Method for preparing MnO2/silver composite cathode of Li-Mn cell

A technology of manganese dioxide and lithium-manganese batteries, which is applied in electrode manufacturing and other directions, and can solve problems such as poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

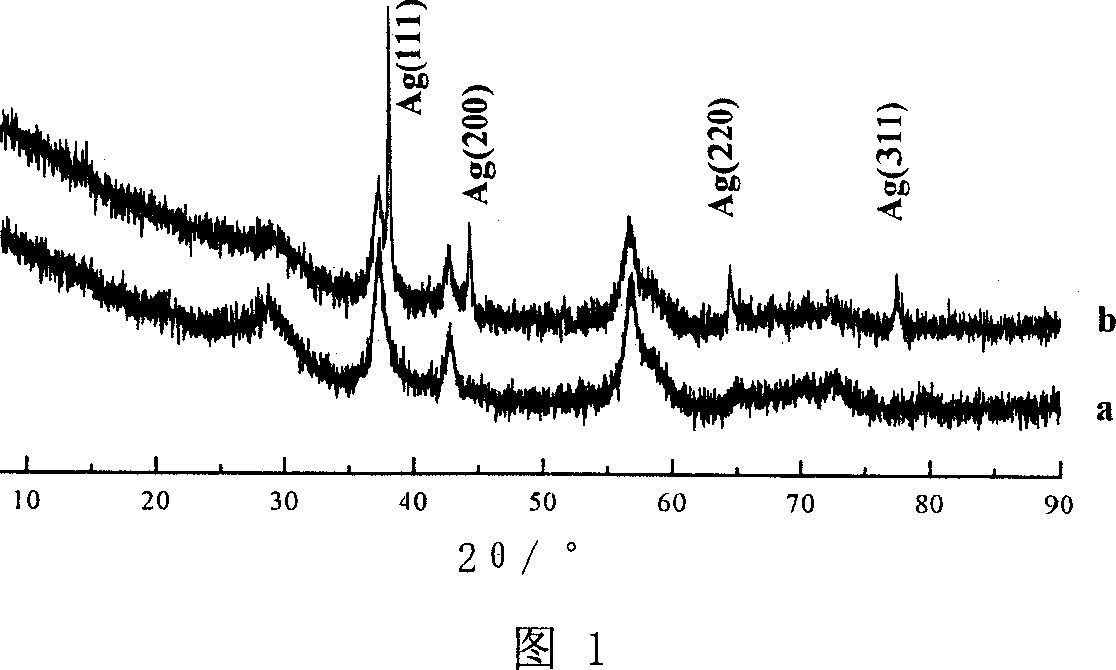

[0020] Heat-treat electrolytic manganese dioxide at 375°C for 12 hours to obtain manganese dioxide for lithium-manganese batteries (see Figure 1a), mix manganese dioxide and acetylene black at a ratio of 50:5, add a certain amount of PTFE emulsion, and adjust to a uniform of sticky matter, filling it in an apparent area of 1.5cm 2 In the nickel foam, dry at 80°C, press-molded at 12MPa, and vacuum-dry at 120°C for 24h to obtain a manganese dioxide electrode.

Embodiment 2

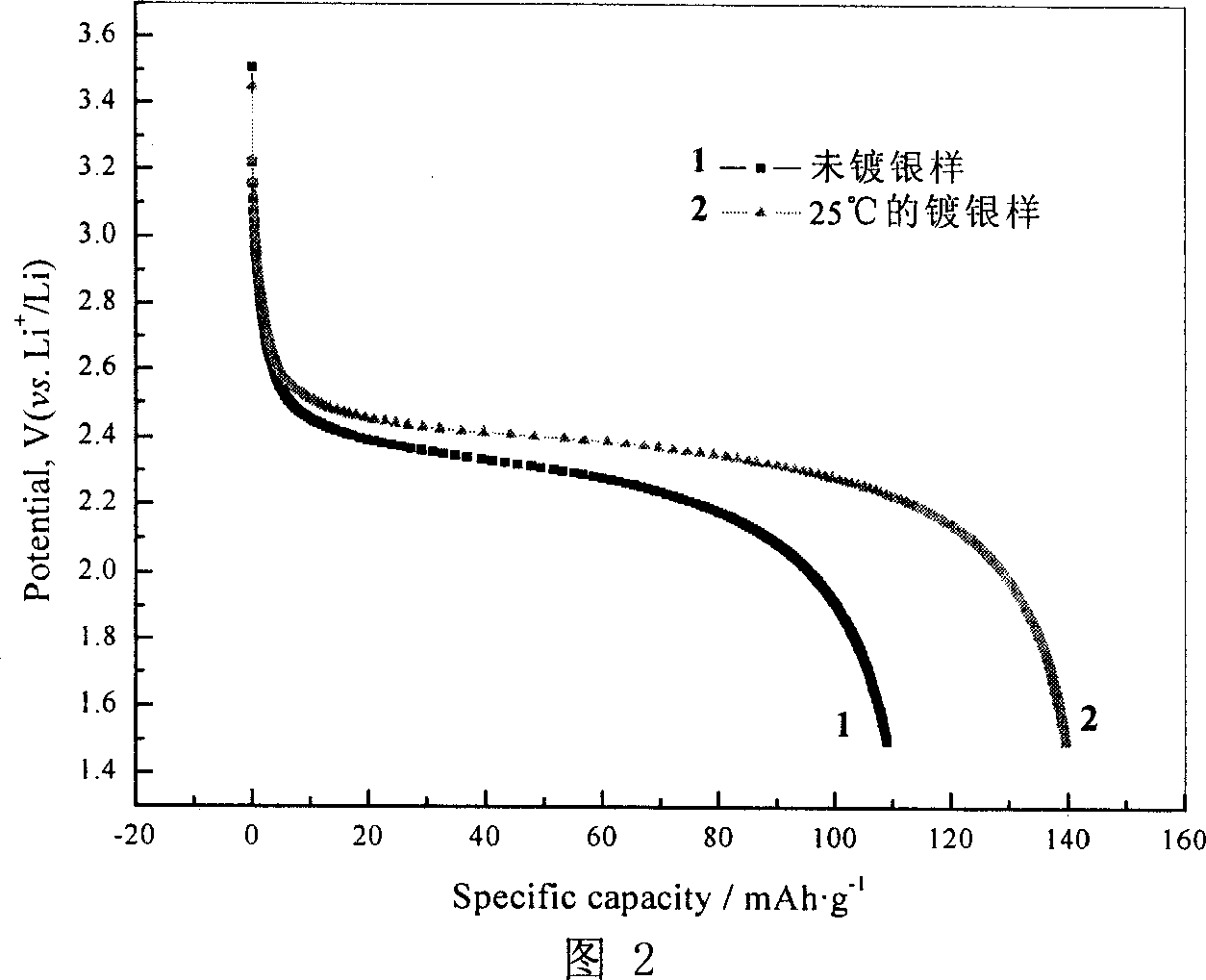

[0022] Pour the electrolytic manganese dioxide heat-treated at 375°C for 12 hours into the silver plating solution, stir at an appropriate speed at 25°C for 12 hours, filter and wash three times, then vacuum-dry at 110°C for 24 hours to obtain manganese dioxide / silver composite (see Figure 1b). The amount of silver plating was 3.5 wt%. As in Example 1, a manganese dioxide electrode was prepared by replacing the manganese dioxide in Example 1 with a manganese dioxide / silver composite material.

Embodiment 3

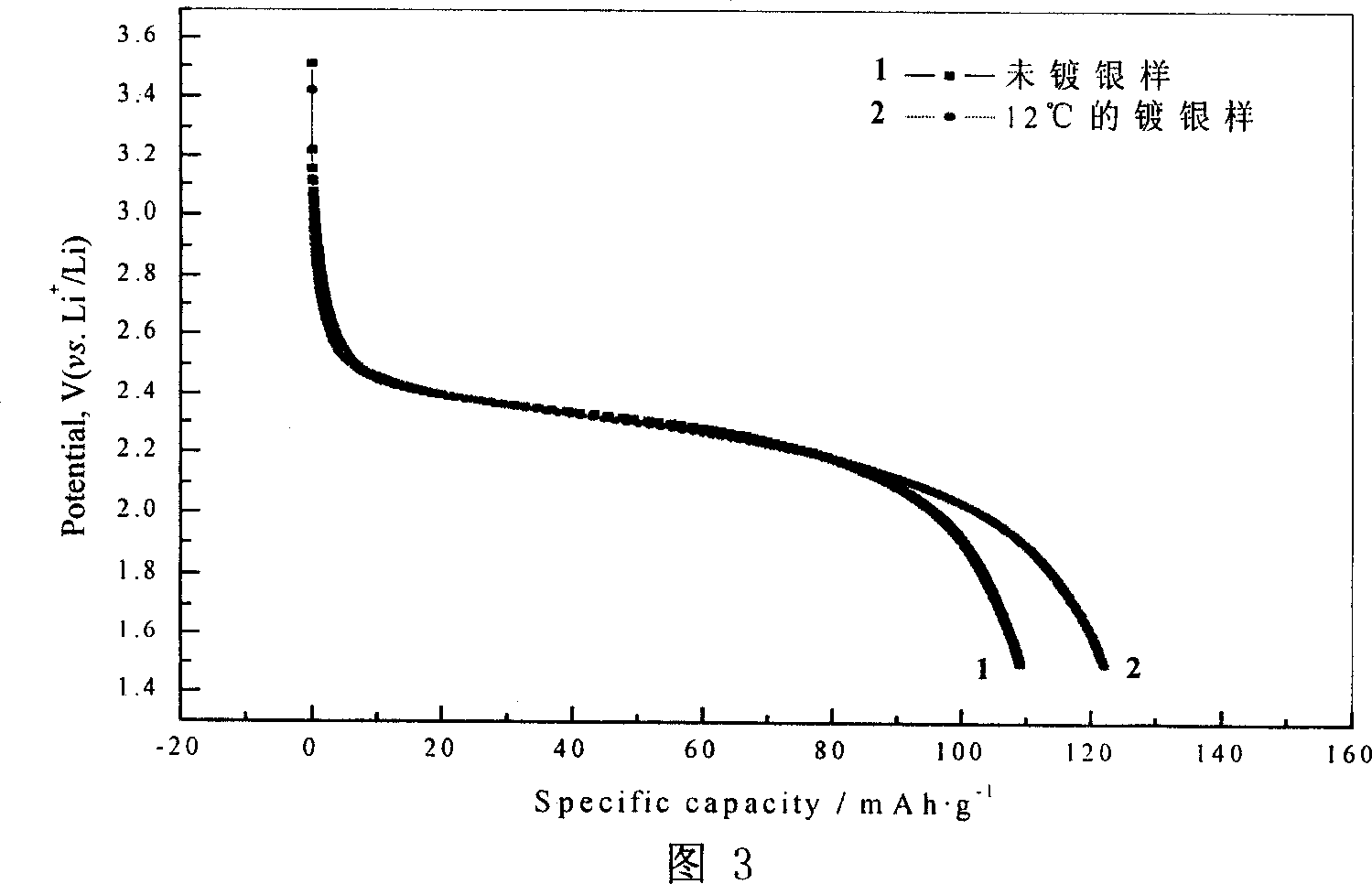

[0024] During the silver plating process, the temperature was controlled at 12° C., and a manganese dioxide / silver composite material was prepared with reference to Example 2. And referring to Example 1, a manganese dioxide electrode was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com