Combined filter tube element pulse dust-collector

A technology of pulse dust collector and dust collector, which is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., and can solve the problems of large volume, filter bag wear, high steel consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

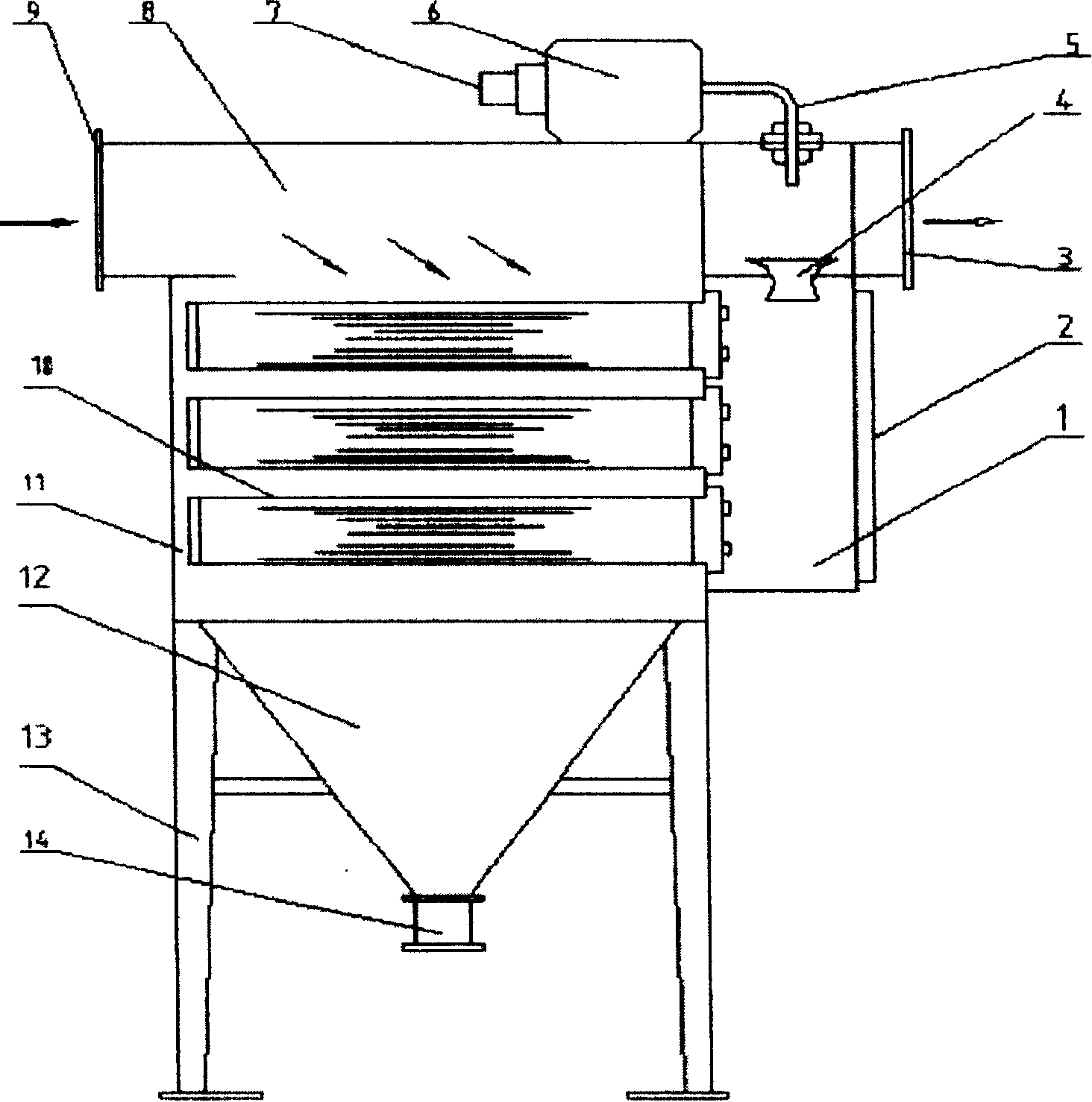

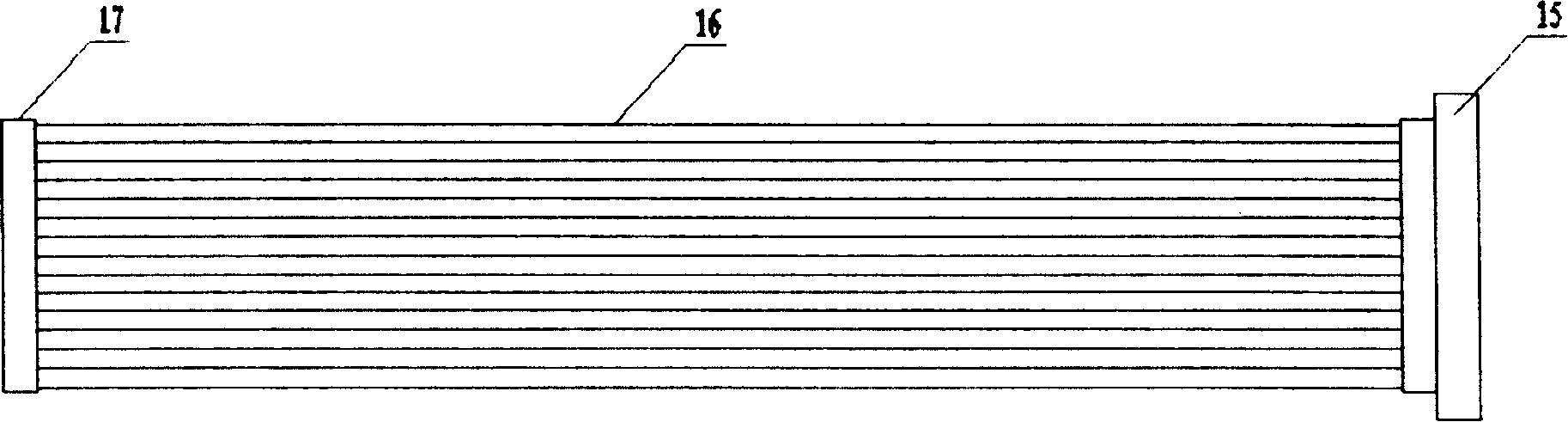

[0027] The structure of the combined filter tube element chamber pulse dust collector is as follows: figure 1 shown. In the figure: 1-clean air box, 2-manhole, 3-exit, 4-injection pipe, 5-reverse blow pipe, 6-air bag, 7-electromagnetic pulse valve, 8-flue, 9-inlet, 10 - filter unit, 11 - dust box, 12 - ash hopper, 13 - bracket, 14 - ash discharge valve. The inlet 9 of the dust collector communicates with the flue 8, and the main box communicated with it is set under the flue 8. Bag 6, air bag 6 is connected with blowback pipe 5, the dust collector is set on the bracket 13 as a whole, the main box is divided into dust gas box 11 and clean gas box 1, clean gas box 1 is connected with outlet 3, dust gas box 11 A plurality of filter units 10 that are convenient to be replaced are arranged inside, and the filter unit 10 is composed of a plurality of filter tubes 16; the connection between the clean air box 1 and the outlet 3 is provided with a trumpet-shaped inlet with a large op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com