Proton exchange membrane fuel cell plate comprising combined flow channel

A fuel cell plate and proton exchange membrane technology, which is applied to fuel cell components, battery electrodes, circuits, etc., can solve problems such as poor drainage capacity, and achieve the effects of prolonging residence time, increasing heat dissipation area, and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

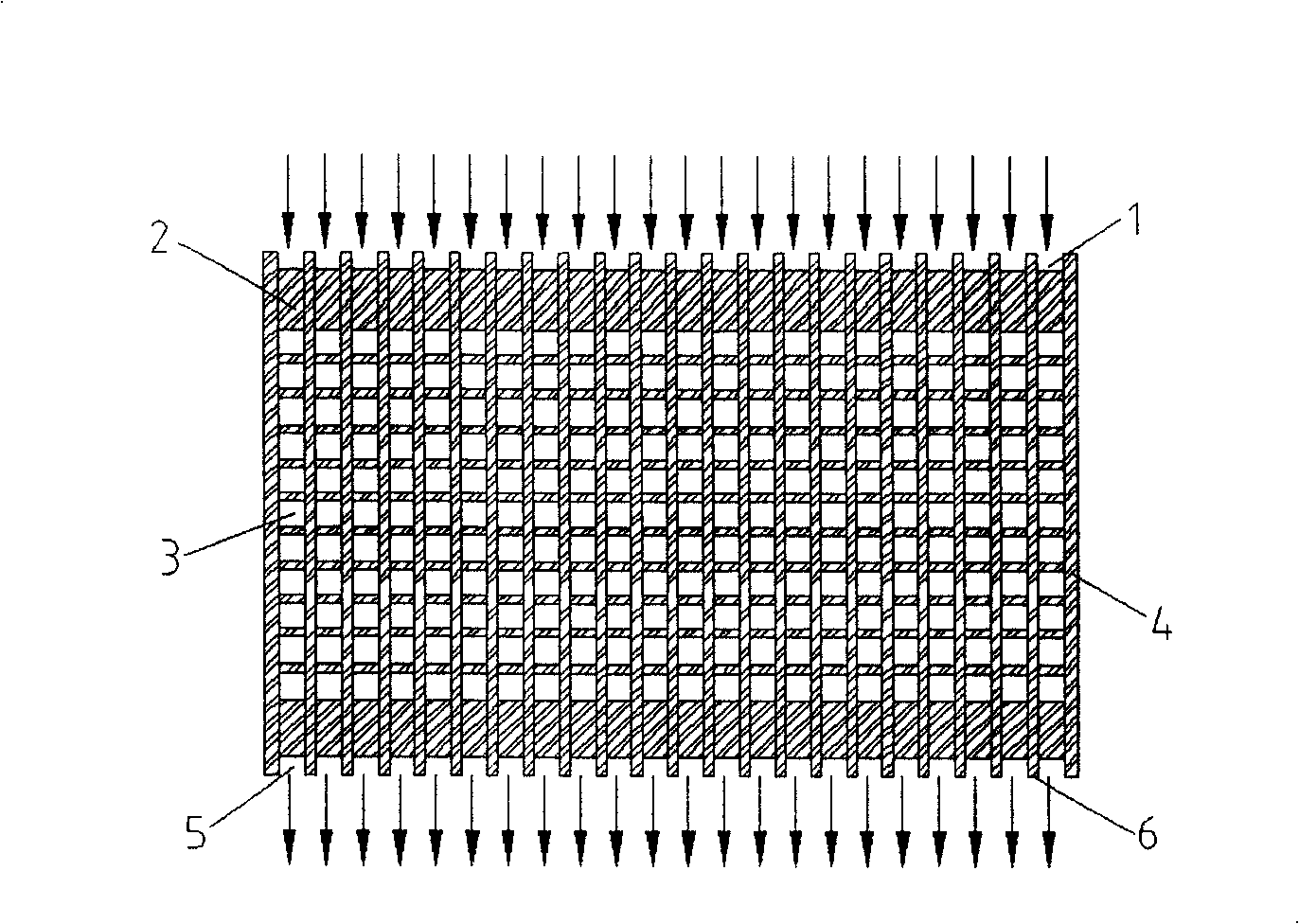

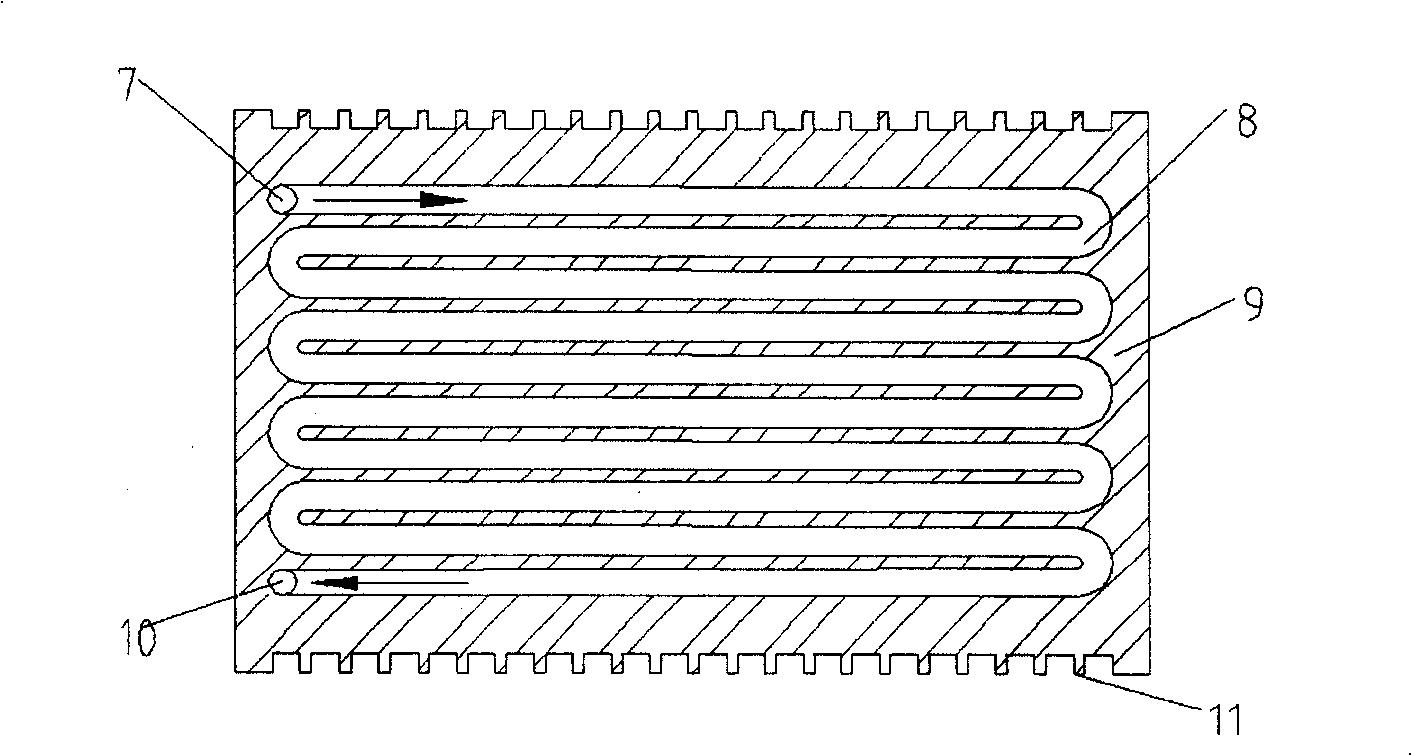

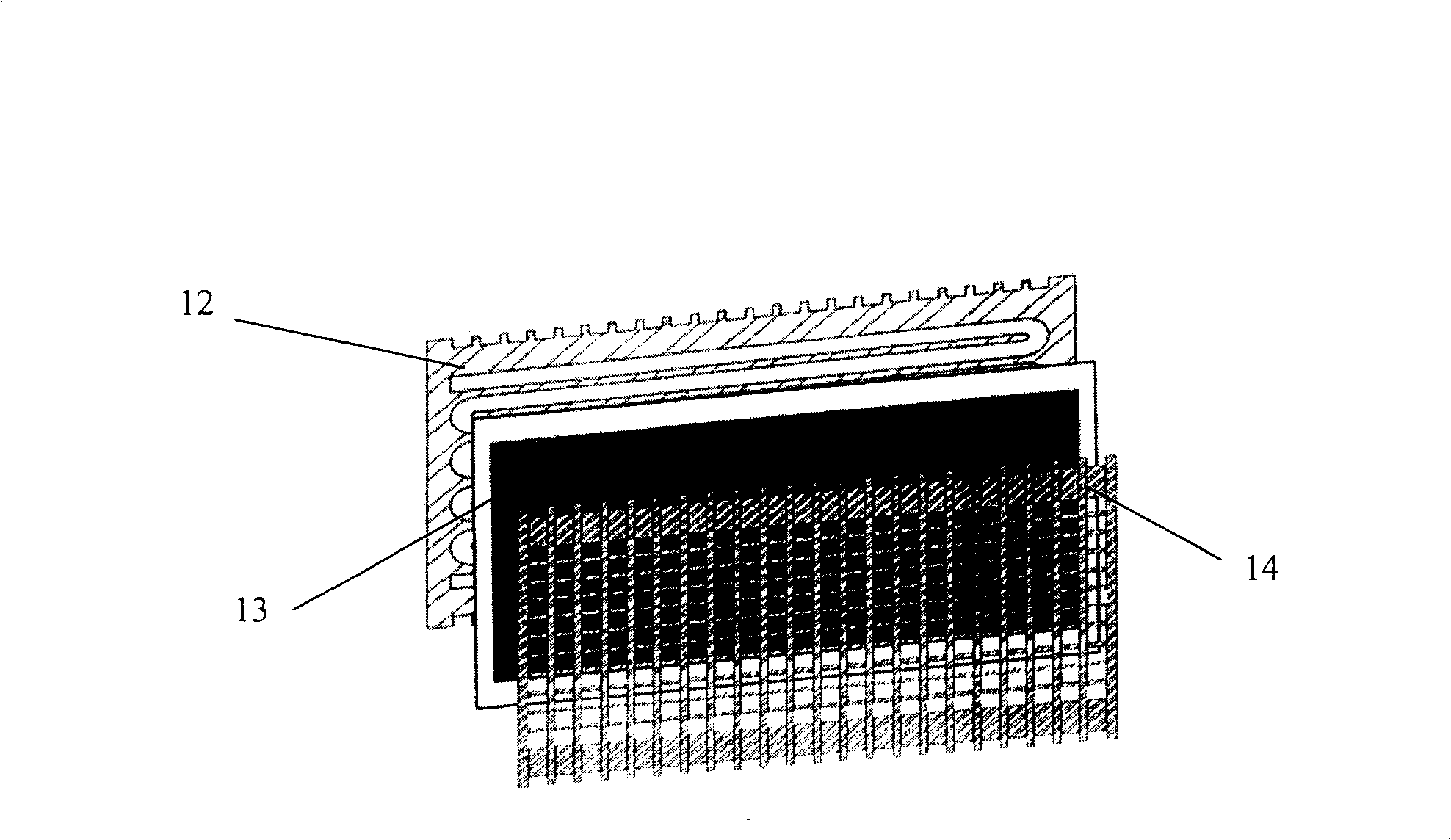

[0025] Align parallel runners and matrix vias according to the appendix figure 1 A two-in-one combination is performed to form a combined flow channel, and the parallel flow channels run through both ends of the cathode plate, wherein: the width and height of the grooves of the parallel flow channels are 0.5 mm and 0.8 mm, respectively. The through hole is a circular through hole, the hole depth is 0.6mm, and the through hole accounts for 60% of the area of the parallel flow channel. Set the snake runner according to the appendix figure 2 through both ends of the anode plate. Parallel thorns are arranged on the edge of one side of the anode and cathode plates according to 0.5 times the number of parallel flow channels. Attached image 3 The above-mentioned anode plate, cathode plate and ten membrane electrodes are used to form a fuel cell stack, the size of which is 30mm×60mm×60mm. The fuel cell stack operates stably at normal pressure and 50°C, with an output power of ...

Embodiment 2

[0027] Align parallel runners and matrix vias according to the appendix figure 1 A two-in-one combination is performed to form a combined flow channel, and the parallel flow channels run through both ends of the cathode plate, wherein: the width and height of the grooves of the parallel flow channels are 1.3 mm and 2.2 mm, respectively. By engraving parallel flow channels on both sides of the cathode plate, a square through hole is formed, the hole depth is 1mm, and the through hole accounts for 70% of the area of the parallel flow channel. Set the snake runner according to the appendix figure 2 through both ends of the anode plate. Parallel thorns are arranged on the edge of one side of the anode and cathode plates according to 1.2 times the number of parallel flow channels. Attached image 3 The above-mentioned anode plate, cathode plate and ten membrane electrodes are used to form a fuel cell stack, the size of which is 30mm×60mm×60mm. The fuel cell stack operates st...

Embodiment 3

[0029] Align parallel runners and matrix vias according to the appendix figure 1A two-in-one combination is performed to form a combined flow channel, and the parallel flow channels run through both ends of the cathode plate, wherein: the width and height of the grooves of the parallel flow channels are 2.5 mm and 2.8 mm, respectively. By engraving parallel flow channels on both sides of the cathode plate, a square through hole is formed, the hole depth is 1.3mm, and the through hole accounts for 50% of the area of the parallel flow channel. Set the snake runner according to the appendix figure 2 through both ends of the anode plate. Parallel thorns are arranged on the edge of one side of the anode and cathode plates according to 1.5 times the number of parallel flow channels. Attached image 3 The above-mentioned anode plate, cathode plate and ten membrane electrodes are used to form a fuel cell stack, the size of which is 30mm×60mm×60mm. A common fan is installed alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com