Motor

A motor and housing technology, applied in the field of motors, can solve the problems of reduced magnetic saturation feed accuracy, limited use environment, large leakage magnetic flux, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

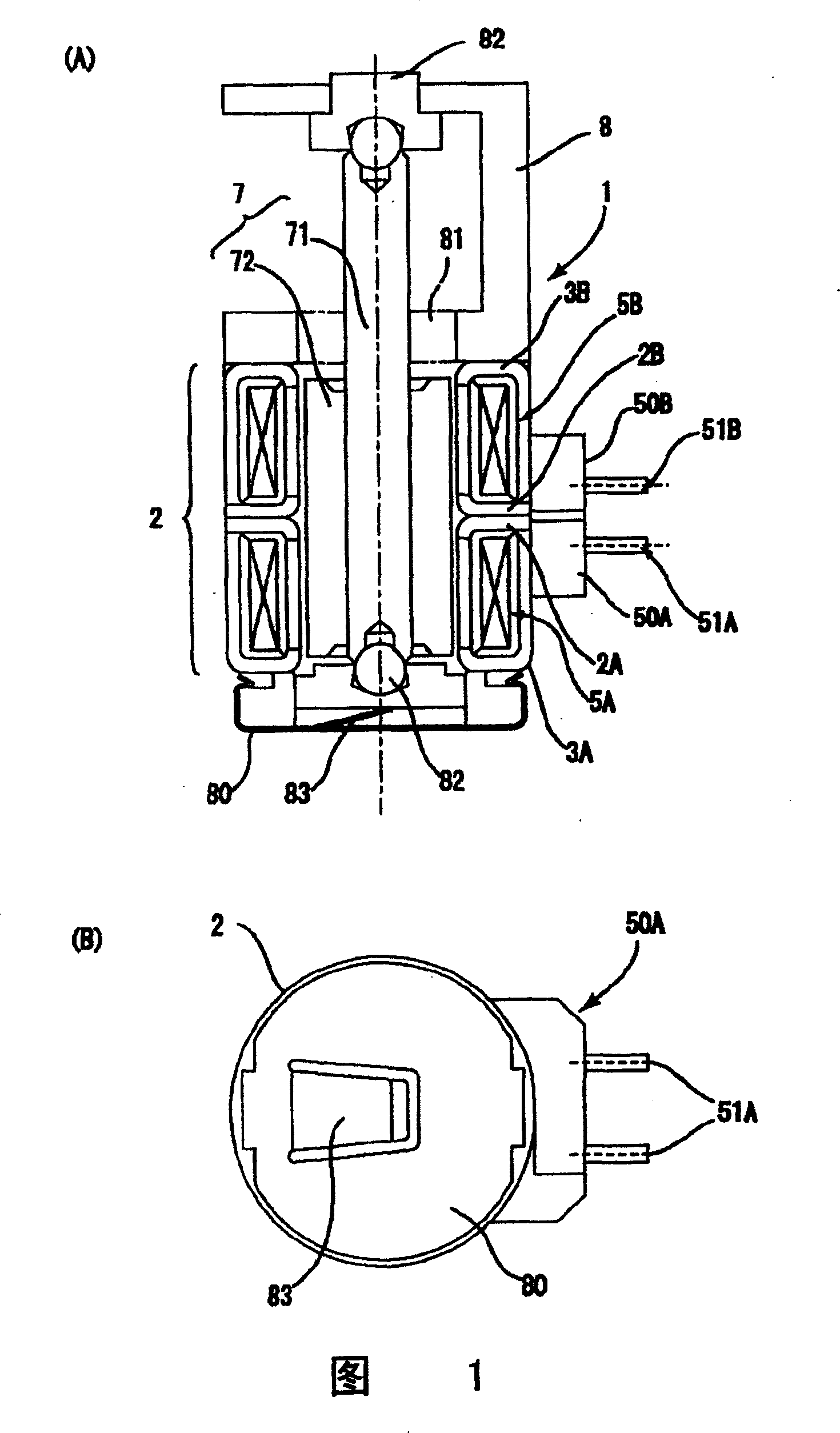

[0019] Embodiments of the present invention will be described with reference to the drawings. In addition, since the basic structure of the stepping motor to which the present invention is applied is also described with reference to FIG. 1(A), description of the basic structure will be omitted, and only the characteristic parts will be described below.

[0020] [Embodiment 1]

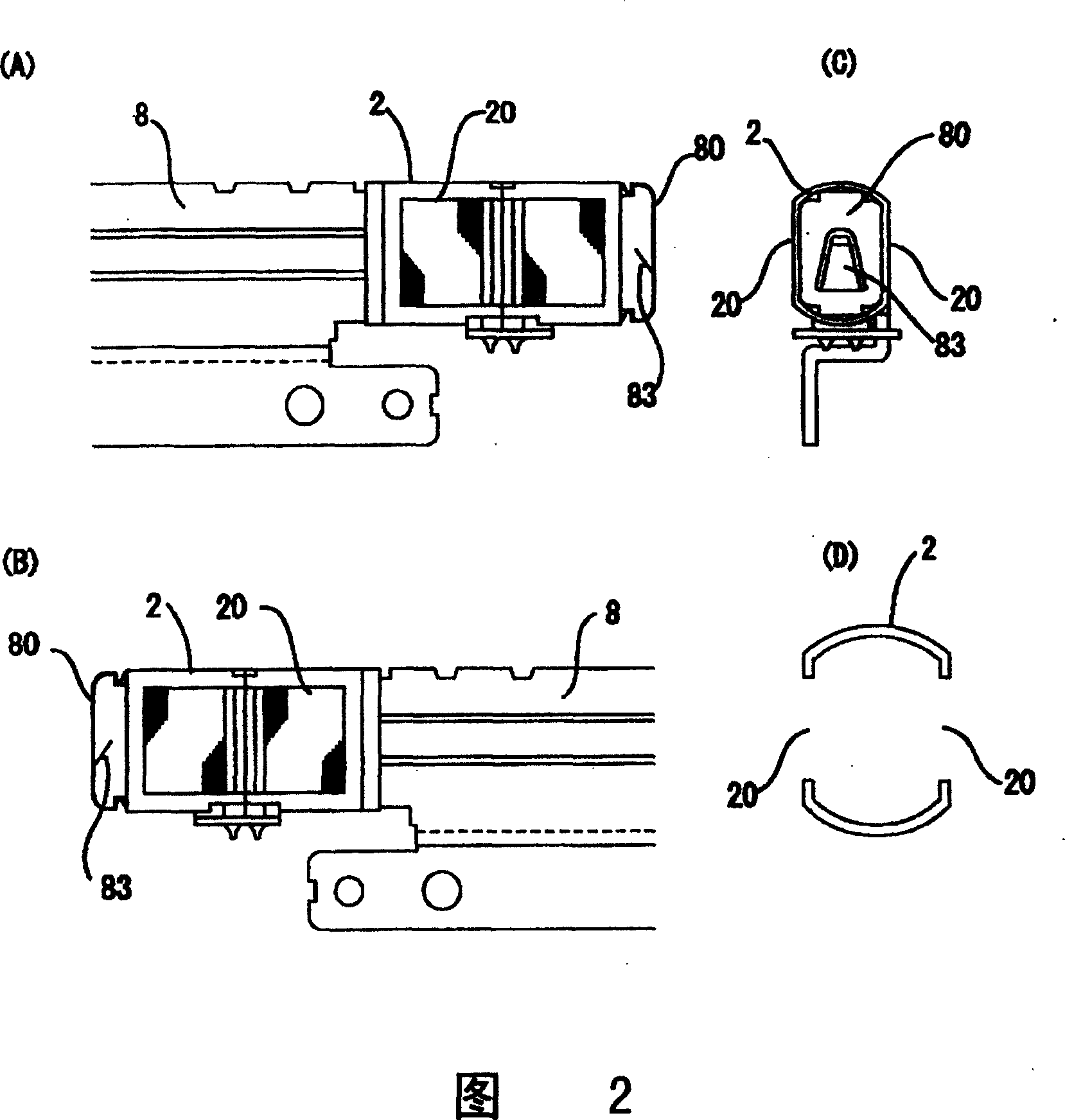

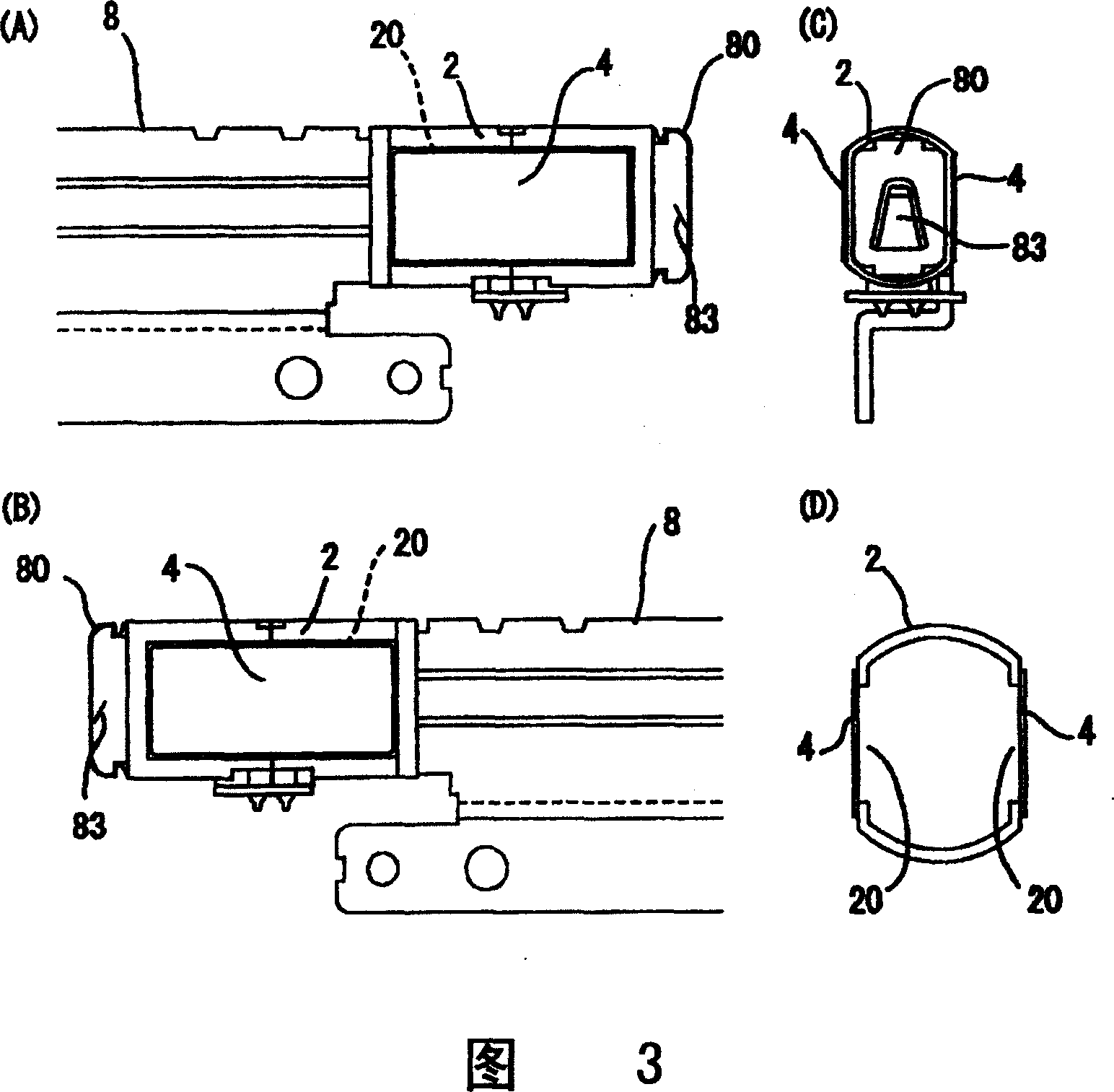

[0021] Fig. 2 (A), (B), (C), (D) are the left side view, the right side view, the bottom view and the casing of the state that the opening is formed on the side of the casing in the stepping motor shown in Fig. 1 respectively. A cut-away end view cut in a direction perpendicular to the motor axis. 3(A), (B), (C), and (D) are left side views showing the state in which the opening formed in the side surface of the casing is covered with a magnetic plate in the stepping motor according to Embodiment 1 of the present invention, respectively. , right view, bottom view and cut-off end view after cutting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com