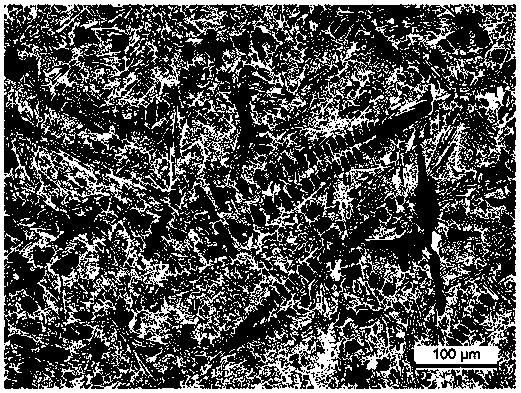

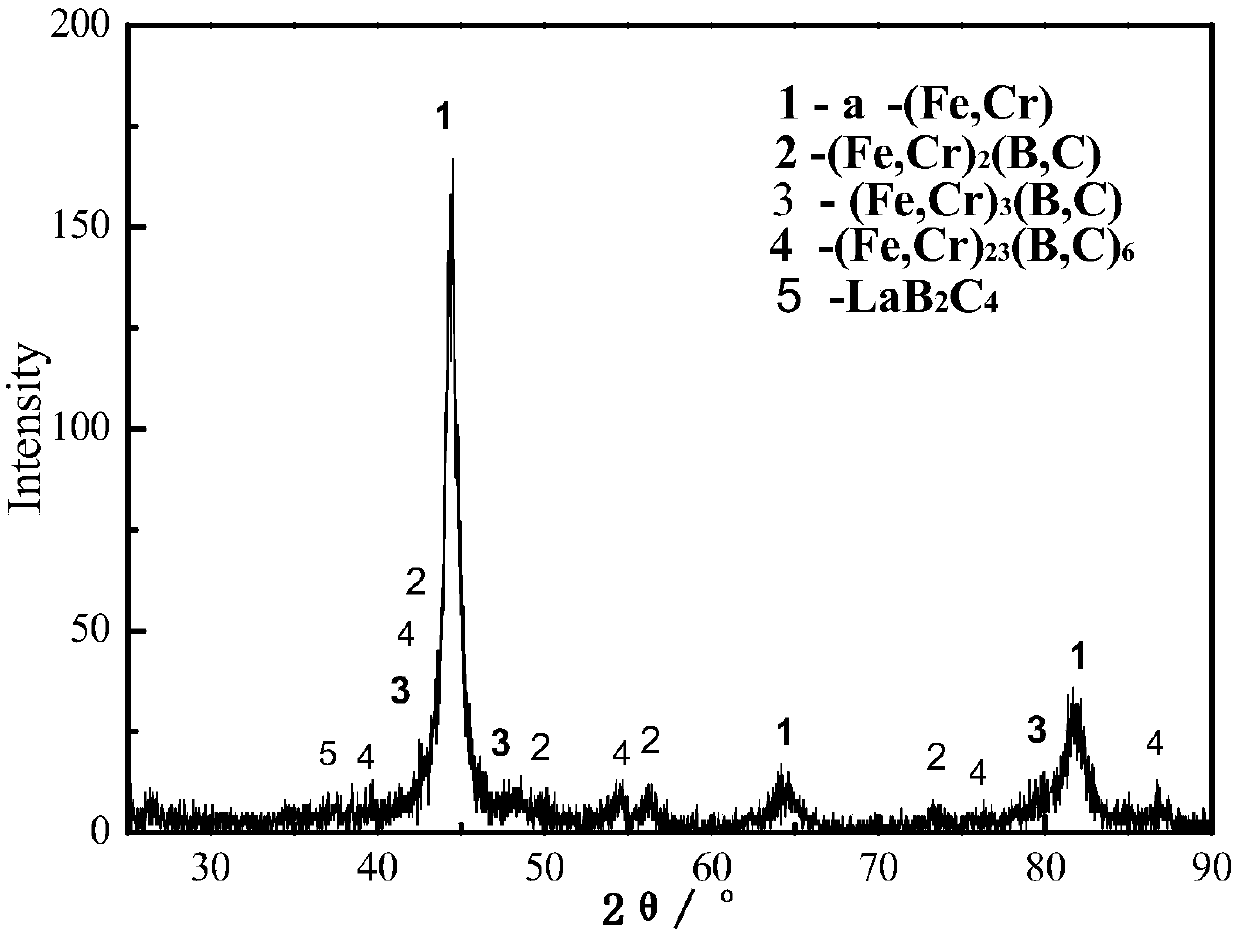

Rare earth lanthanum toughened high-hardness alloy and casting and heat treatment method thereof

The invention discloses rare earth lanthanum toughened high-hardness alloy and a casting and heat treatment method thereof. The rare earth lanthanum toughened high-hardness alloy comprises the following elements in percentage by mass: 9.0 to 13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, smaller than 0.3 percent of Mn, 0.05to 0.5 percent of La, smaller than or equal to 0.01 percent of S and P, and Fe for the surplus, wherein the total percent of C and B is 3.3 to 3.6 percent; the content ratio of C / Cr is 0.06 to 0.08; the total percent of Nb and V is 0.5 to 1.0. The method comprises the steps of firstly preparing Fe-La2O3 powder compact, performing alloy batching, smelting and modification treatment, performing alloy casting, and then performing quenching-tempering treatment. The global hardness of a cast ingot reaches HRC 67.4 to 70.2, the impact toughness reaches 10.2 to 12.8J / cm<2>, and the bending strength reaches 960 to 1080MPa.

Owner:CENT SOUTH UNIV

Yttrium carbonate metamorphic toughened high hardness alloy and casting method thereof

The invention discloses an yttrium carbonate metamorphic toughened high hardness alloy and a casting method thereof. The yttrium carbonate metamorphic toughened high hardness alloy comprises the elements of, 9.0-13.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, less than 0.3 of Mn, 0.08-1.6 of Y and the balance Fe. The total amount of C and B is 3.3-3.6, the content ratio of C / Cr is 0.06-0.08, and the total amount of Nb and V is 0.5-1.0. The casting method comprises the steps that first, Fe-yttrium carbonate powder is prepared and pressed into blocks, and the alloy is cast after alloy batching, smelting and metamorphosing treatment. The average hardness HRC of a cast ingot of the yttrium carbonate metamorphic toughened high hardness alloy is 66.92-70.3, the impact toughness reaches 12.0-16.0 J / cm<2>, and the bending strength reaches 1432-1690 MPa.

Owner:CENT SOUTH UNIV

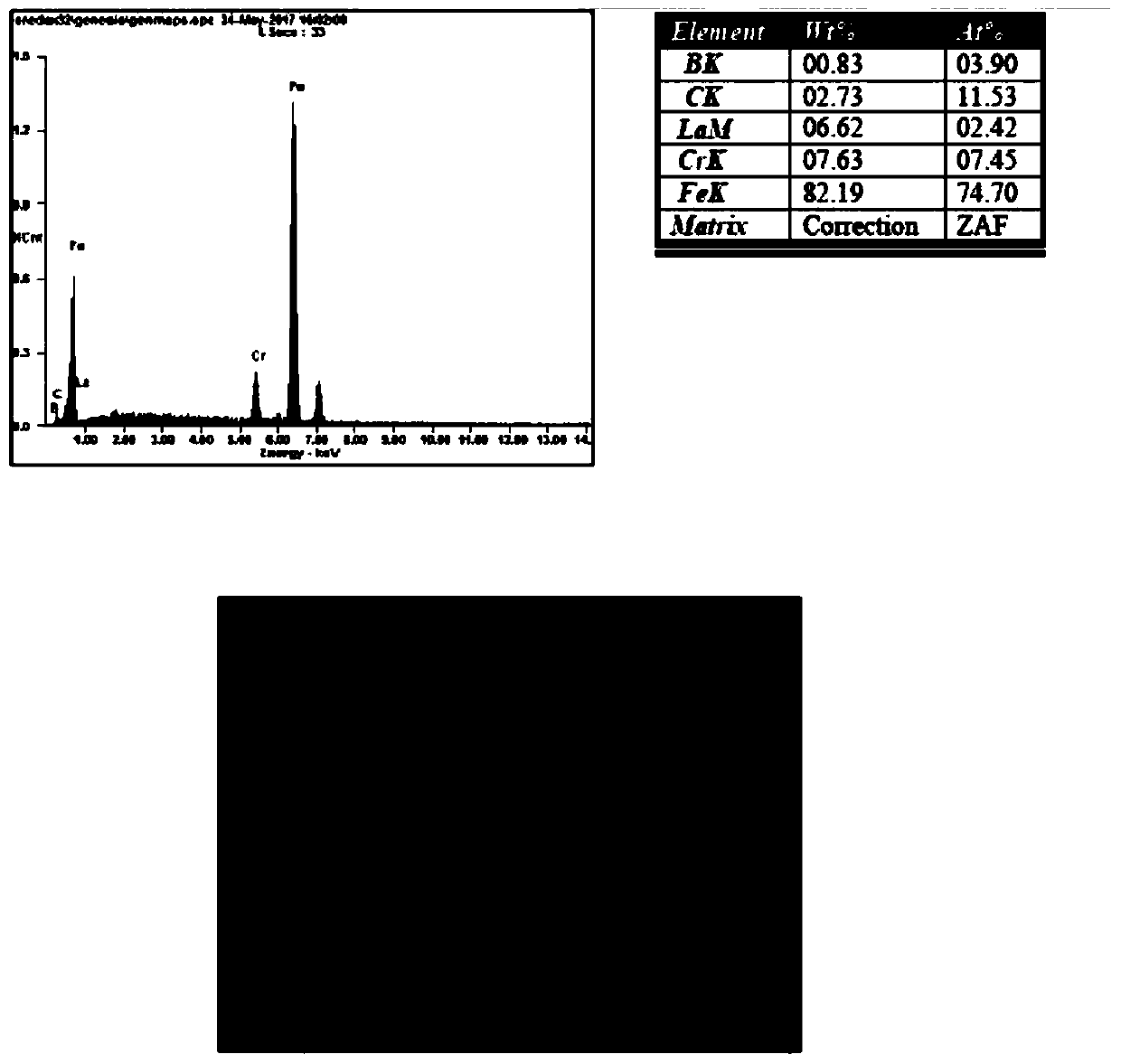

Lanthanum toughened high-hardness alloy and casting and heat treatment method thereof

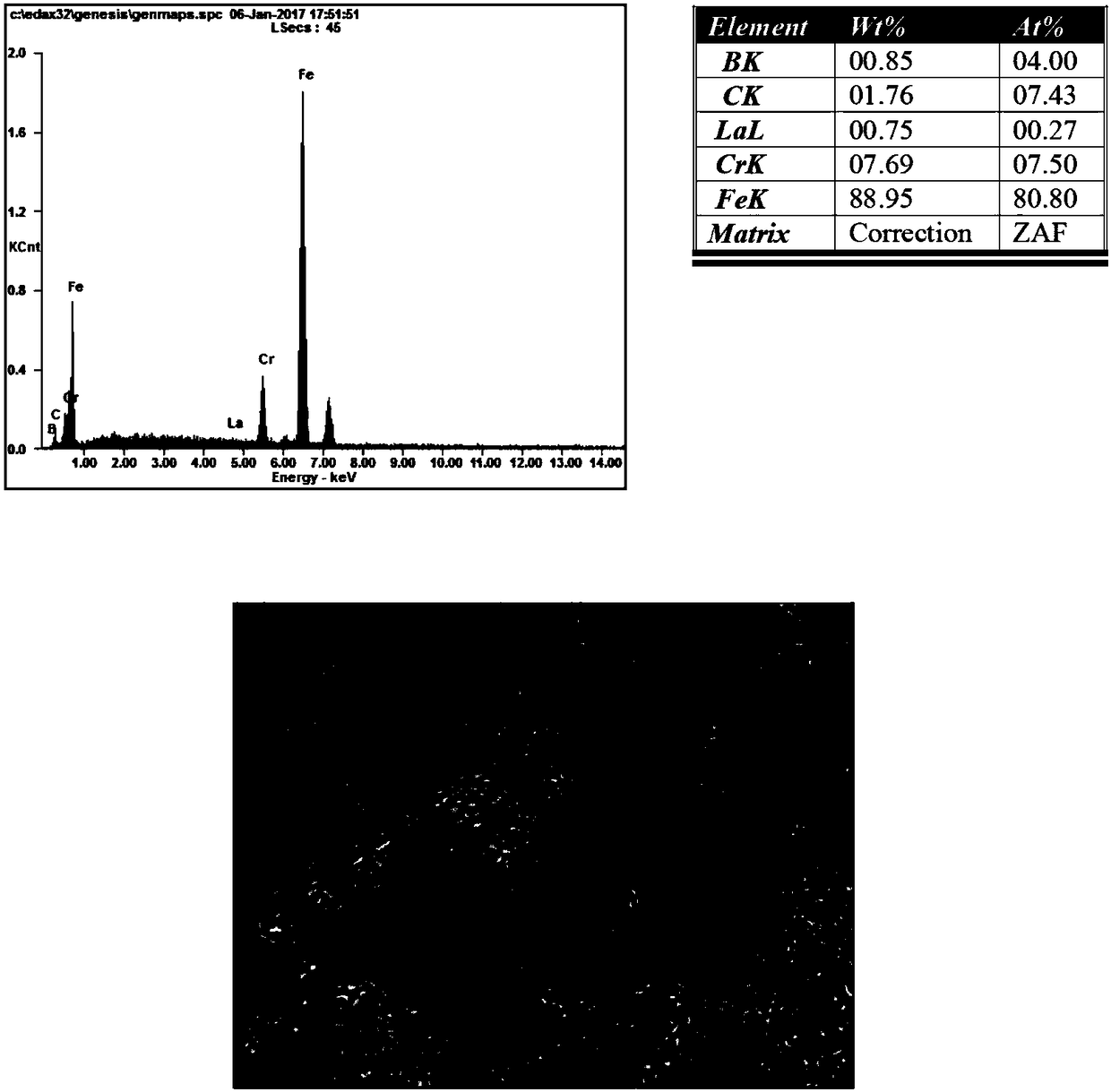

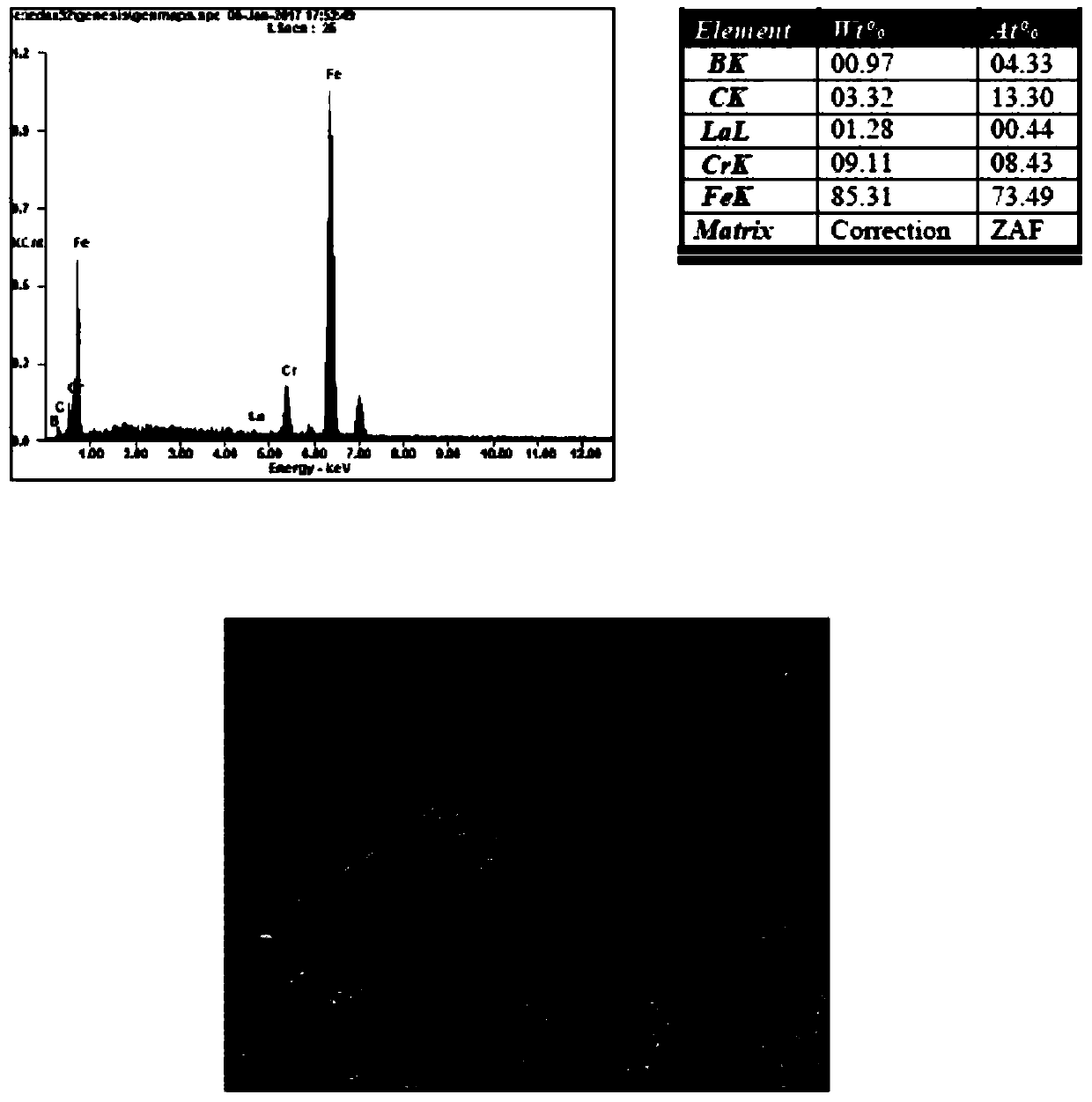

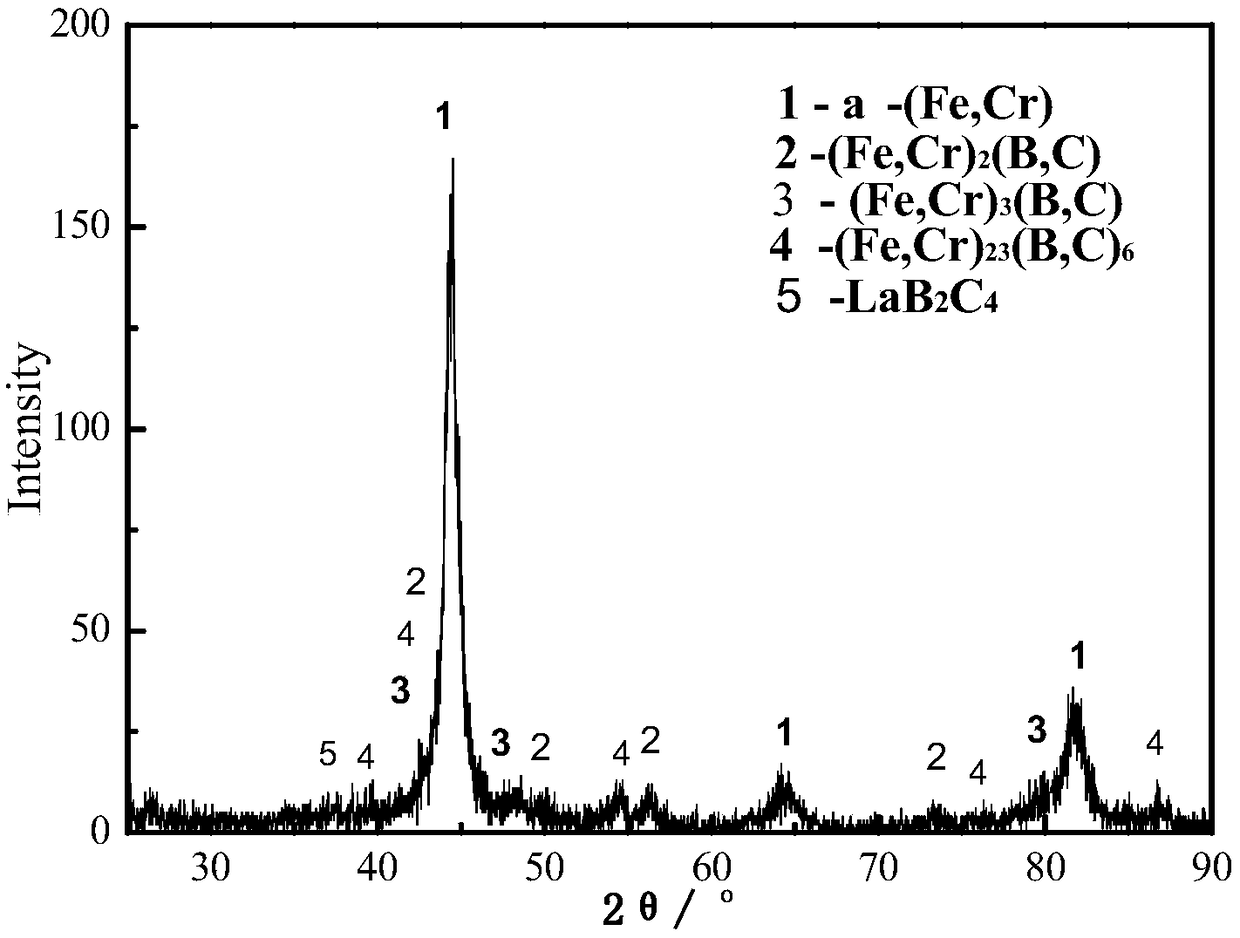

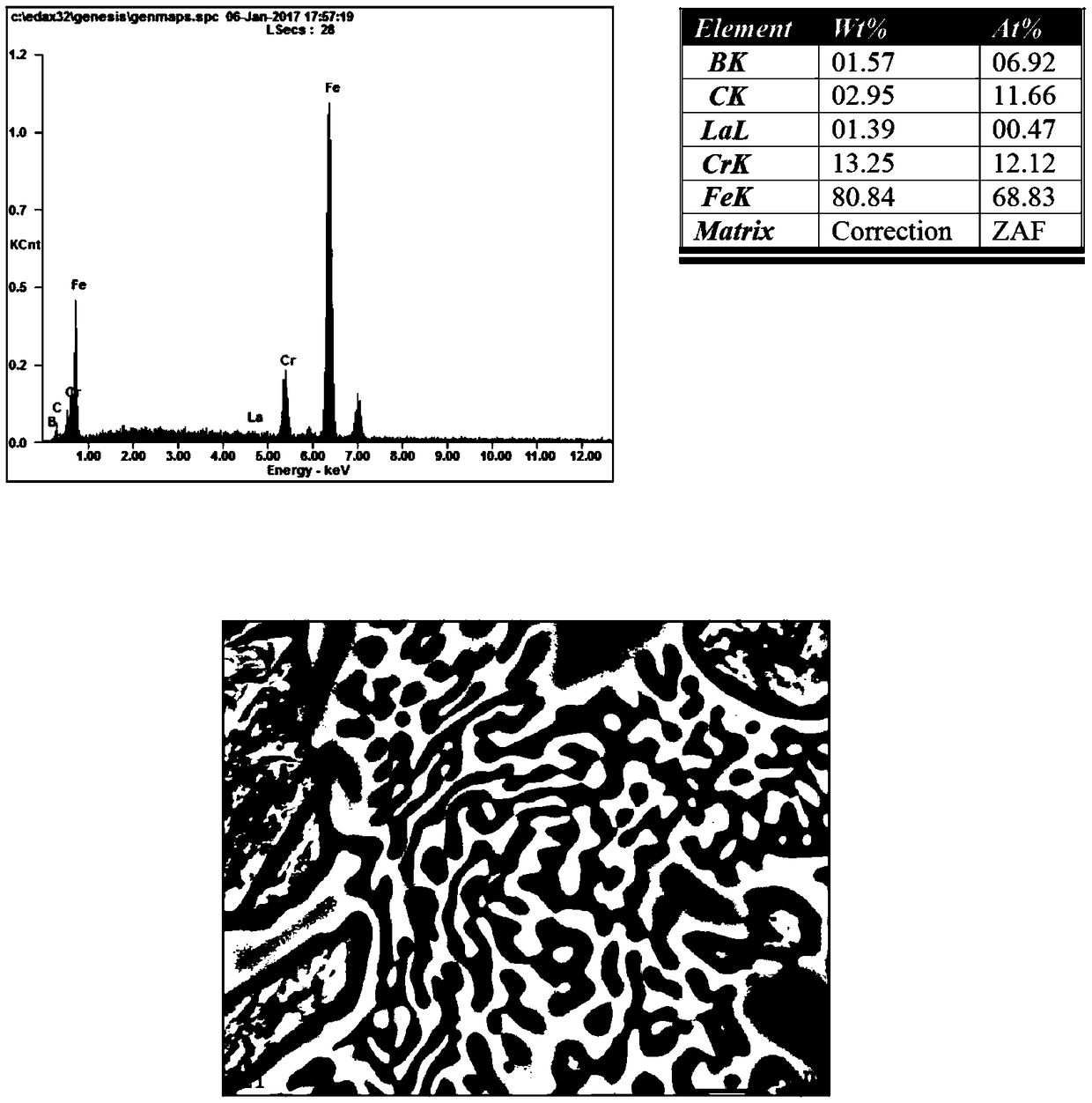

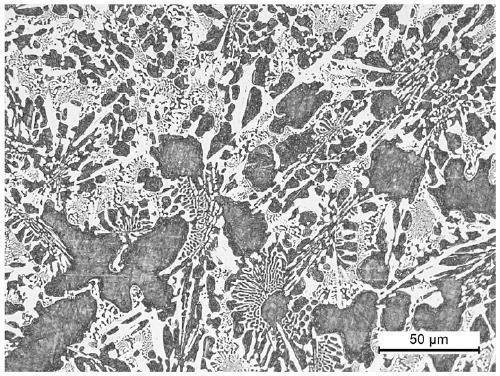

InactiveCN110106450APromote formationPlay a role in metamorphism and tougheningIngotLanthanum nitrate

The invention discloses a lanthanum toughened high-hardness alloy and a casting and heat treatment method thereof. The lanthanum toughened high-hardness alloy comprises, by mass, Cr: 9.0-13.0%, B: 2.6-2.9%, C: 0.7-0.9%, Nb: 0.4-0.8%, V: 0.4-0.8%, Mn: less than or equal to 0.3%, La: 0.03-0.7%, S: less than or equal to 0.01%, P: less than or equal to 0.01%, and the balance Fe, wherein the sum of C and B is 3.3-3.6%, the ratio of C to Cr is 0.06-0.08 %, and the sum of Nb and V is 0.5-1.0%. Firstly, an Fe-La2O3 powder compact, an Fe-lanthanum carbonate powder compact or a lanthanum nitrate powdercompact are prepared, then after burdening, smelting and modification treatment of an alloy, the alloy is cast with the casting temperature of 1250-1320 DEG C, and quenching-tempering treatment is adopted. Integral hardness of the cast ingot reaches HRC 65.1-70.2, impact toughness reaches 10.2-16.4 J / cm<2>, and bending strength reaches 960-1540 MPa.

Owner:CENT SOUTH UNIV

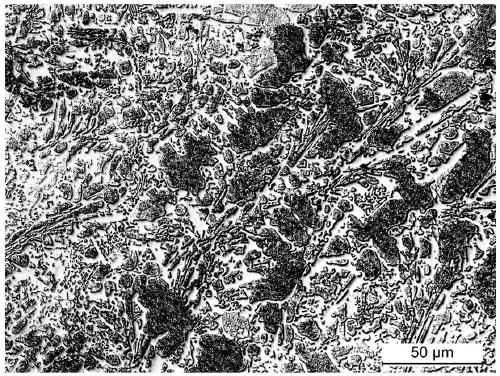

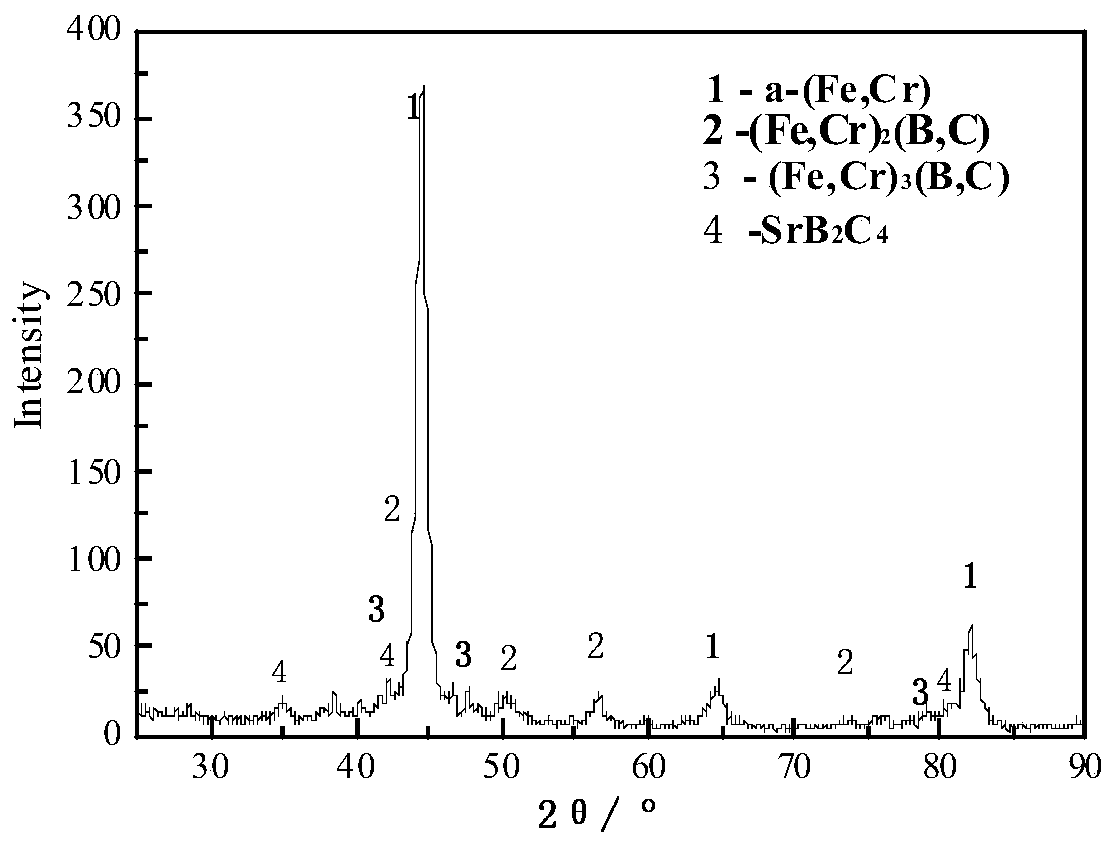

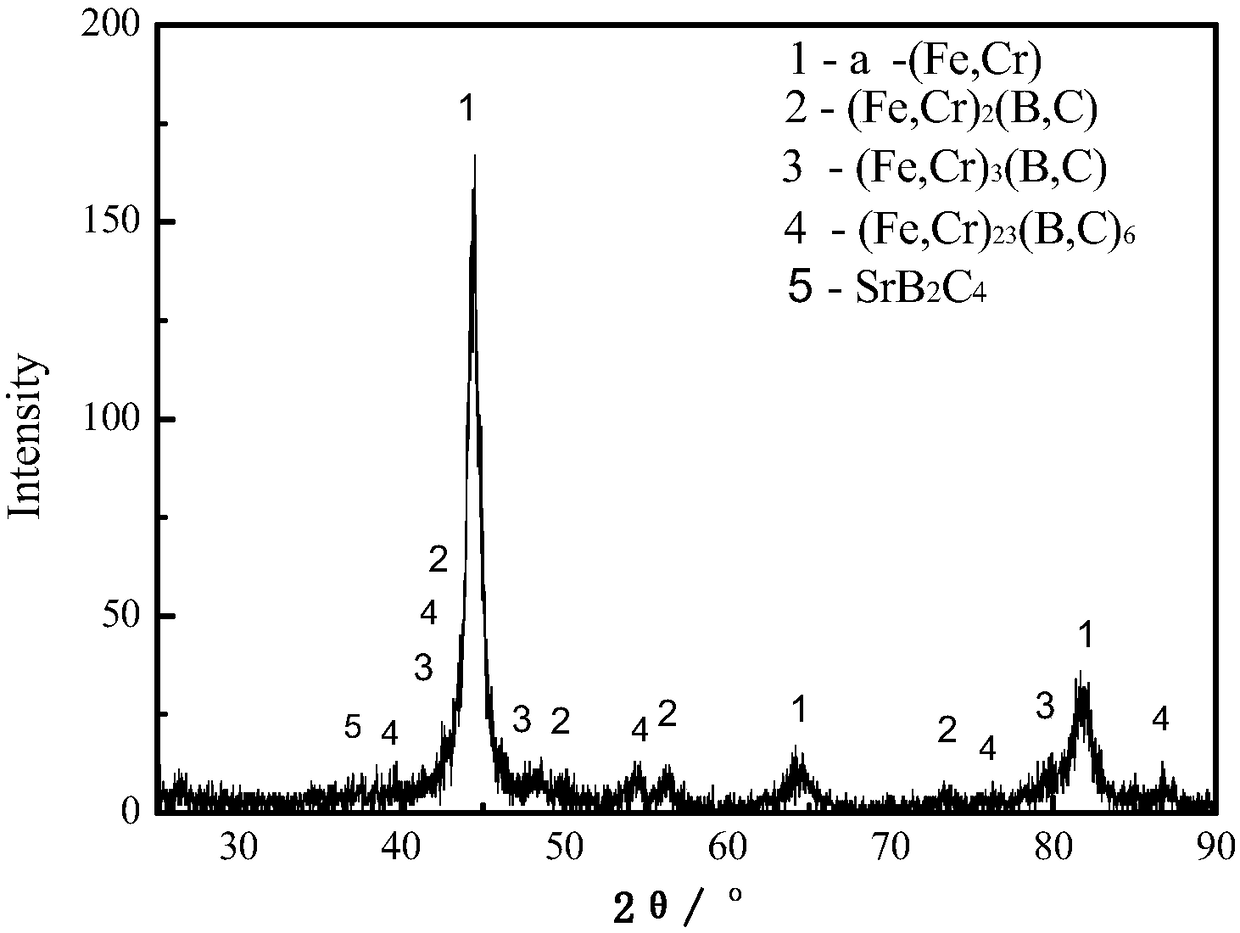

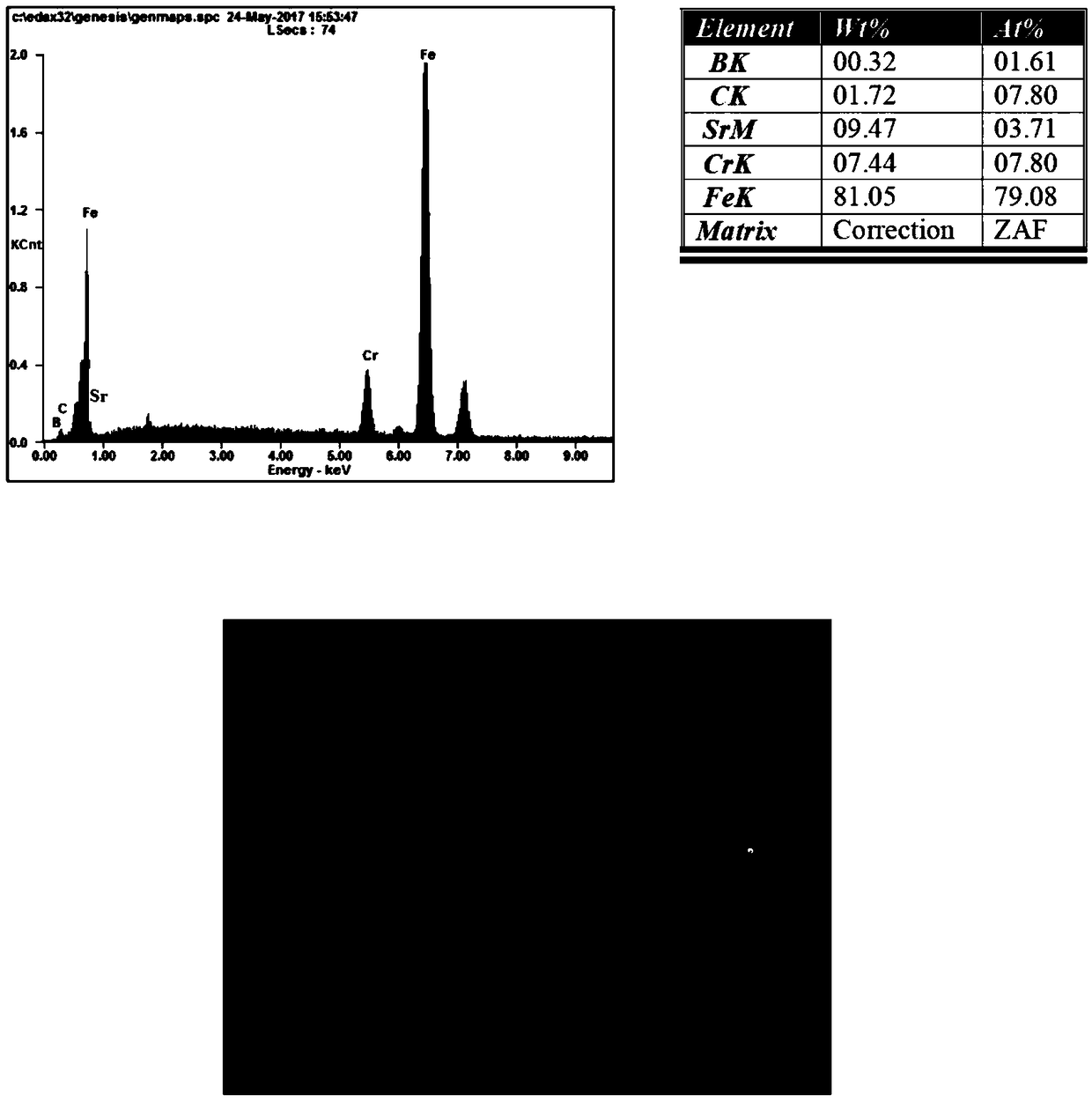

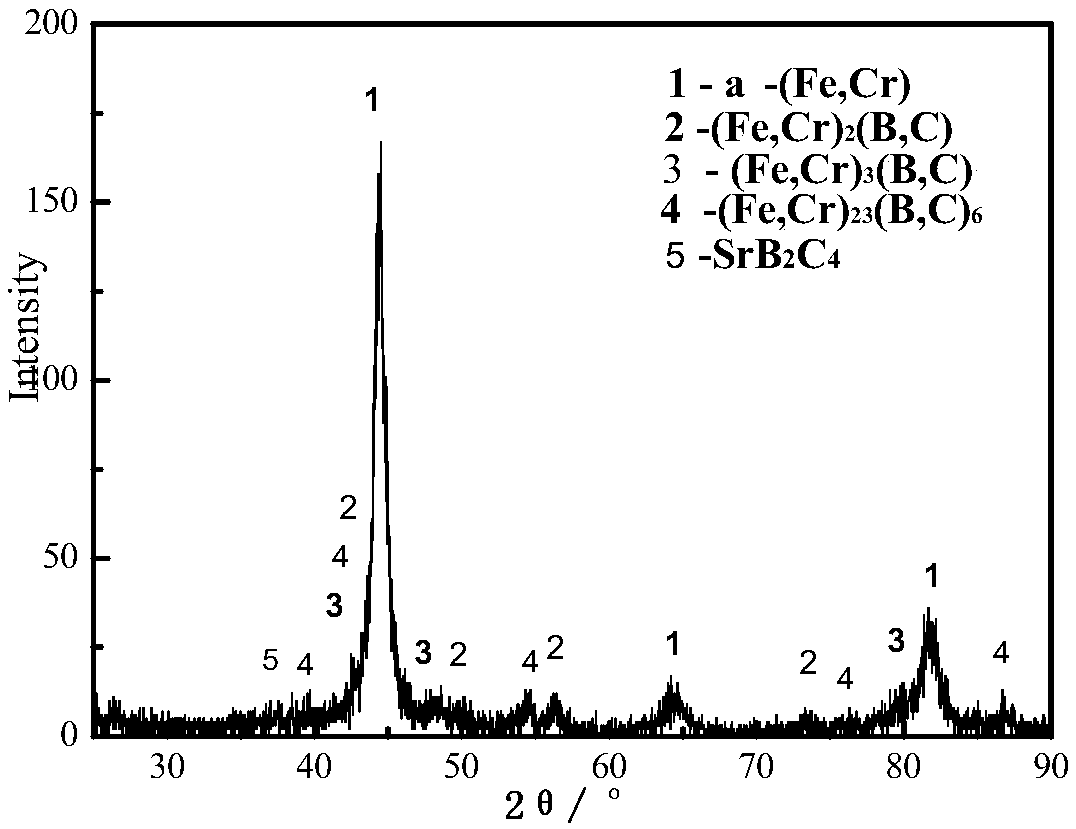

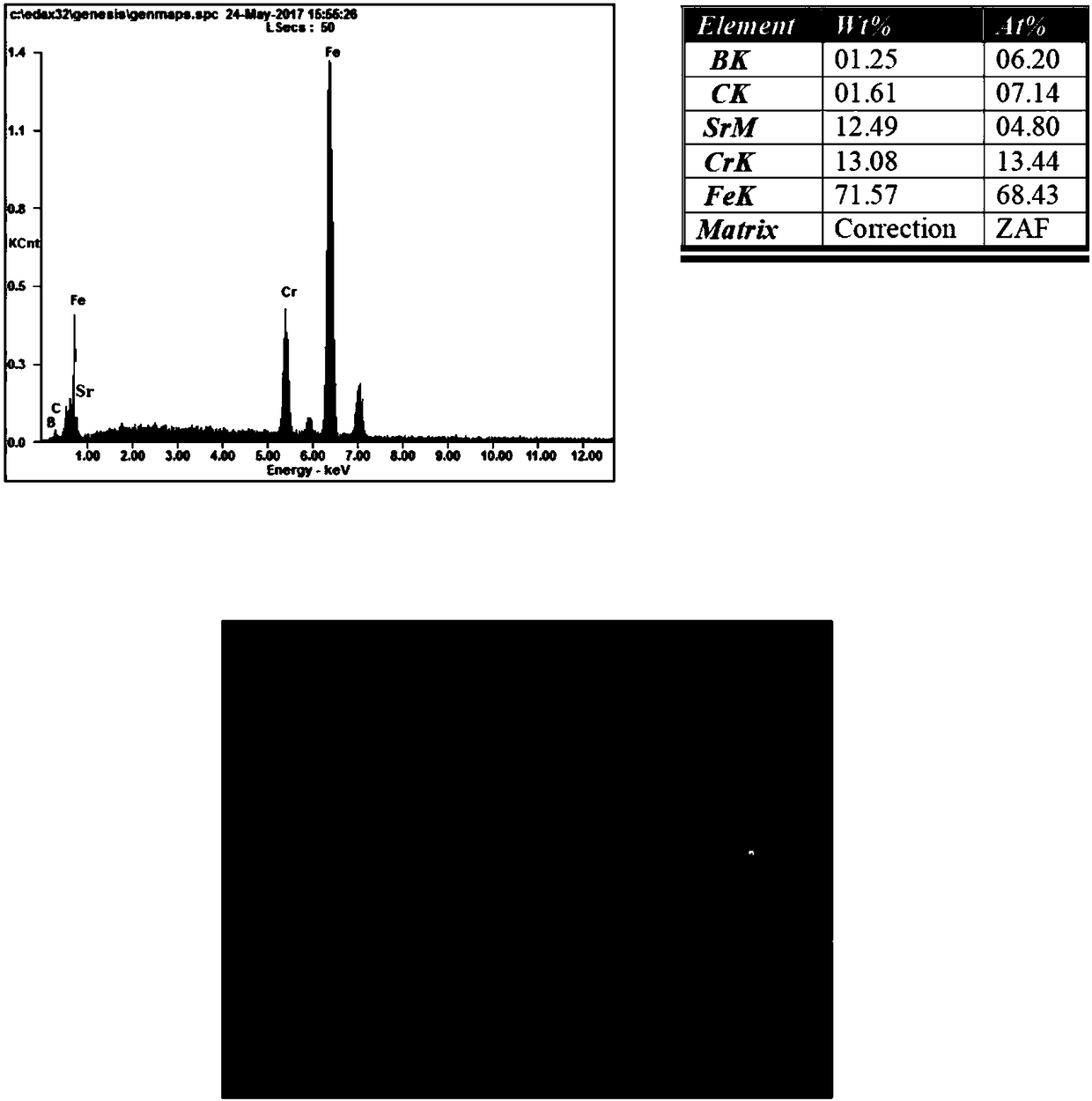

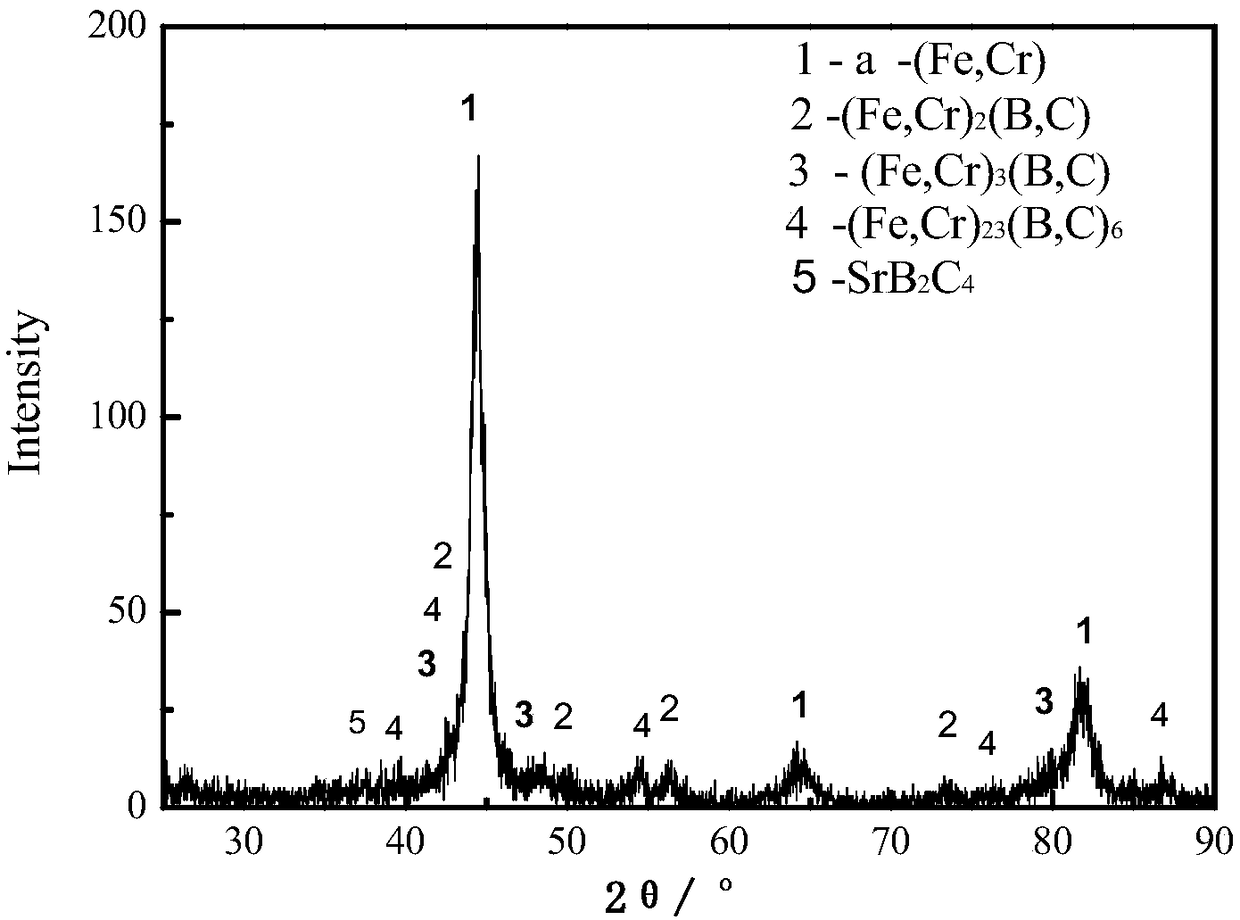

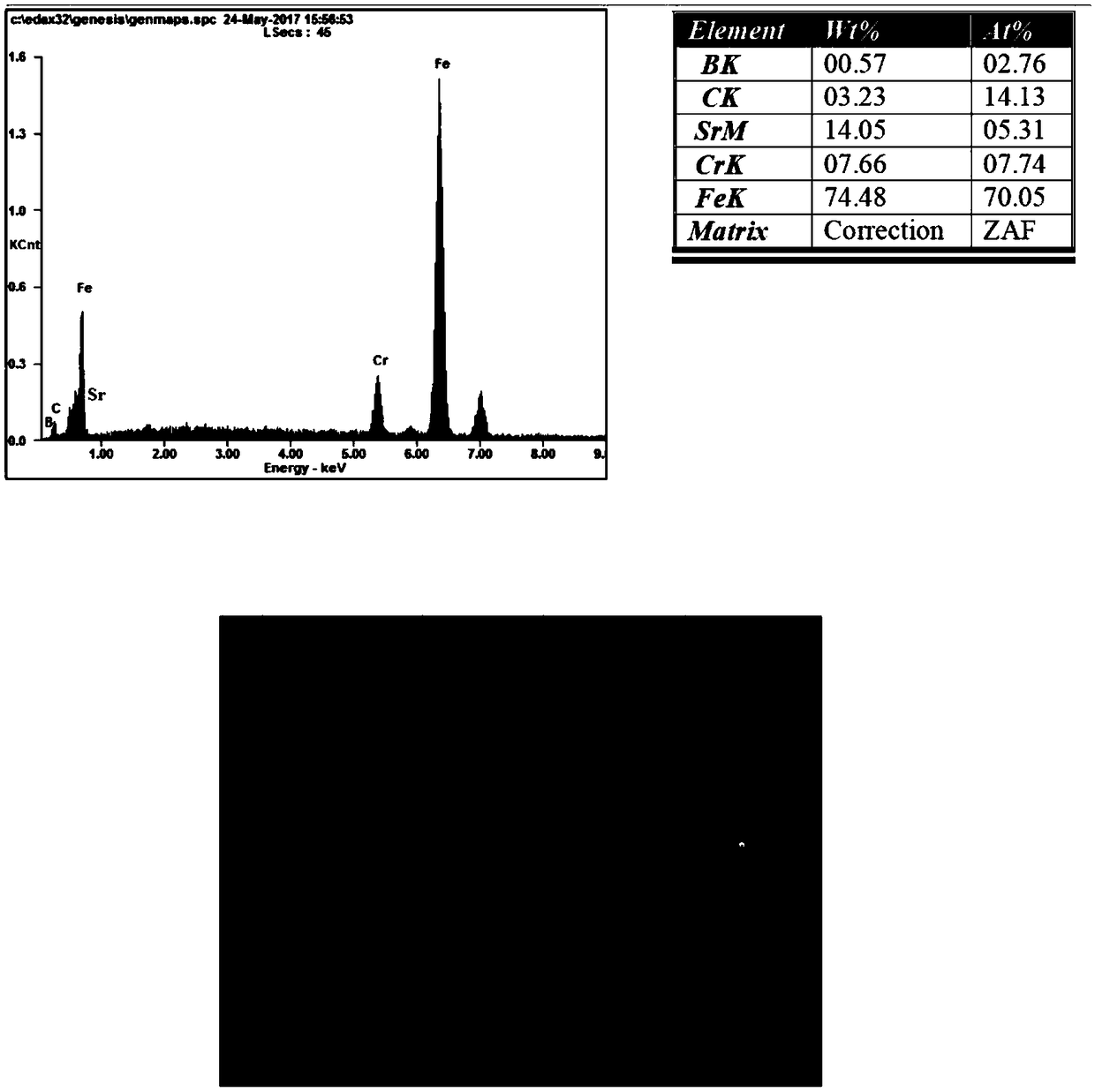

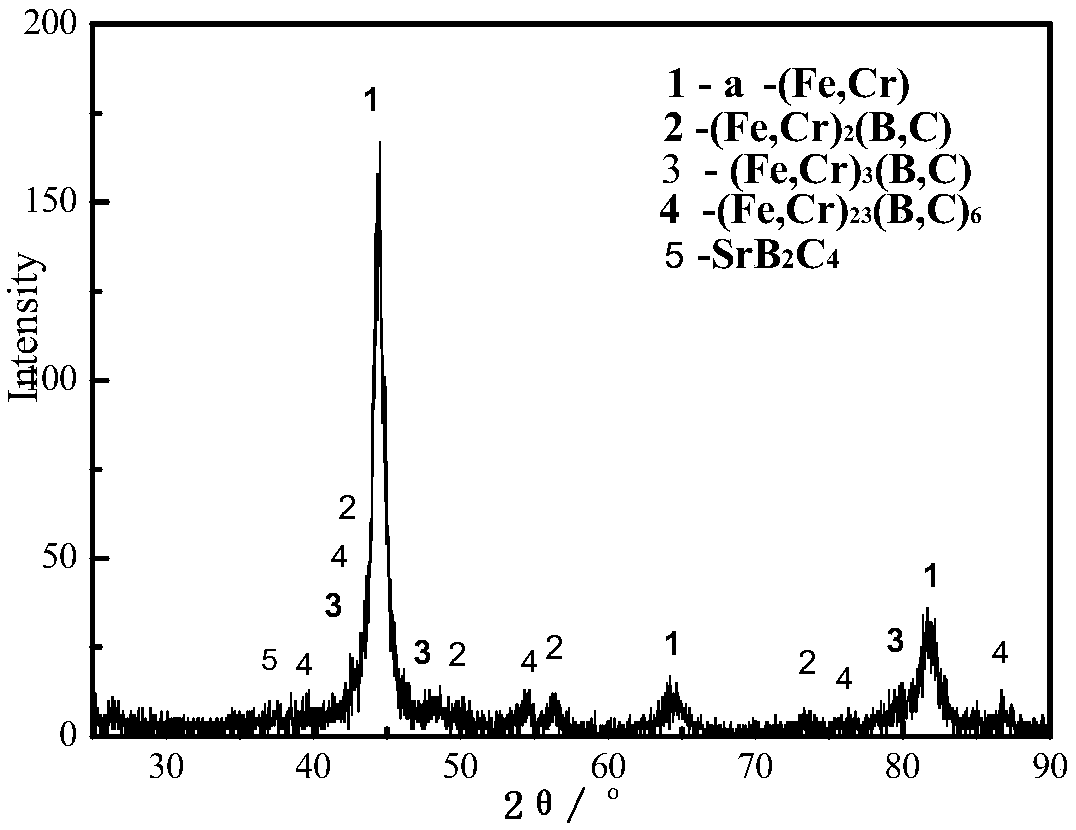

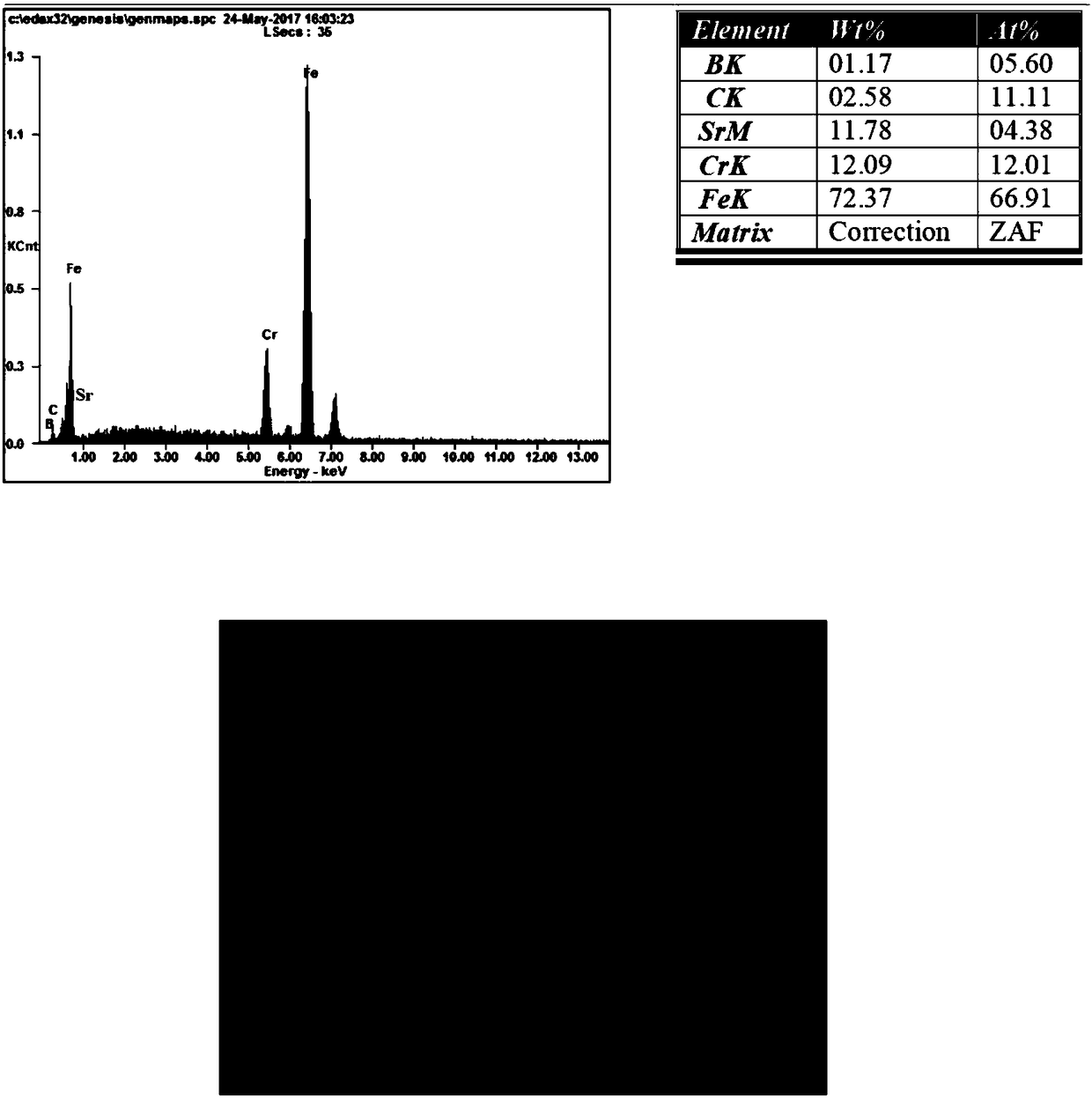

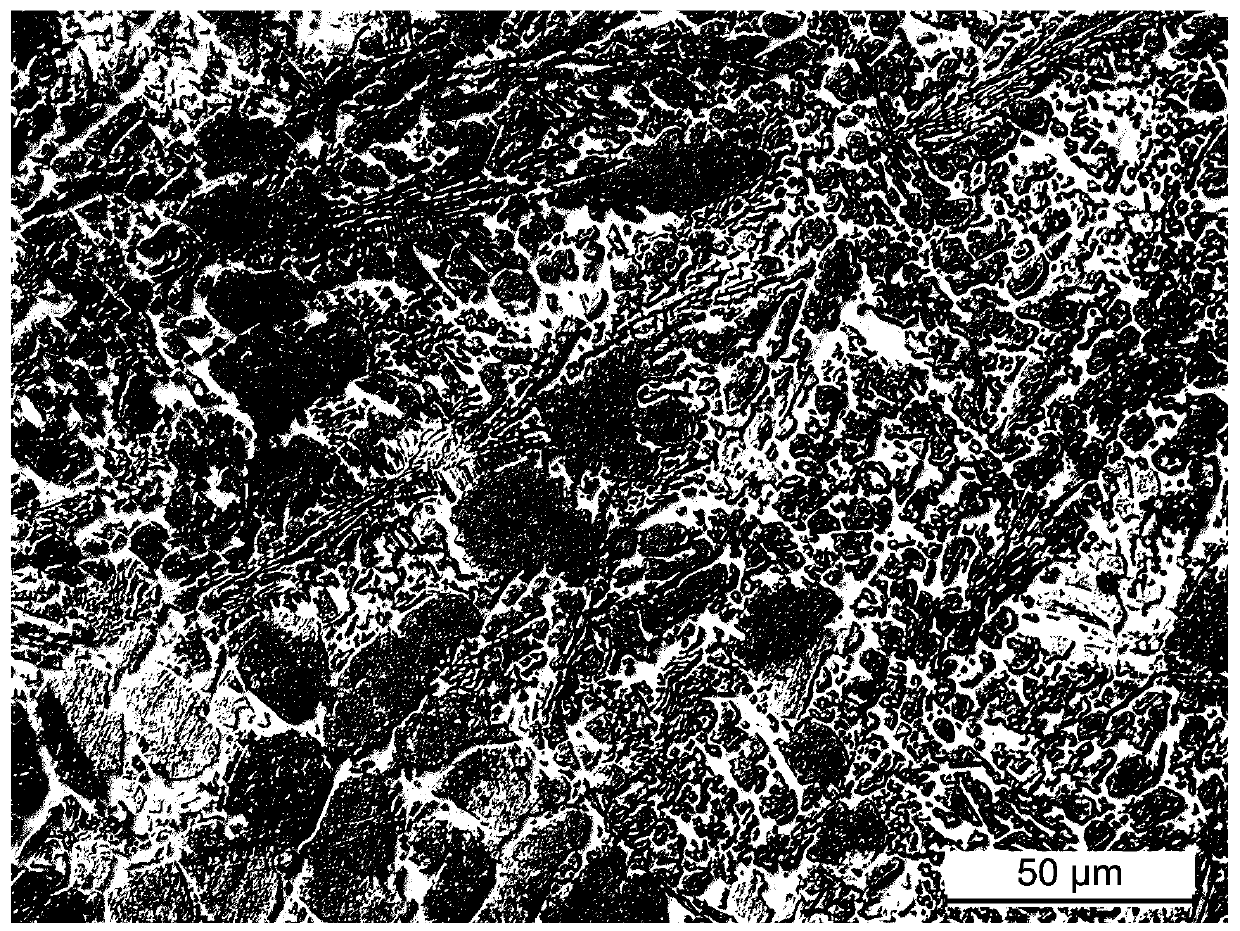

Sr-toughened high-hardness alloy and casting method thereof

The invention discloses a Sr-toughened high-hardness alloy and a casting method thereof. the alloy is prepared from elements, including, 9.0-13.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, less than 0.3 of Mn, 0.02-1.2 of Sr and the balance of Fe; the total quantity of C and B ranges from 3.3 to 3.6; the content ratio of C / Cr ranges from 0.06 to 0.08; the total quantity of Nband V ranges from 0.5 to 1.0. Firstly, Fe-SrO powder briquetting preparation is made, alloy ingredients are subjected to smelting and modification treatment for casting of the alloy, and the casting temperature ranges from 1,250 DEG C to 1,300 DEG C. The average hardness of cast ingots of the alloy ranges from HRC66.5 to HRC69.6, the impact toughness ranges from 12.5 J / cm<2> to 16.3 J / cm<2>, and the bending strength ranges from 1,260 MPa to 1,662 MPa.

Owner:CENT SOUTH UNIV

Lanthanum carbonate modified and toughened high-hardness alloy and casting method thereof

Disclosed are lanthanum carbonate modified and toughened high-hardness alloy and a casting method thereof. The alloy comprises, by mass, 9.0-13.0% of Cr, 2.6-2.9% of B, 0.7-0.9% of C, 0.4-0.8% of Nb,0.4-0.8% of V, less than 0.3% of Mn, 0.03-0.7% of La and the balance Fe, wherein the total content of C and B is 3.3-3.6%, the content ratio of C to Cr is 0.06-0.08, and the total content of Nb and Vis 0.5-1.0%. Firstly, Fe-lanthanum carbonate powder briquettes are prepared, and after alloy burdening, smelting and modifying treatment, the alloy is cast. According to a cast ingot, the hardness isHRC66.2-70.0, the impact toughness reaches 10.7-14.6 J / cm<2>, and the bending strength reaches 1000-1345 MPa.

Owner:CENT SOUTH UNIV

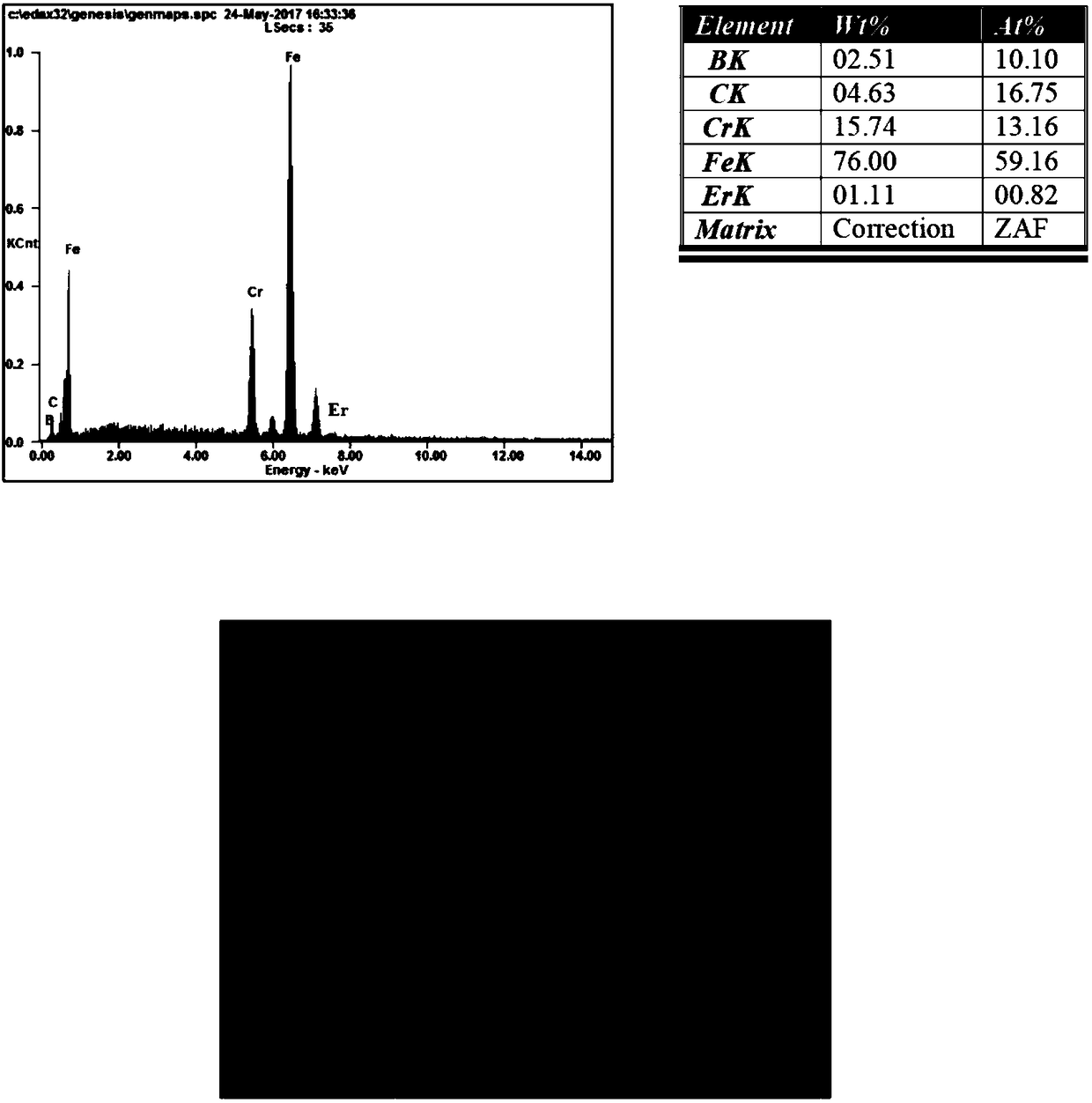

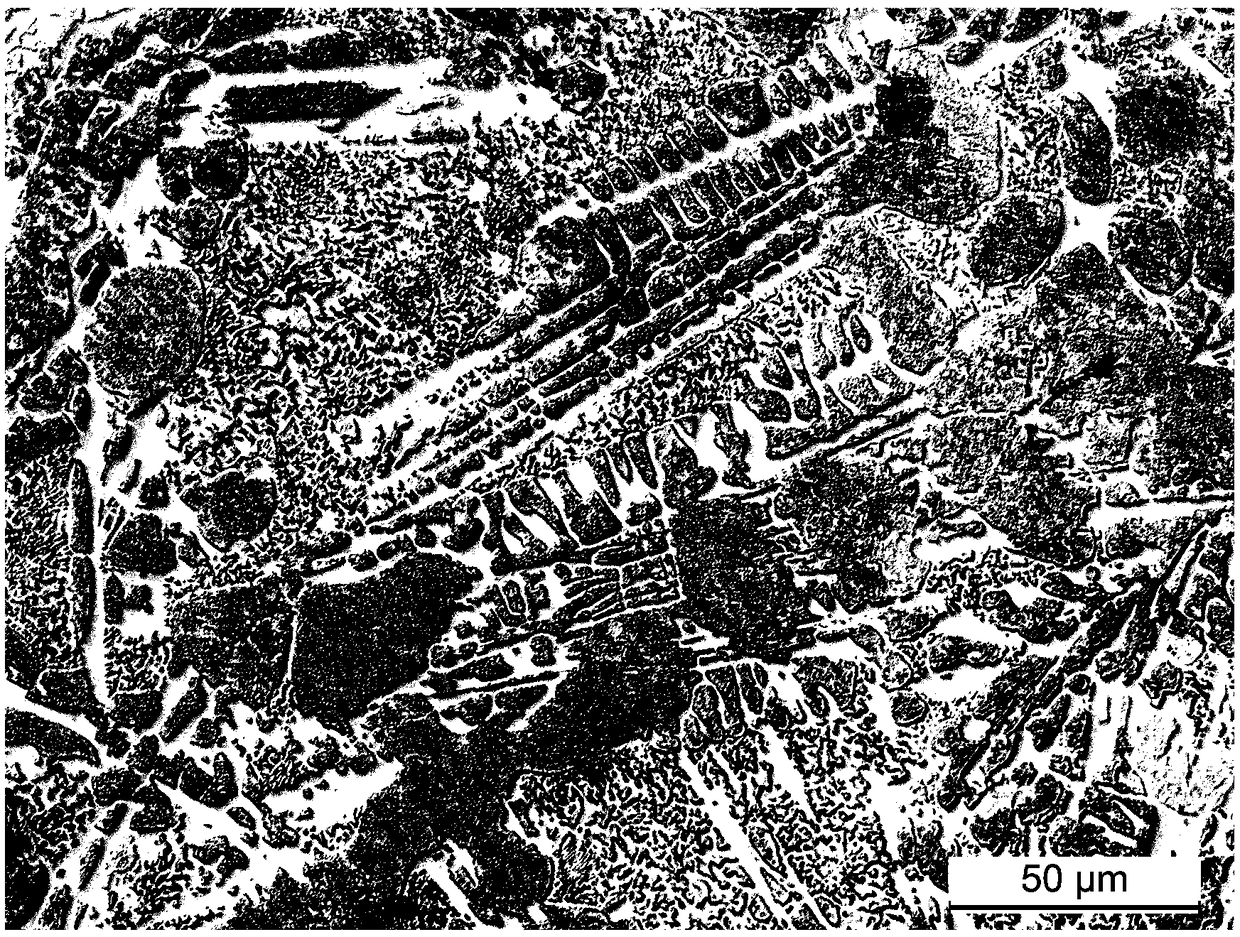

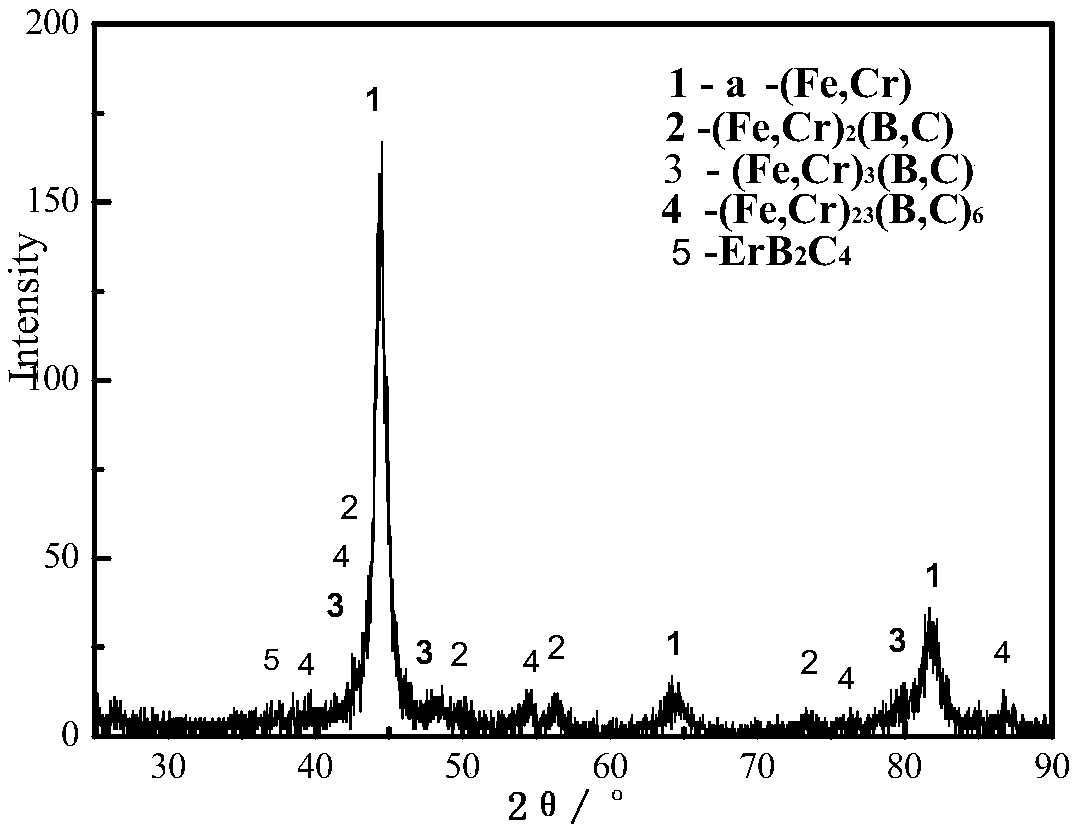

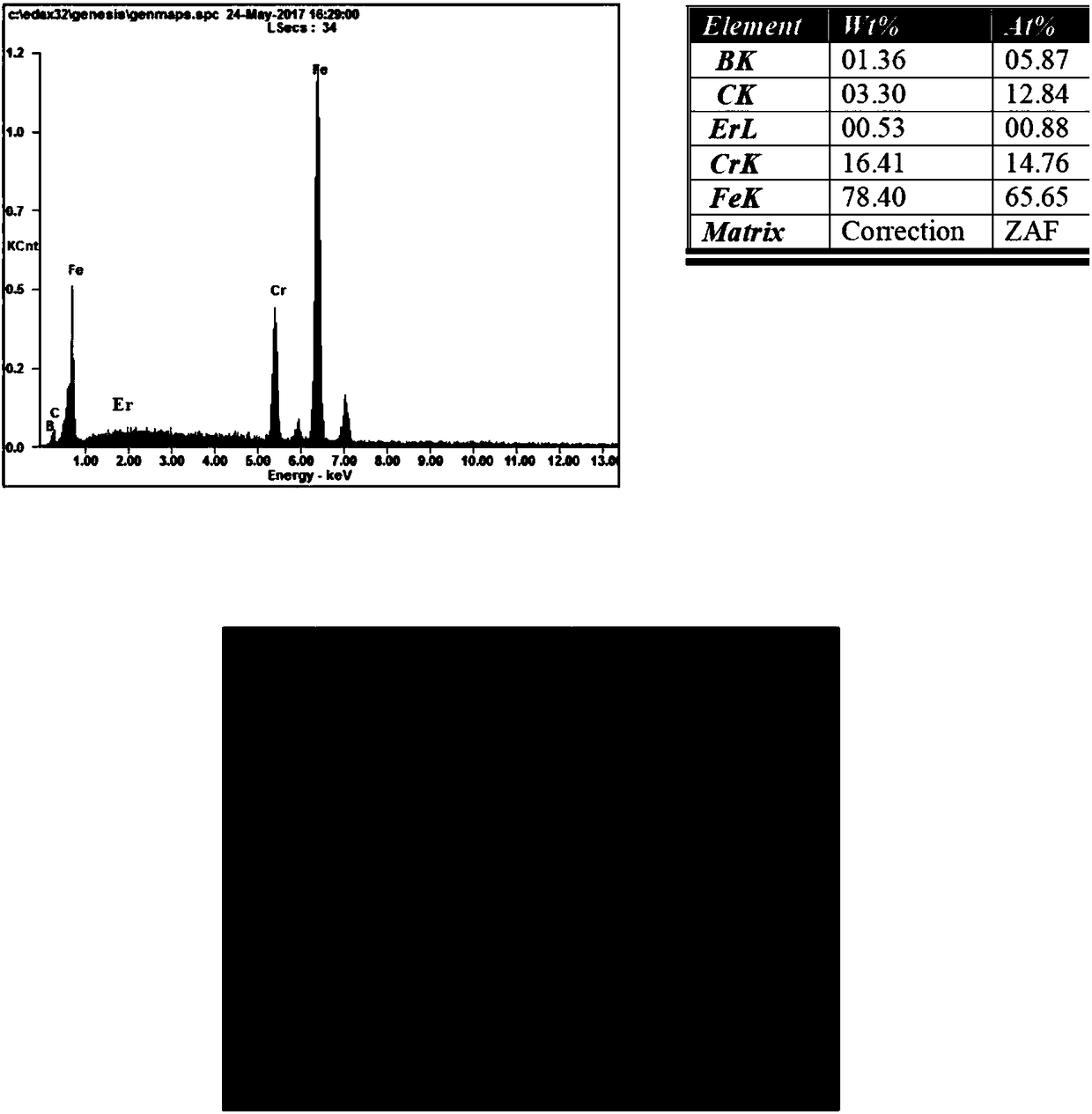

Erbium nitrate modified toughened high-hardness alloy and casting method thereof

The invention discloses erbium nitrate modified toughened high-hardness alloy and a casting method thereof. The alloy comprises the elements of, by mass, 9.0-13.0% of Cr, 2.6-2.9% of B, 0.7-0.9% of C,0.4-0.8% of Nb, 0.4-0.8% of V, less than 0.3% of Mn, 0.04-1.0% of Er, less than or equal to 0.01% of S, less than or equal to 0.01% of P and the balance Fe, wherein the sum of C and B is 3.3-3.6%, the mass ratio of C to Cr is 0.06-0.08, and the sum of Nb and V is 0.5-1.0%. A Fe-erbium nitrate powder briquette is prepared at first, and alloy pouring is conducted after alloy blending, smelting andmodifying treatment. Through the erbium nitrate modified toughened high-hardness alloy and the casting method thereof, the global hardness of a cast ingot is 67.4-70.9 HRC, the impact toughness reaches 12.4-16.6 J / cm<2>, and the bending strength reaches 1218-1546 MPa.

Owner:CENT SOUTH UNIV

Strontium carbonate toughened high-hardness alloy and casting and heat treatment method thereof

The invention discloses a strontium carbonate toughened high-hardness alloy and a casting and heat treatment method thereof. The alloy comprises, by mass percent, 9.0 to 13.0% of Cr, 2.6 to 2.9% of B,0.7 to 0.9% of C, 0.4 to 0.8% of Nb, 0.4 to 0.8% of V, smaller than 0.3% of Mn, 0.08 to 1.6% of Sr, not larger than 0.01% of S and P, and the balance Fe. The sum of C and B ranges from 3.3 to 3.6, the ratio of C to Cr ranges from 0.06 to 0.08, and the sum of Nb and V ranges from 0.5 to 1.0. The method comprises the steps that Fe-strontium carbonate powder is prepared firstly and is pressed into blocks, alloy burdening, smelting and modification are carried out, alloy casting is carried out, and quenching-tempering treatment is carried out; the whole hardness of a casting ingot reaches HRC 65.8 to 69.2, the impact toughness ranges from 12.7 to 16.7J / cm<2>, and the bending strength ranges from 1462 to 1740 MPa.

Owner:CENT SOUTH UNIV

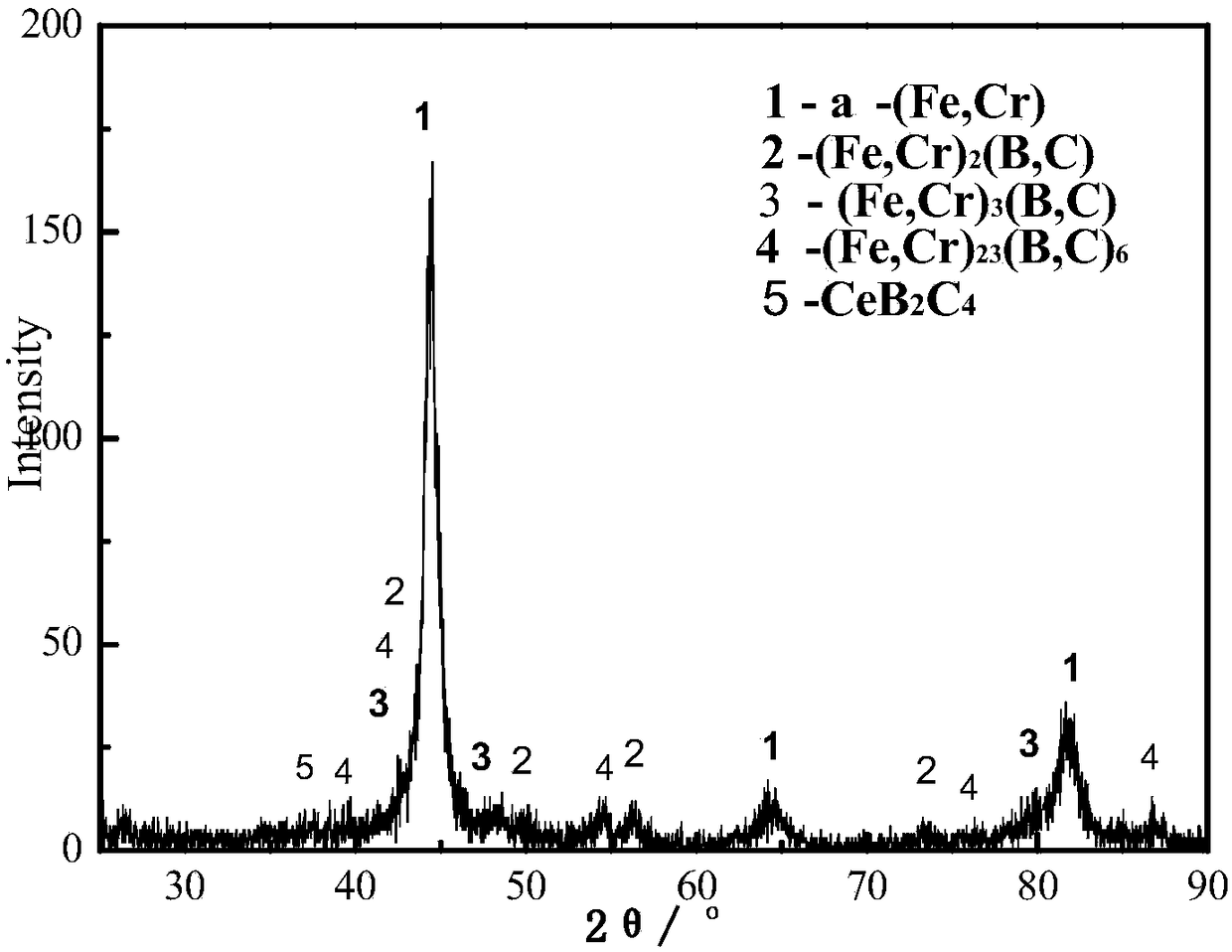

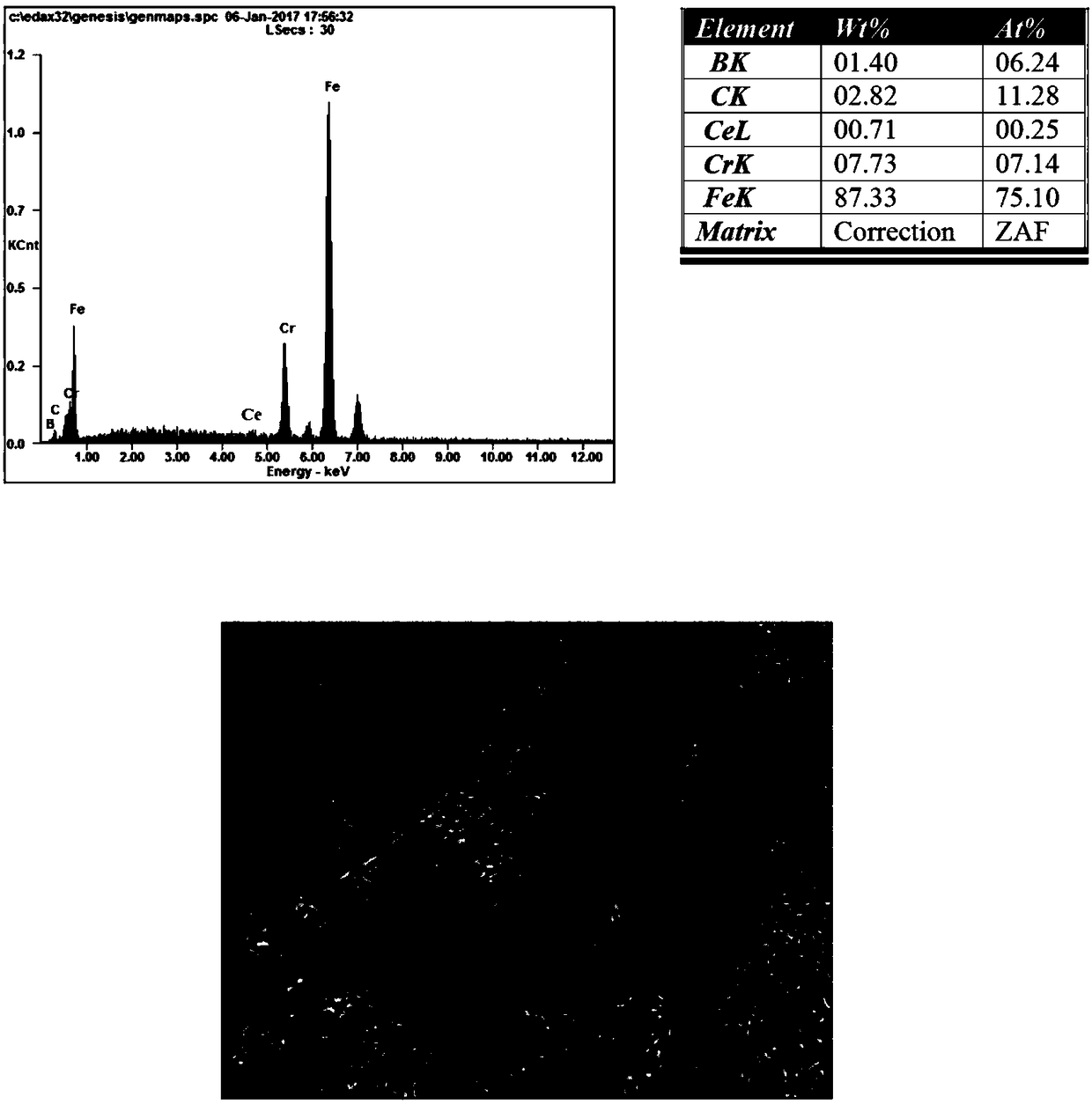

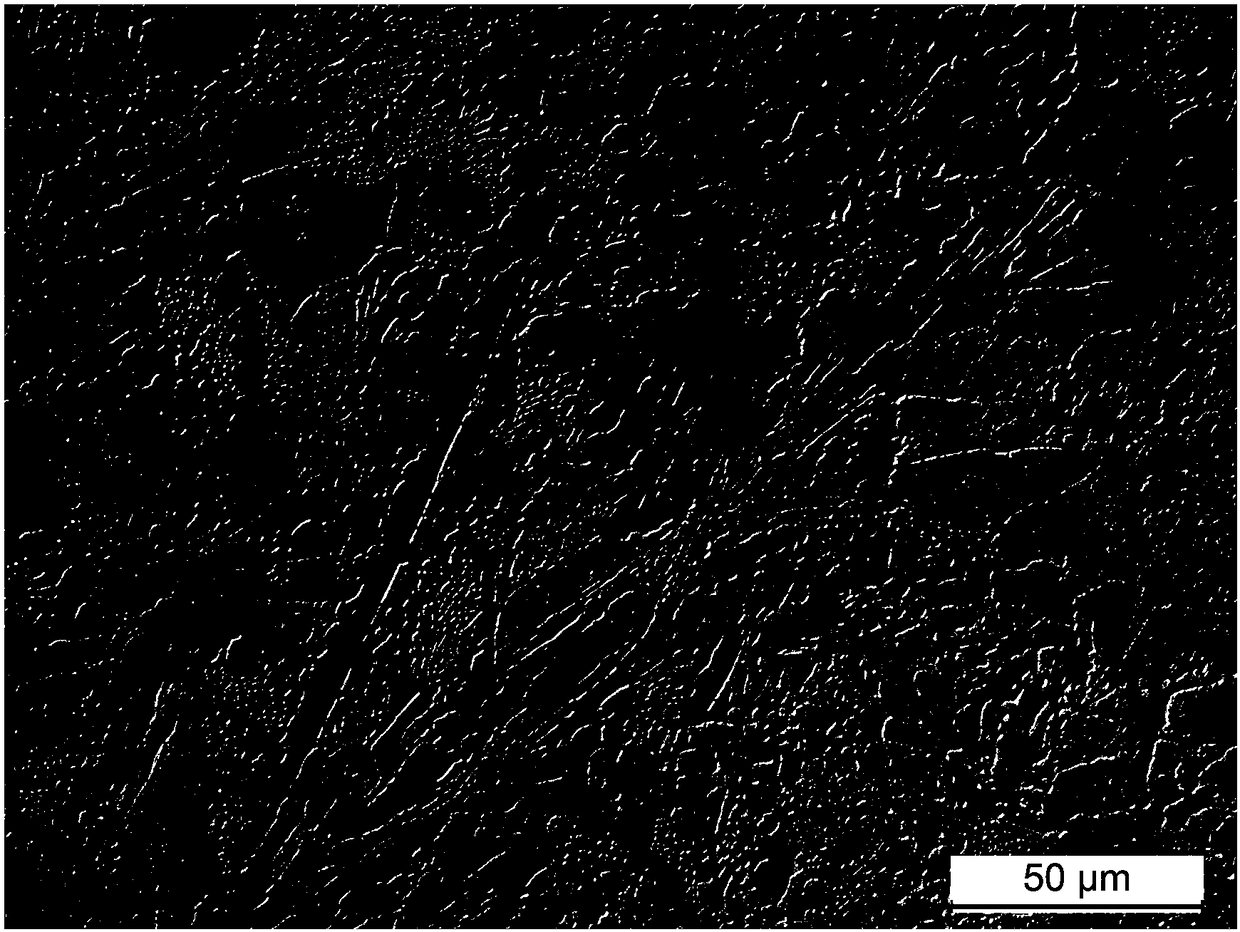

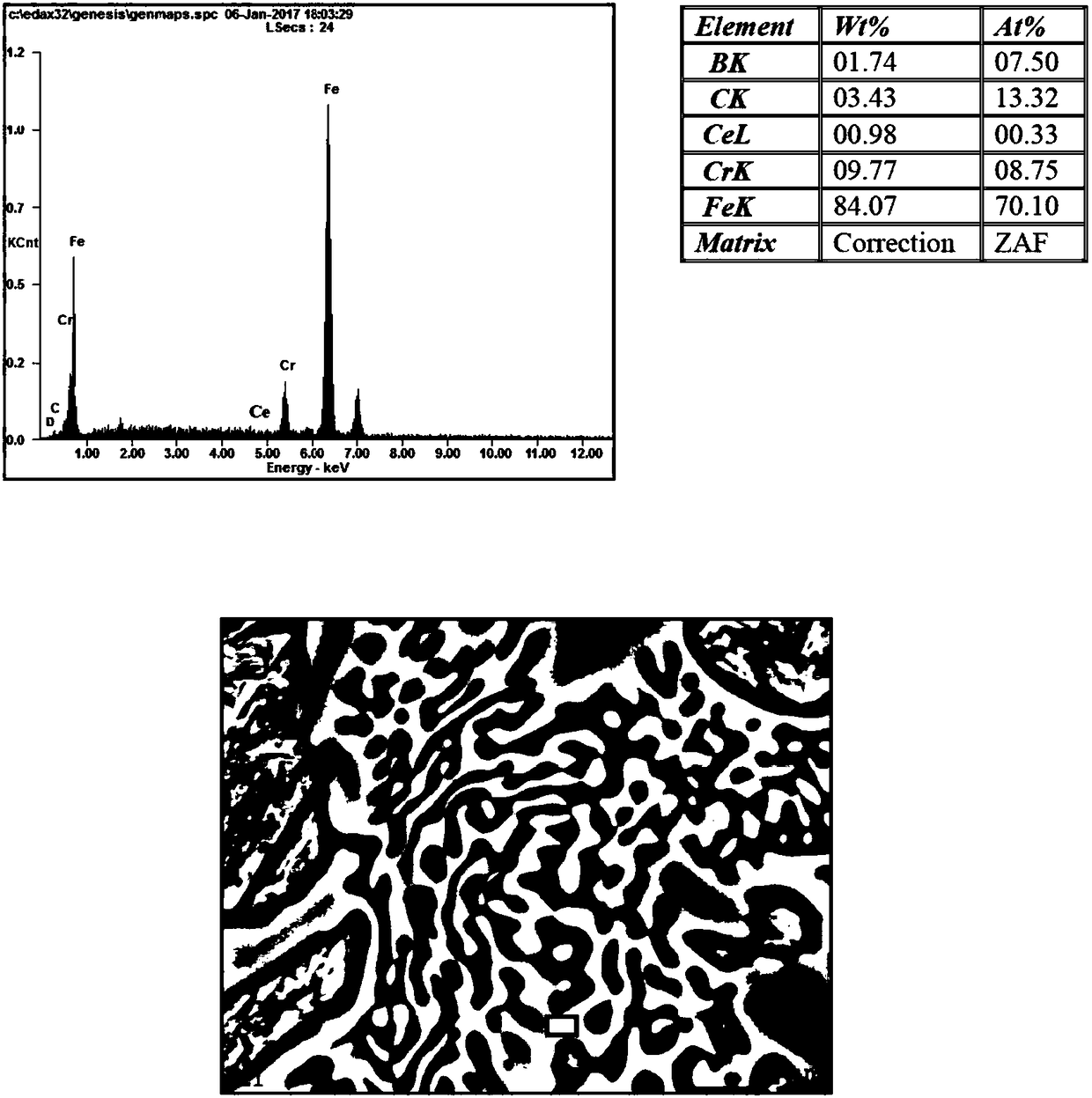

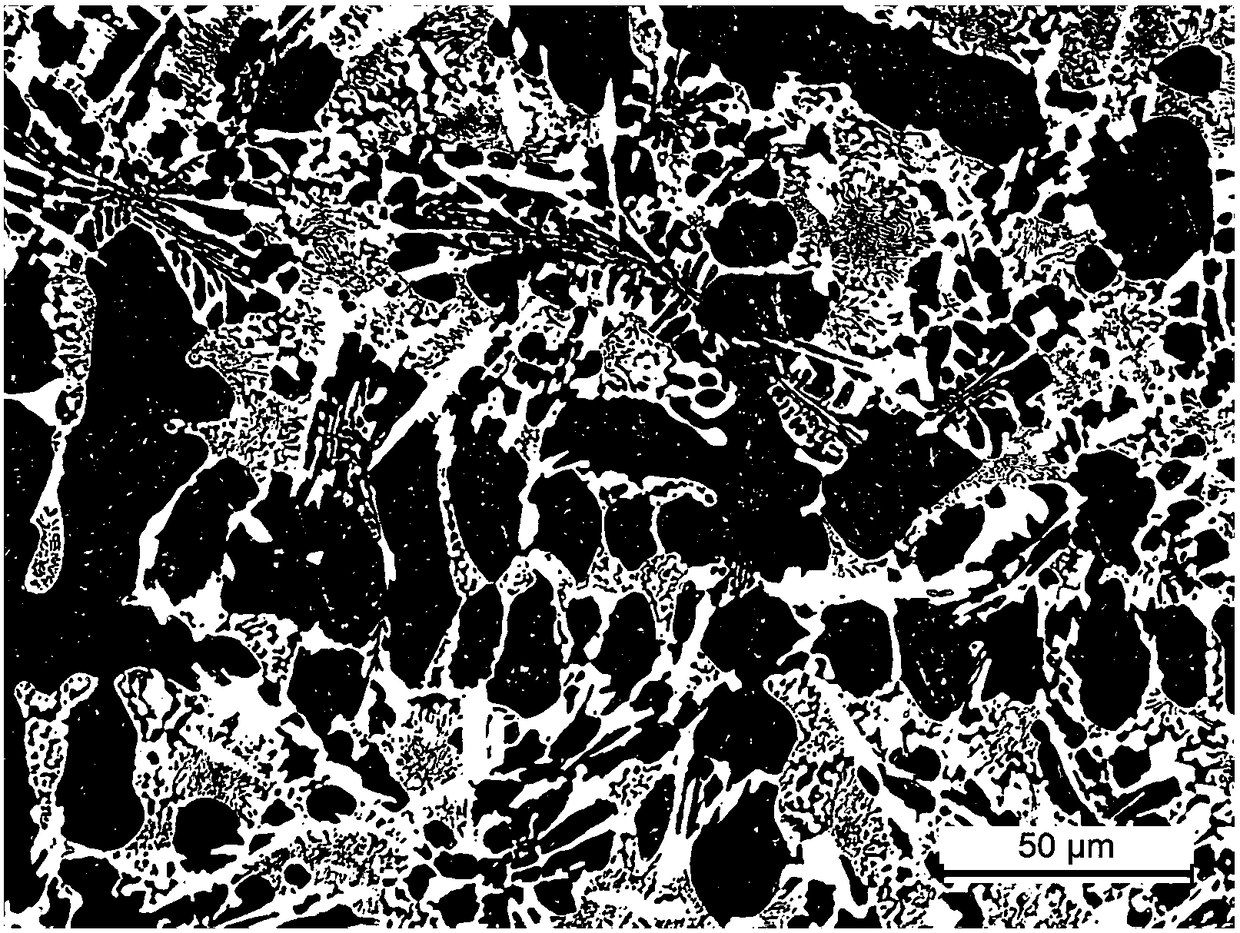

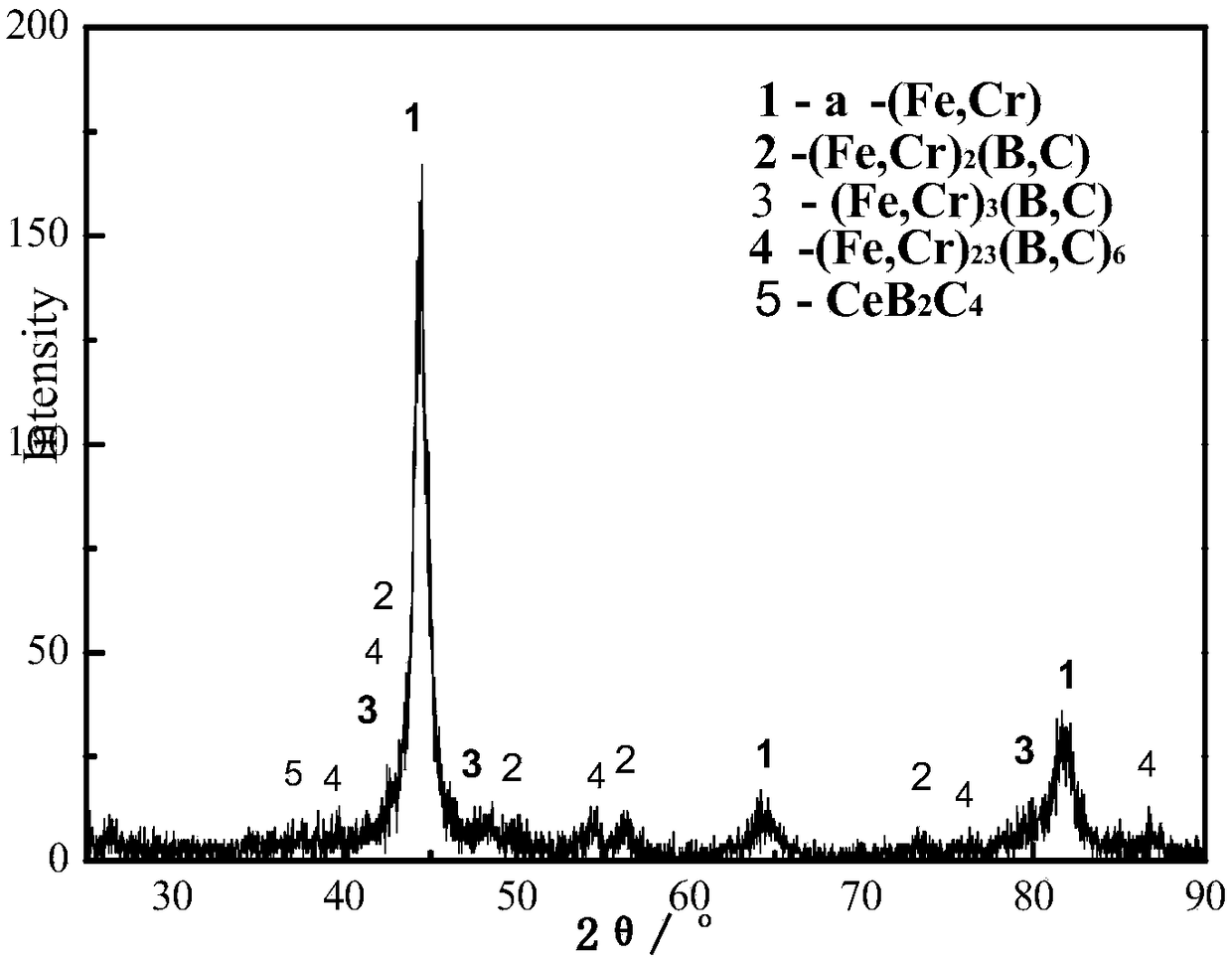

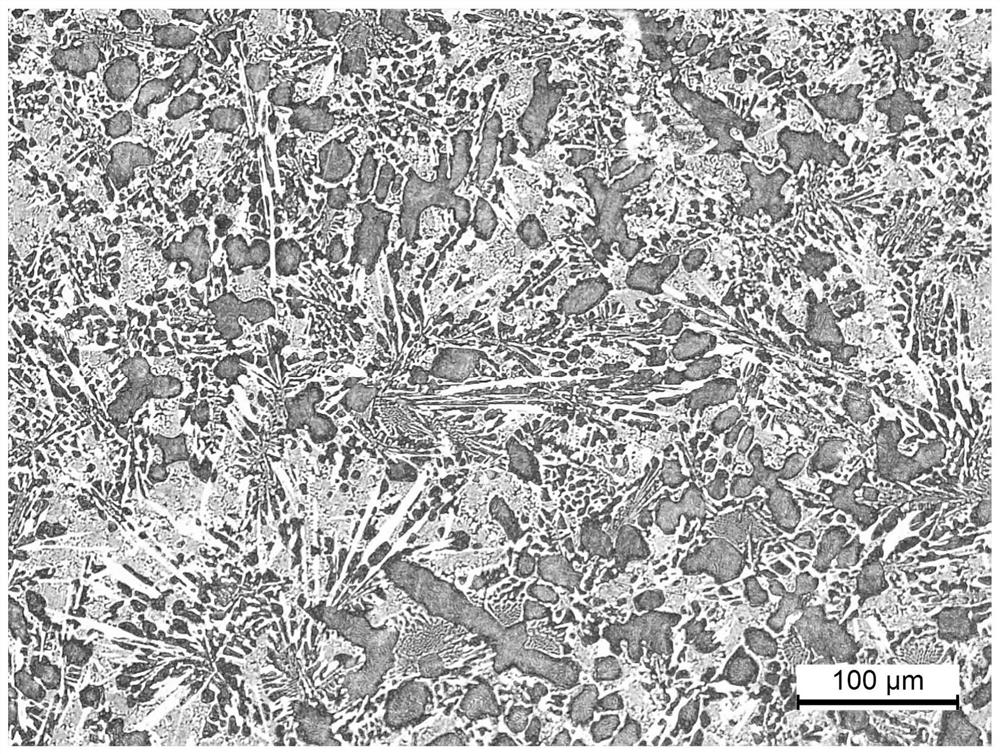

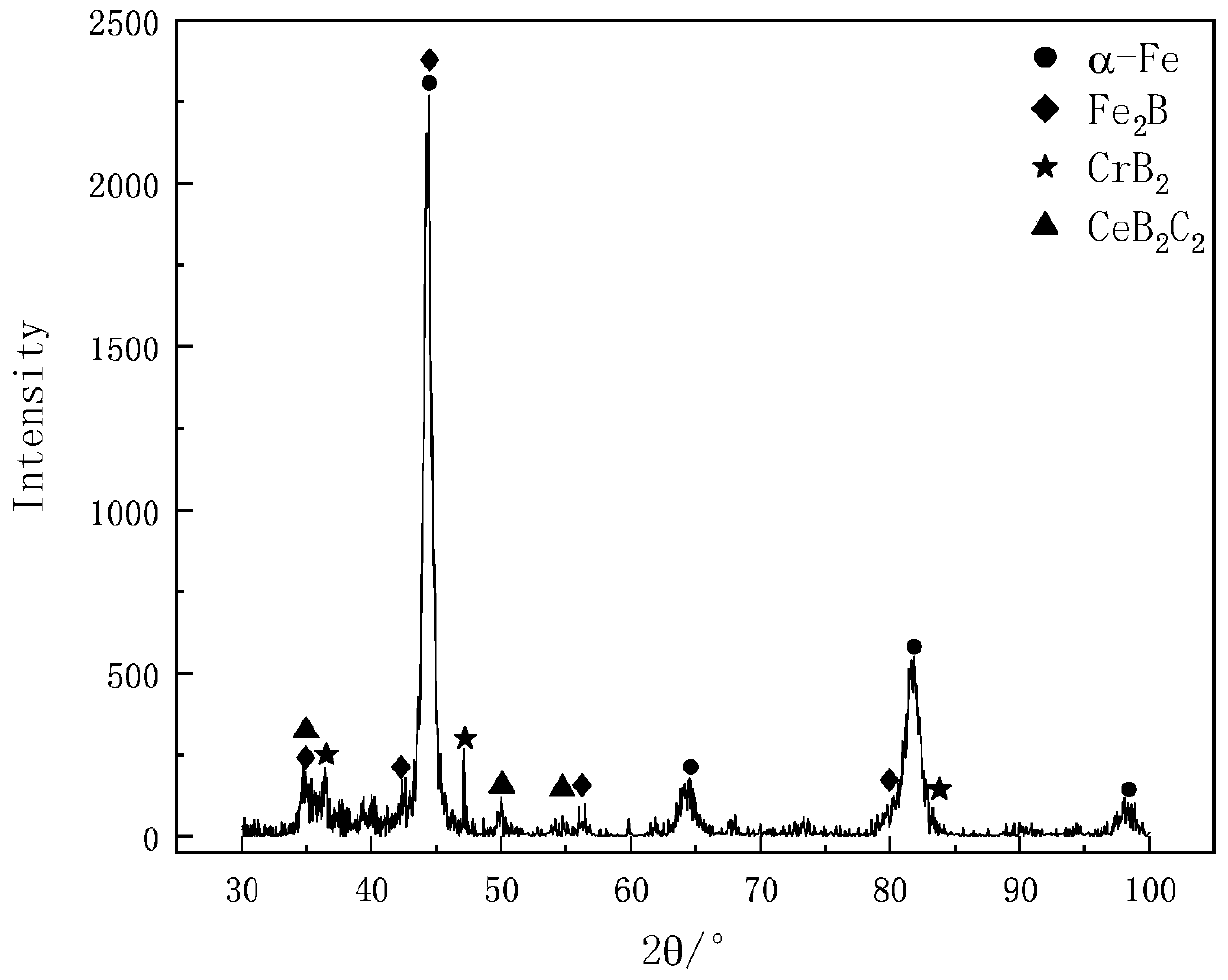

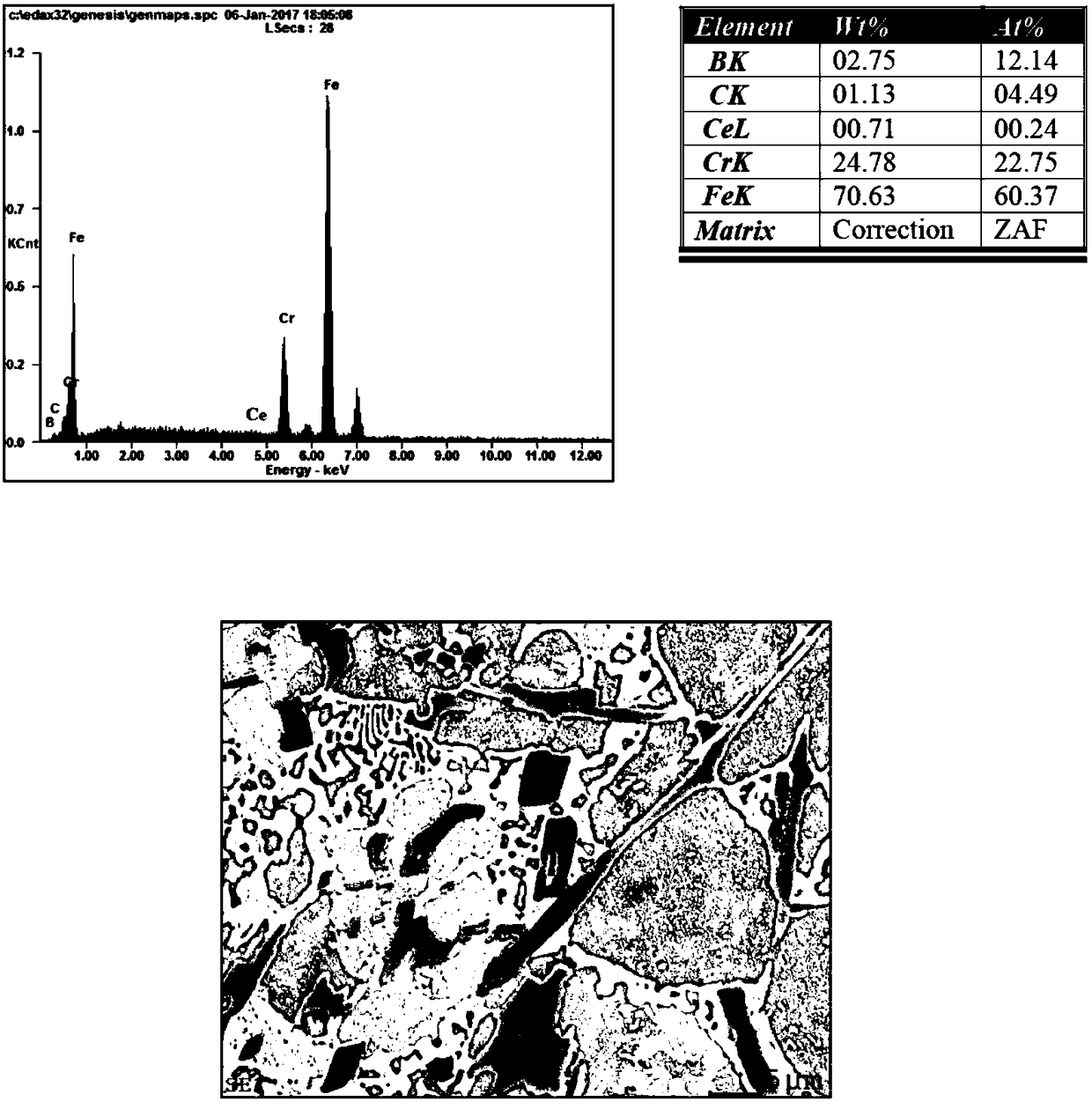

Rare-earth cerium metamorphosed and toughened high-hardness alloy and casting method thereof

The invention provides a rare-earth cerium metamorphosed and toughened high-hardness alloy and a casting method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.03 to 0.8 percent of Ce and the balance of Fe,wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nb and the V is 0.5 to 1.0. Firstly, prepared Fe-Ce2O3 powder is pressed into a block,and materials of the alloy are prepared, melted and subjected to modification treatment and then are poured into the alloy. According to the rare-earth cerium metamorphosed and toughened high-hardness alloy, the HRC of a casting ingot is 66.4 to 71.0, the impact toughness reaches 11.8 to 15.6 J / cm<2> and the bending strength reaches 1216 to 1546 MPa.

Owner:CENT SOUTH UNIV

Yttrium nitrate toughened high-hardness alloy and casting and heat treatment method thereof

The invention provides an yttrium nitrate toughened high-hardness alloy and a casting and heat treatment method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.05 to 1.0 percent of Y, less than or equal to 0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nb and the V is 0.5 to 1.0. Firstly, prepared Fe-yttrium nitrate powder is pressed into a block, and materials of the alloy are prepared, melted and subjected to modification treatment and then are pouredinto the alloy; then the alloy is subjected to quenching-annealing treatment. According to the yttrium nitrate toughened high-hardness alloy, the whole hardness HRC of a casting ingot is 65.9 to 69.4,the impact toughness reaches 12.6 to 16.6 J / cm<2> and the bending strength reaches 1420 to 1750 MPa.

Owner:CENT SOUTH UNIV

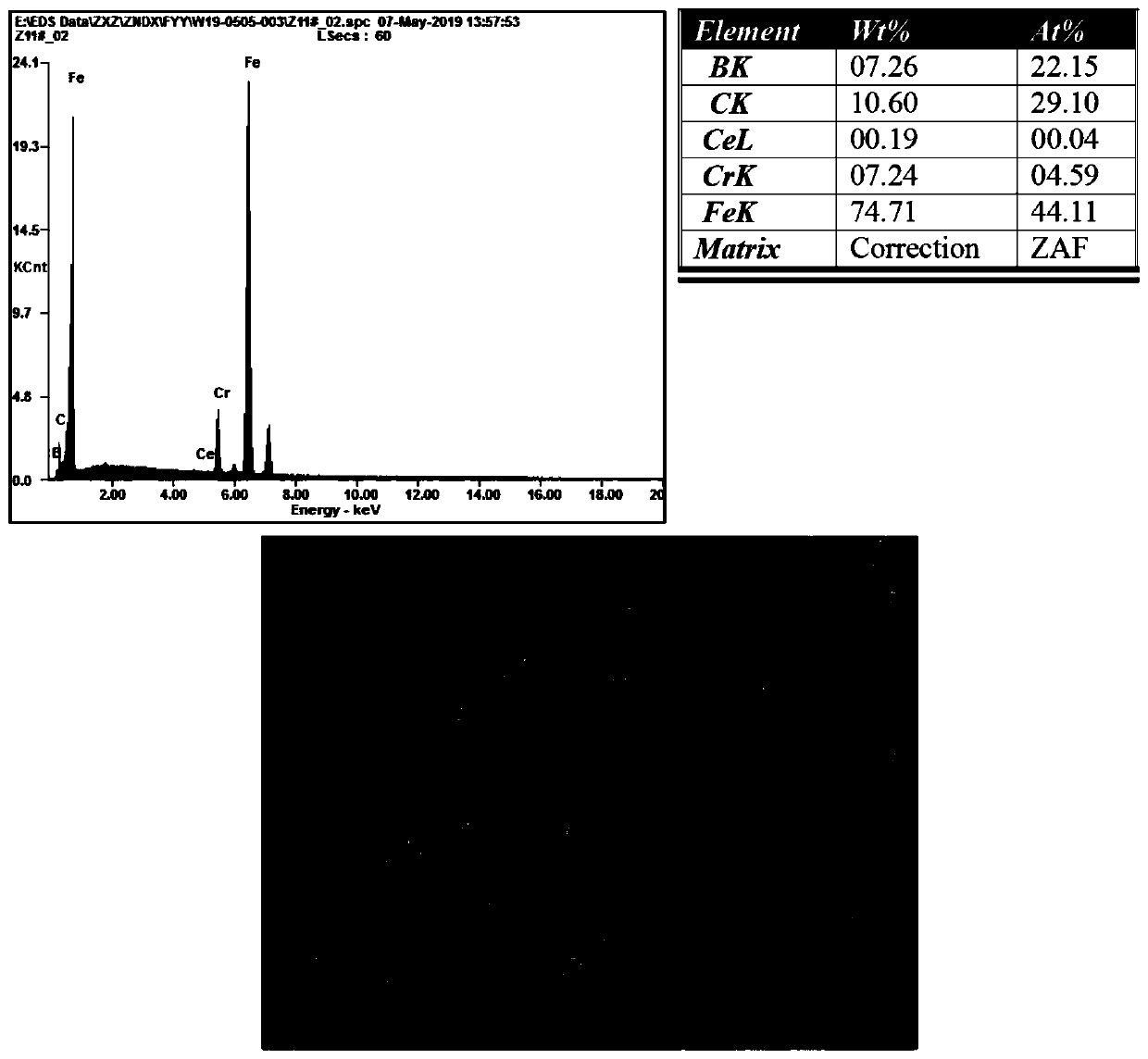

Cerium nitrate metamorphosed and toughened high-hardness alloy and casting method thereof

The invention provides a cerium nitrate metamorphosed and toughened high-hardness alloy and a casting method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to 13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.04 to 1.0 percent of Ce and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nb and the V is 0.5 to 1.0. Firstly, prepared Fe-Ce2O3 powder is pressed into a block, and materials of the alloy are prepared, melted and subjected to modification treatment and then are poured into the alloy. According to the cerium nitrate metamorphosed and toughened high-hardness alloy, the average hardness HRC of a casting ingot is 67.4 to 70.9, the impact toughness reaches 12.4 to 16.6 J / cm<2> and the bending strength reaches 1218 to 1546 MPa.

Owner:CENT SOUTH UNIV

A kind of cerium metamorphic wear-resistant alloy and casting method thereof

A cerium metamorphic wear-resistant alloy and its casting method. The content of each element of the alloy is Cr: 9.0-13.0, B: 2.6-2.9, C: 0.7-0.9, Nb: 0.4-0.8, V: 0.4-0.8, Mn The content is less than 0.3, Ce: 0.03~1.2, the balance is Fe, the total amount of C and B is 3.3~3.6; the content ratio of C / Cr: 0.06~0.08; the total amount of Nb and V is 0.5~1.0, first prepare Fe -Ce 2 o 3 , Fe-cerium nitrate or Fe-cerium carbonate powder briquette, alloy batching, melting and modification treatment, casting alloy, casting temperature range is 1250 ~ 1320 ℃. The ingot HRC66.4~71.5 of the present invention, the impact toughness reaches 11.8~16.6J / cm 2 , the bending strength reaches 1216-1546MPa.

Owner:CENT SOUTH UNIV

Lanthanum modified high-hardness alloy and casting method thereof

The invention discloses a lanthanum modified high-hardness alloy and a casting method thereof. The alloy comprises 9.0 to 13.0% of Cr, 2.6 to 2.9% of B, 0.7 to 0.9% of C, 0.4 to 0.8% of Nb, 0.4 to 0.8% of V, smaller than 0.3% of Mn, 0.03 to 0.7% of La, and the balance Fe; the total amount of C and B ranges from 3.3 to 3.6, the content ratio of C / Cr ranges from 0.06 to 0.08, and the total amount ofNb and V ranges from 0.5 to 1.0. Firstly, Fe-La2O3, Fe-lanthanum carbonate or Fe-lanthanum nitrate powder compacts are prepared, after alloy burdening, smelting and modifying treatment, alloy castingis carried out, the casting temperature ranges from 1250 to 1320 DEG C, the alloy HRC ranges from 66.2 to 71.0, the impact toughness reaches 8.6 to 14.6 J / cm<2>, and the bending strength reaches 800to 1345 MPa.

Owner:CENT SOUTH UNIV

Cerium modified abrasion-resisting alloy and casting method thereof

The invention discloses a cerium modified abrasion-resisting alloy and a casting method thereof. The alloy is prepared from the elements in percentage by mass that 9.0-13.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, less than 0.3 of Mn, 0.03-1.2 of Ce and the balance of Fe, wherein the total amount of the C and the B is 3.3-3.6, the content ratio of the C / the Cr is 0.06-0.08,the total amount of the Nb and the V is 0.5-1.0, Fe-Ce2O3, Fe-cerium nitrate or Fe-cerium carbonate powder briquette is firstly prepared, after batching, melting and modification treatment are conducted on the alloy, the alloy is casted, and the range of the casting temperature is 1250-1320 DEG C. According to the cerium modified abrasion-resisting alloy and the casting method thereof, casting ingot HRC is 66.4-71.5, impact toughness reaches 11.8-16.6 J / cm<2>, and bending strength reaches 1216-1546 MPa.

Owner:CENT SOUTH UNIV

Erbium nitrate toughening high-hard alloy and casting and heat treatment method thereof

The invention discloses an erbium nitrate toughening high-hard alloy and a casting and heat treatment method thereof. The erbium nitrate toughening high-hard alloy comprises, by mass, 9.0-13.0% of Cr,2.6-2.9% of B, 0.7-0.9% of C, 0.4-0.8% of Nb, 0.4-0.8% of V, no more than 0.3% of Mn, 0.08-1.6% of Er, less than or equal to 0.01% of S and P, and the balance Fe. The total mass content of C and B is3.3-3.6 %; the component ratio of C to Cr is 0.06-0.08; and the total mass content of the Nb and V is 0.5-1.0%. Fe-carbonic acid erbium powder block pressing is prepared, proportion, smelting and modification of alloy are carried out, and smelting, casting and heat treatment are carried out. Global hardness of ingot casting prepared by the casting and heating treatment method reaches HRC66.3-67.8, impact toughness reaches 10.7-14J / cm<2>, and bending strength reaches 1096-1316MPa.

Owner:CENT SOUTH UNIV

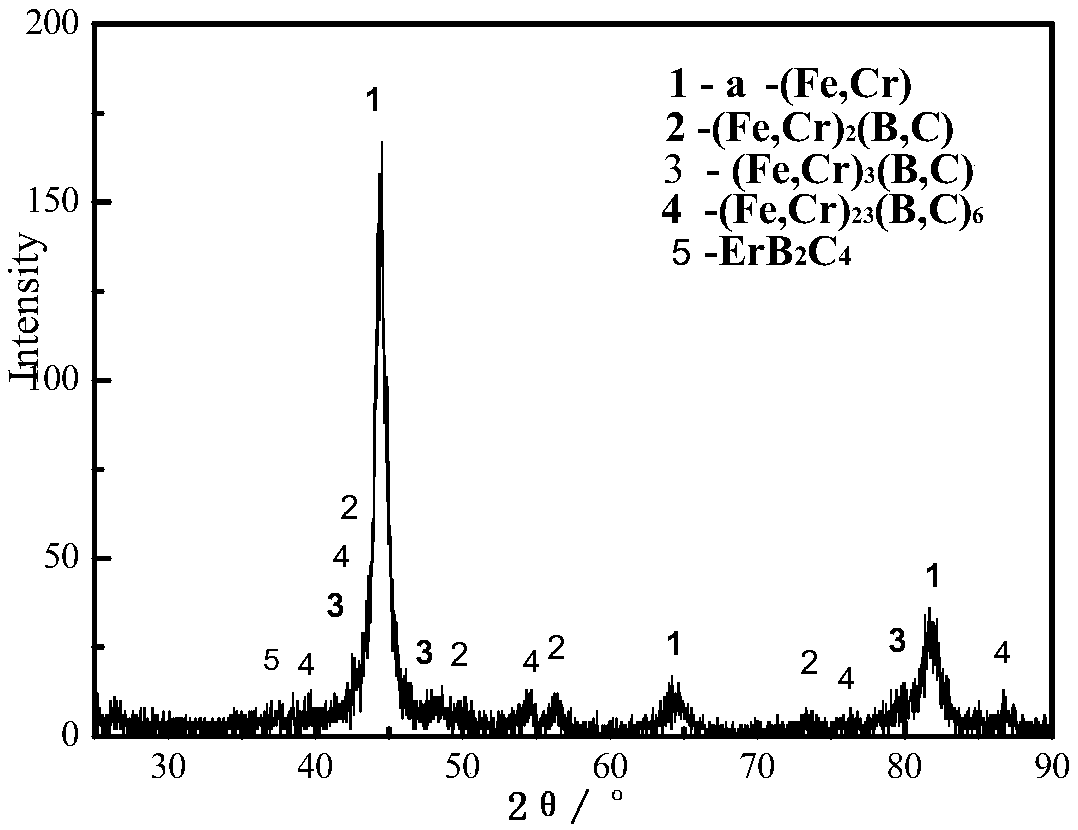

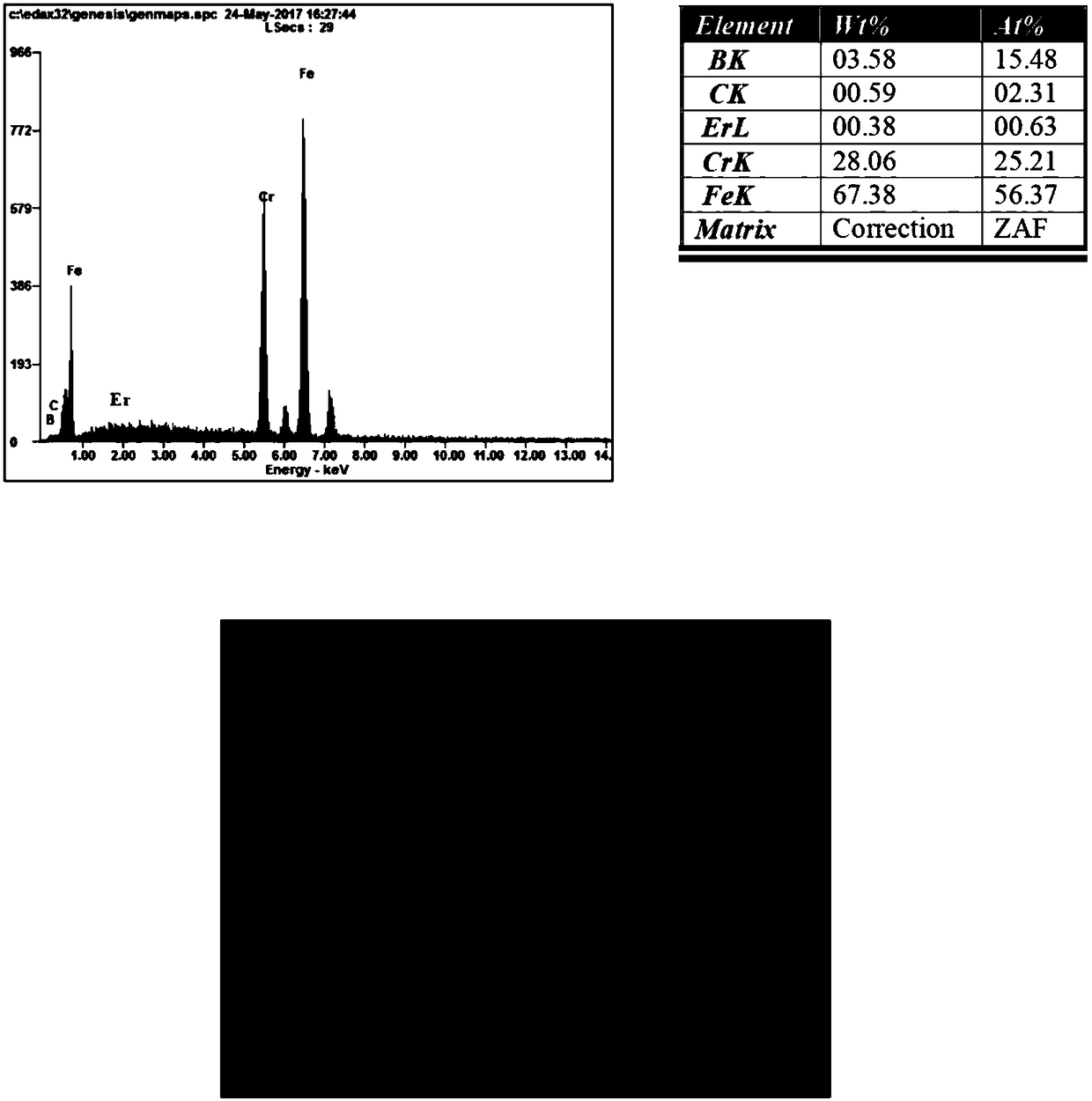

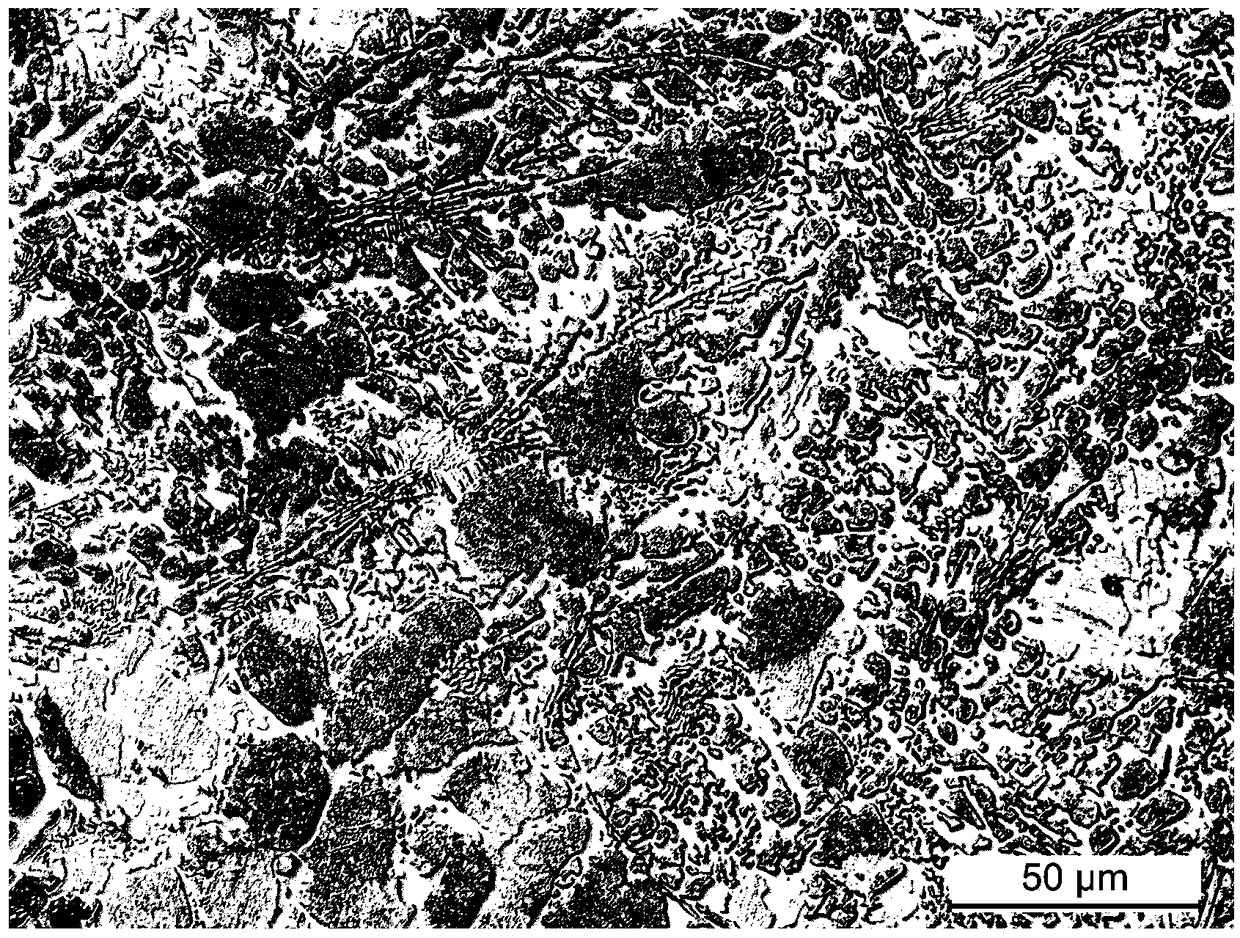

Rare-earth erbium toughened high-hardness alloy and casting and heat treatment method thereof

The invention provides a rare-earth erbium toughened high-hardness alloy and a casting and heat treatment method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to 13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.03 to 0.8 percent of Er, less than or equal to0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nband the V is 0.5 to 1.0. Firstly, prepared Fe-erbium carbonate powder is pressed into a block for later use, and materials of the alloy are prepared, melted and subjected to modification treatment, and are melted, poured and subjected to heat treatment. According to the rare-earth erbium toughened high-hardness alloy, the whole hardness HRC of a casting ingot is 65.8 to 70.4, the impact toughnessreaches 13.1 to 16.9 J / cm<2> and the bending strength reaches 1328 to 1571 MPa.

Owner:CENT SOUTH UNIV

Erbium-carbonate toughened high-hardness alloy and casting and heat treatment method thereof

The invention discloses an erbium-carbonate toughened high-hardness alloy and a casting and heat treatment method thereof. The alloy comprises the elements, by mass percentage: 9.0-13.0% of Cr, 2.6-2.9% of B, 0.7-0.9% of C, 0.4-0.8% of Nb, 0.4-0.8% of V, less than 0.3% of Mn, 0.08-1.6% of Er, less than or equal to 0.01% of S and P and the balance Fe, wherein the total mass percentage of the C andthe B is 3.3-3.6%, the content ratio of the C to the Cr accounts for 0.06-0.08, the total mass percentage of the Nb and the V is 0.5-1.0%. The method comprises the steps of firstly carrying out briquetting on prepared Fe-erbium carbonate powder, then carrying out alloy proportioning, smelting and modification treatment, and carrying out smelting, casting and heat treatment. The erbium-carbonate toughened high-hardness alloy and the casting and heat treatment method thereof have the advantages that the overall hardness of a prepared cast ingot can reach HRC 65.8-69.2, the impact toughness can reach 12.7-16.7 J / cm<2>, and the bending strength can reach 1462-1740 MPa.

Owner:CENT SOUTH UNIV

Erbium carbonate metamorphosed and toughened high-hardness alloy and casting method thereof

The invention provides an erbium carbonate metamorphosed and toughened high-hardness alloy and a casting method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.03 to 0.7 percent of Er, less than or equal to0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nb and the V is 0.5 to 1.0. Firstly, prepared Fe-erbium carbonate powder is pressed into a block, and materials of the alloy are prepared, melted and subjected to modification treatment and then are poured into the alloy. According to the erbium carbonate metamorphosed and toughened high-hardness alloy, the whole hardness HRC of a casting ingot is 66.2 to 70.0, the impact toughness reaches 10.7 to 14.6 J / cm<2> and the bending strength reaches 1000 to 1345MPa.

Owner:CENT SOUTH UNIV

Cerium carbonate metamorphosed and toughened high-hardness alloy and casting method thereof

The invention provides a cerium carbonate metamorphosed and toughened high-hardness alloy and a casting method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.05 to 1.2 percent of Ce and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nb and the V is 0.5 to 1.0. Firstly, prepared Fe-cerium carbonate powder is pressed into a block, and materials of the alloy are prepared, melted and subjected to modification treatment and then are poured into the alloy. According to the cerium carbonate metamorphosed and toughened high-hardness alloy, the average hardness HRC of a casting ingot is 68.0 to 71.5, the impact toughness reaches 11.4 to 15.6 J / cm<2> and the bending strength reaches 1118 to 1446 MPa.

Owner:CENT SOUTH UNIV

High-hardness alloy modified and toughened through rare earth yttrium and casting method thereof

The invention provides a high-hardness alloy modified and toughened through rare earth yttrium and a casting method thereof. Elements of the alloy comprise, by content, 9.0-13.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, smaller than 0.3 of Mn, 0.02-0.6 of Y and the balance Fe, wherein the total content of C and B is 3.3-3.6, the content ratio of C / Cr is 0.06-0.08, and the total content of Nb and V is 0.5-1.0. At first, Fe-Y2O3 powder is prepared and pressed into blocks, and after alloy dosing, smelting and modifying treatment, the alloy is cast. The average hardness HRC of ingots is 66.5-69.6, the impact toughness reaches 12.5-16.3 J / cm2, and the bending strength reaches 1260-1662 MPa.

Owner:CENT SOUTH UNIV

Rare-earth strontium metamorphosed and toughened high-hardness alloy and casting method thereof

The invention provides a rare-earth strontium metamorphosed and toughened high-hardness alloy and a casting method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0to 13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.02 to 0.6 percent of Sr and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nb and the V is 0.5 to 1.0. Firstly, prepared Fe-SrO powder is pressed into a blockfor later use, and materials of the alloy are prepared, melted and subjected to modification treatment and then are poured into the alloy. According to the rare-earth strontium metamorphosed and toughened high-hardness alloy, the average hardness HRC of a casting ingot is 66.5 to 69.6, the impact toughness reaches 12.5 to 16.3 J / cm<2> and the bending strength reaches 1260 to 1662 MPa.

Owner:CENT SOUTH UNIV

Cerium carbonate toughened high-hardness alloy and casting and heat treatment method thereof

The invention provides a cerium carbonate toughened high-hardness alloy and a casting and heat treatment method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.05 to 1.2 percent of Ce, less than or equal to0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr mass ratio is 0.06 to 0.08; the total sum of the Nb and the V is 0.5 to 1.0. Firstly, prepared Fe-cerium carbonate powder is pressed into a block, and materials of the alloy are prepared, melted and subjected to modification treatment and then are poured into the alloy; then the alloy is subjected to quenching-annealing treatment. According to the cerium carbonate toughened high-hardness alloy, the whole hardness HRC of a casting ingot is 66.9 to 70.4, the impact toughness reaches 12.9 to 17.0 J / cm<2> and the bending strength reaches 1242 to 1570 MPa.

Owner:CENT SOUTH UNIV

A kind of lanthanum modified high hardness alloy and casting method thereof

A lanthanum-modified high-hardness alloy and its casting method, the content of each element of the alloy is Cr: 9.0-13.0, B: 2.6-2.9, C: 0.7-0.9, Nb: 0.4-0.8, V: 0.4-0.8, Mn The content is less than 0.3, La: 0.03-0.7, the balance is Fe, the total amount of C and B is 3.3-3.6; the C / Cr content ratio: 0.06-0.08; the total amount of Nb and V is 0.5-1.0, first prepare Fe ‑La 2 o 3 , Fe-lanthanum carbonate or Fe-lanthanum nitrate powder briquette, alloy ingredients, smelting and modification treatment, and casting alloy, the casting temperature range is 1250 ~ 1320 ℃. The alloy of the present invention has HRC66.2~71.0, and the impact toughness reaches 8.6~14.6J / cm 2 , the bending strength reaches 800~1345MPa.

Owner:CENT SOUTH UNIV

High-hardness alloy modified and toughened through lanthanum nitrate and casting method thereof

The invention provides a high-hardness alloy modified and toughened through lanthanum nitrate and a casting method thereof. Elements of the alloy comprise, by content, 9.0-13.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, smaller than 0.3 of Mn, 0.04-0.6 of La and the balance Fe, wherein the total content of C and B is 3.3-3.6, the content ratio of C / Cr is 0.06-0.08, and the total content of Nb and V is 0.5-1.0. At first, Fe-La2O3 powder is prepared and pressed into blocks, and after alloy dosing, smelting and modifying treatment, the alloy is cast. The HRC of ingots is 67.5-69.0, the impact toughness reaches 8.9-12.2 J / cm2, and the bending strength reaches 900-1120 MPa.

Owner:CENT SOUTH UNIV

Yttrium element metamorphic high-hardness alloy and casting method thereof

The invention discloses yttrium element metamorphic high-hardness alloy and a casting method thereof. The alloy comprises 9.0-13.0 of Cr, 2.6-2.9 of B, 0.7-0.9 of C, 0.4-0.8 of Nb, 0.4-0.8 of V, smaller than 0.3 of Mn, 0.02-1.6 of Y and the balance Fe; the sum of C and B is 3.3-3.6; the ratio of C to Cr is 0.06-0.08; the sum of Nb and V is 0.5-1.0. The casting method comprises the steps that a Fe-Y2O3, Fe-yttrium carbonate or Fe-yttrium nitrate powder briquette is prepared at first, and after alloy batching, smelting and modification, alloy casting is conducted, wherein the casting temperatureis 1250-1320 DEG C. According to the yttrium element metamorphic high-hardness alloy and the casting method thereof, the average hardness HRC of a cast ingot is 66.5-70.5, the impact toughness is 11.8-16.3 J / cm<2>, and the bending strength is 1260-1690 MPa.

Owner:CENT SOUTH UNIV

A kind of yttrium toughened wear-resistant alloy and its casting and heat treatment method

A yttrium toughened and wear-resistant alloy and its casting and heat treatment method, the mass percent content of each element of the alloy is Cr: 9.0-13.0, B: 2.6-2.9, C: 0.7-0.9, Nb: 0.4-0.8, V: 0.4~0.8, Mn content is less than 0.3, Y: 0.02~1.6, S, P: ≤0.01, the balance is Fe. Among them, the sum of C and B: 3.3-3.6; the mass ratio of C / Cr: 0.06-0.08; the sum of Nb and V is 0.5-1.0. Get your Fe‑Y ready first 2 o 3 , Fe-yttrium carbonate or Fe-yttrium nitrate powder briquette, alloy ingredients, melting and modification treatment, casting alloy, and then quenching-tempering treatment, casting temperature is 1250 ~ 1320 ° C. The overall hardness of the ingot of the present invention is HRC65.4-69.4, and the impact toughness reaches 12.6-17.1J / cm 2 , the bending strength reaches 1340-1750MPa.

Owner:CENT SOUTH UNIV

Strontium nitrate modified toughened high-hardness alloy and casting method thereof

The invention relates to a strontium nitrate modified toughened high-hardness alloy and a casting method of the strontium nitrate modified toughened high-hardness alloy. The alloy comprises, by mass percentage, 9.0-13.0% of Cr, 2.6-2.9% of B, 0.7-0.9% of C, 0.4-0.8% of Nb, 0.4-0.8% of V, less than 0.3 of Mn, 0.04-1.0% of Sr and the balance Fe, wherein by mass percentage, the total content of C andB is 3.3-3.6%, the C / Cr content ratio is 0.06-0.08, and the total content of Nb and V is 0.5-1.0%; and firstly, Fe-strontium nitrate powder is prepared and pressed into blocks, and the alloy is castand formed after alloy burdening, smelting and modification. The average hardness of a cast ingot of the strontium nitrate modified toughened high-hardness alloy is HRC 67.4-70.9, the impact toughnessreaches 12.4-16.6 J / cm<2>, and the bending strength reaches 1,218-1,546 MPa.

Owner:CENT SOUTH UNIV

Strontium nitrate toughened high-hardness alloy and casting and heat treatment method thereof

The invention provides a strontium nitrate toughened high-hardness alloy and a casting and heat treatment method thereof. The alloy is prepared from the following elements in percentage by mass: 9.0 to 13.0 percent of Cr, 2.6 to 2.9 percent of B, 0.7 to 0.9 percent of C, 0.4 to 0.8 percent of Nb, 0.4 to 0.8 percent of V, less than 0.3 percent of Mn, 0.04 to 1.0 percent of Sr, less than or equal to0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe, wherein the total sum of the C and the B is 3.3 to 3.6; the C / Cr content ratio is 0.06 to 0.08; the total sum of theNb and the V is 0.5 to 1.0. Firstly, prepared Fe-strontium nitrate is pressed into a block, and materials of the alloy are prepared, melted and subjected to modification treatment and then are pouredinto the alloy; then the alloy is subjected to quenching-annealing treatment. According to the strontium nitrate toughened high-hardness alloy, the whole hardness HRC of a casting ingot is 66.5 to 70.0, the impact toughness reaches 13.8 to 18.0 J / cm<2> and the bending strength reaches 1336 to 1664 MPa.

Owner:CENT SOUTH UNIV

Strontium modified high hard alloy and casting and heat treatment method thereof

The invention relates to a strontium modified high hard alloy and casting and a heat treatment method thereof. The strontium modified high hard alloy is prepared from the elements in percentage by mass: 9.0-13.0% of Cr, 2.6-2.9% of B, 0.7-0.9% of C, 0.4-0.8% of Nb, 0.4-0.8% of V, less than 0.3% of Mn, 0.04-1.6% of Sr, less than or equal to 0.01% of S and P, and the balance of Fe, wherein the sum of C and B is 3.3-3.6%, the content ratio of C to Cr is 0.06-0.08, and the sum of Nb and V is 0.5-1.0%. The heat treatment method includes the steps that firstly, Fe-SrO and Fe-strontium nitrate powdercompacts or Fe-strontium carbonate powder compacts are prepared, an alloy is poured after being subjected to preparing, smelting and modification, then quenching-tempering treatment is adopted, and the pouring temperature is 1250-1300 DEG C. According to the strontium modified high hard alloy and casting and the heat treatment method thereof, the integral hardness HRC of a cast ingot reaches 65.8-70.2, the impact toughness reaches 10.2-18.0 J / cm<2>, and the bending strength reaches 960-1740 MPa.

Owner:CENT SOUTH UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com