Frequency conversion grating rosette production method

A technology of grating strain and manufacturing method, which is applied in the field of optics and can solve problems such as the inability to realize grating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

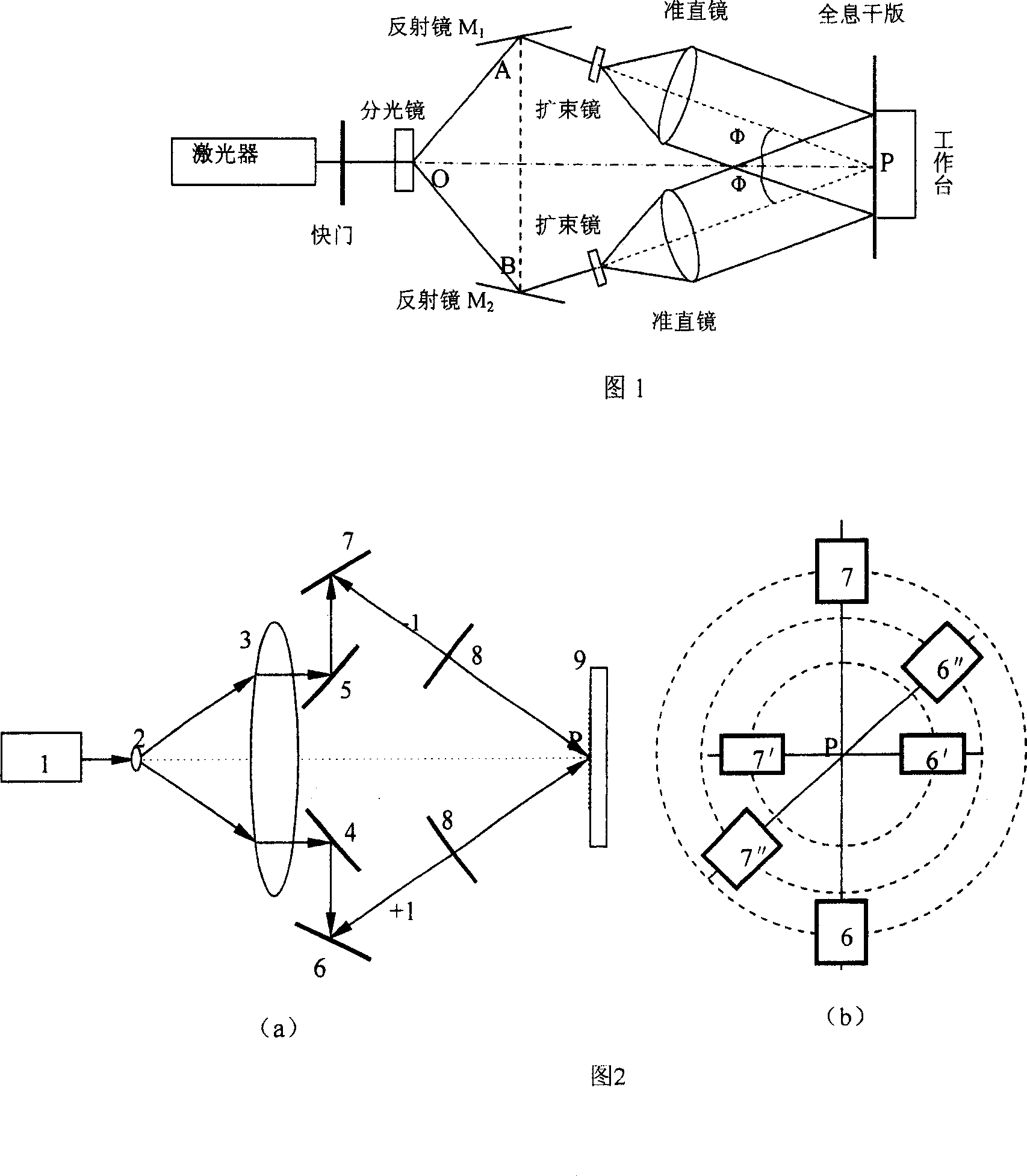

[0018] As shown in Figure 1, each device in Figure 1 is described as follows:

[0019] Laser: wavelength 633×10 -9 m, power 40mW, is a coherent light source;

[0020] Shutter: Control the exposure time;

[0021] Beam splitter: Divide the laser light emitted by the laser into two beams of equal intensity;

[0022] Mirror M 1 , M 2 : change the direction of light propagation;

[0023] Beam expander: 40×, to expand the laser light of the point source and become a spherical wave propagation;

[0024] Spatial filter: 15μm, to filter out the noise existing in the expanded laser;

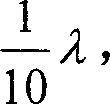

[0025] Collimating mirror: diameter 200mm, phase difference less than 1 10 λ , Collimate the spherical wave from the beam expander to obtain a uniform plane wave front;

[0026] Holographic dry plate: record interference fringes;

[0027] Workbench: Fix the holographic dry plate and change the exposure direction of the holographic dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com