Block (co)polymer, block copolymer composition for asphalt modification, process for producing the same, and asphalt composition

A technology for block copolymer and asphalt modification, which is applied in the field of block (co)polymer, block copolymer composition for asphalt modification, its manufacture and asphalt composition, and can solve the increase of asphalt melt viscosity. , The block copolymer has reduced the solubility of asphalt, and has not been satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

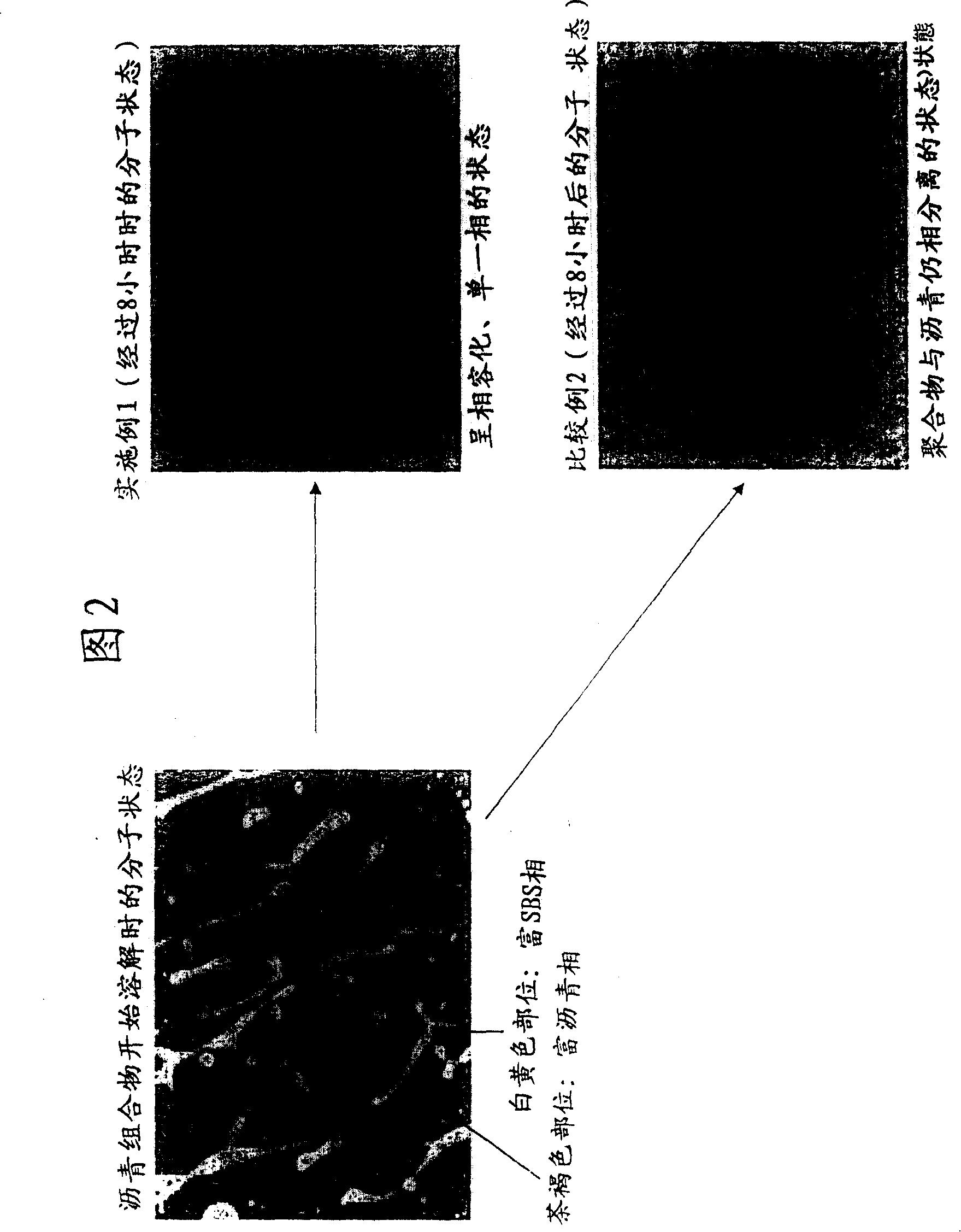

Examples

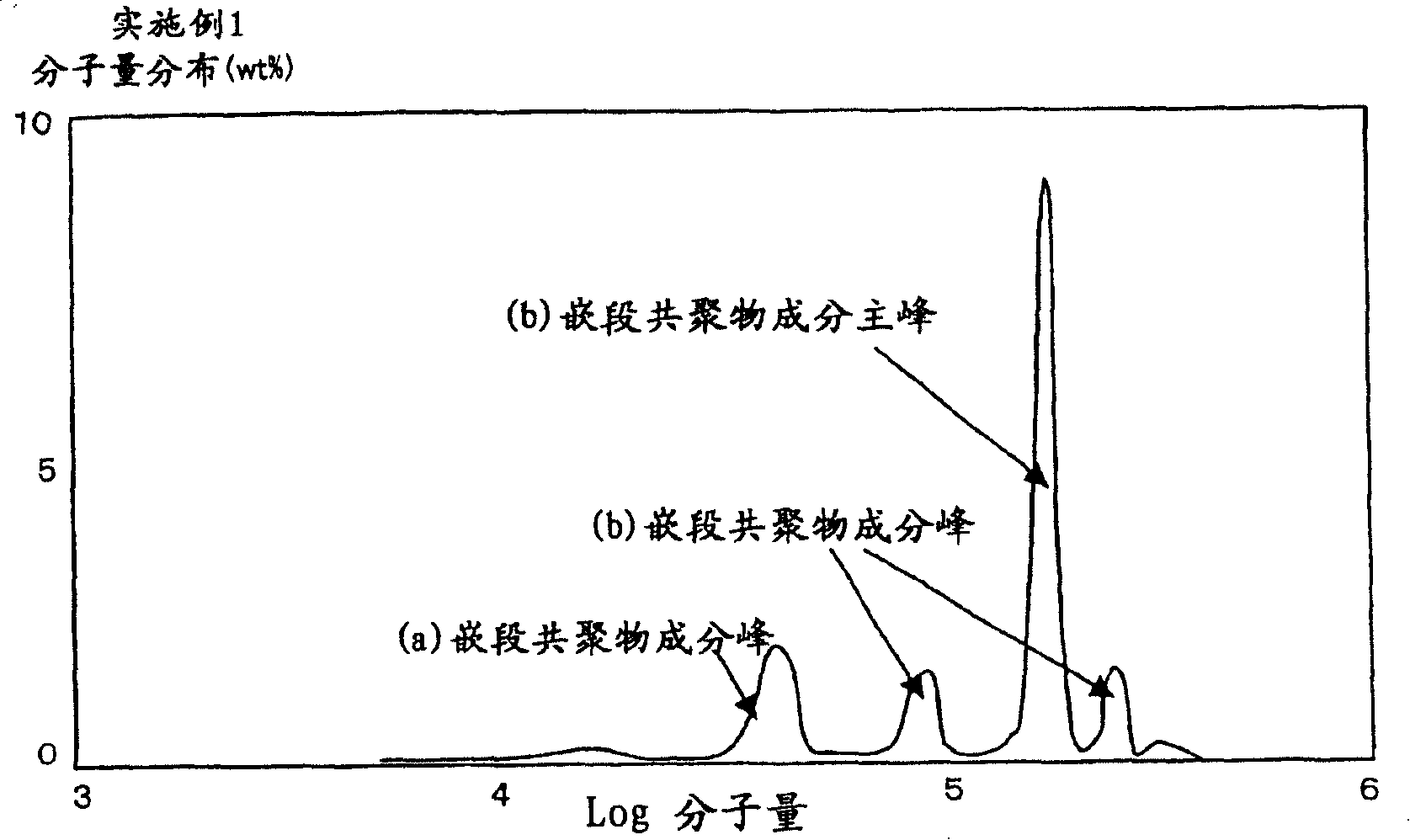

Embodiment 1

[0123] Manufacture of block copolymer compositions

[0124] (1) (a) Polymerization of block (co)polymers

[0125] A stainless steel polymerization vessel with an internal volume of 100 liters equipped with a jacket and a stirrer was fully replaced with nitrogen, 20 kg of cyclohexane and 0.6 kg of styrene were added, and warm water was passed through the jacket to bring the contents to 40°C.

[0126] Then, 6 g of sec-butyl lithium was added to start polymerization. After the styrene polymerization was completed, 1.4 kg of 1,3-butadiene was slowly added while adjusting the temperature so that the temperature of the contents became 80°C.

[0127] After the polymerization of the B block was completed, 3 ml of methanol was added, and after stirring for 10 minutes, the liquid was transferred to a mixing vessel.

[0128] (2) (b) Polymerization of block copolymers

[0129] In the same manner as (1), after fully replacing the stainless steel polymerization vessel with an internal vo...

Embodiment 2、5~7、13、15、16、18、20、23、24

[0138] In addition to changing the addition of styrene, 1,3-butadiene, and sec-butyllithium, other block copolymers represented in Tables 1 and 2, and block copolymers for asphalt modification were obtained in the same manner as in Example 1. composition, manufacture bituminous composition, and evaluate the performance of the composition. Tables 1 and 2 show the evaluation results of each property.

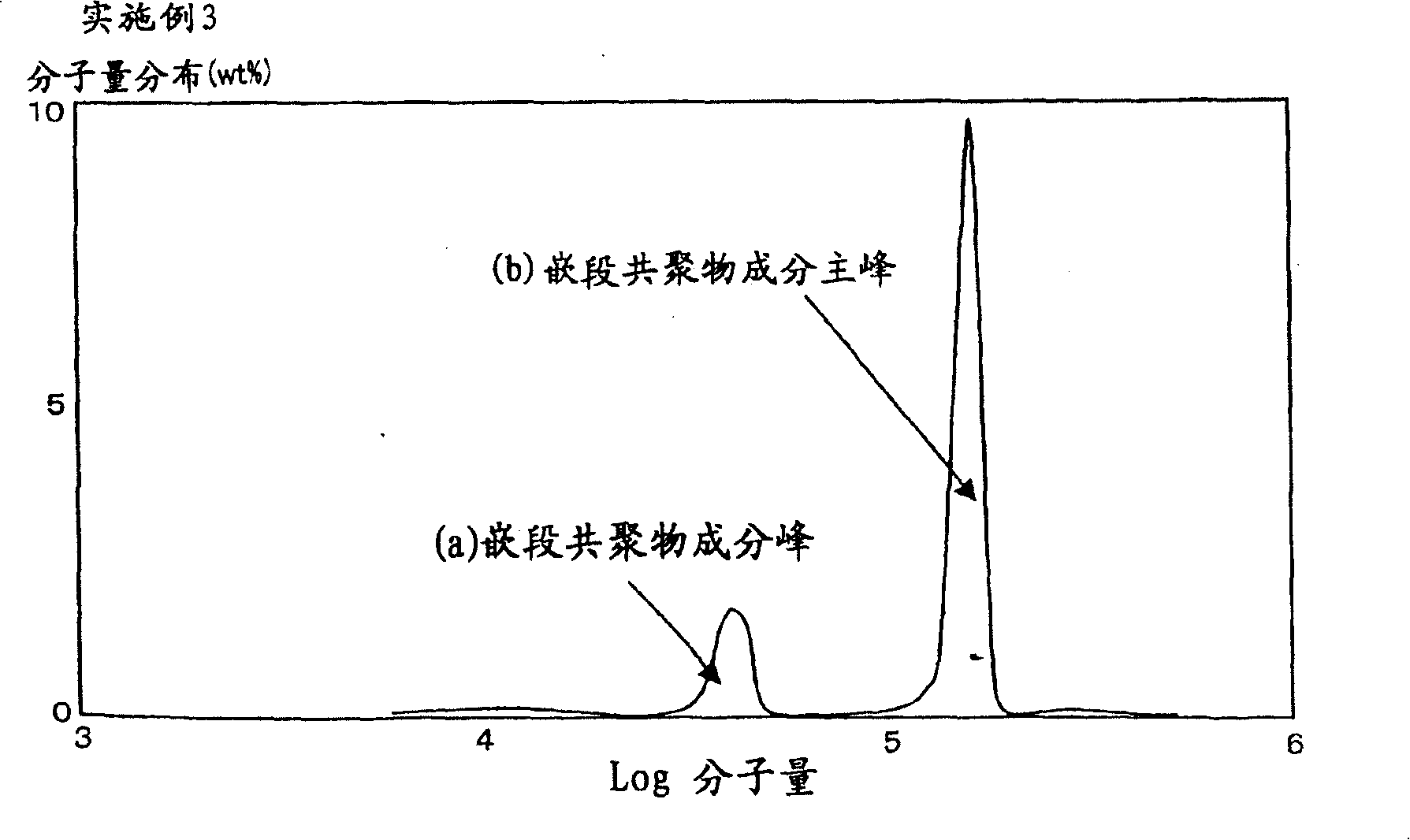

Embodiment 3

[0140] (b) block copolymer, add 50kg hexanaphthene, 1.2g ethylene glycol diethyl ether, 1.2kg styrene in the same stainless steel polymerization container as embodiment 1, lead warm water to make content be 40 in the jacket °C, and then, 6 g of sec-butyllithium was added to start polymerization, and after styrene polymerization was completed, 5.6 kg of 1,3-butadiene was slowly added while passing cold water into the jacket to bring the contents to 80 °C. After the polymerization of the butadiene block was completed, 1.2 kg of styrene was added, and after the polymerization reaction was almost completely completed, 1 ml of methanol was added, stirred for 10 minutes, and then transferred to a mixing container. Then, after mixing the same block copolymer (a) as in Example 1 and the above-mentioned component (b), the same operation as in Example 1 was performed to evaluate the performance of the block copolymer composition. Table 1 shows the evaluation results of each characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com