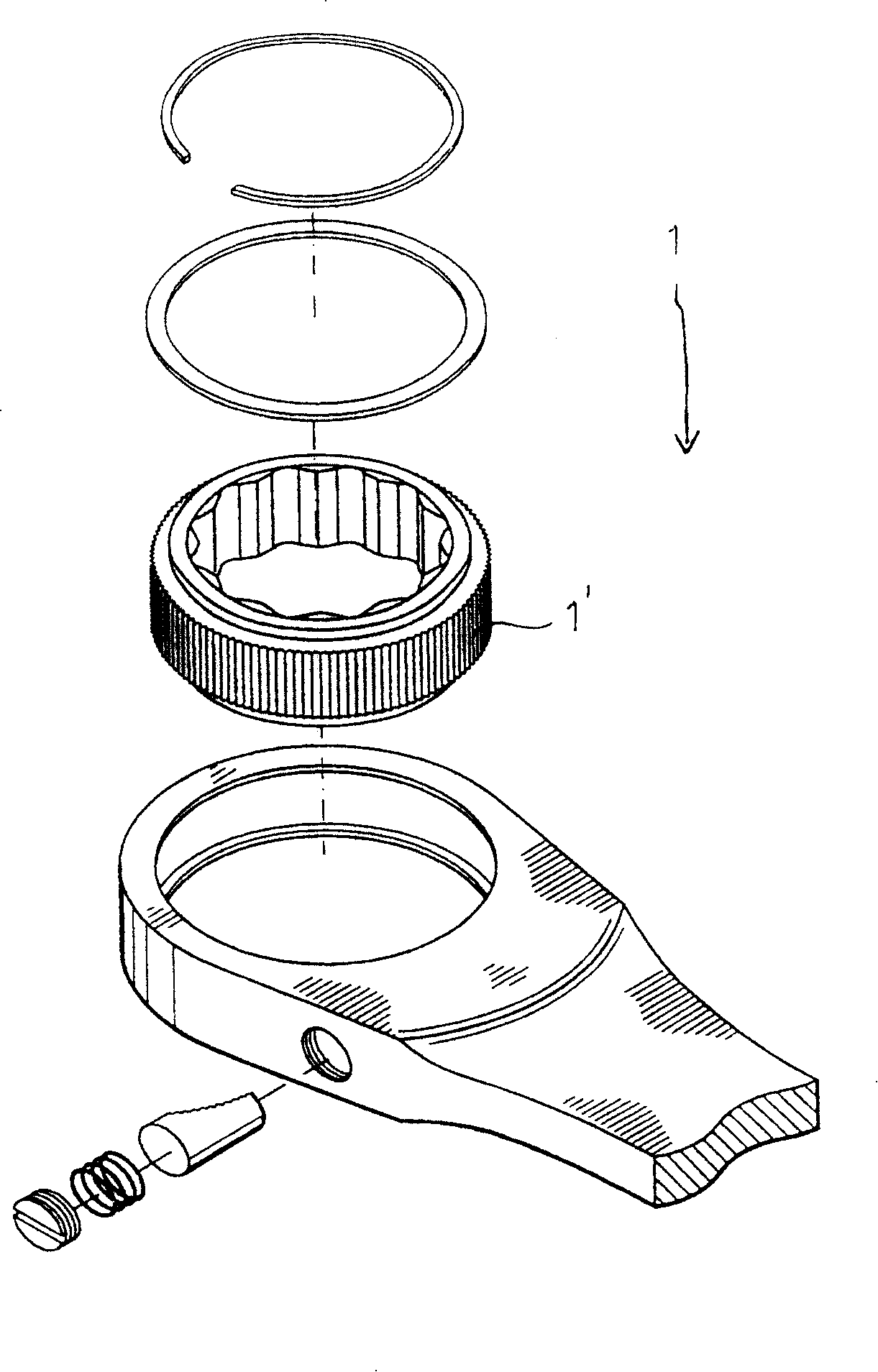

Manufucturing method of notch wheel having 90-180 teeth and notch wheel made by said method

A manufacturing method, ratchet technology, applied in the field of mechanical parts, can solve problems such as insufficient tooth depth, insufficient torque, slow speed, etc., and achieve the effect of simple and convenient manufacturing method and good meshing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific manufacturing method, features and effects according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

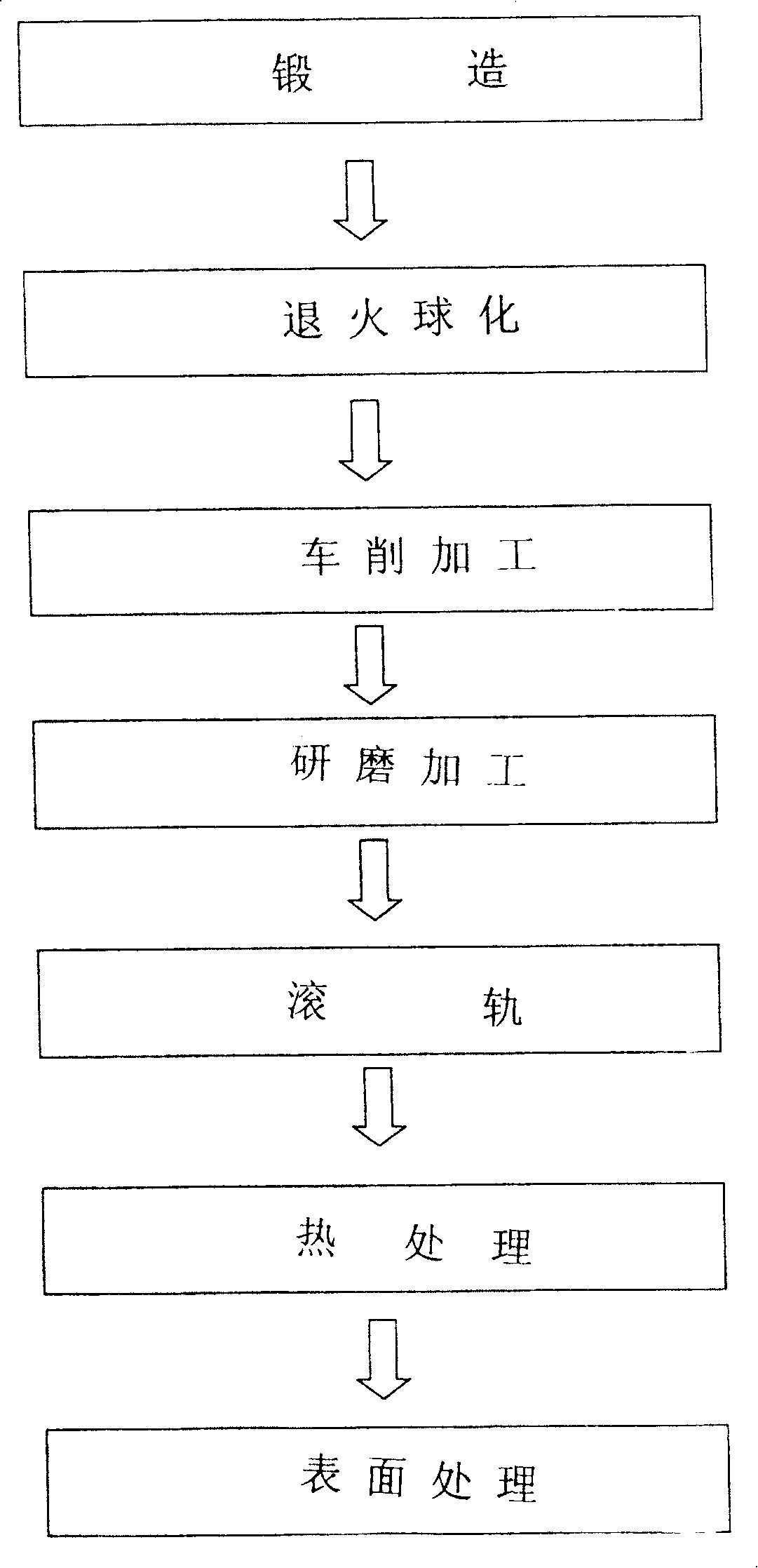

[0042] The present invention has a manufacturing method of 90 to 180 tooth ratchet, such as figure 2 As shown, it includes the following main steps:

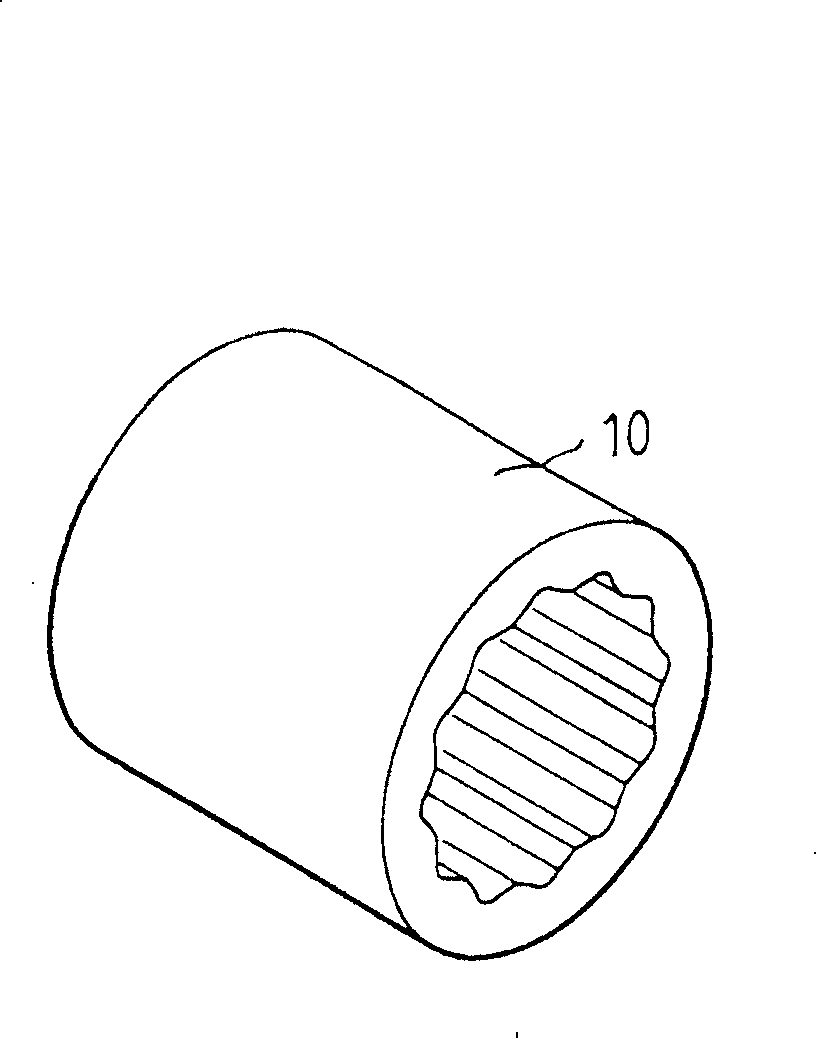

[0043] ① Forging, using forging technology to forge the rough body 10 of the ratchet, such as image 3 shown;

[0044] ②Annealing and spheroidizing, performing at least one annealing and spheroidizing treatment on the rough forged ratchet body to obtain a fine ratchet body. The purpose of this step is to eliminate the stress caused by forging and strengthen its structural stability;

[0045] ③Turning processing, the ratchet body fine embryo is subjected to fine turning processing to obtain the ratchet wheel body secondary fine embryo 12;

[0046] ④Grinding process, grinding the secondary fine blank of the ratchet body after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com