Process meter

A technology for process measurement and measuring instruments, which is applied in the direction of measuring capacity, measuring devices, specific gravity measurement, etc., and can solve problems such as increased installation and wiring costs, increased manufacturing costs, and increased probability of sensor failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

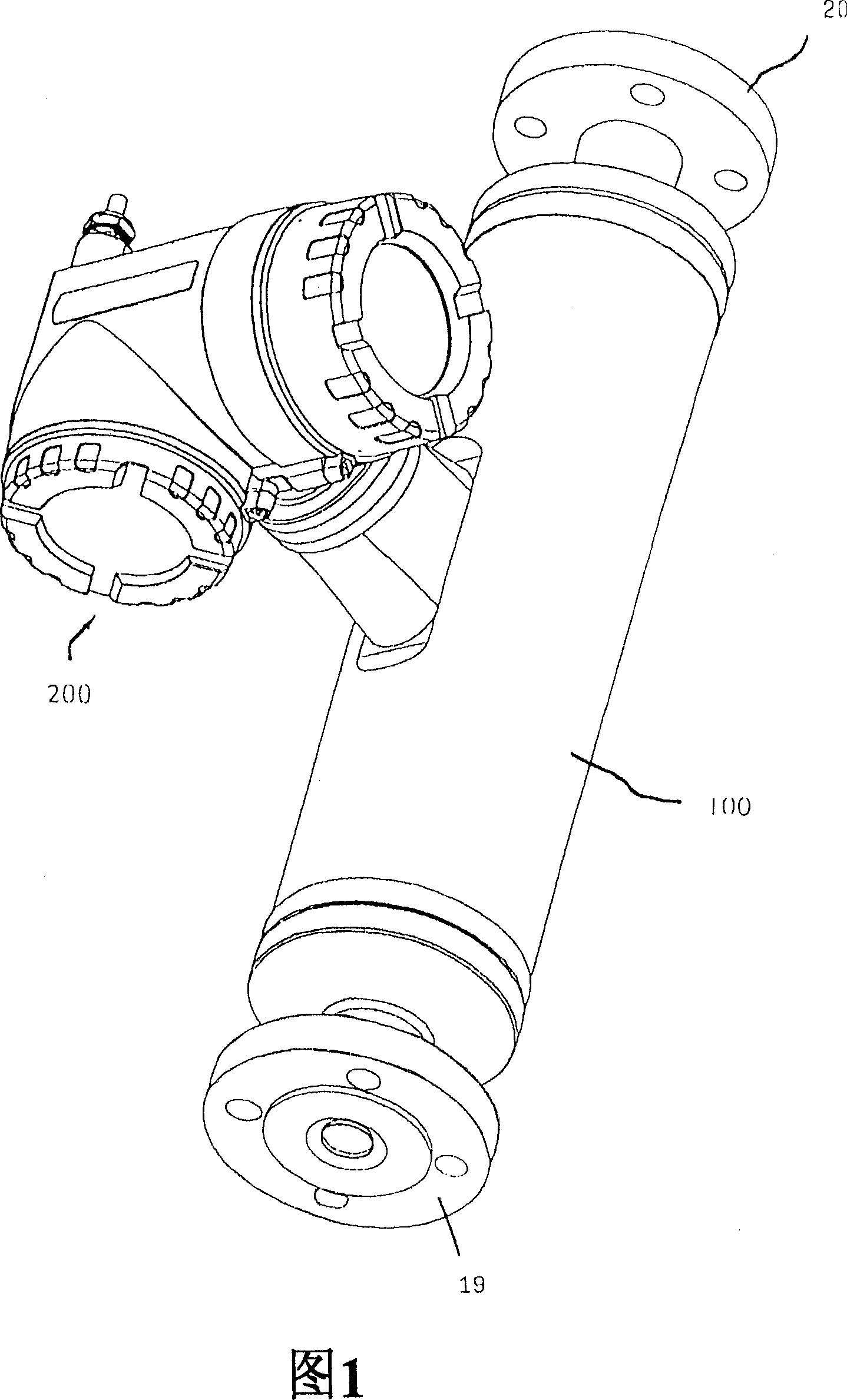

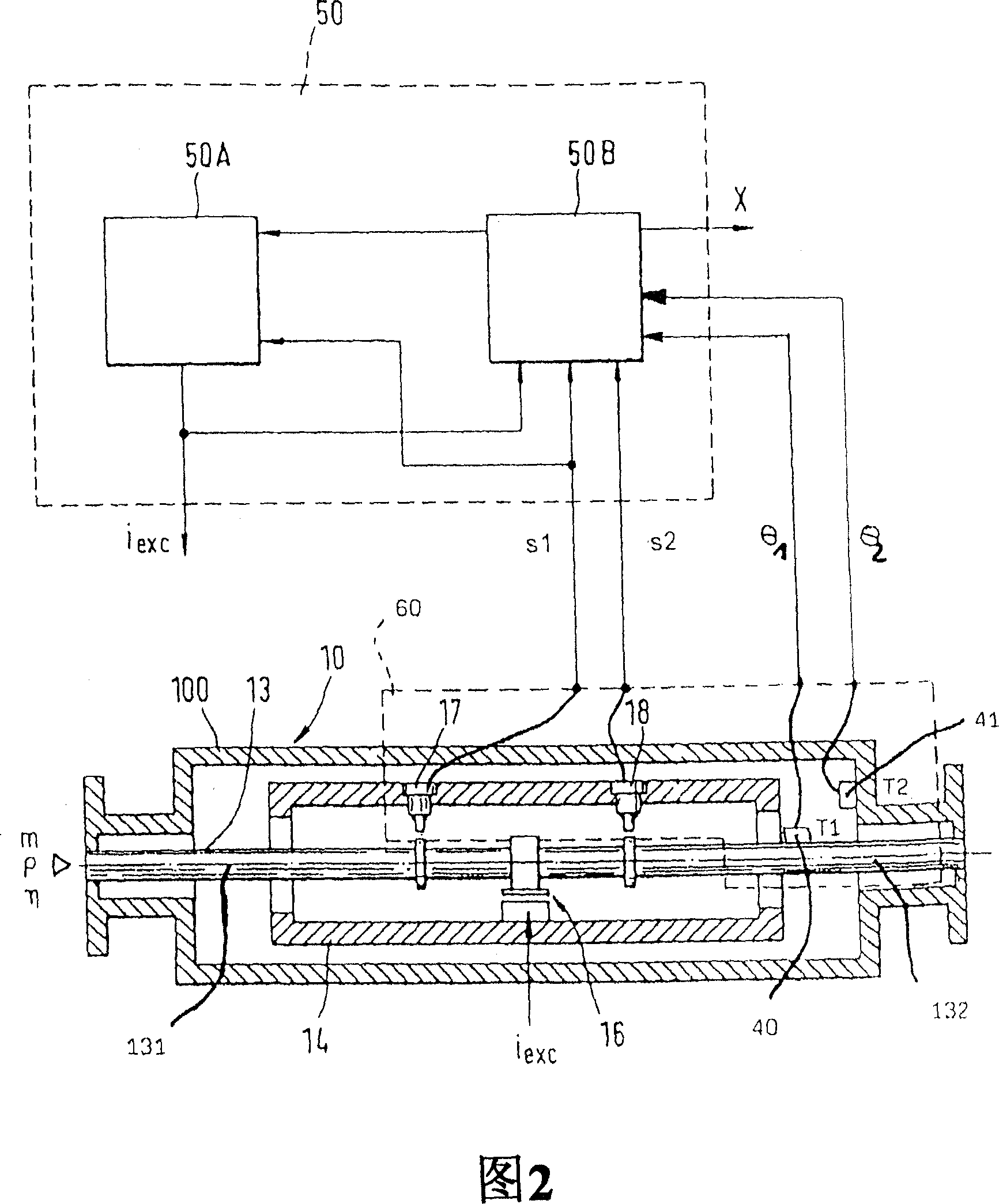

[0071] In FIGS. 1 and 2 , an embodiment of a process measuring instrument, such as a Coriolis flow meter, a density meter and / or a viscometer 1 , is shown comprising a vibratory transducer preferably housed within a transducer housing 100 10, and the electronic device housing 200, the electronic device housing 200 accommodates the measuring instrument electronic device 50 electrically connected with the converter 10.

[0072] The process measuring instrument 1 is used to detect a process quantity of a fluid flowing in a pipeline, such as mass flow, density and / or viscosity, and to map this process quantity to a measured value signal currently representing it; the pipeline is not shown for clarity.

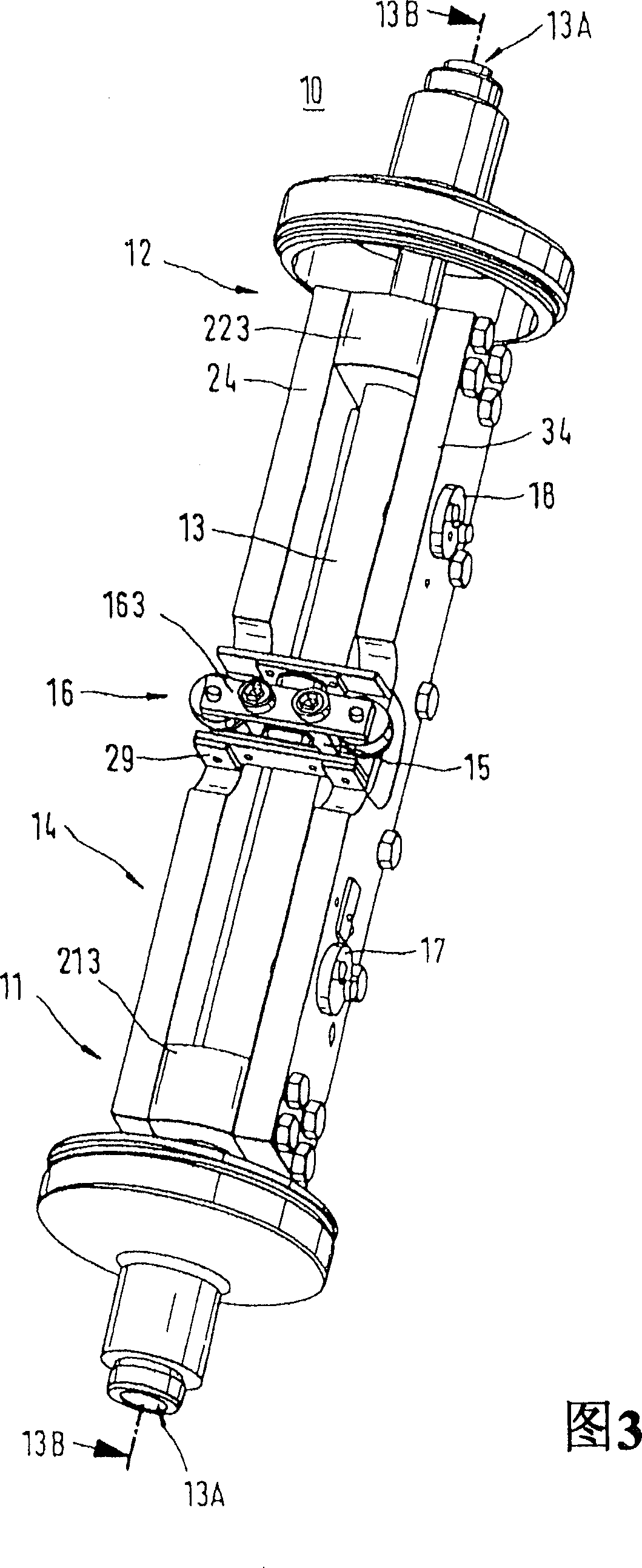

[0073] In order to guide the fluid, the transducer 10 comprises a measuring tube 13 which, in operation, preferably vibrates in a bending mode such that reaction forces of sufficient strength are generated in the fluid flowing therein, such as Coriolis forces, acceleration forces an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com