Polyester enameled wire lacquer suitable for lacquered flat copper wire and preparation method thereof

A technology for polyester enameled wire paint and flat copper wire, applied in the field of enameled wire paint, can solve the problems of complex production process, insufficient heat resistance, poor thermal shock resistance, etc., and achieves reduced pollution, less pollution, and high thermal shock resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

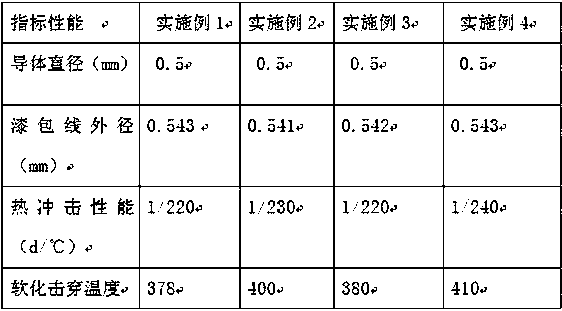

Examples

Embodiment 1

[0018] A polyester enamelled wire varnish suitable for enamelled flat copper wires consists of the following raw materials in parts by mass: 60 parts of methanol, 20 parts of sulfuric acid, 10 parts of terephthalic acid, 10 parts of 2-methyl terephthalic acid, 70 parts of glycerin, 20 parts of ethylene glycol, 5 parts of butanol, 5 parts of polydiacid, 40 parts of cresol, 2-7 parts of xylene, 32 parts of dimethyl mixed dibasic acid, 13 parts of benzyl alcohol, catalyst 10 share.

[0019] Described catalyst is made up of zinc acetate, dibutyltin dilaurate, stannous octoate, zinc acetate, and the mass and number ratio of described zinc acetate, dibutyltin dilaurate, stannous octoate, zinc acetate is 2:1:3: 4;

[0020] The preparation method of described catalyst is as follows:

[0021] Add zinc acetate, dibutyltin dilaurate, stannous octoate, and zinc acetate to the reaction kettle, start the stirring device, the stirring speed is 150-200 rpm, and stop stirring after stirring ...

Embodiment 2

[0029] A polyester wire enamel suitable for enamelled flat copper wires, comprising the following raw materials in parts by mass: 100 parts of methanol, 40 parts of sulfuric acid, 30 parts of terephthalic acid, 30 parts of 2-methyl terephthalic acid, glycerin 80 parts, 35 parts of ethylene glycol, 10 parts of butanol, 8 parts of polydiacid, 52 parts of cresol, 7 parts of xylene, 46 parts of dimethyl mixed dibasic acid, 20 parts of benzyl alcohol, and 20 parts of catalyst.

[0030] The catalyst is dibutyltin dilaurate.

[0031] A preparation method for polyester enamelled wire varnish suitable for enamelled flat copper wire, comprising the following steps:

[0032] (1) Add terephthalic acid and 2-methyl terephthalic acid into the reaction kettle, methanol and sulfuric acid are added into the reaction kettle with a delivery pump, start the stirring device, the stirring speed is 200 rpm, and stop stirring after stirring evenly , heat up to 172°C and hold for 12 hours;

[0033] ...

Embodiment 3

[0038] A polyester wire enamel suitable for enamelled flat copper wires, comprising the following raw materials in parts by mass: 80 parts of methanol, 30 parts of sulfuric acid, 20 parts of terephthalic acid, 20 parts of 2-methyl terephthalic acid, glycerin 75 parts, 25 parts of ethylene glycol, 7 parts of butanol, 6 parts of polydiacid, 44 parts of cresol, 4 parts of xylene, 40 parts of dimethyl mixed dibasic acid, 17 parts of benzyl alcohol, dimethyl dibasic acid 32-46 parts, 13-20 parts of benzyl alcohol, 10-20 parts of catalyst.

[0039] The catalyst is stannous octoate.

[0040] A preparation method for polyester enamelled wire varnish suitable for enamelled flat copper wire, comprising the following steps:

[0041] (1) Add terephthalic acid and 2-methyl terephthalic acid into the reaction kettle, methanol and sulfuric acid are added into the reaction kettle with a delivery pump, start the stirring device, the stirring speed is 300 rpm, and stop stirring after stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com