High-hardness alloy modified and toughened through rare earth yttrium and casting method thereof

A high-hardness, alloy technology, used in the preparation of wear-resistant and corrosion-resistant cast iron alloys and their components, and the manufacture of mechanical wear-resistant parts, can solve the problems of insufficient impact toughness, low strength index, and low flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

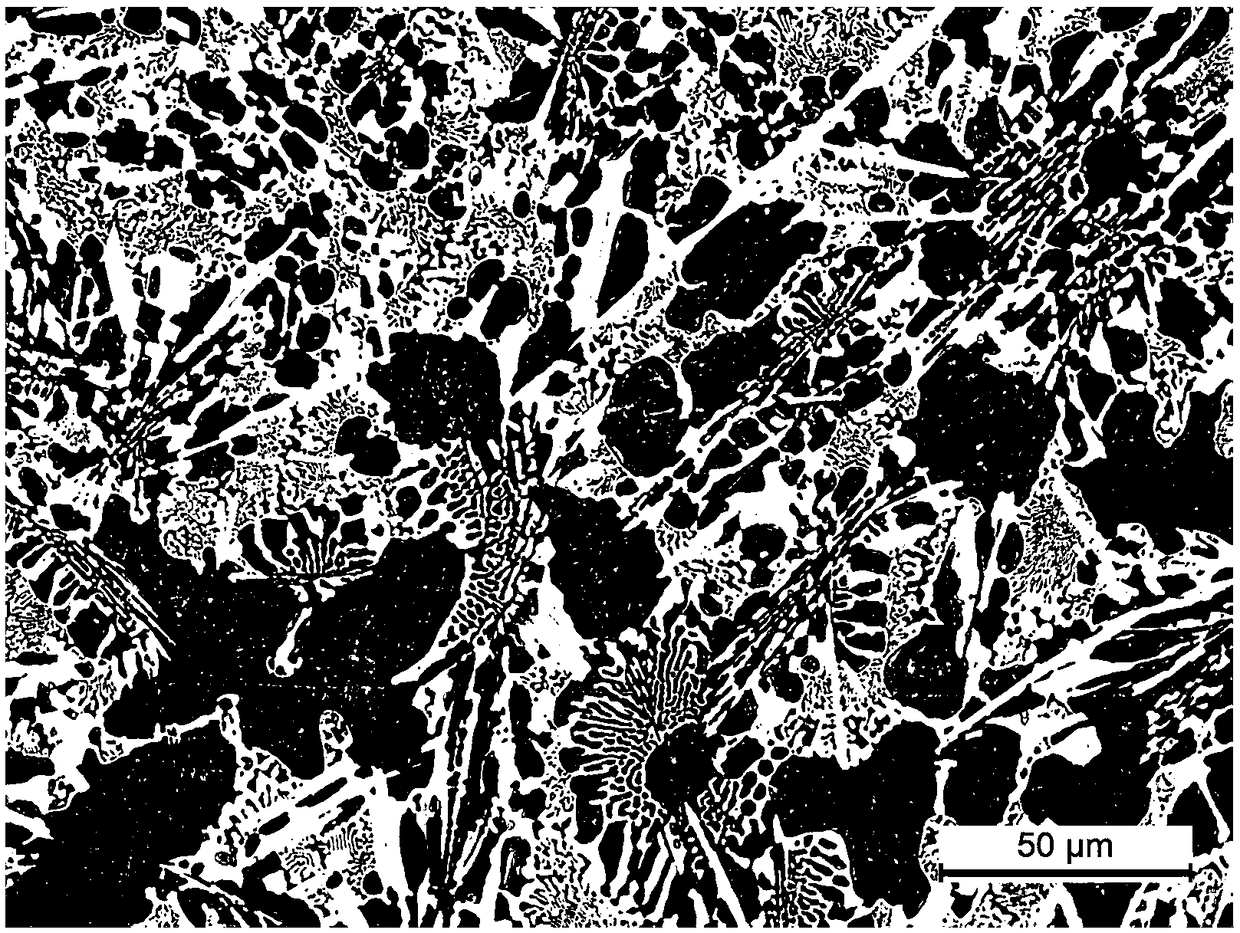

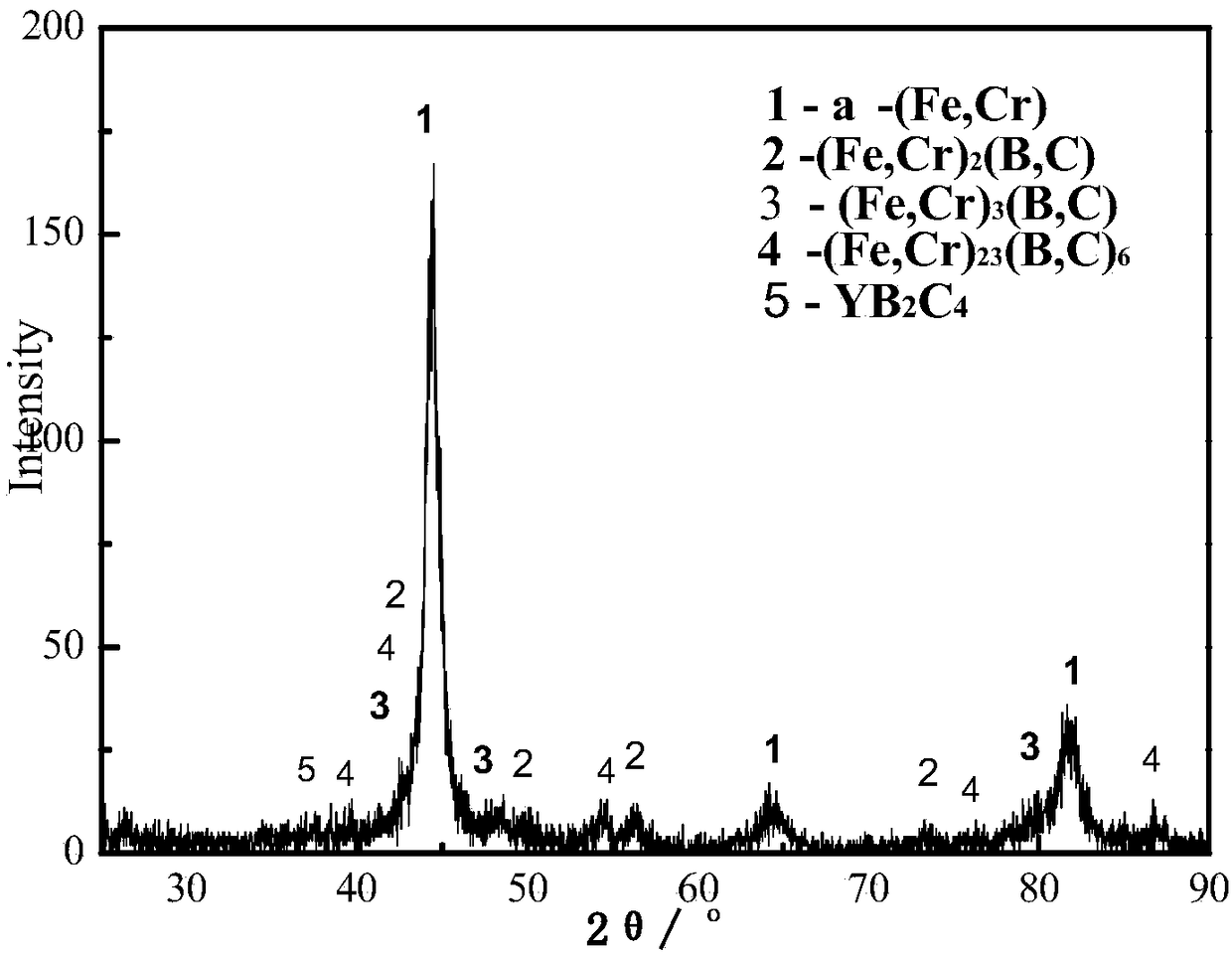

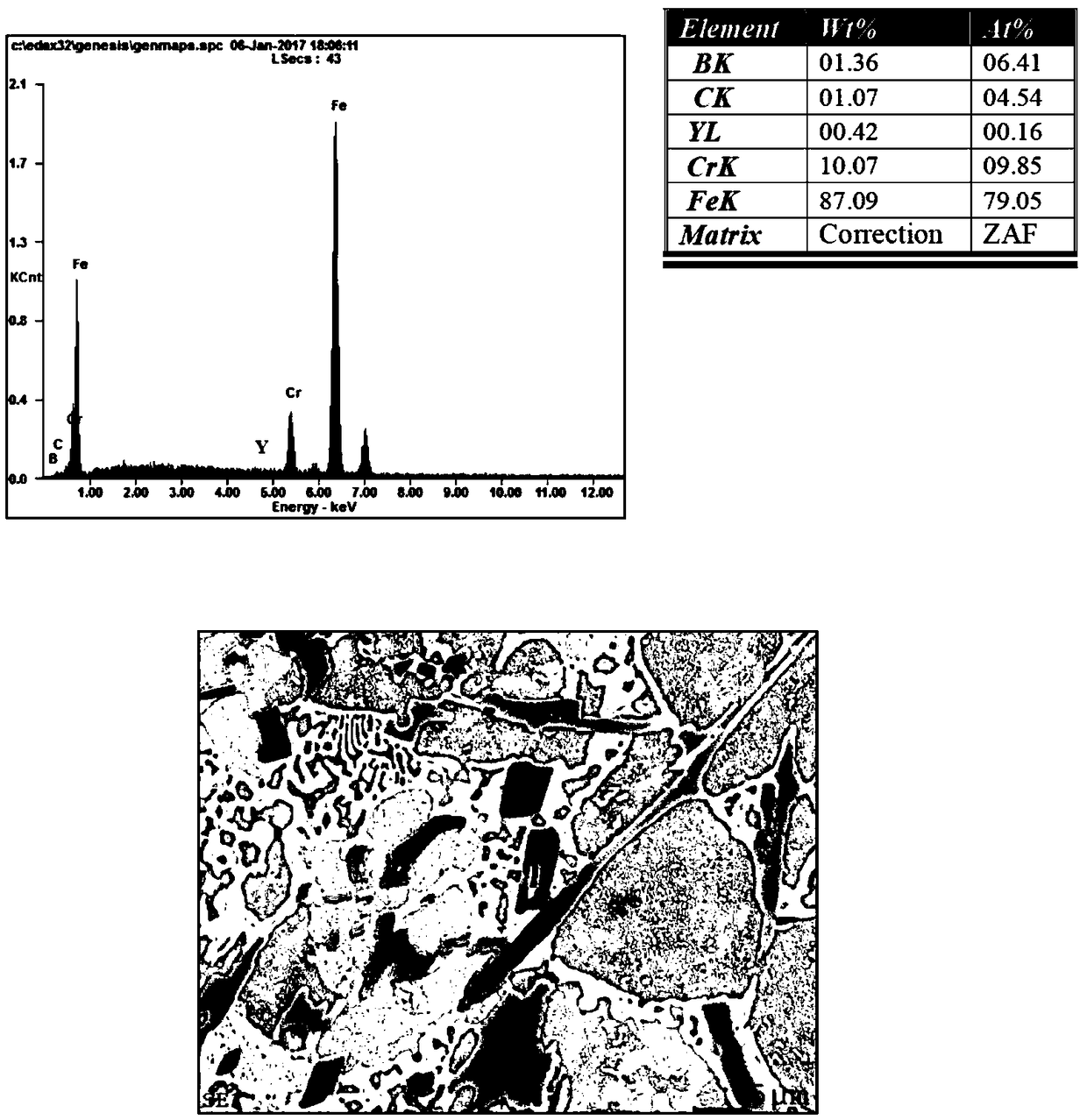

Embodiment 1

[0041] Example 1. Using iron powder and Y 2 O 3 After the powder is evenly mixed, it is molded into powder compacts. Y 2 O 3 The weight ratio of powder to iron powder is roughly 1:3, i.e. Fe-Y forming Fe-19.71wt.%Y 2 O 3 Mixed briquette. As a carrier for rare earth Y metamorphism.

[0042] Select high-carbon ferrochromium, micro-carbon ferrochromium, ferroboron, ferroniobium, ferrovanadium, industrial pure iron and the above Fe-Y 2 O 3 The mixed briquette is used as the raw material, and the composition range is as follows: Cr: 10.0wt.%; B: 2.9wt.%; C: 0.7wt.%; Nb: 0.4wt.%; V: 0.2wt.%; Y: 0.6wt. %; see Table 2 for the control of impurity elements. A small amount of impurities such as Al, Mn, N, etc. will not cause fundamental changes in the properties of the alloy, so it is not listed in Table 2.

[0043] After weighing the corresponding raw materials according to the composition requirements, induction melting and sand mold casting are used. The specific steps are:...

Embodiment 2

[0047] Example 2. Using iron powder and Y 2 O 3 After the powder is evenly mixed, it is molded into powder compacts. Y 2 O 3 The weight ratio of powder to iron powder is roughly 1:19, i.e. Fe-Y forming Fe-3.94wt.%Y 2 O 3 Mixed briquette. As a carrier for rare earth Y metamorphism.

[0048] Select high carbon ferrochromium, metallic chromium, ferroboron, ferroniobium, industrial pure iron and the above Fe-Y 2 O 3 The mixed briquette is used as raw material, and the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.7wt.%; Nb: 0.5wt.%; Y: 0.02wt.%; 2. A small amount of impurities such as Al, Mn, N, etc. will not cause fundamental changes in the properties of the alloy, so it is not listed in Table 2.

[0049] After weighing the corresponding raw materials according to the composition requirements, vacuum induction furnace smelting and water-cooled iron mold casting can be used. The specific steps are:

[0050] the Fe-Y 2 O 3 Powder compacts are placed ...

Embodiment 3

[0053] Example 3. Using iron powder and Y 2 O 3 After the powder is evenly mixed, it is molded into powder compacts. Y 2 O 3 The weight ratio of powder to iron powder is roughly 1:10, i.e. Fe-Y forming Fe-7.17wt.%Y 2 O 3 Mixed briquette. As a carrier for rare earth Y metamorphism.

[0054] Select high-carbon ferrochromium, micro-carbon ferrochromium, ferroboron, ferroniobium, industrial pure iron and the above Fe-Y 2 O 3 The mixed briquette is the raw material, and the composition range is as follows: Cr: 10.0wt.%; B: 2.7wt.%; C: 0.8wt.%; Nb: 0.6wt.%; Y: 0.10wt.%; 2. A small amount of impurities such as Al, Mn, N, etc. will not cause fundamental changes in the properties of the alloy, so it is not listed in Table 2.

[0055] After weighing the corresponding raw materials according to the composition requirements, induction melting and investment casting are used. The specific steps are:

[0056] the Fe-Y 2 O 3 Powder compacts are placed on the bottom of the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com