Preparation method and application of polyacrylamide-loaded magnetic chitosan adsorbent

A technology of polyacrylamide and chitosan, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as difficult recycling, high cost, and poor effect, and achieve Improves adsorption performance, facilitates recovery and reuse, and has the effect of enriching raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

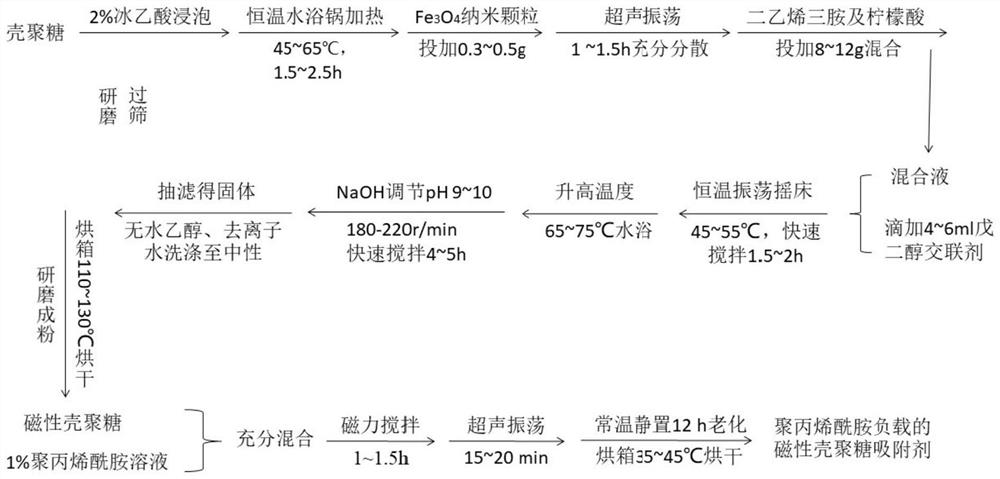

[0028] Such as figure 1 Shown, the preparation method of the magnetic chitosan adsorbent of a kind of polyacrylamide load, comprises the steps:

[0029] Step 1, first soak a certain quality of chitosan in a glacial acetic acid solution with a concentration of 2%, and place it in a constant temperature water bath to heat and dissolve at a temperature of 45°C for 1.5 hours, then add 0.5g of Fe 3 o 4 Nanoparticles, ultrasonic 1.5h to fully disperse, then add 10g of diethylenetriamine and citric acid to mix, and then stir quickly through a constant temperature shaking shaker to make a fully uniform reaction, set the temperature at 45°C during the process, and drop 5ml of Pentylene glycol acts as a crosslinking agent. After 1.5 hours, raise the temperature to 65°C in a water bath, and adjust the pH of the mixed solution to 9-10 with NaOH solution, and stir rapidly at a speed of 220r / min for 4 hours. After the reaction is complete, the solid product is obtained by suction filtrati...

Embodiment 2

[0032] Such as figure 1 Shown, the preparation method of the magnetic chitosan adsorbent of a kind of polyacrylamide load, comprises the steps:

[0033] Step 1, first soak a certain quality of chitosan in a glacial acetic acid solution with a concentration of 2%, and place it in a constant temperature water bath to heat and dissolve at a temperature of 45°C for 1.5 hours, then add 0.5g of Fe 3 o 4 Nanoparticles, ultrasonic 1.5h to fully disperse, then add 10g of diethylenetriamine and citric acid to mix, and then stir quickly through a constant temperature shaking shaker to make a fully uniform reaction, set the temperature at 45°C during the process, and drop 5ml of Pentylene glycol acts as a crosslinking agent. After 1.5 hours, raise the temperature to 65°C in a water bath, and adjust the pH of the mixed solution to 9-10 with NaOH solution, and stir rapidly at a speed of 220r / min for 4 hours. After the reaction is complete, the solid product is obtained by suction filtrati...

Embodiment 3

[0037] Such as figure 1 Shown, the preparation method of the magnetic chitosan adsorbent of a kind of polyacrylamide load, comprises the steps:

[0038] Step 1, first soak a certain quality of chitosan in a glacial acetic acid solution with a concentration of 2%, and place it in a constant temperature water bath to heat and dissolve at a temperature of 45°C for 1.5 hours, then add 0.5g of Fe 3 o 4 Nanoparticles, ultrasonic 1.5h to fully disperse, then add 10g of diethylenetriamine and citric acid to mix, and then stir quickly through a constant temperature shaking shaker to make a fully uniform reaction, set the temperature at 45°C during the process, and drop 5ml of Pentylene glycol acts as a crosslinking agent. After 1.5 hours, raise the temperature to 65°C in a water bath, and adjust the pH of the mixed solution to 9-10 with NaOH solution, and stir rapidly at a speed of 220r / min for 4 hours. After the reaction is complete, the solid product is obtained by suction filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com