Blanking static logic controller for alumina blanking scale

A technology of static logic and unloading scale, applied in the field of logic control system, can solve problems such as being difficult to use, and achieve the effects of stable performance, reduced size and high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

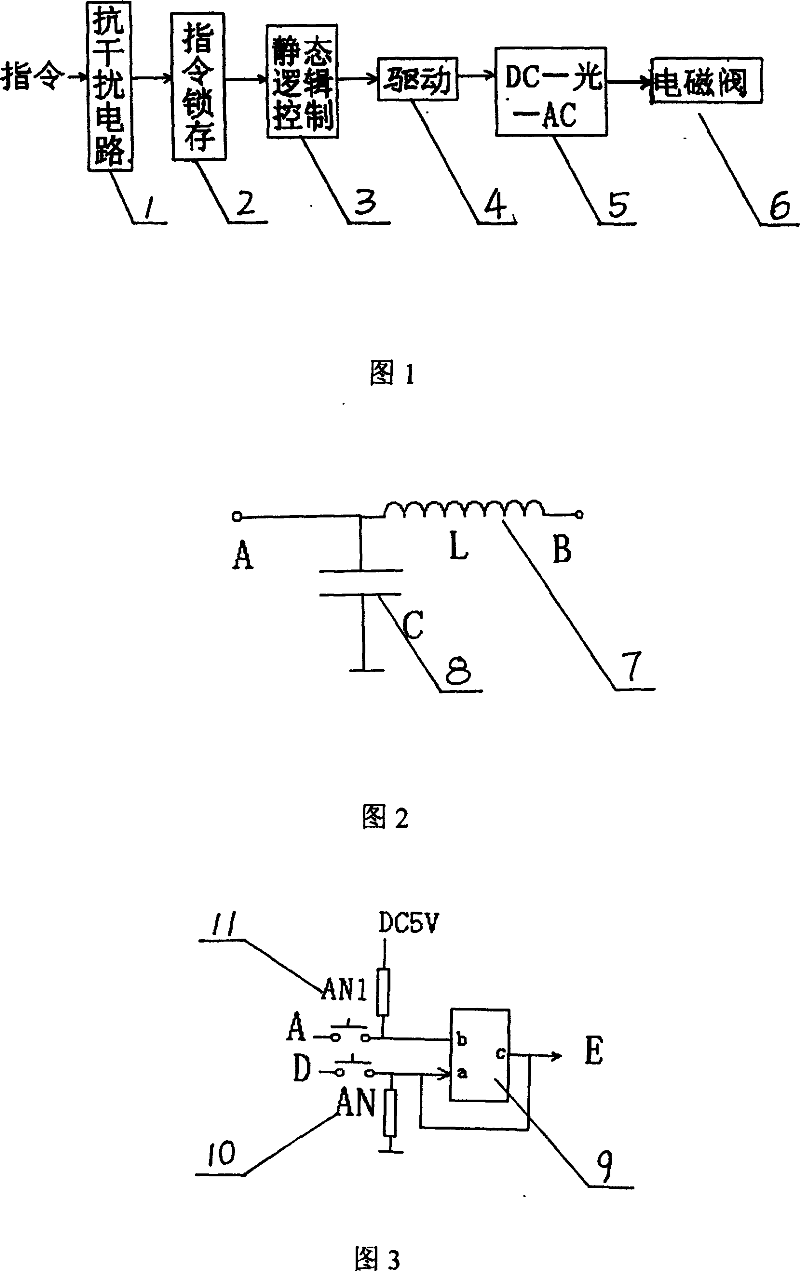

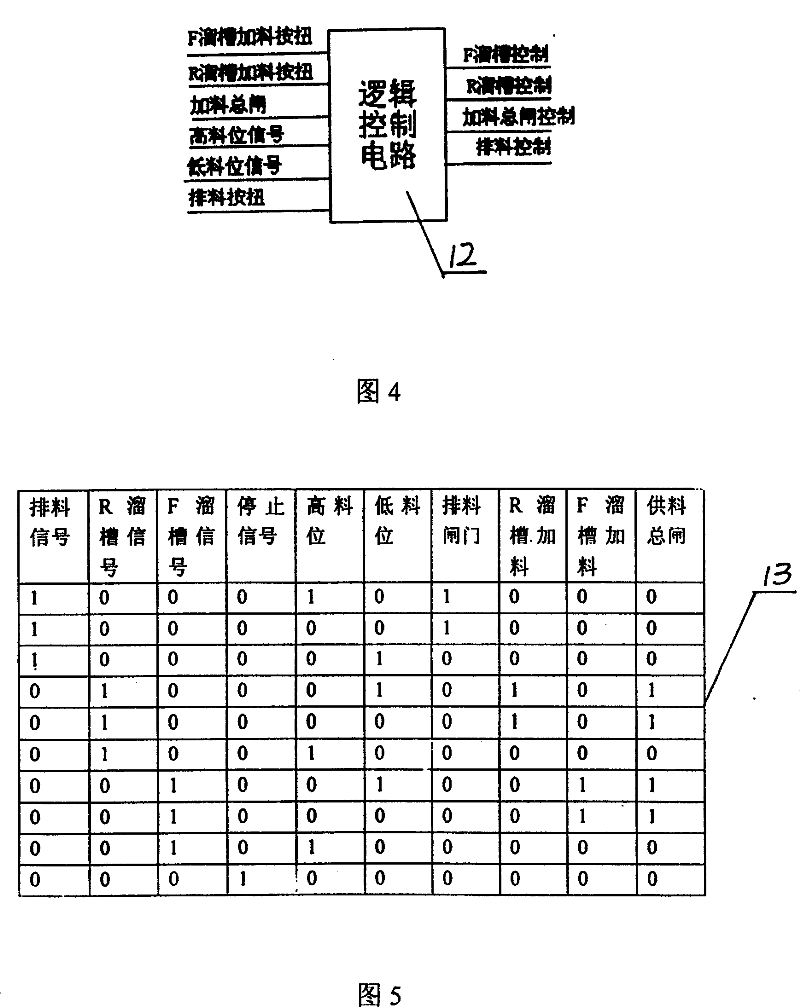

[0014] As shown in Figure 1. The static logic controller for the blanking of the alumina blanking scale of the present invention is composed of five parts: an anti-interference circuit 1, an instruction latch circuit 2, a static logic control circuit 3, a drive circuit 4, and DC-light-AC. The anti-interference circuit 1 consists of an impedance coil 7 and a capacitor 8, as shown in Figure 2; the command latch circuit 2 consists of a gate circuit 9 that can write control discharge, feeding, and stop signals, a high-level button switch 10 and a low-voltage Flat button switch 11 is formed, as shown in Figure 3; Described static logic control circuit 3 is by control R chute blanking, F chute blanking and discharging three working states of R chute blanking, F chute blanking, supply A logic control circuit 12 composed of 6 signals of material master gate, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com