Speed controlling apparatus of work cylinder

A technology of speed control device and working cylinder, which is applied in the direction of fluid pressure actuator, servo motor, servo meter circuit, etc., can solve the problems of poor control accuracy and high cost, and achieve the effect of improving accuracy, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

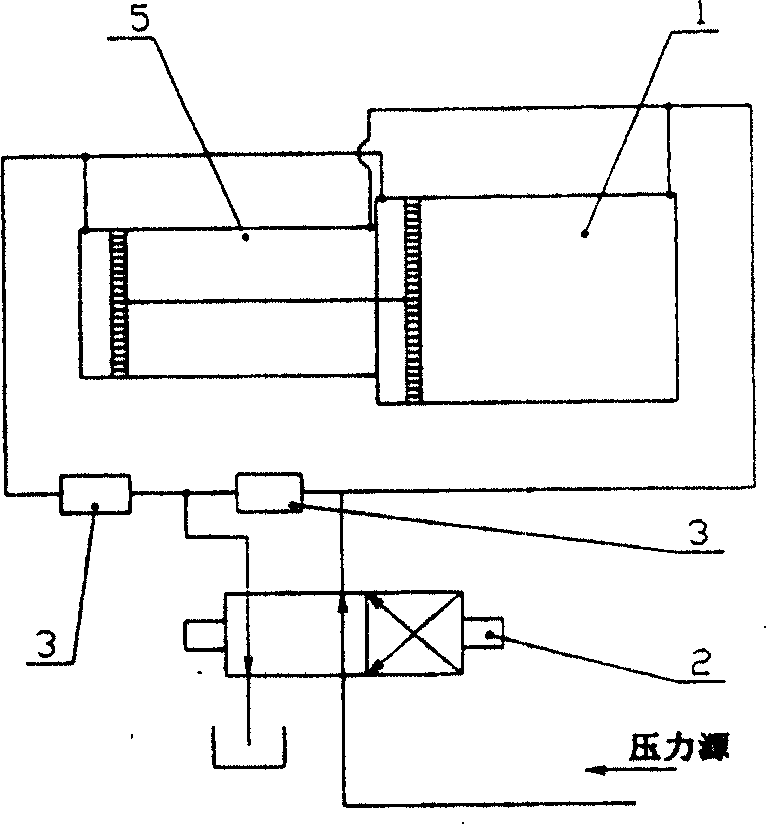

[0025] Such as image 3 As shown, the double working cylinder 1 has a common piston rod 5 connected in parallel, one end of the double cylinder is connected with one end of the first differential flow adjustable shuttle valve 3 and the medium port of the two-position four-way reversing valve 2, and the medium passes through the triple piece from The pressure source enters the reversing valve; the other end of the double cylinder is connected to one end of the second differential flow adjustable shuttle valve 3, and the other end of the first and second differential flow adjustable shuttle valves is connected to the two-position four-way reversing valve. The medium port is connected, and the medium enters the storage tank through the reversing valve. When the reversing valve is reversing, its inlet port and outlet port are exchanged and connected with the above-mentioned elements of the fixed interface.

Embodiment 2

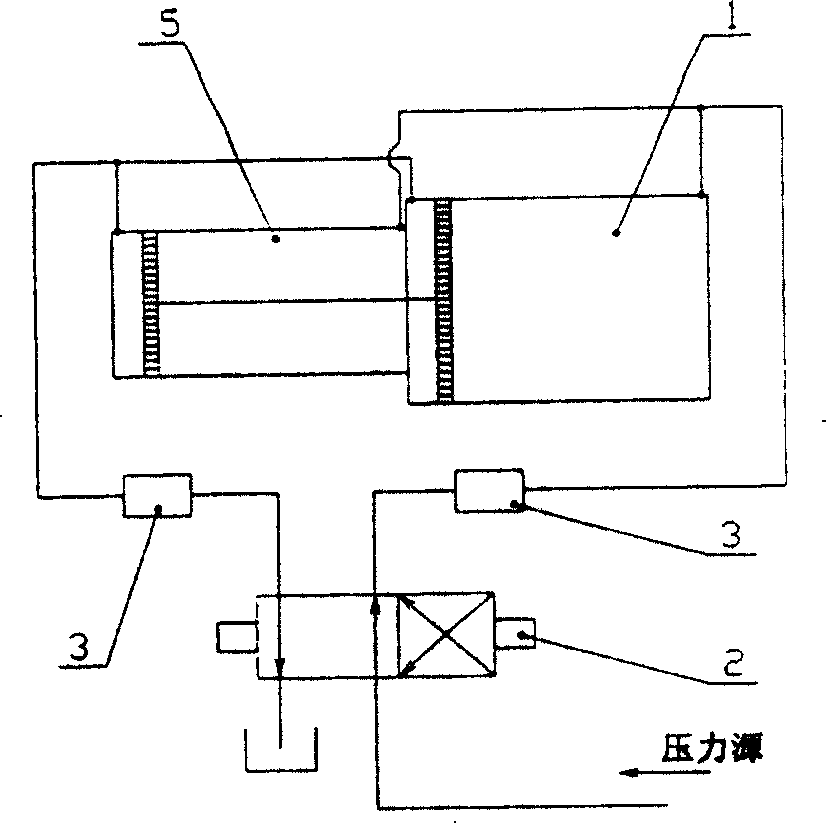

[0027] Such as figure 1 As shown, the double working cylinders 1 have a common piston rod 5 connected in parallel, one end of the double cylinders is connected to one end of the first differential flow adjustable shuttle valve 3, and the other end of the first differential flow adjustable shuttle valve 3 is connected to the two-position four-way The medium outlet of the reversing valve 2 is connected; the other end of the double cylinder is connected to one end of the second differential flow adjustable shuttle valve 3, and the other end of the second differential flow adjustable shuttle valve is connected to the medium of the two-position four-way reversing valve 2 Ingress connection.

Embodiment 3

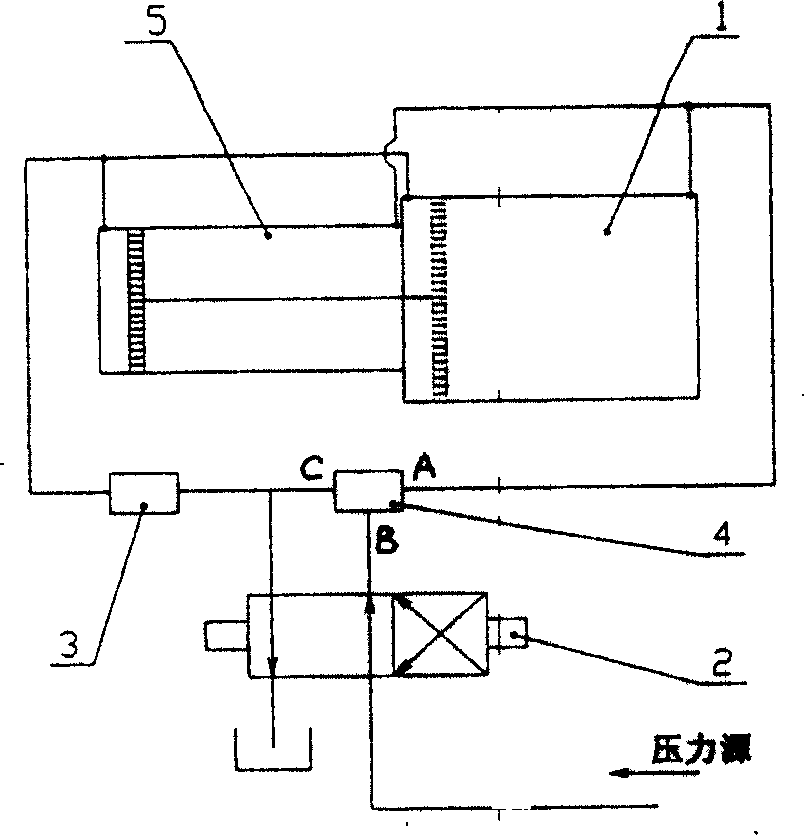

[0029] Such as figure 2 As shown, the double cylinder 1 is connected in series, one end of which is connected to the port A of the shuttle type three-way shunt regulating valve 4, the port B of the shunt regulating valve is connected to the medium inlet port of the two-position four-way reversing valve 2, and the port of the shunt regulating valve C is connected to one end of the differential flow adjustable shuttle valve 3 and the medium outlet port of the two-position four-way reversing valve 2, and the other end of the differential flow adjustable shuttle valve 3 is connected to the other end of the double cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com