Method and apparatus for enhancing measuring sensitivity of rotating corner

A roll angle measurement and sensitivity technology, applied in the field of angle optical measurement, can solve the problems of expensive lasers, uncompact instrument structure, inconvenient on-site measurement, etc., and achieve the effect of eliminating additional errors, compact structure, and convenient on-site measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

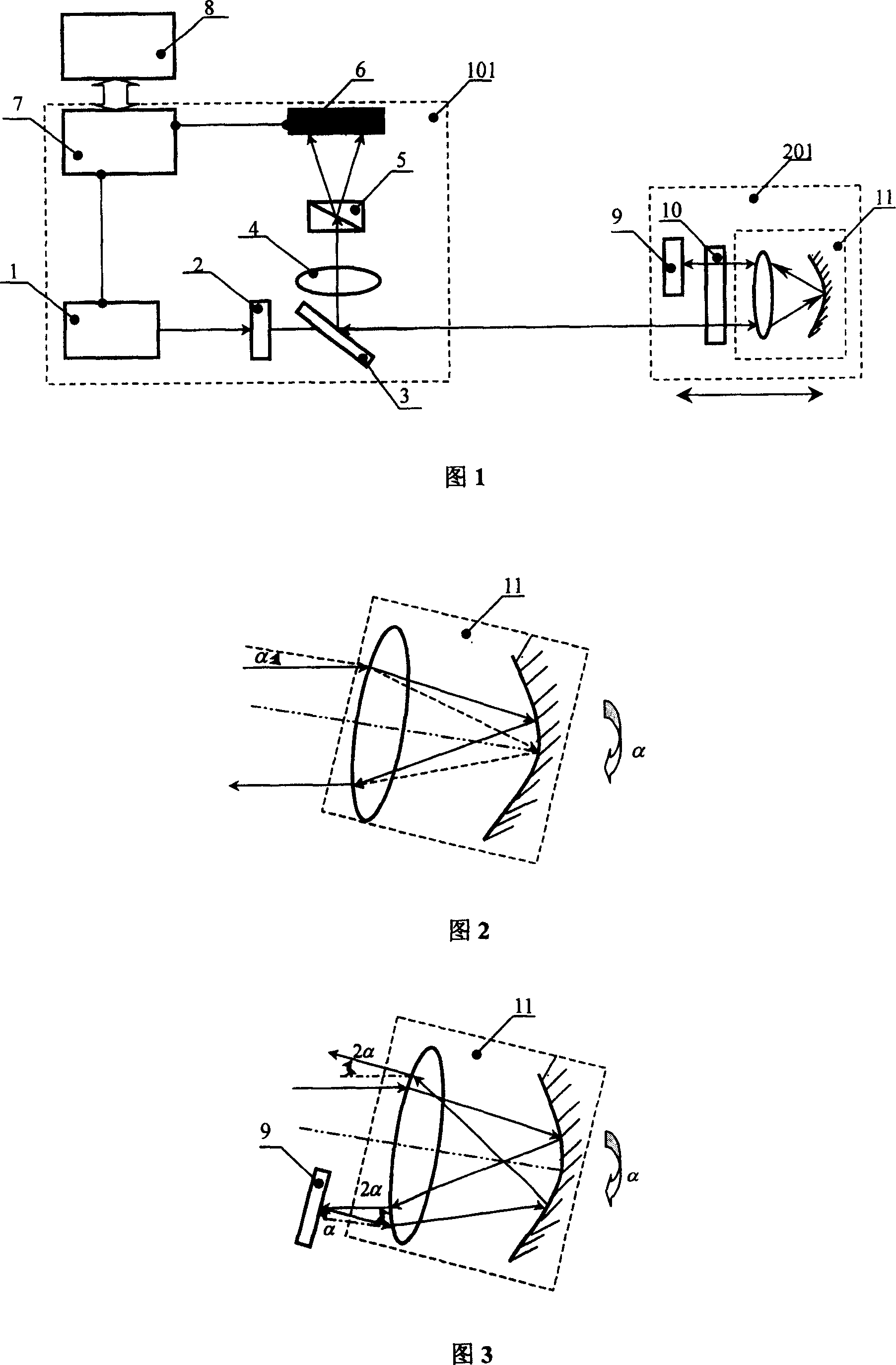

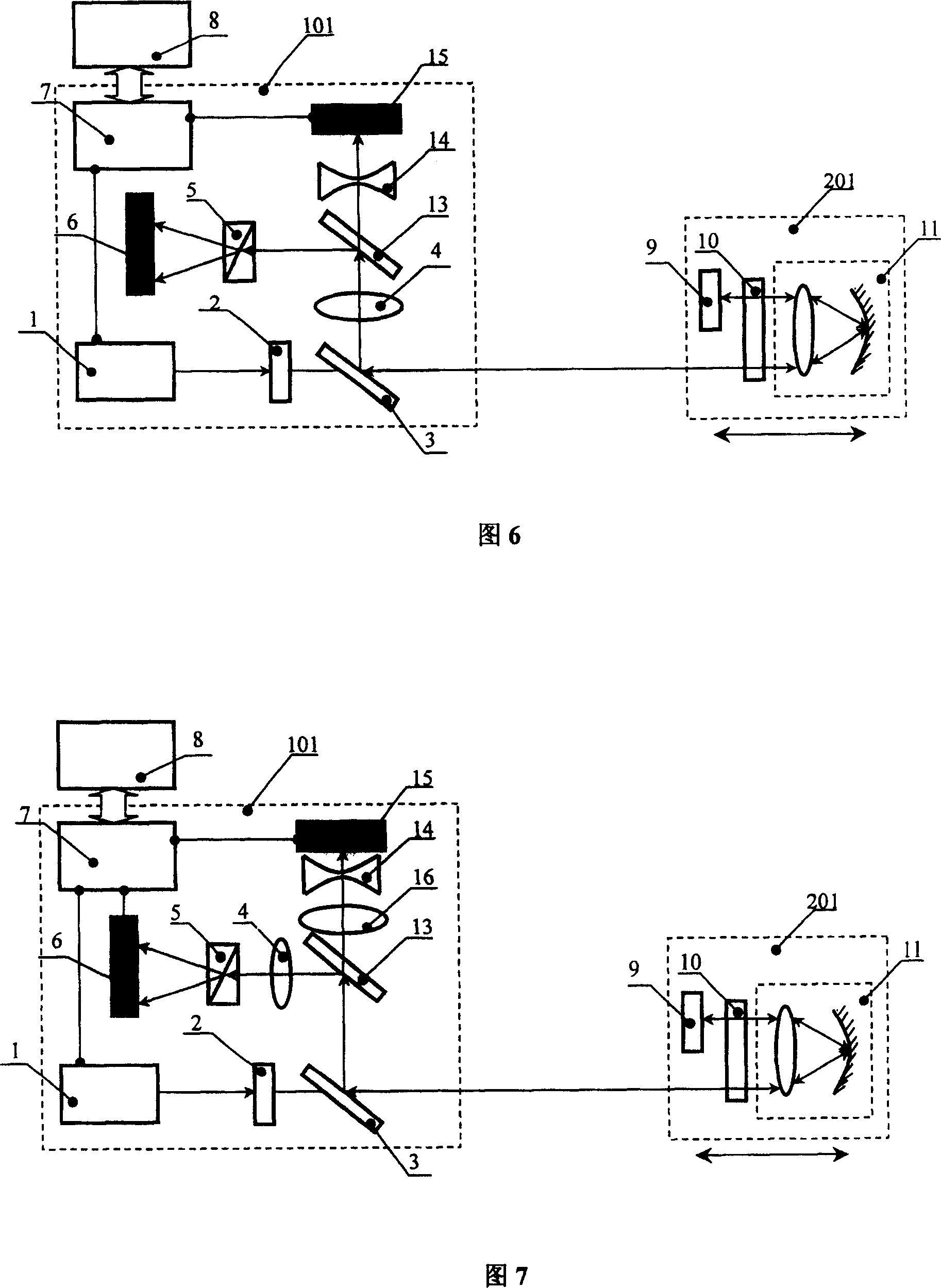

[0049] Embodiment 1 (Figure 1)

[0050] A device for improving the sensitivity of roll angle measurement, comprising: a laser 1, a polarizer 2, a beam splitter 3, a convex lens 4, a Wollaston prism 5, a detector 6, a signal processing circuit 7, a computer 8, and a plane mirror 9 , quarter wave plate 10, reflector 11;

[0051] The beam splitter 3 is placed in the fixed unit 101, on the optical path between the polarizer 2 and the mobile unit 201; the quarter wave plate 10, the reflector 11 and the plane reflector 9 are along the direction of the incident light Arranged in the mobile unit 201 in sequence; the convex lens 4 is placed between the beam splitter 3 and the Wollaston prism 5 or between the detector 6 and the Wollaston 5; the detector 6 is placed on on the focal plane of the convex lens 4.

[0052] The reflector also includes: a corner cube prism or a rectangular prism.

[0053] A method for improving roll angle measurement sensitivity is as follows:

[0054] 1. The...

Embodiment approach 2

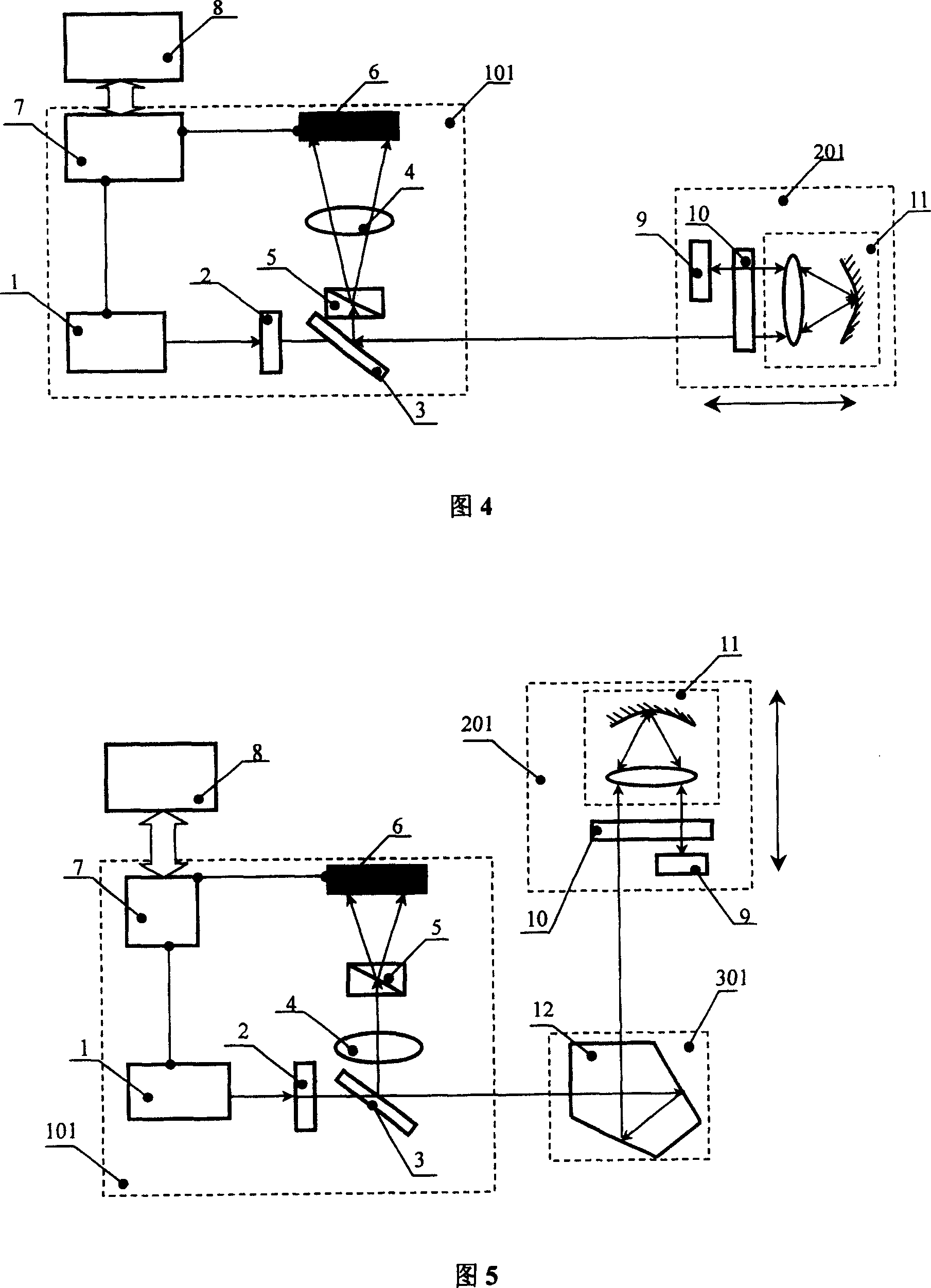

[0060] Embodiment 2 (Fig. 4):

[0061] Its components and parameters are basically the same as those in the first embodiment, but the positions of the Wollaston prism 5 and the convex lens 4 are reversed to obtain the same measurement effect.

Embodiment approach 3

[0062] Embodiment 3 (Fig. 5):

[0063] Its components and parameters are basically the same as the first embodiment, except that a steering unit 301 (pentagonal prism 12) is added between the mobile unit 101 and the fixed unit 201, so that the device can be directly applied to the roll angle measurement of the vertical guide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com