High-density textile for air bag

A high-density, fabric-based technology for fabrics, textiles, textiles, and paper making that can address issues such as increased manufacturing costs, reduced softness, and difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3 and comparative example 1-2

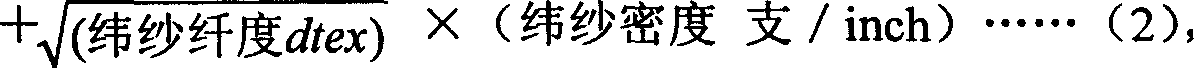

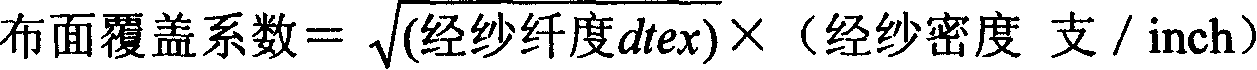

[0041] Utilize the water-jet loom to weave the raw yarn 350dtex / 108f (single yarn denier: 3.3dtex) of the physical properties shown in Table 1 through plain weaving through the warp yarn and weft yarn, then carry out shrinkage processing with boiling water, and carry out drying processing at 130°C to obtain the warp yarn An uncoated fabric with a density of 60 counts / inch and a weft density of 60 counts / inch, the evaluation results of the airbag fabric are shown in Table 1 below

[0042] Table 1

[0043]

Embodiment 4-5 and comparative example 3-5

[0045] Weave raw yarn 350dtex / 72f (single yarn fineness (4.9dtex)) with the physical properties shown in Table 1 by plain weaving warp and weft on a water jet loom, shrink in boiling water, and dry and shape at 150°C , to obtain an uncoated fabric with a warp density of 62 counts / inch and a weft density of 62 counts / inch. The evaluation results of the airbag fabric are shown in Table 2 below.

[0046] Table 2

[0047]

[0048] As the airbag fabric, the present invention obtains the required light weight and stable fabric strength physical properties and low air permeability under high pressure and reduces the impact on the occupant under high pressure when the airbag is stretched, and can provide a high-density fabric suitable for the airbag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com