Method and apparatus for lubricating a bearing assembly

A technology of bearing components, sealing devices, applied in the direction of bearing elements, bearings, shafts and bearings, which can solve the problem of insufficient prevention of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will now be illustrated by means of non-limiting examples.

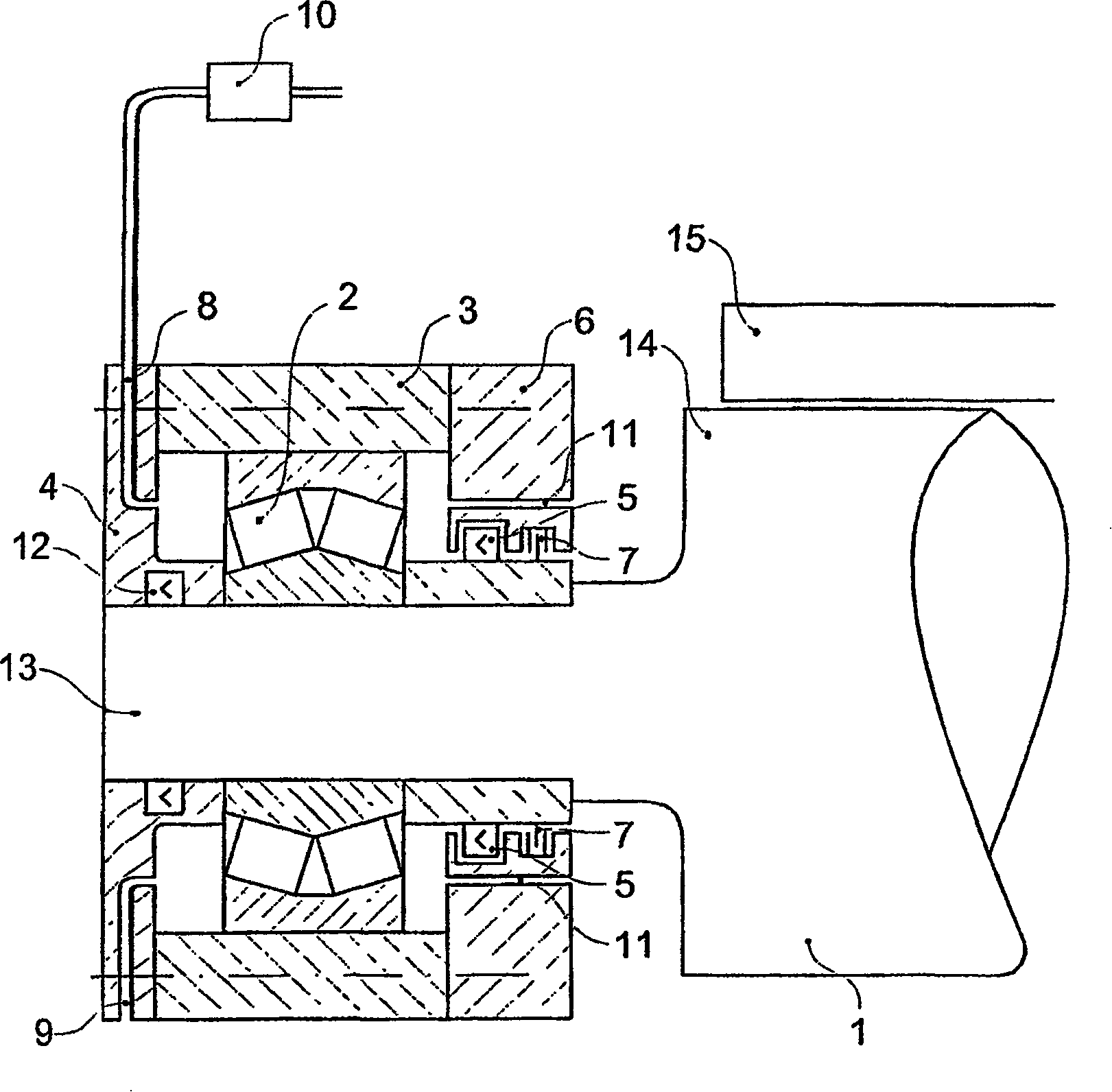

[0030] figure 1 Shows a portion of a roller bearing assembly of a conveyor roll of a continuous casting machine in the steelmaking industry.

[0031]The conveyor rollers 1 are supported by roller elements 2 in bearing housings 3 . The delivery roller comprises a shaft portion 13 and a bearing portion 14 for supporting a load, which is a cast steel plate 15 in this example. The side of the bearing housing closest to the conveyor roller 1 is the inner side of the bearing, and the side of the bearing furthest from the conveyor roller 1 is the outer side. The outer end cover 4 of the bearing housing includes an elastomeric seal 12 positioned to prevent the loss of grease and gas flowing through the outer end cover, thereby forcing it out of the bearing housing on the rollers or the inside of the bearing housing. The inner end cover or inner end seal carrier 6 of the bearing housing comprises seals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com