Narrow-pitch connector, electrostatic actuator, piezoelectric actuator, ink jet head

A narrow-pitch, connector technology, applied in the field of electronic devices and inkjet printers, can solve the problems of fine wiring 9 fusing and other problems, and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Embodiment 1

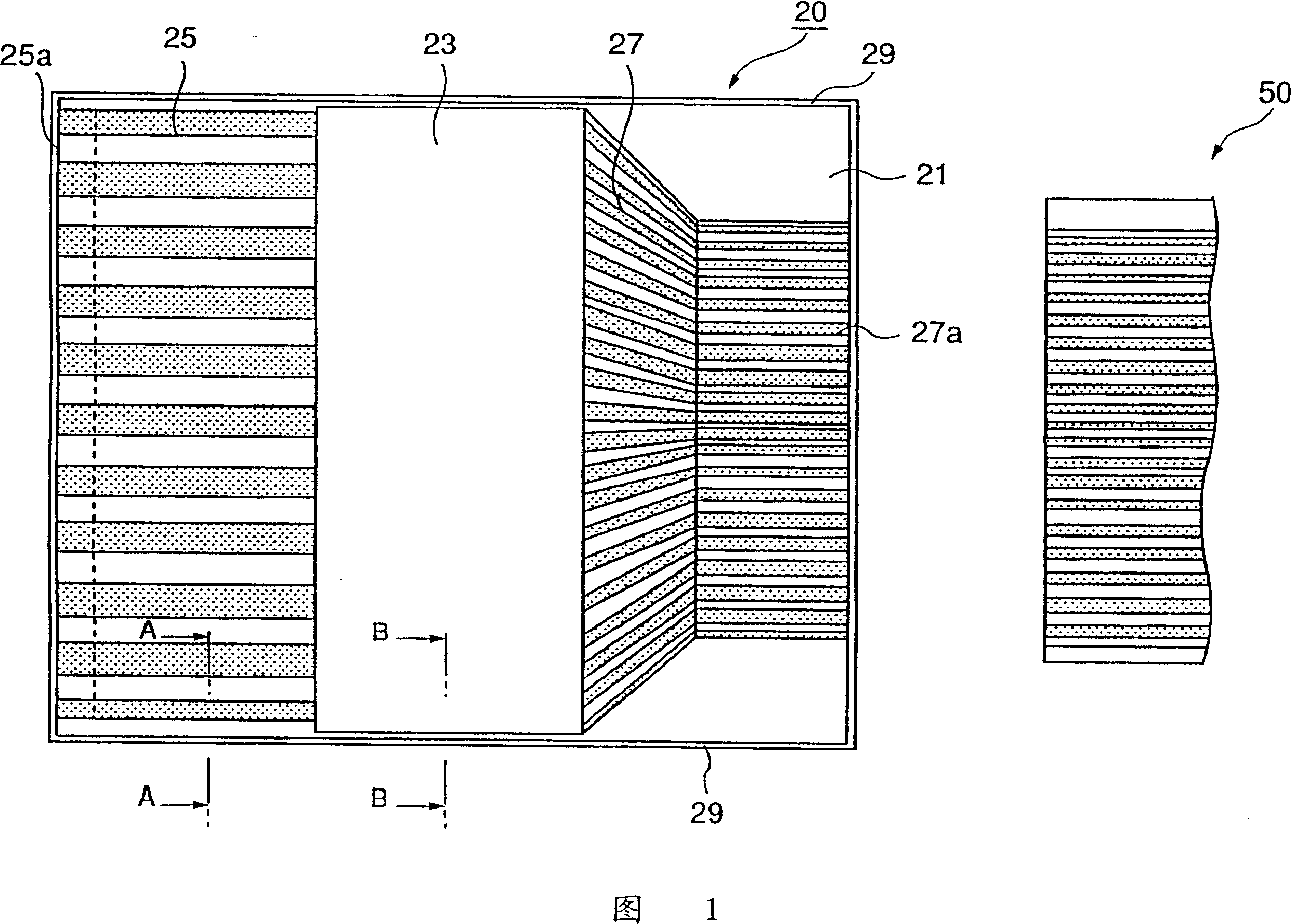

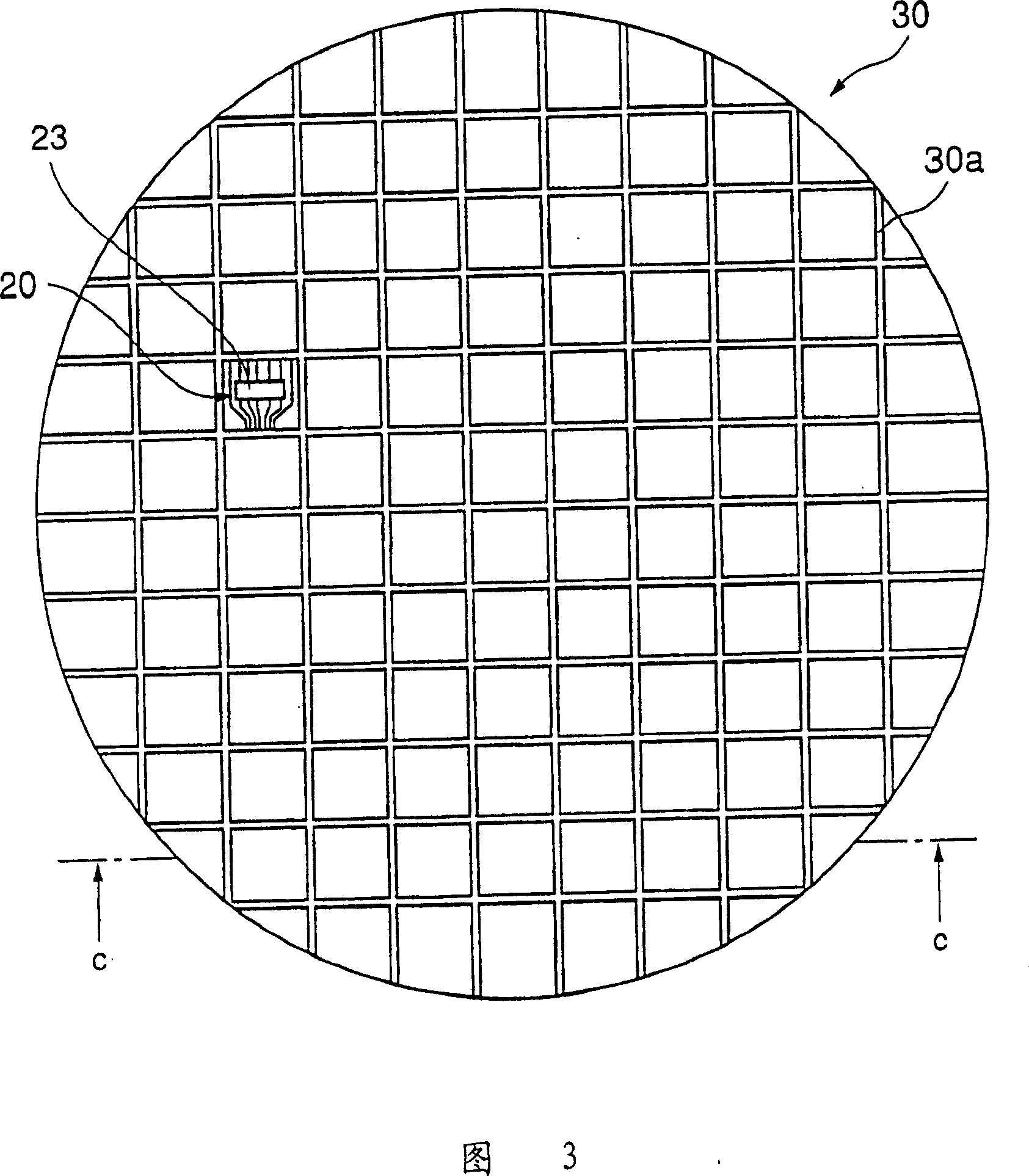

[0090]Fig. 1 is a plan view of a connector for a narrow pitch according to Embodiment 1 of the present invention. In the narrow-pitch connector 20, as shown in FIG. 1, an input wiring 25 and an output wiring 27 are formed on a substrate 21 made of single crystal silicon via an insulating layer, and a driver IC 23 is mounted. The ends of the input wiring 25 and the output wiring 27 become terminal electrodes 25a and 27a, respectively. In addition, the number of wirings and the wiring pitch on the input side and output side are changed.

[0091] In addition, the number of terminal electrodes 25a, 27a differs with the connection object 50 connected to the output side. In the case of the electrostatic actuator in which the object 50 is attached to the print head, it varies depending on the number of objects. However, it may be several tens or more on the input side and several hundred on the output side.

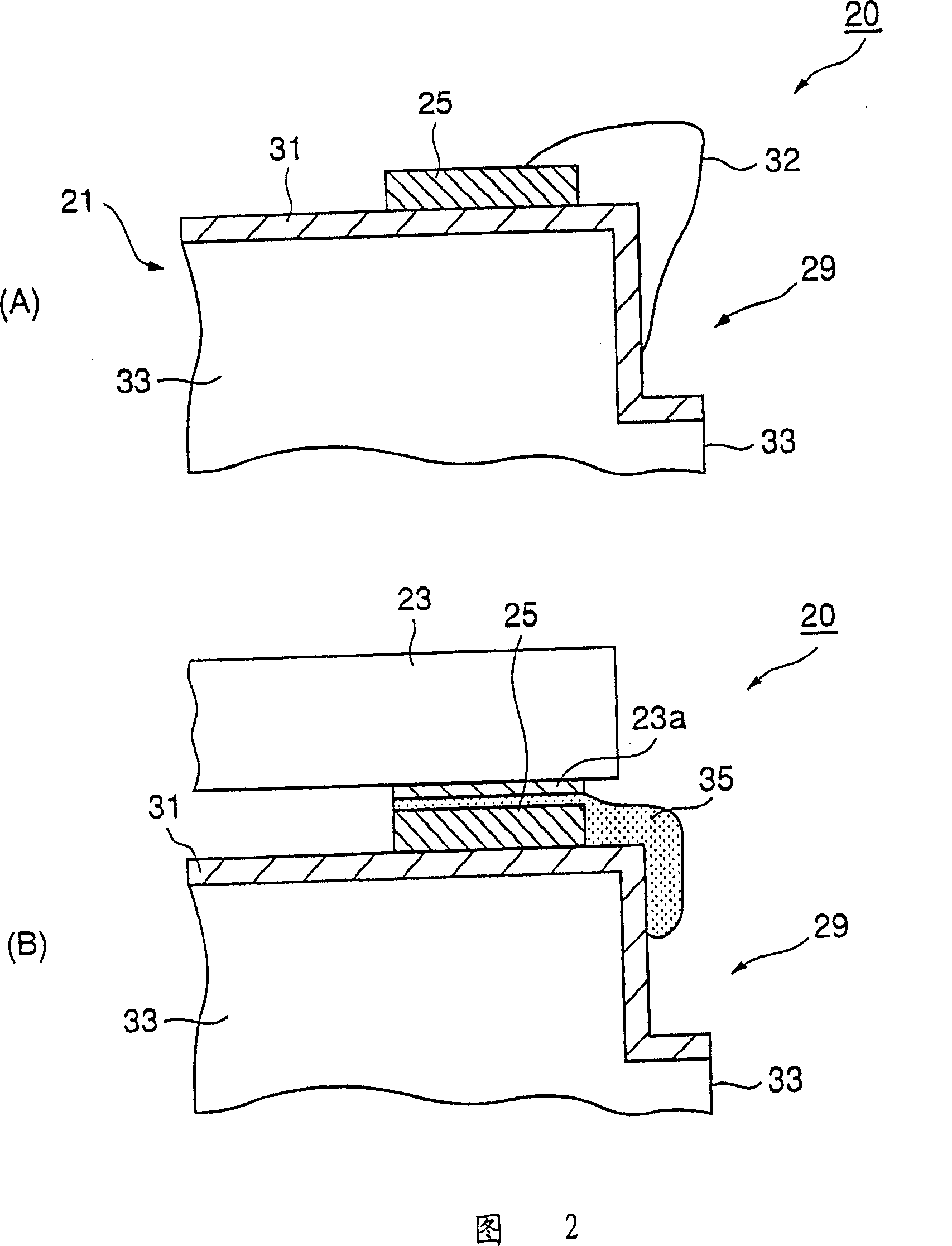

[0092] A step 29 recessed from the surface to the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com