Method for mfg. crystal boundary layer ceramic medium material and substrate for single layer capacitor and substrate thereof

A technology of a ceramic substrate and a manufacturing method, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, ceramics, etc., can solve the problem of undiscovered, achieve good flatness and roughness, high resistivity, low dielectric loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 64.66 parts by weight of SrCO 3 , 35.10 parts by weight of TiO 2 , 0.24 parts by weight Nb 2 o 5 , 0.05 parts by weight SiO 2 , 0.1 parts by weight MnO 2 , 1 part by weight CaCO 3 After drying, sieve; raw material is synthesized at 1200°C; the synthesized clinker is crushed and sieved; slurry is prepared, clinker powder is added with adhesive to make slurry, and the slurry is made many times Cast film, with a total thickness of 0.25mm; then cut into films according to the size requirements, spray on the adhesive slurry; stack the films into a bowl, and discharge the glue at a rate of 50 °C per hour to 1150 °C; cool and pack Put it into a hydrogen-nitrogen mixture atmosphere furnace, heat up at a rate of 100°C per hour to 1420°C for 2 hours for sintering; put the fired tiles into an ultrasonic cleaning tank to clean the adhesive separator and separate the tiles at the same time Open; sandwich the ceramic tiles between two smooth and flat alumina plates, and flatten...

Embodiment 2-6

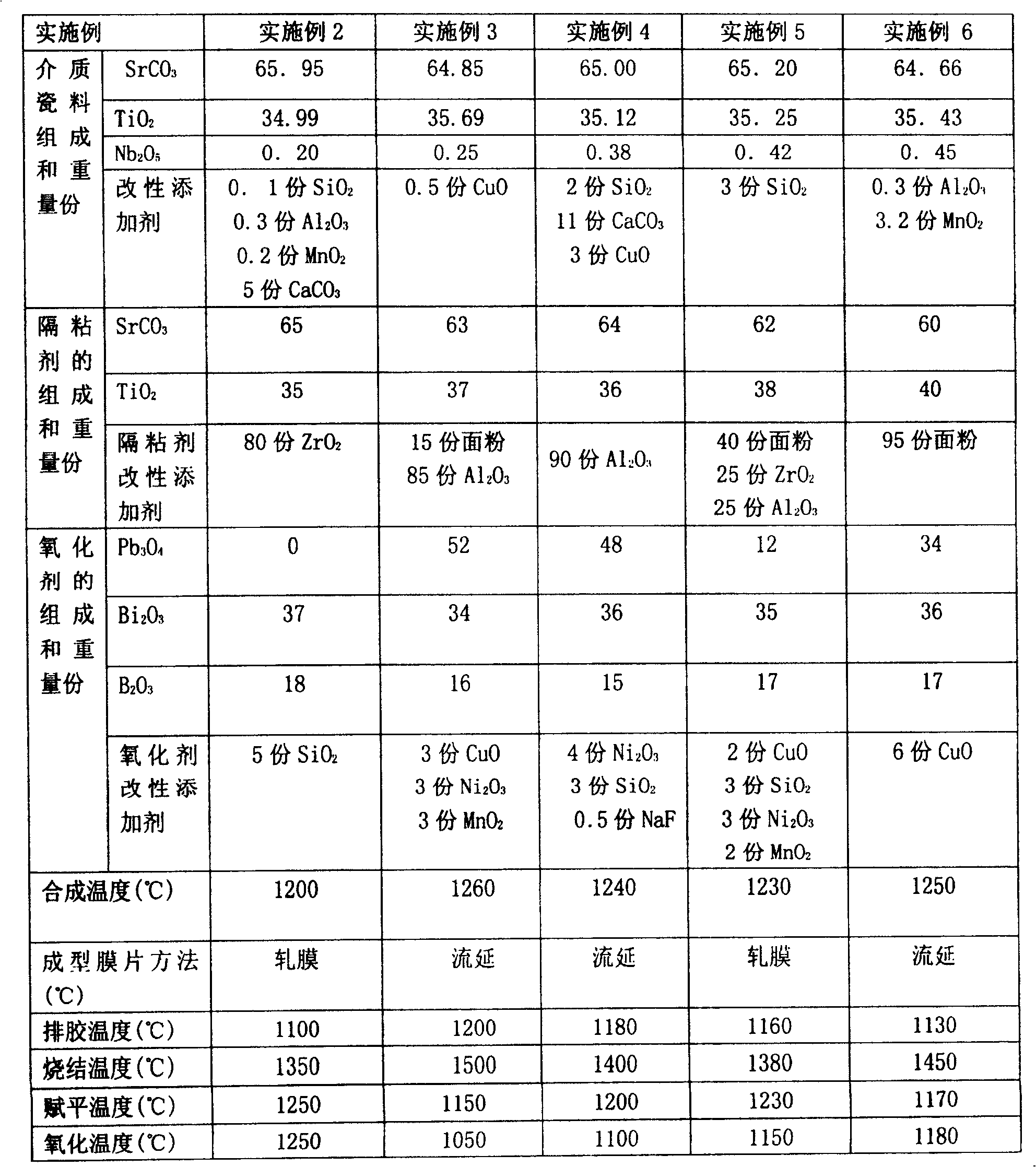

[0055] Below are several other embodiments of the present invention, disclosing the composition and weight percentage of the dielectric ceramic materials of the grain boundary layer ceramics for single-layer capacitors of these several embodiments, adopting the composition and weight parts of the adhesive separator and the composition of the oxidizing agent as follows And parts by weight and process parameters, according to the steps of the manufacturing method of the grain boundary layer ceramic substrate for the single layer capacitor of the present invention, prepare the grain boundary layer ceramic substrate for the single layer capacitor of the present invention.

[0056]

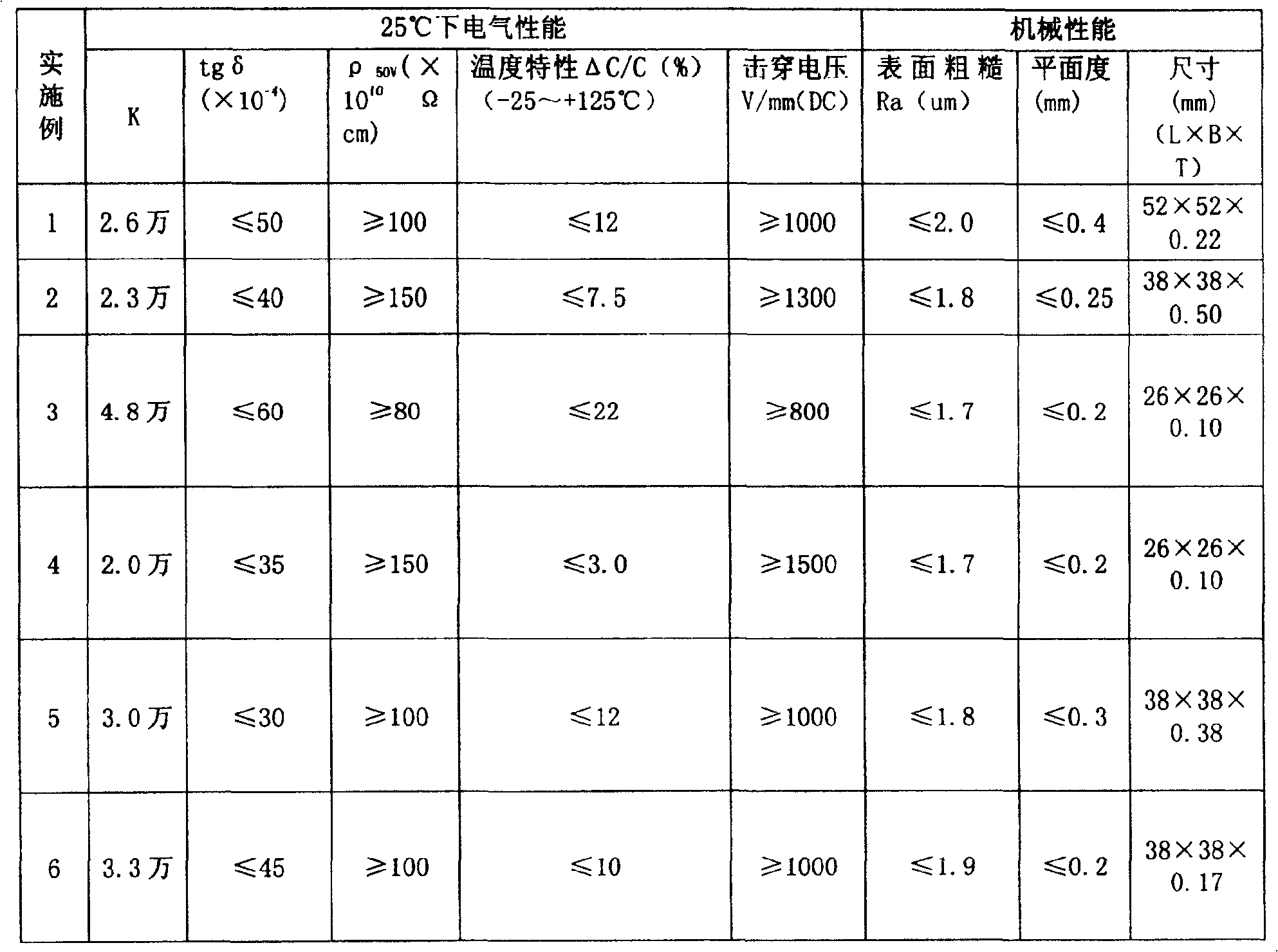

[0057] Sampling the grain boundary layer ceramic substrate for the single-layer capacitor prepared in the above embodiment, sputtering the metal electrode; cutting the sputtered electrode into 2×2mm 2 Chips; measure the mechanical and electrical properties of the chips.

[0058] According to K=11.3C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com