Magnetic memory medium and its manufacturing method

A magnetic storage and media technology, applied in information storage, record carrier manufacturing, recorded information storage, etc., can solve the problems of increased storage surface density, uniform particle size of magnetic particles, and uncertainty of uniform particle size of magnetic particles, etc. Achieve the effects of increasing recording density, high perpendicular anisotropy, and high coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

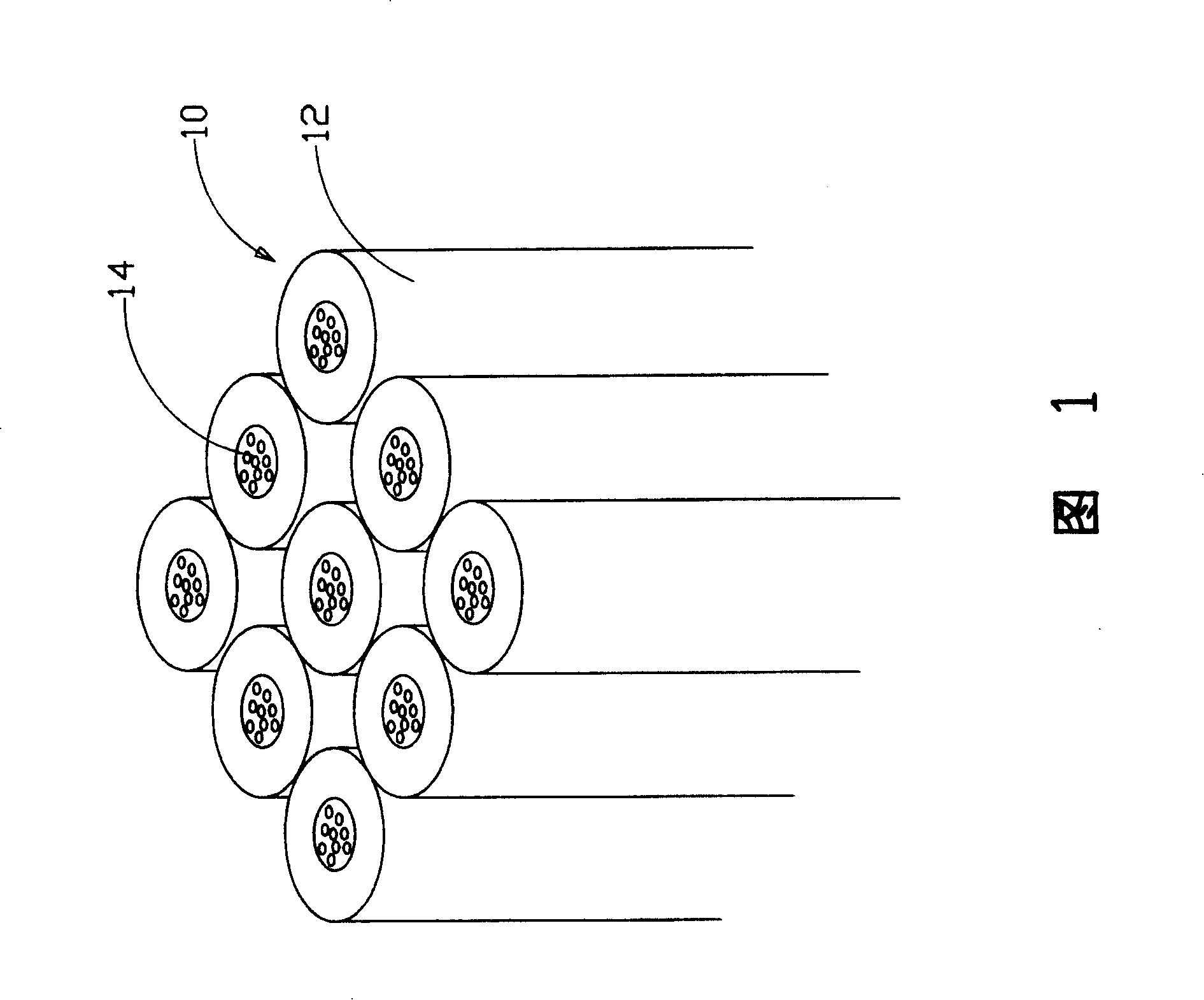

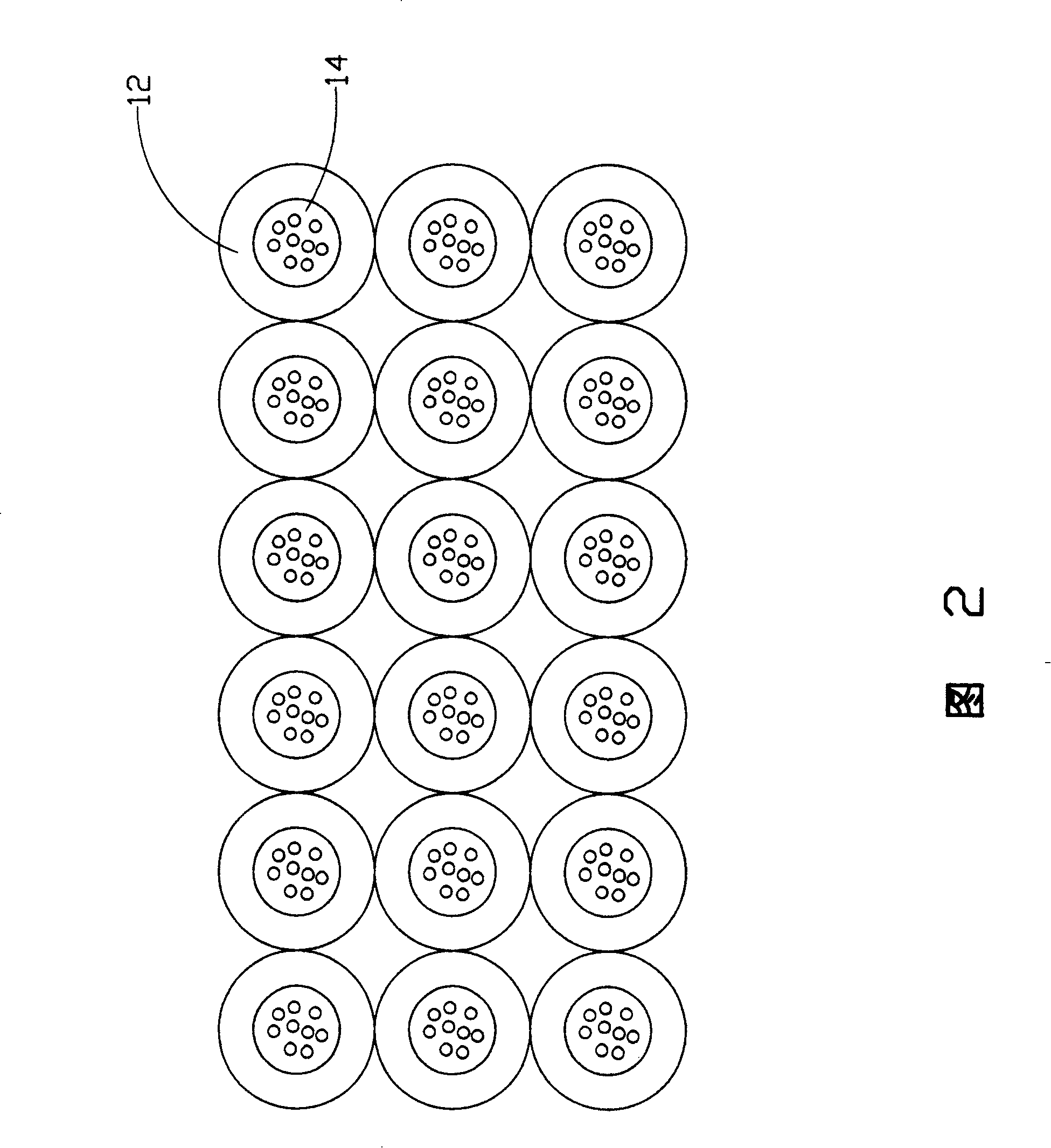

[0017] Referring to Fig. 1 and Fig. 2, the magnetic storage medium 10 selected by the present invention comprises: a substrate, the substrate has a micropore array uniformly arranged; a magnetic material, the magnetic material is deposited in the micropore array of the substrate, wherein, The substrate is a carbon nanotube array 12, and the magnetic material is CoCrXYZ, wherein X is tantalum (Ta), niobium (Nb) or zirconium (Zr), and Y is platinum (Pt), palladium (Pd) or gold (Au) , Z is boron (B), phosphorus (P), nitrogen (N) or oxygen (O). The carbon nanotube array 12 can be formed by passing carbon source gas such as methane into the reaction chamber, and under the action of a catalyst, the carbon nanotube array 12 can be formed after a certain period of chemical reaction. The diameters of the carbon nanotubes are uniformly 1 to 5 nanometers, preferably 1 to 3 nanometers, closely distributed between the carbon nanotubes, and the spacing is 2 to 10 nanometers, and the preferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com