Submerged solid fermentation method of fungus fermentation lacquer producing enzyme and its device

A solid fermentation device and solid fermentation technology, applied in the direction of fungi, oxidoreductase, etc., can solve the problems of unfavorable growth of microorganisms, reduce the use volume of fermenters, etc., and achieve the effects of improving gas exchange efficiency, saving equipment costs, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

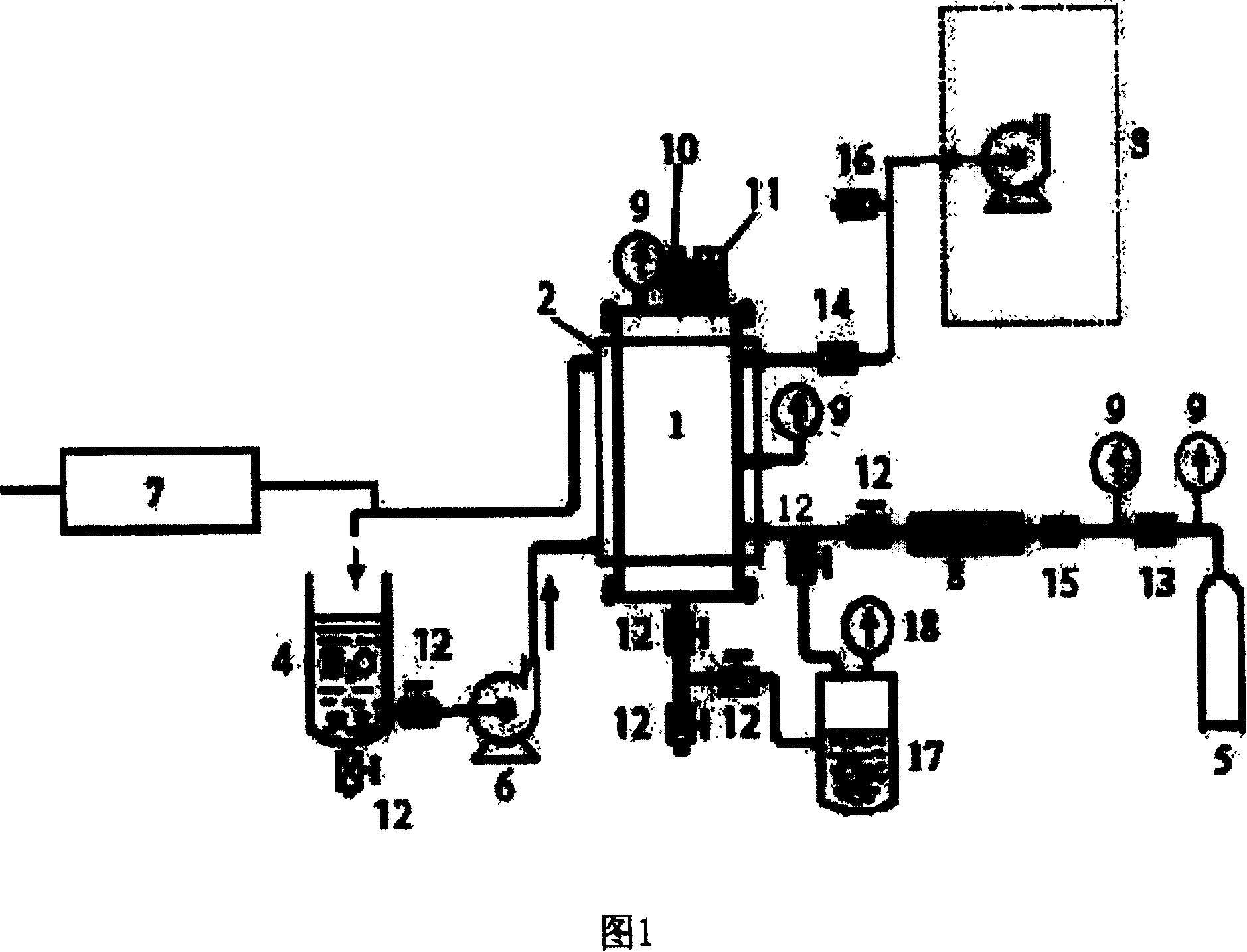

[0027] As shown in Figure 1, the submerged solid fermentation device for producing laccase by fungus fermentation includes a fermenter 1, a vacuum pump 3, an oxygen cylinder 5, a steam generator 17, and a control system. The fermenter 1 is a constant temperature tank with a volume of 0.020 to 1.0 m 3 , its upper part is connected with the vacuum pump 3, its lower part is connected with the oxygen cylinder 5 and the steam generator 17 respectively, and the control system is connected with the fermenter 1, the vacuum pump 3 and the oxygen cylinder 5 respectively.

[0028] The vacuum pump 3 is connected to the upper part of the fermentation tank 1 through the relief solenoid valve 16 and the exhaust solenoid valve 14, and the oxygen cylinder 5 is connected to the bottom of the fermentation tank 1 through the pressure reducing valve 13, the inflation solenoid valve 15, and the gas filter 8 in turn, and the relief solenoid valve 16 , suction solenoid valve 14, and inflation solenoi...

Embodiment 2

[0035] The submerged solid fermentation method of producing laccase by fungus fermentation, the steps are:

[0036] (1) Pick 5 slices of mycelium pieces with a diameter of 1cm from the plate culture fungal strains (Gerium in white rot fungus), and insert them into 100 ml of synthetic liquid medium (add inorganic salts to 1 liter of potato juice). salt, 5 grams of potassium dihydrogen phosphate, 0.5 grams of magnesium sulfate, and 1 gram of calcium chloride), after 5 days of shaking culture at 28 ° C, transfer to a synthetic liquid medium filled with 1000 ml, and shake it for 3 days to obtain bacterial species liquid, i.e. the mycelia liquid used for expanding the inoculation;

[0037] (2) Put the wheat straw into the fermentation tank, generate steam through the steam generator and pass it into the fermentation tank, the steam pressure is 1.0kg / cm 2 , the time is 40min to sterilize the inside of the fermenter and the wheat straw;

[0038] (3) Take out the sterilized wheat st...

Embodiment 3

[0042] The submerged solid fermentation method of producing laccase by fungus fermentation, the steps are:

[0043] (1) Pick 5 slices of mycelium blocks with a diameter of 1em from the plate culture fungal strains (Germia in white rot fungi), and insert 100 ml of synthetic liquid medium (in 1 liter of potato juice, add inorganic salt, 5 grams of potassium dihydrogen phosphate, 0.5 grams of magnesium sulfate, and 1 gram of calcium chloride), and after 5 days of shaking culture at 28 ° C, transfer to a synthetic liquid medium containing 1000 ml, and then shake it for 3 days to obtain strains liquid, i.e. the mycelia liquid used for expanding the inoculation;

[0044] (2) Put the straw into the fermentation tank, generate steam through the steam generator and pass it into the fermentation tank, the steam pressure is 1.0kg / cm 2 , the time is 40min to sterilize the inside of the fermenter and the straw;

[0045] (3) Take out the sterilized straw from the fermenter, and mix the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com