Diaphragm-holding device for test

A technology of diaphragm and testing mechanism, which is applied in the direction of measuring device casing, electronic circuit testing, etc., can solve the problems of increased false detection rate, easy wear and tear of electrical connection film, and inability to fit tightly, so as to improve the false detection rate and save consumable consumption Cost, effect of improving noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

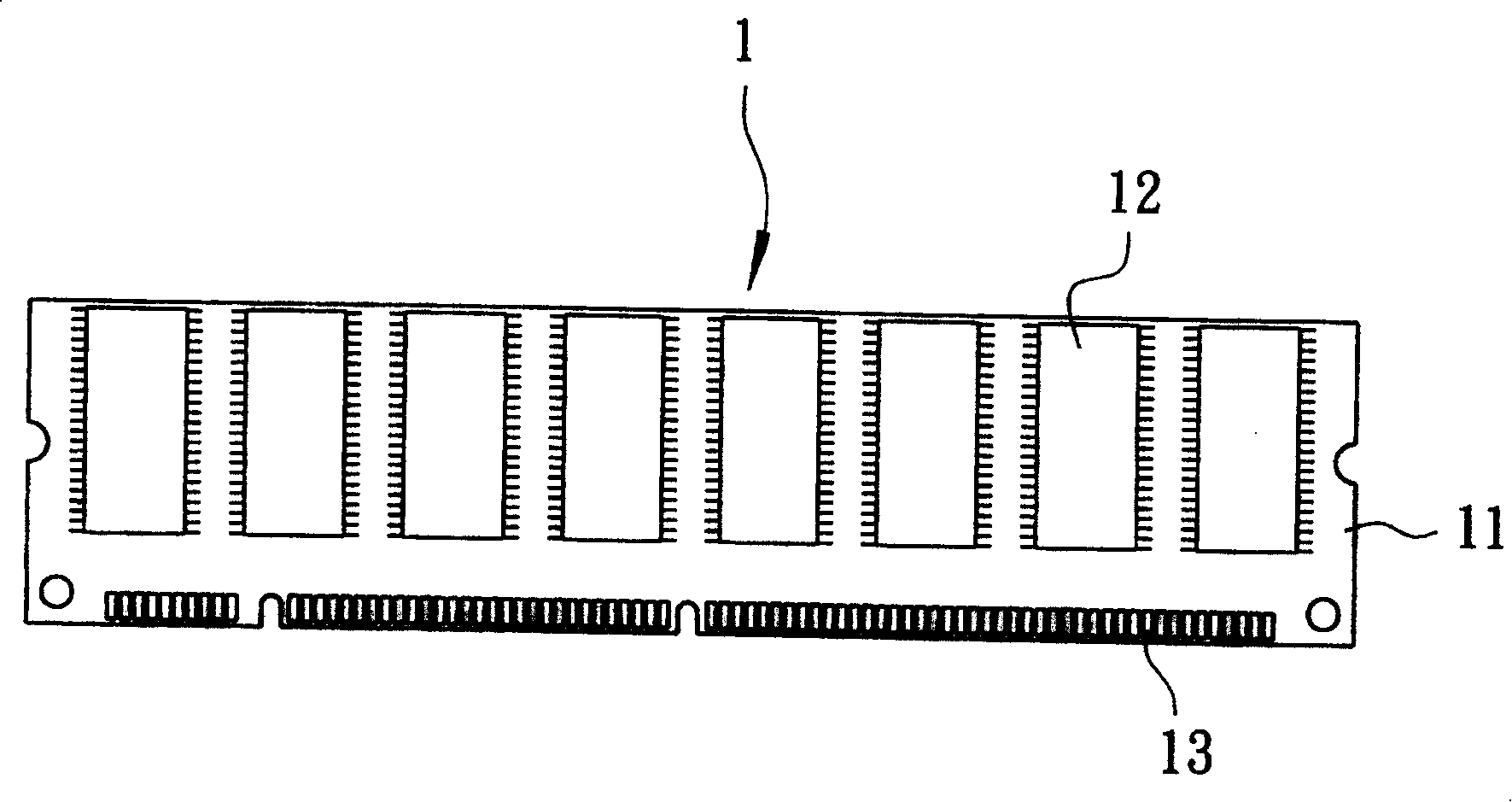

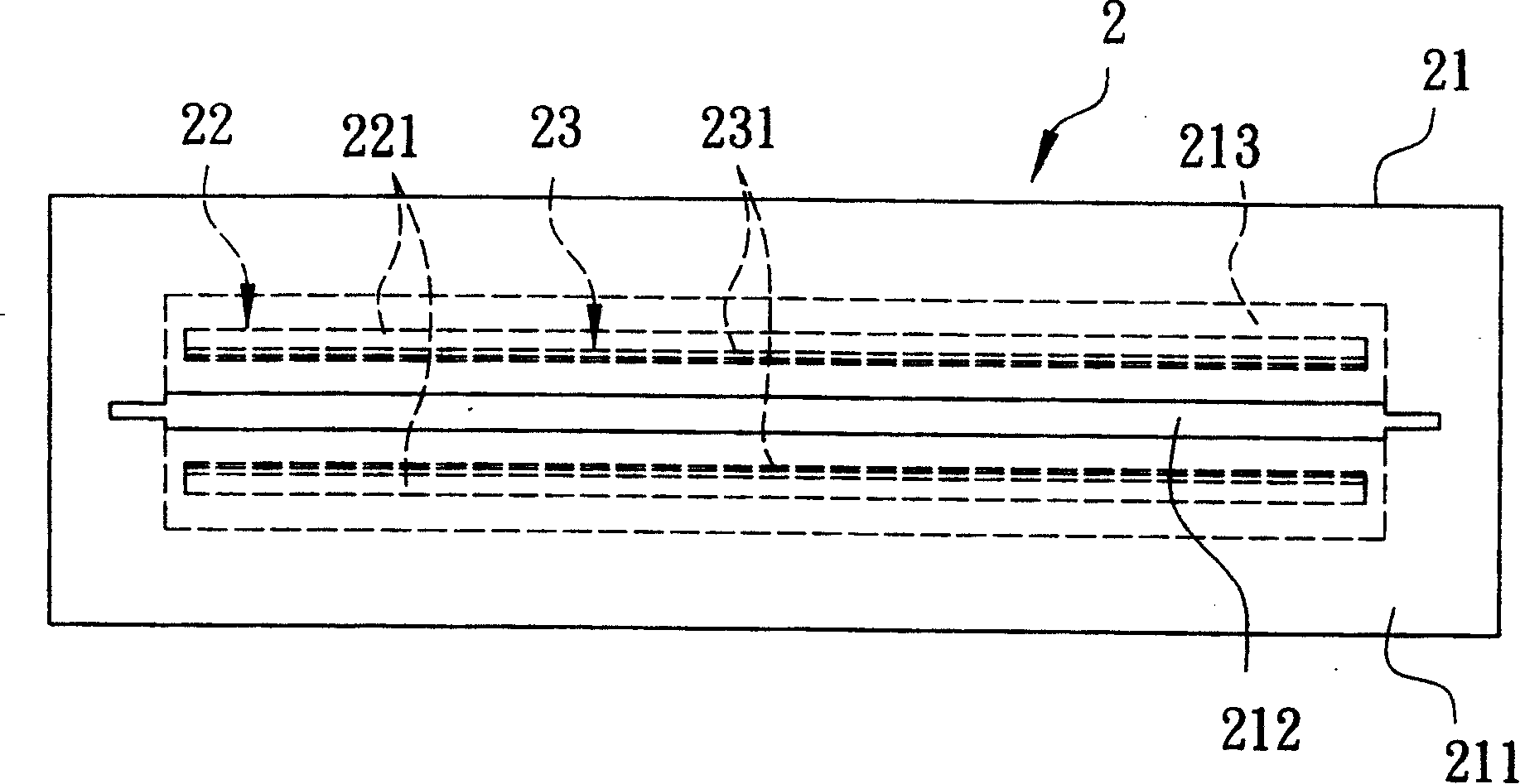

[0037] refer to Image 6 and Figure 7 , a first preferred embodiment of the present invention's testing membrane clamping device 3 is similar to the above-mentioned existing membrane clamping device 2, and is a replaceable holding device such as figure 1 The electronic module 1 shown in the figure further electrically connects the electronic module 1 to a testing mechanism 200 (shown only schematically in the figure) preset with testing software, so as to conduct an electrical test on the electronic module 1 .

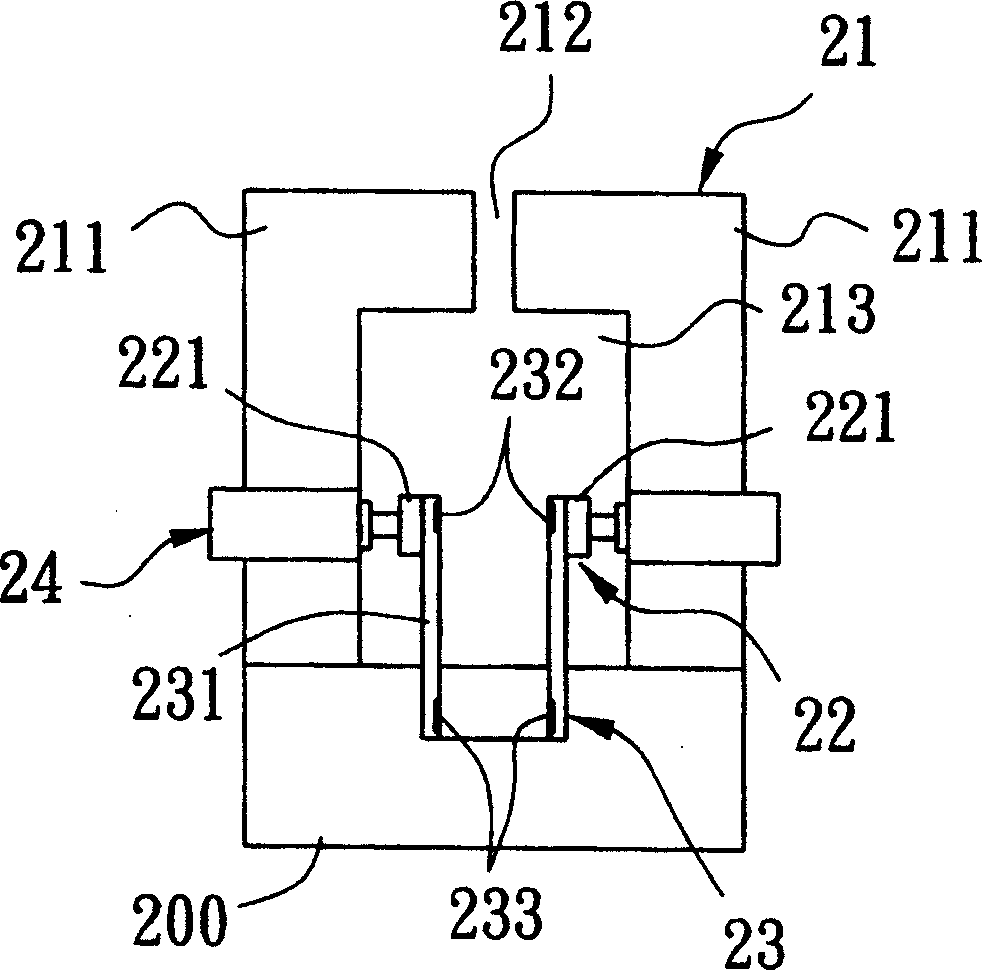

[0038] The test diaphragm clamping device 3 includes a fixing base 4 , a clamping piece 5 , an electrical connection unit 6 and an air control unit 7 .

[0039] The fixing base 4 has two opposite fixed pieces 41, the two fixed pieces 41 jointly define a slot 42, and an electrical connection sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com