Composite portland cement produced by full utilization of industrial waste slag

A composite Portland and Portland cement technology, which is applied in cement production, clinker production, etc., can solve the problems of not using industrial waste residue, etc., and achieve the effects of reducing fCaO content, improving clinker quality, and improving burnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

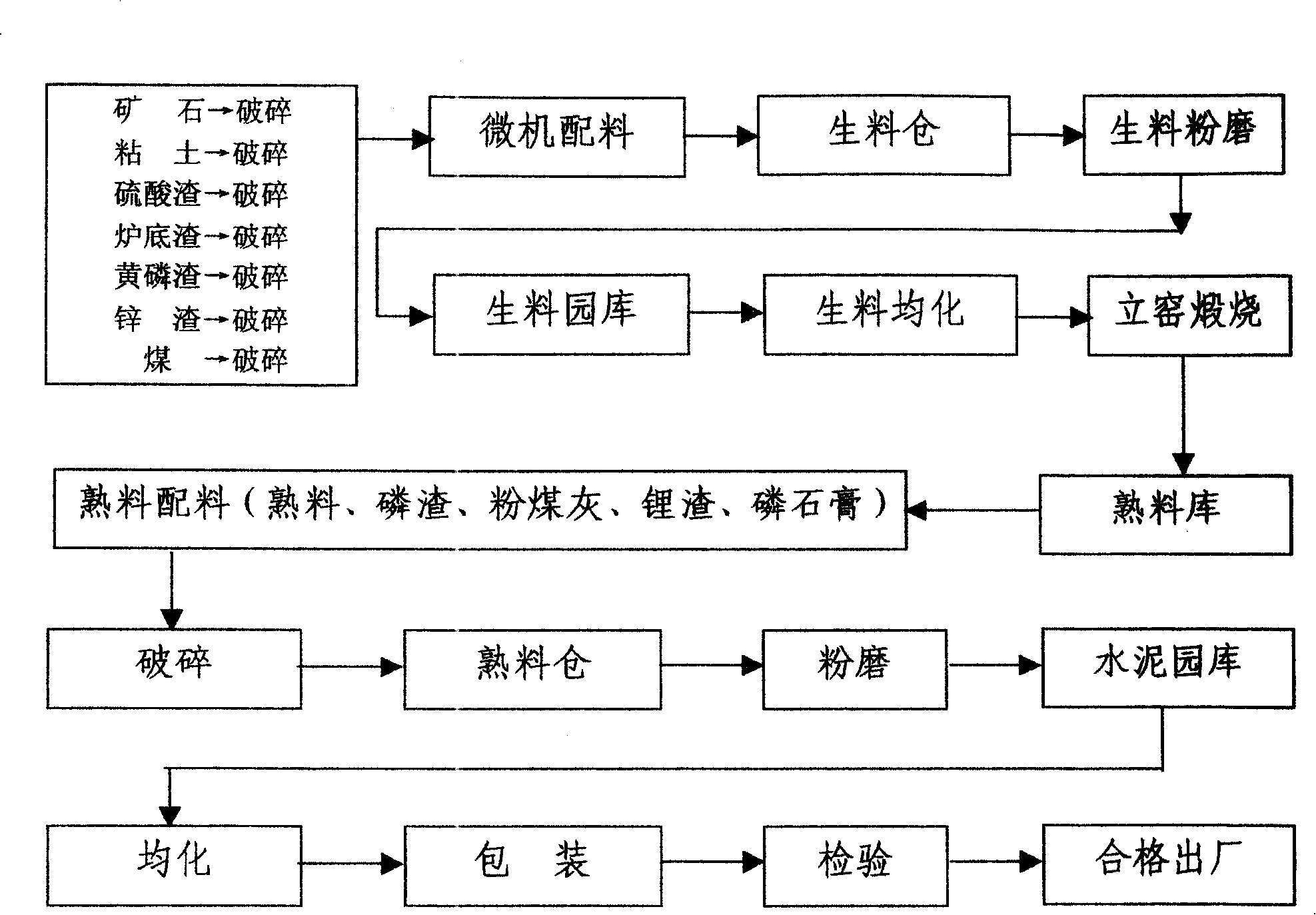

Method used

Image

Examples

Embodiment Construction

[0024] The chemical composition of the raw fuel material of the present invention is shown in Table 1.

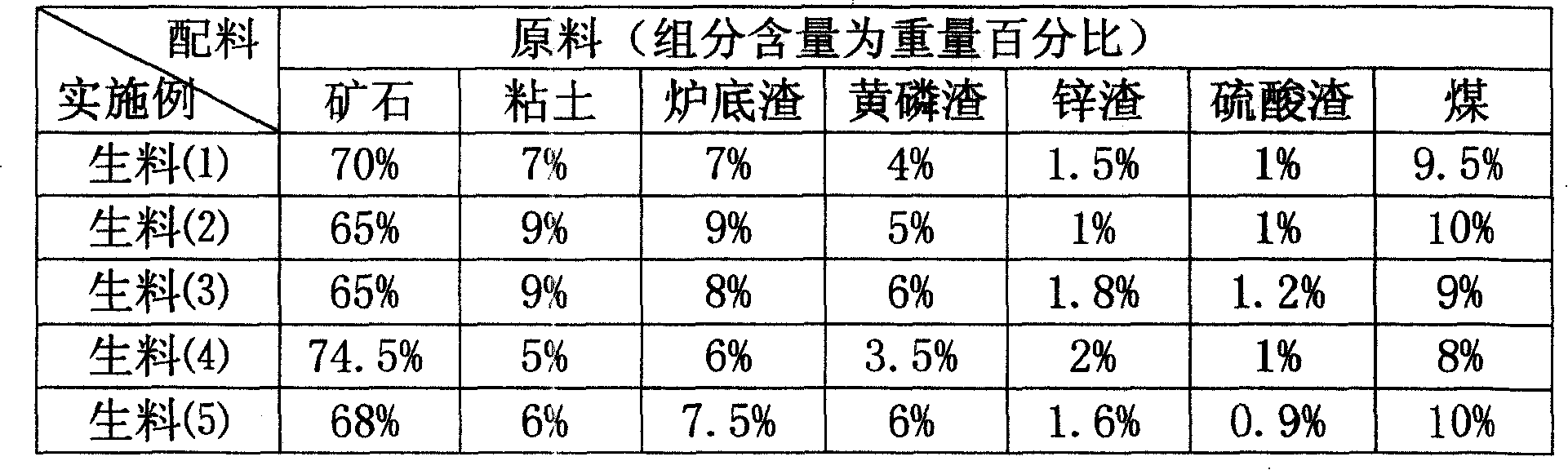

[0025] Raw meal ingredients of the present invention, see the embodiment (1)-(5) of following table two.

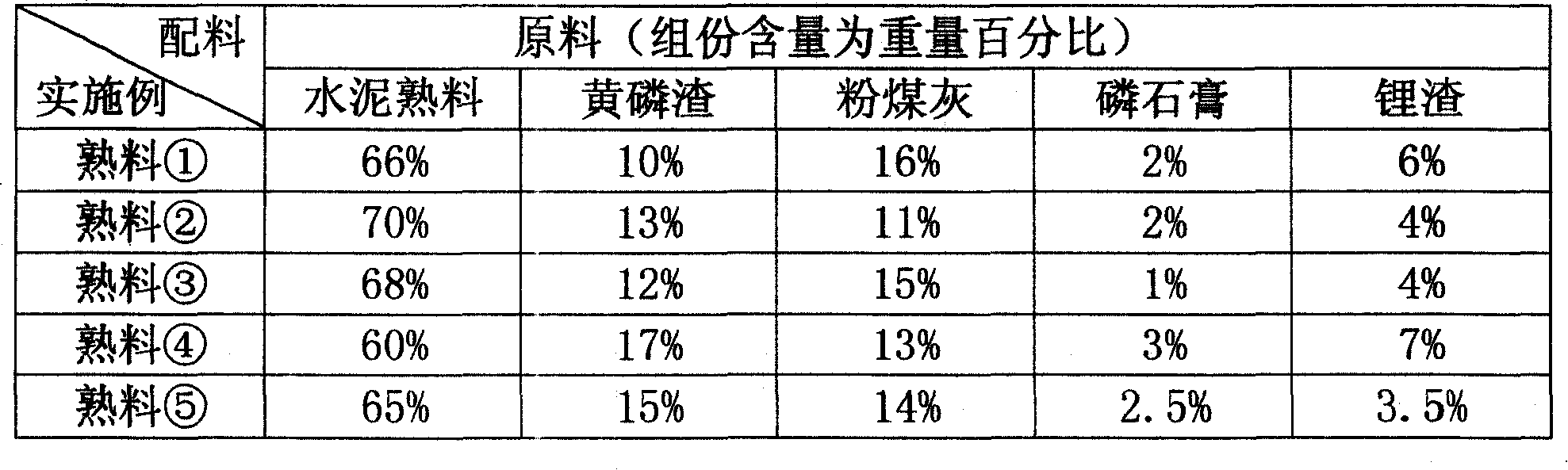

[0026] Clinker batching of the present invention, see the embodiment 1.-5. of following table three.

[0027] Table 1 Chemical Composition of Raw Materials

[0028] name

LOSS

SiO 2

al 2 o 3

Fe 2 o 3

CaO

MgO

SO 3

∑

ore

42.5

0.75

1.70

0.46

53.1

0.77

99.28

clay

9.7

57.60

12.20

4.60

9.50

2.90

96.50

Bottom slag

14.8

48.30

17.10

14.20

3.30

1.20

98.90

Yellow phosphorus slag

-0.20

40.98

4.70

0.43

48.94

1.09

95.94

7.70

39.10

7.30

20.1

14.6

3.4

92.2

Sulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com