Preparation method of nickel-plated copper mica winding wire

A nickel-plated copper, winding wire technology, used in cable/conductor manufacturing, heat treatment equipment, and conductor/cable insulation, etc. The effect of improving the withstand voltage capability, uniform and qualified size, and improving the electrical performance of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

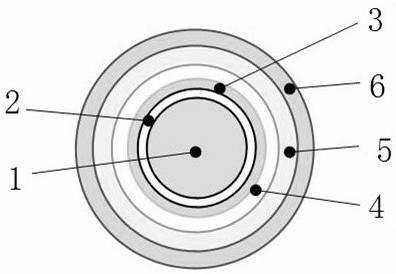

[0033] Such as figure 1 Shown, a kind of preparation method of nickel-plated copper mica winding wire, comprises the following steps:

[0034] a, coating the outer surface of the copper conductive core 1 with a nickel-plated layer 2 to form a nickel-copper wire;

[0035] b. Calibrate the nickel-copper wire;

[0036] c. Preheat the corrected nickel-copper wire at 60-80°C, then coat the nickel-plated layer 2 with a silicone resin layer A3, and coat the silicone resin layer A3 at a temperature of 90-110°C The semi-cured coating layer is formed under the baking;

[0037] d. Winding a layer of corona-resistant mica layer 4 on the silicone resin layer A3;

[0038] e, on the corona-resistant mica layer 4, the single layer is 360 alkali-free and boron-free glass fiber layers 5, then impregnated with silicone resin, and pre-cured at a temperature of 110-130 ° C to form a silicone resin layer B6;

[0039] f. After baking and drying at a temperature of 150-160°C, the baking and dryi...

Embodiment 2

[0060] A preparation method of nickel-plated copper mica winding wire, comprising the following steps:

[0061] a, coating the outer surface of the copper conductive core 1 with a nickel-plated layer 2 to form a nickel-copper wire;

[0062] b. Calibrate the nickel-copper wire;

[0063] c, carry out the preheating treatment of 60 ℃ to the nickel-copper wire after correction, stop preheating after correction finishes, then coat organosilicon resin layer A3 on the nickel-plated layer 2, coat organosilicon resin layer A3 at a temperature of Baking at 90°C forms a semi-cured coating layer;

[0064] f. Winding a layer of corona-resistant mica layer 4 on the silicone resin layer A3;

[0065] E, on the corona-resistant mica layer 4, the single layer is 360 non-alkali and boron-free glass fiber layers 5, then impregnated with silicone resin, and through the pre-curing treatment at 110 ° C, the silicone resin layer B6 is formed;

[0066] f. After baking and drying at a temperature of...

Embodiment 3

[0068] A preparation method of nickel-plated copper mica winding wire, comprising the following steps:

[0069] a, coating the outer surface of the copper conductive core 1 with a nickel-plated layer 2 to form a nickel-copper wire;

[0070] b. Calibrate the nickel-copper wire;

[0071] c, carry out the preheating treatment of 80 ℃ to the nickel-copper wire after correction, stop the preheating after correction, then coat the silicone resin layer A3 on the nickel-plated layer 2, and coat the silicone resin layer A3 at a temperature of Form a semi-cured coating layer under baking at 110°C;

[0072] f. Winding a layer of corona-resistant mica layer 4 on the silicone resin layer A3;

[0073] E, on the corona-resistant mica layer 4, the single layer is 360 alkali-free and boron-free glass fiber layers 5, then impregnated with silicone resin, and through the pre-curing treatment at 130 ° C, the silicone resin layer B6 is formed;

[0074] f. After baking and drying at a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com