Bohou sieve

A screening equipment and screen surface technology, applied in the direction of screen, solid separation, grid, etc., can solve the problems of unsatisfactory coal screening effect, mechanical strength and process effect can not have both, to achieve high screening efficiency, treatment powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below according to accompanying drawing:

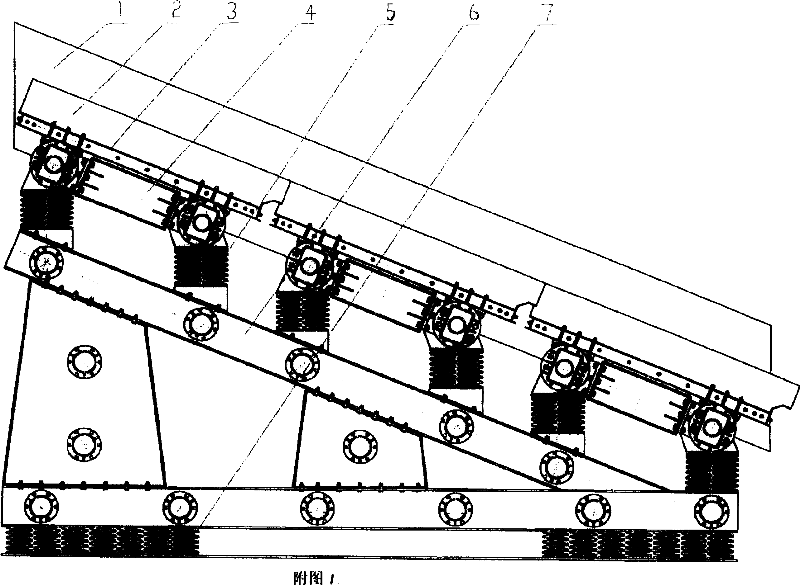

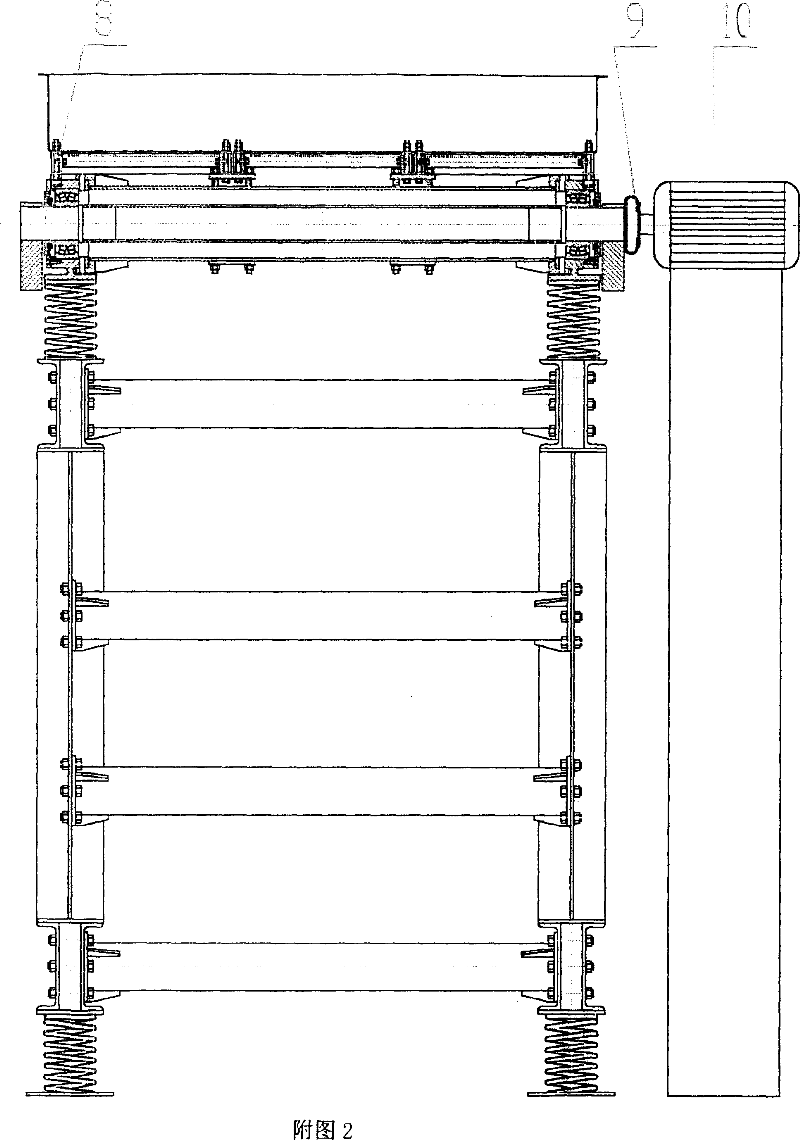

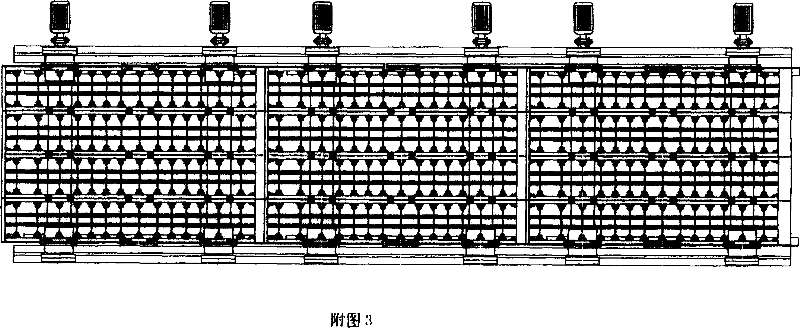

[0024] In accompanying drawing 1, sieve box 1: The sieve box is used for retaining material, does not participate in vibration. Blocking plate 2: Participate in the vibration of the sieve, used for blocking and supporting the screen wire plate. Screen surface 3: The screen surface of the present invention is fastened to the rectangular beam of the exciter, and vibrates synchronously with the exciter, and the vibration direction is perpendicular to the screen surface to realize linear vibration. The size of the screen surface can be combined freely in multiple sections according to the installation conditions and processing capacity requirements on site. The screen wires on the screen surface are arranged in a forward direction. During the screening process, the screen wires have a secondary vibration function, and the movement of materials on the screen surface Ability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com