A kind of yttrium toughened wear-resistant alloy and its casting and heat treatment method

A heat treatment method and a wear-resistant alloy technology, which are applied in the preparation of wear-resistant and corrosion-resistant cast iron alloys and their components, and in the field of mechanical wear-resistant parts manufacturing, can solve the problems of insufficient impact toughness, low strength index, and low bending strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

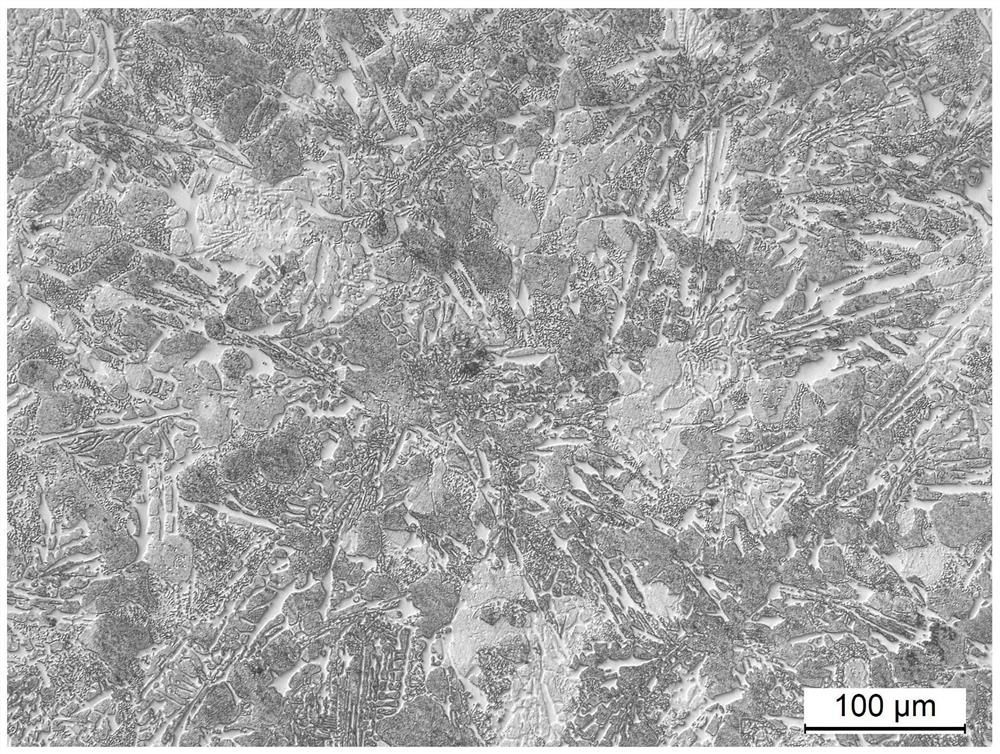

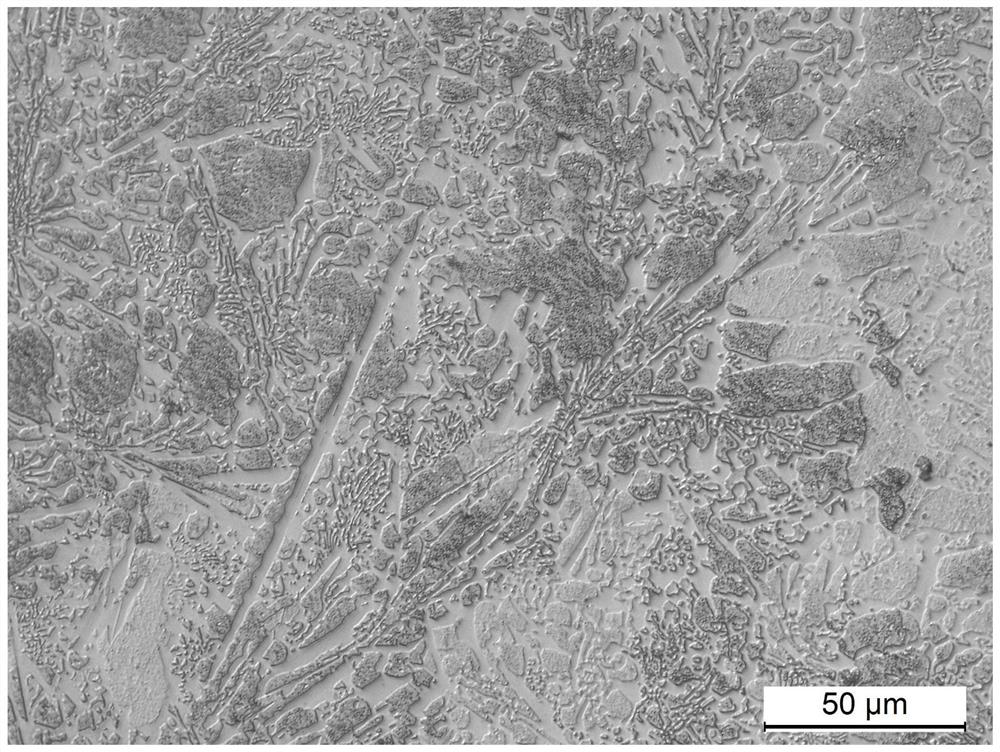

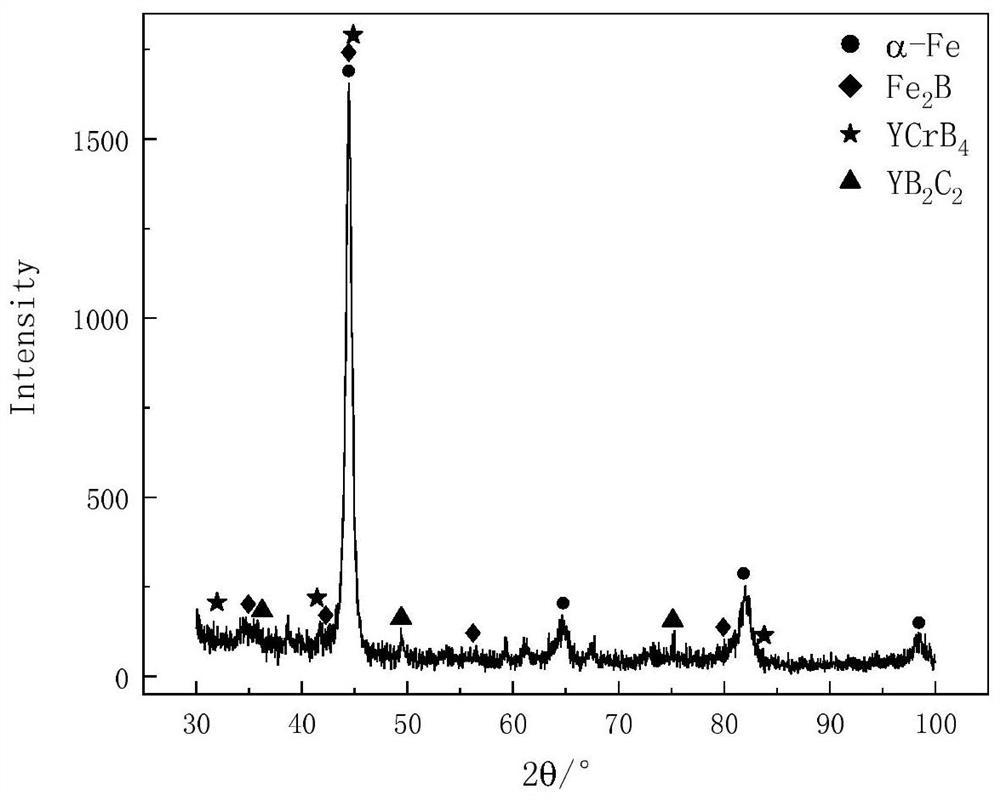

Embodiment 1

[0052] Embodiment 1. After adopting iron powder and yttrium carbonate powder to mix uniformly, molded into powder briquettes. The mass ratio of yttrium carbonate powder to iron powder is about 1:3, that is to form Fe-yttrium carbonate mixed compact of Fe-10.8wt.%Y. As the carrier of rare earth Y metamorphism.

[0053] High-carbon ferrochrome, micro-carbon ferrochrome, ferroboron, ferroniobium, ferrovanadium, industrial pure iron and the above-mentioned Fe-yttrium carbonate mixed briquette are selected as raw materials, and the composition range is as follows: Cr: 10.0wt.%; B: 2.9wt .%; C: 0.7wt.%; Nb: 0.4wt.%; V: 0.2wt.%; Y: 1.6wt.%; Small amounts of impurities such as Al, Mn, N, etc. do not cause fundamental changes in alloy properties and are therefore not listed in Table 2. After weighing the corresponding raw materials according to the composition requirements, induction melting and sand mold casting are adopted. The specific steps are:

[0054] Place the Fe-yttrium ca...

Embodiment 2

[0056] Embodiment 2. After iron powder and yttrium carbonate powder are uniformly mixed, molded into a powder briquette. The mass ratio of yttrium carbonate powder to iron powder is about 1:13, that is to form Fe-yttrium carbonate mixed briquettes of Fe-3.09wt.%Y. As the carrier of rare earth Y metamorphism.

[0057] Select high-carbon ferrochrome, metal chromium, ferroboron, ferroniobium, industrial pure iron and the above-mentioned Fe-Y2 o 3 Mixed briquettes are used as raw materials, and the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.7wt.%; Nb: 0.5wt.%; Y: 0.08wt.%; 2. Small amounts of impurities such as Al, Mn, N, etc. do not cause fundamental changes in alloy properties and are therefore not listed in Table 2. After weighing the corresponding raw materials according to the composition requirements, the vacuum induction furnace can be used for melting and water-cooled iron mold casting. The specific steps are:

[0058] Place the Fe-yttrium carbona...

Embodiment 3

[0059] Embodiment 3. After adopting iron powder and yttrium carbonate powder to mix uniformly, molded into powder briquettes. The mass ratio of yttrium carbonate powder to iron powder is about 1:10, that is to form Fe-yttrium carbonate mixed briquette with Fe-3.93wt.%Y. As the carrier of rare earth Y metamorphism.

[0060] Select high-carbon ferrochrome, micro-carbon ferrochrome, ferroboron, ferroniobium, industrial pure iron and the above-mentioned Fe-Y 2 o 3 The mixed briquettes are used as raw materials, and the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.8wt.%; Nb: 0.6wt.%; Y: 0.1wt.%; 2. Small amounts of impurities such as Al, Mn, N, etc. do not cause fundamental changes in alloy properties and are therefore not listed in Table 2. After weighing the corresponding raw materials according to the composition requirements, induction melting and investment casting are adopted. The specific steps are:

[0061] Place the Fe-yttrium carbonate powder briqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com