Electrostatic chuck for accelerating wafer etching uniformity

An electrostatic chuck and uniform technology, applied in the field of microelectronics, can solve the problems of affecting the heat conduction of the electrostatic chuck to the edge of the wafer, affecting the etching rate of the plasma to the wafer, difficult to control the temperature of the edge of the wafer, etc. Controllable and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

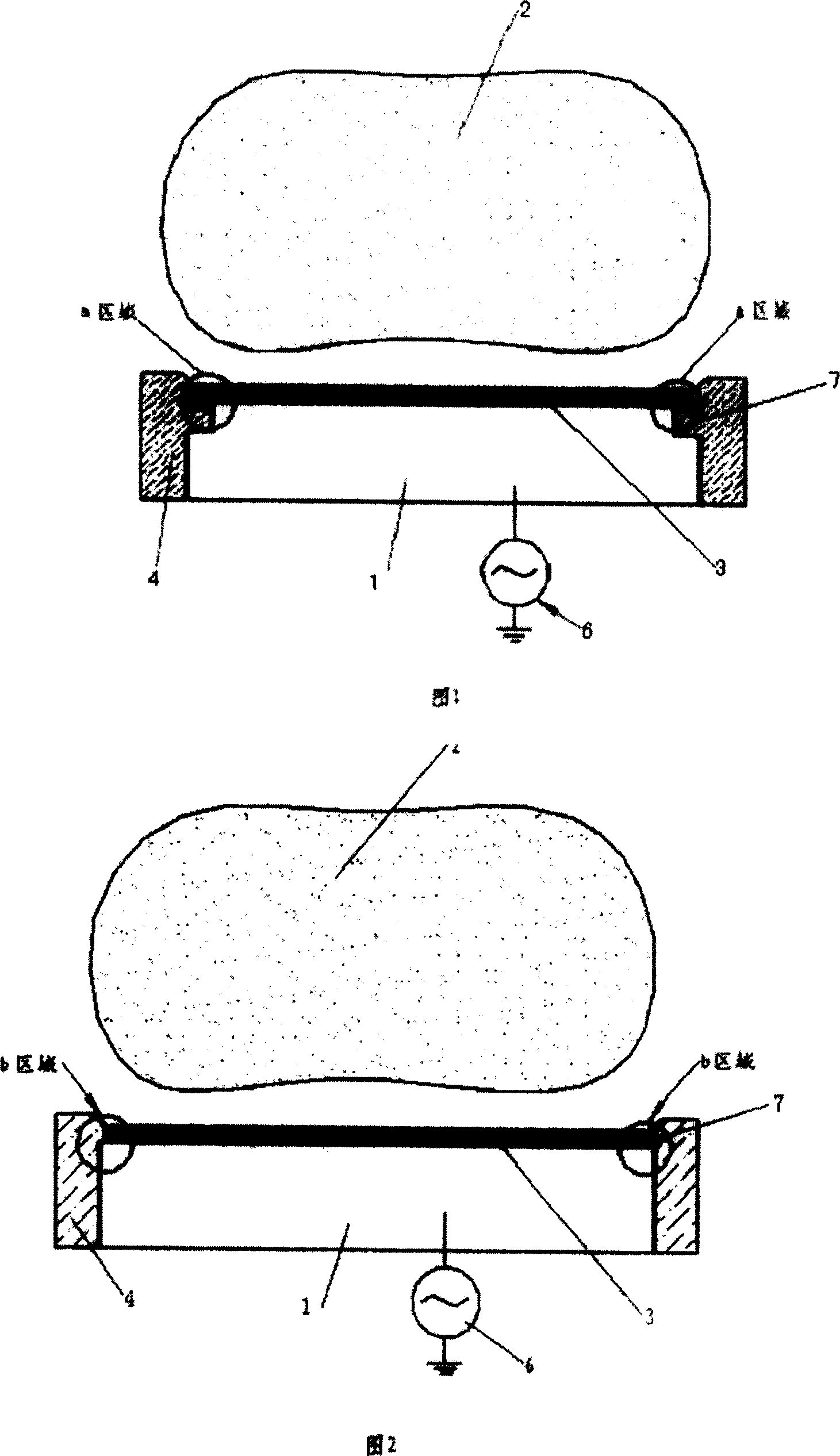

[0023] The specific implementation of the electrostatic chuck for promoting uniform wafer etching of the present invention will be further described in detail below in conjunction with the accompanying drawings, but it is not used to limit the protection scope of the present invention.

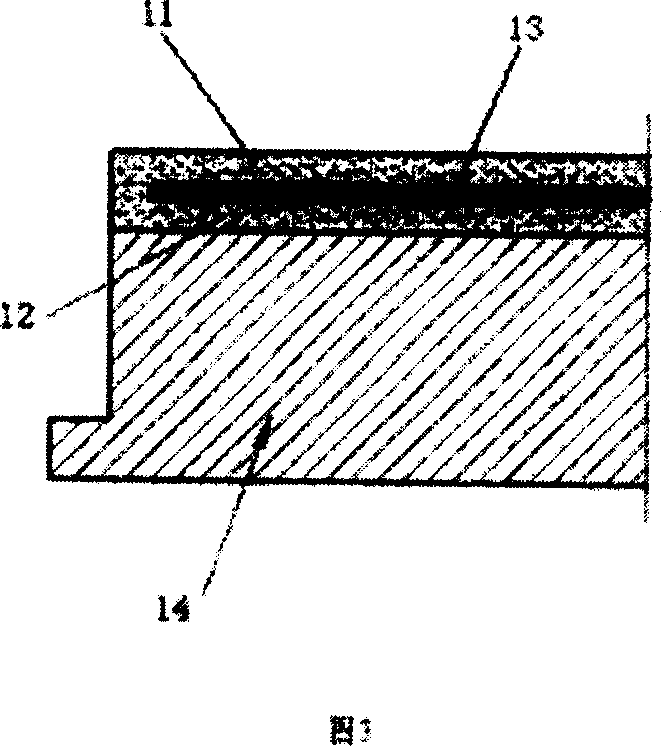

[0024] See Figure 2. The electrostatic chuck for promoting uniform wafer etching of the present invention includes an electrostatic chuck 1 and a focus ring 4 fitted on the outer circumference of the electrostatic chuck 1 , and a convex ring 7 integrated with the focus ring 4 is provided. Wherein the electrostatic chuck 1 has no boss on it, it is a plane, and the diameter of its upper surface is 2 mm larger than the diameter of the wafer 3 to be etched, and the range is 0.5-5 mm. Both are feasible; the lower surface of the protruding ring 7 cooperates with the upper surface of the electrostatic chuck 1 to protect the exposed part of the electrostatic chuck. In the present invention, a plurali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com