Amorphous nanoparticle liquid metal magnetic fluid and preparation method thereof

A nanoparticle and liquid metal technology, applied in the direction of magnetic objects, nanomagnetism, magnetic liquid, etc., can solve the problems of insufficient stability of liquid metal magnetic fluid, and achieve excellent magnetic properties, low volatility, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

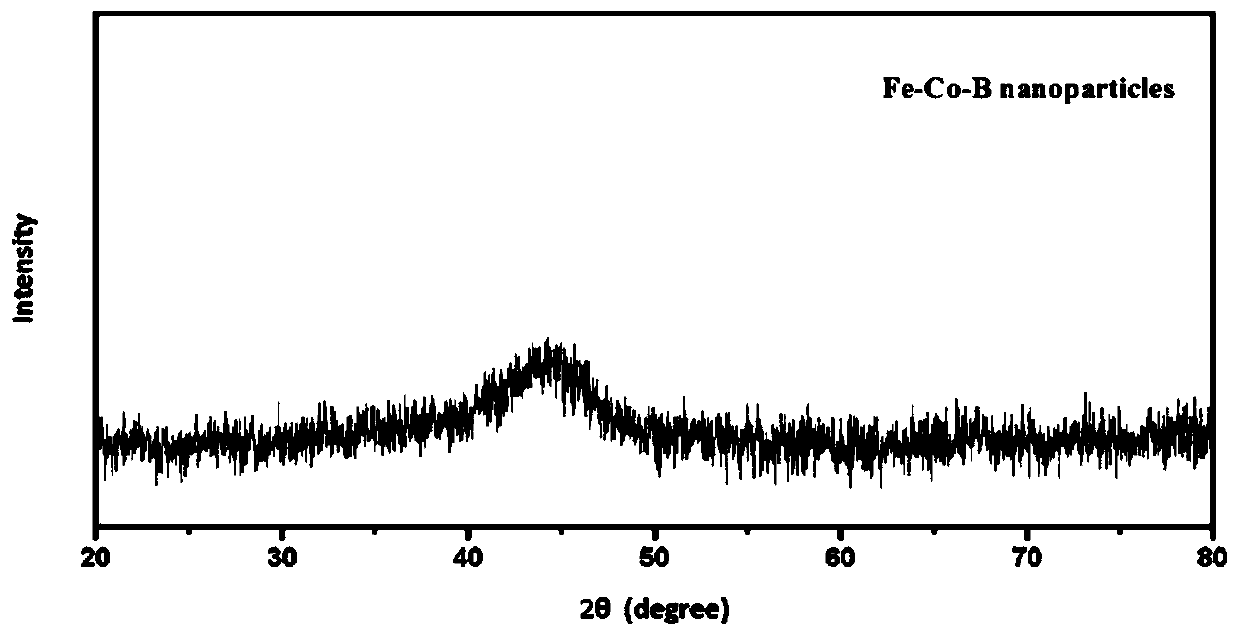

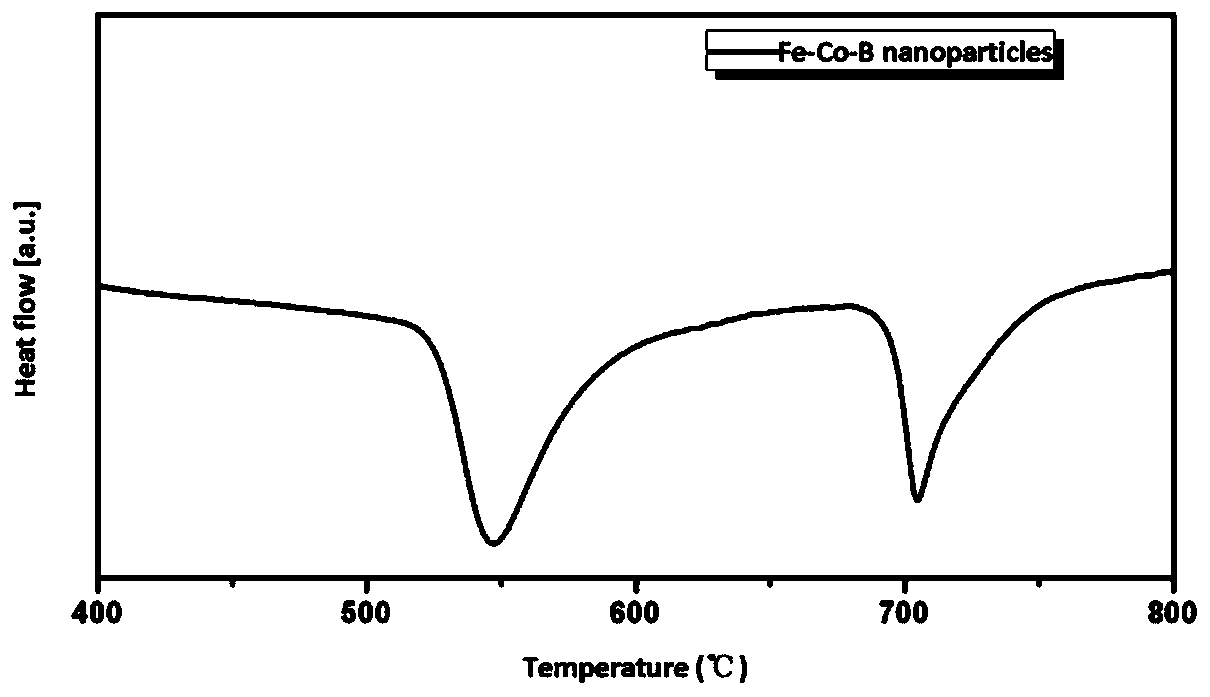

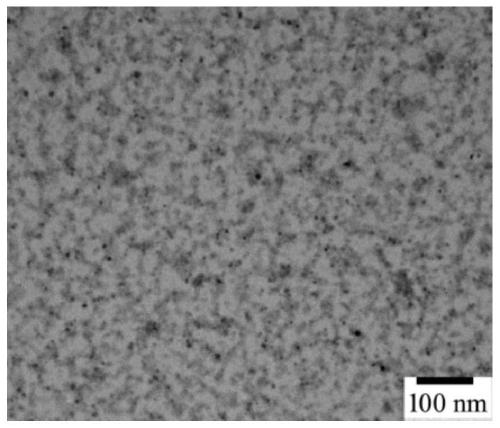

[0024] Step 1: Preparation of Fe-Co-B amorphous nanoparticles

[0025] Fe-Co-B amorphous nanoparticles can be prepared by chemical reduction method or chemical co-precipitation method. In this example, Fe—Co—B amorphous nanoparticles were prepared by chemical reduction method. Configure FeCl 2 4H 2 O and CoCl 2 ·6H 2 O mixed solution 100ml, wherein, Fe in the mixed solution 2+ and Co 2+ The molar ratio is 2:1. While stirring, add a first predetermined volume of NaBH to the mixed solution 4 solution. In the case of mechanical stirring and ultrasonic dispersion, the first predetermined volume of NaBH can be added to the mixed solution at a uniform speed 4 solution. The first predetermined capacity according to Fe 2+ and Co 2+The molar ratio is determined. Put the mixed solution into a three-necked flask for mechanical stirring and ultrasonic dispersion, then add 30 ml of 0.8 mol NaBH at a rate of 1.5 ml per minute at room temperature 4 solution. Use NaOH to adjust...

Embodiment 2

[0038] Step 1: Preparation of Fe-Co-B amorphous nanoparticles

[0039] Configure FeCl 2 4H 2 O and CoCl 2 ·6H 2 O mixed solution 100ml, in which Fe 2+ and Co 2+ The molar ratio is 3:1. Put the mixed solution into a three-necked flask for mechanical stirring and ultrasonic dispersion, then add 30 ml of 0.8 mol NaBH at a rate of 1.5 ml per minute at room temperature 4 solution. The pH of the solution was adjusted to 11 with NaOH. After mechanical stirring and ultrasonic dispersion for 1 hour, the suspension is centrifuged at high speed to obtain amorphous Fe-Co-B magnetic particles.

[0040] Step 2: Prepare Fe-Co-B@Al by using Fe-Co-B amorphous nanoparticles and Al salt solution 2 o 3 nanoparticles

[0041] Measure 4g of Fe-Co-B nanoparticles, add to 75ml of Al(NO 3 ) 3 A suspension was obtained in solution, Al(NO 3 ) 3 The solution concentration is 0.5mol / L. Add 0.4g PEG-2000 and 1.5g PEG-400 as dispersants to the suspension, and stir evenly with magnetic force....

Embodiment 3

[0049]Step 1: Preparation of Fe-Co-B amorphous nanoparticles

[0050] Configure FeCl 2 4H 2 O and CoCl 2 ·6H 2 O mixed solution 100ml, in which Fe 2+ and Co 2+ The molar ratio is 3:2. Put the mixed solution into a three-necked flask for mechanical stirring and ultrasonic dispersion, then add 35 ml of 0.8 mol NaBH at a rate of 1.5 ml per minute at room temperature 4 solution. The pH of the solution was adjusted to 12 with NaOH. After mechanical stirring and ultrasonic dispersion for 1 hour, the suspension is centrifuged at high speed to obtain amorphous Fe-Co-B magnetic particles.

[0051] Step 2: Prepare Fe-Co-B@Al by using Fe-Co-B amorphous nanoparticles and Al salt solution 2 o 3 nanoparticles

[0052] Measure 4g of Fe-Co-B nanoparticles, add to 75ml of Al(NO 3 ) 3 A suspension was obtained in solution, Al(NO 3 ) 3 The solution concentration is 0.5mol / L. Add 0.4g PEG-2000 and 1.5g PEG-400 as dispersants to the suspension, and stir evenly with magnetic force. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com