Lithium secondary battery and method for producing same

A lithium battery and recharging technology, used in secondary batteries, electrode manufacturing, lithium storage batteries, etc., can solve the problems of powdering, reducing electrode current collection capacity, shedding, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The invention is illustrated in more detail below by way of examples. The following examples are provided merely to illustrate the practice of the invention and are not intended to limit it. Appropriate changes and modifications can be made without departing from the scope of the present invention.

[0099] (Experiment 1)

[0100] (manufacture of negative electrode)

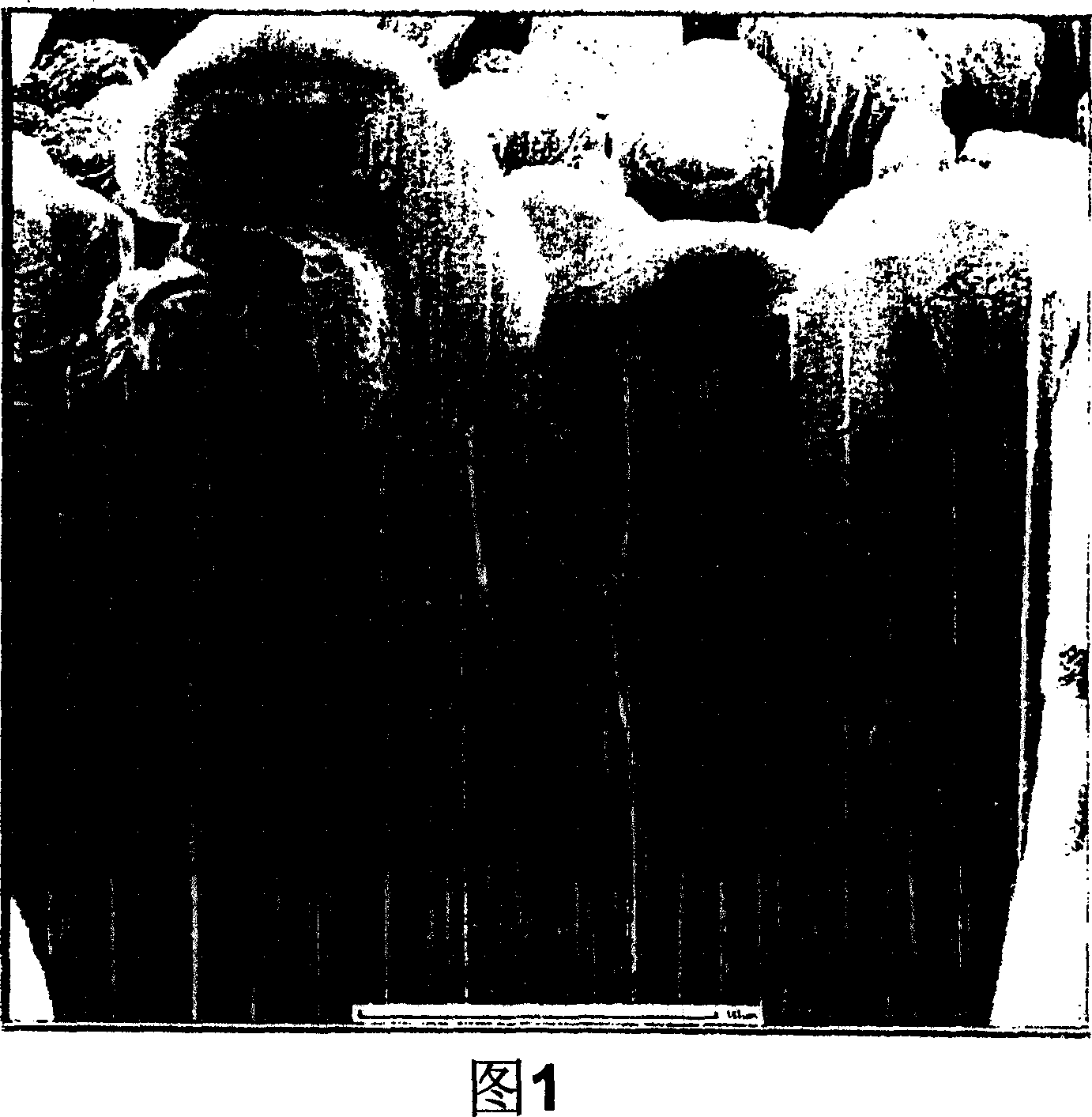

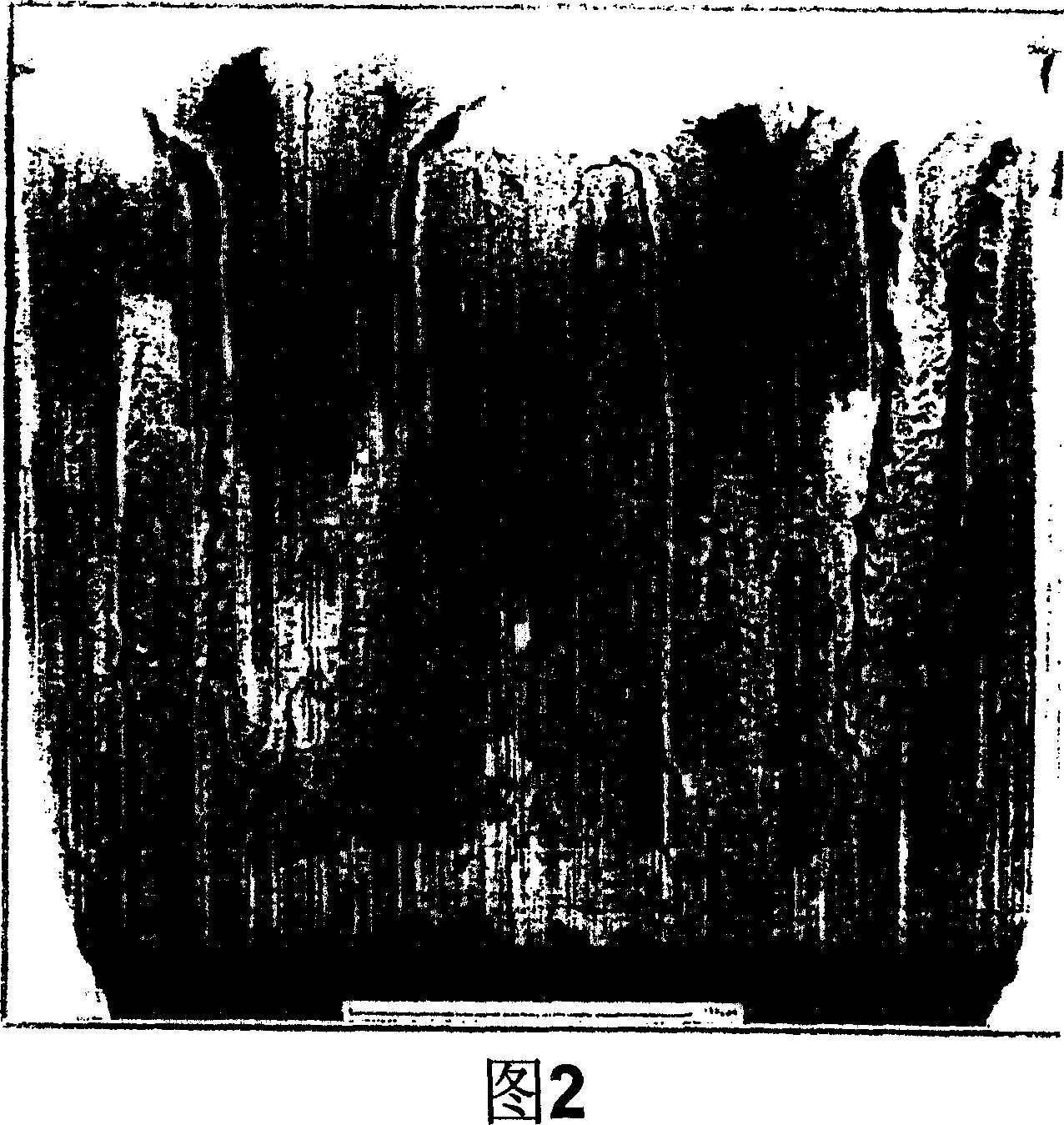

[0101] Copper is electrolytically deposited on the surface of a heat-resistant rolled copper alloy foil consisting of a zirconium-copper alloy (0.015-0.03 wt.% zirconium content) to provide a roughened, heat-resistant copper alloy foil (having an arithmetic average roughness Ra of 0.25 μm, and a thickness of 31 μm) was used as a current collector. A thin film of amorphous silicon was deposited onto the current collector using the sputtering setup shown in FIG. 5 .

[0102] As shown in FIG. 5, a rotating cylindrical substrate holder 2 is housed in the chamber 1. As shown in FIG. The current collector i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com