Wellhead drip medicament charging method by using water pressure to retain constant medicament charging differential pressure

A pressure difference and drip technology, applied in earthwork drilling, wellbore/well parts, cleaning equipment, etc., can solve the problems of large fluctuations in chemical concentration and low effective concentration, and achieve the goal of not being easily damaged or lost, easy to manage, and clean and prevent good wax effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further explained below in conjunction with the drawings and embodiments:

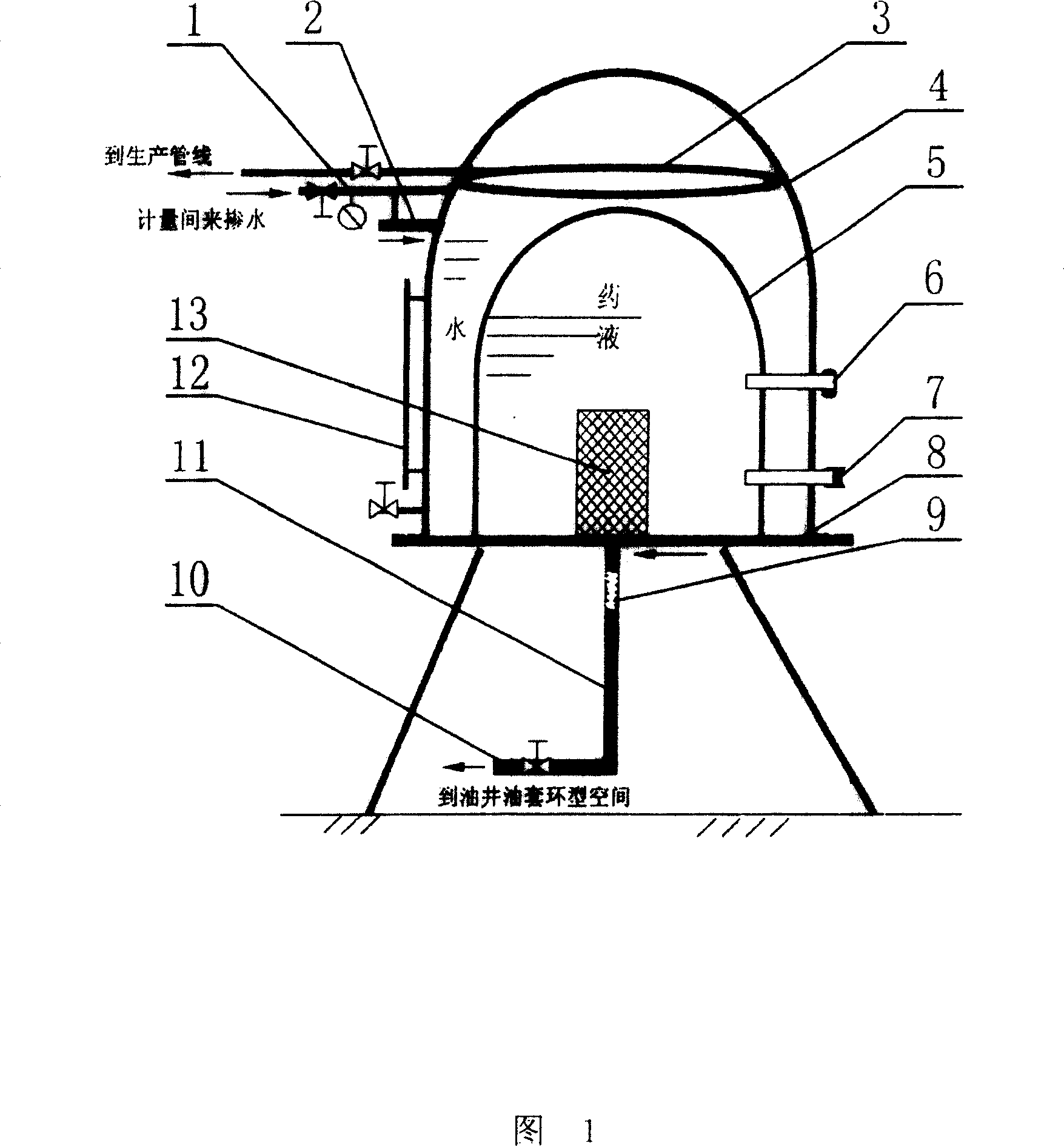

[0010] As shown in Figure 1, a method of spot-dosing medicine at the wellhead using the water mixing pressure to maintain a constant dosing pressure difference. The method of spot-dosing is to control the water inlet nozzle 2 at the inlet to flow out 2~3m from the water mixing pipeline 1. 3 / d of water enters the dosing tank 4, and the mixing pressure is reduced to the pressure in the tank, and then a water outlet nozzle 8 is used to establish a pressure difference between the tank and the sleeve pressure, and a pressure difference is formed on the drug storage capsule 5 in the tank. The constant point drop of medicine controls the pressure difference and accurately controls the dosage of the medicine. The capsule 5 is equipped with a filter 13, and the capillary tube 9 is used to continuously and stably drip the medicine under a small pressure difference into the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com