Automatic gear shifting and lubricating device for wheel and axle loading test table

A technology of loading test and automatic shifting, which is applied in transmission control, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of inability to operate the gearbox and the accident of gearbox tooth burning, so as to facilitate data processing. and analysis, reduce labor intensity, and ensure the effect of equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

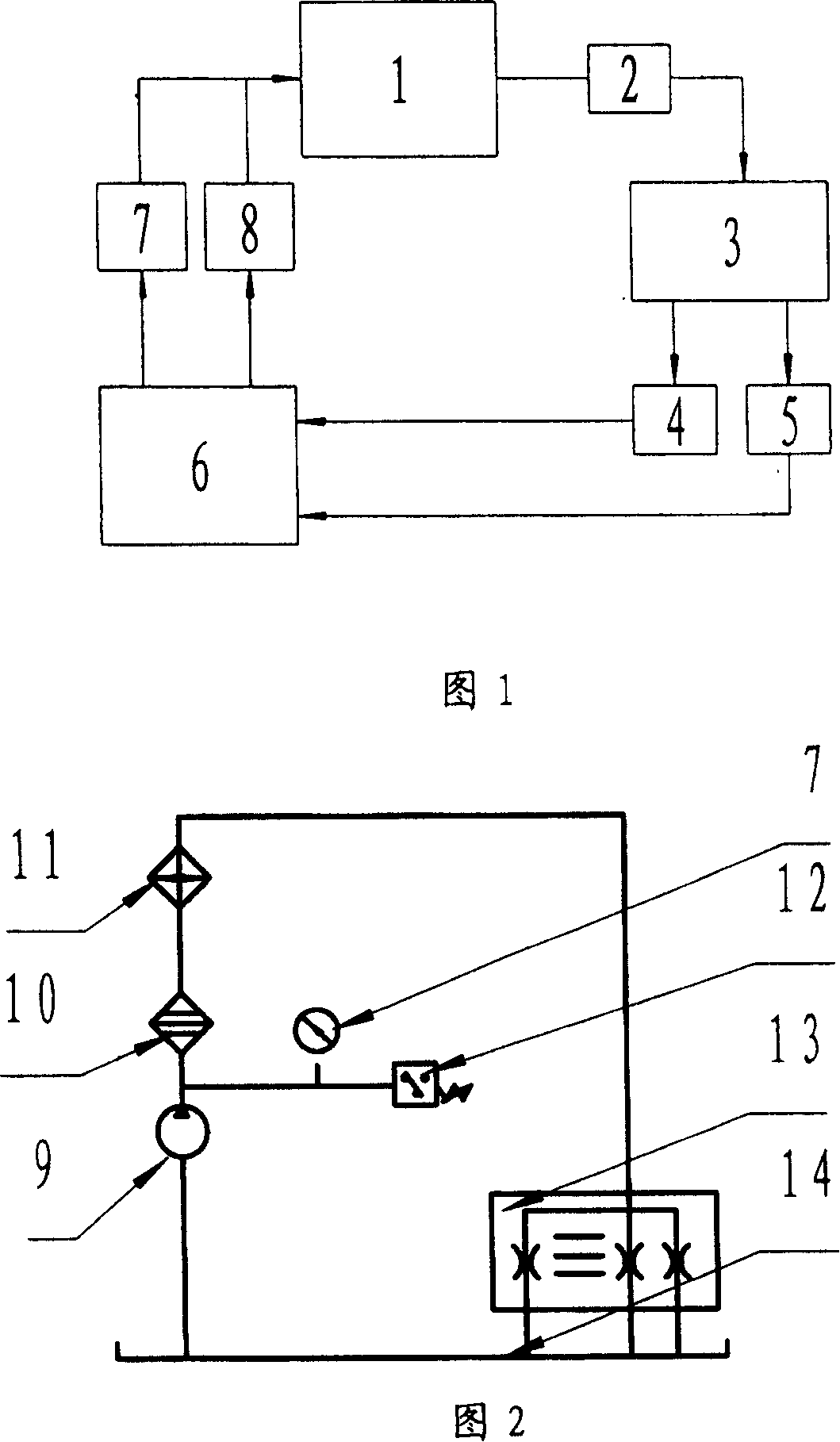

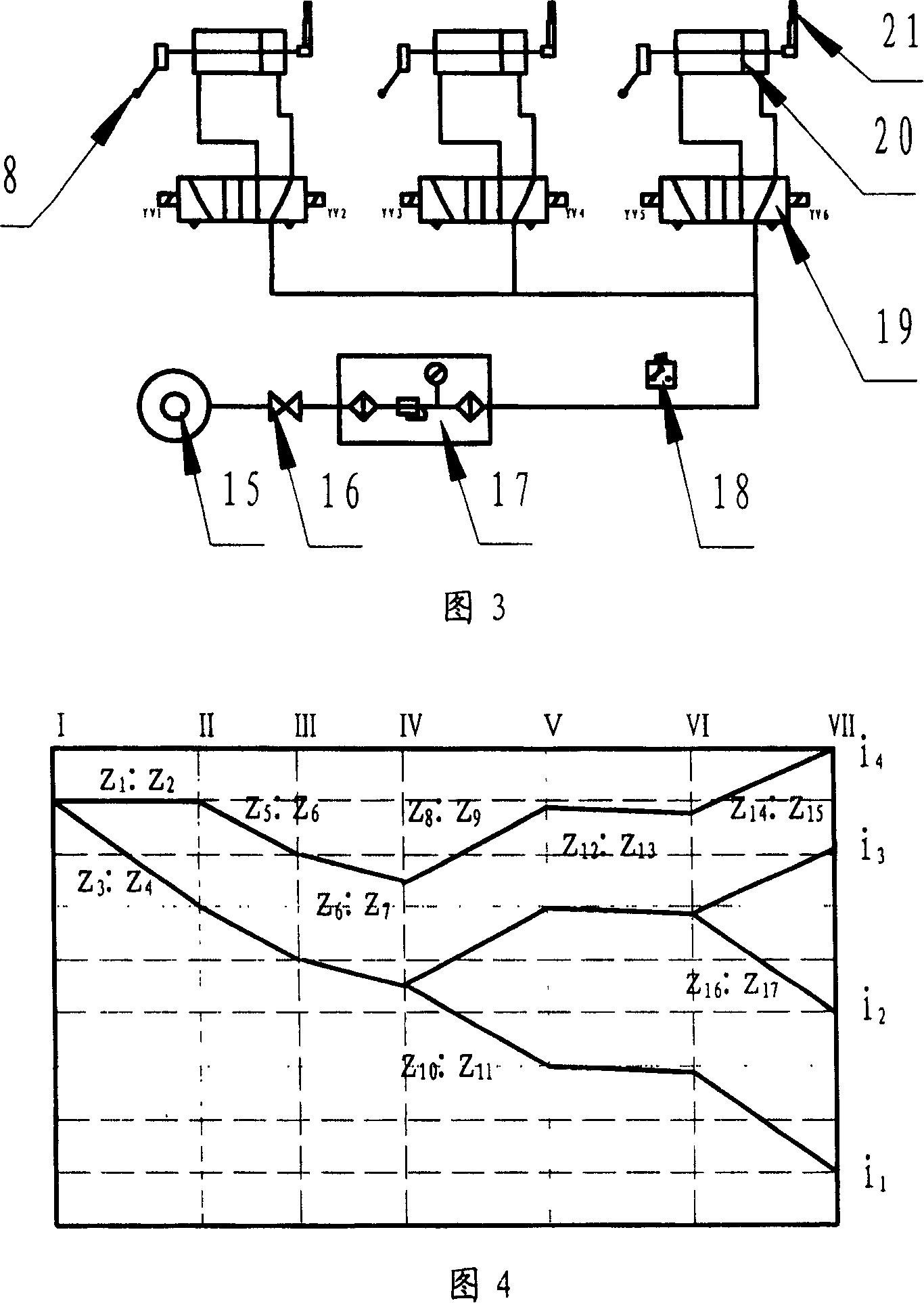

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] Combined with Figure 1, the automatic shifting and lubrication device of the wheel and axle loading test bench consists of task management unit 1, RS485 communication card 2, lubrication and gear management unit 3, lubrication and cooling system 4, pneumatic shift mechanism 5, and gear box 6 , Pressure sensor 7, travel switch 8 form. Its working process is: the task management unit 1 is a program running on a microcomputer, and the computer transmits the processed operation instructions to the lubrication and gear management unit 3 through the RS485 communication card 2, and the lubrication and gear management unit 3 runs on the The program on the programmable logic controller (PLC), the lubrication and gear management unit 3 receives and processes the operation command, drives the corresponding contactor, starts / stops the lubrication cooling system 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com