Composite power unit of engine

A composite power and engine technology, applied in the direction of engine starting, engine ignition, engine components, etc., can solve the problems of difficult maintenance or replacement, easy damage and failure, high cost, etc., to achieve easy maintenance or replacement, avoid damage, and reduce parts. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

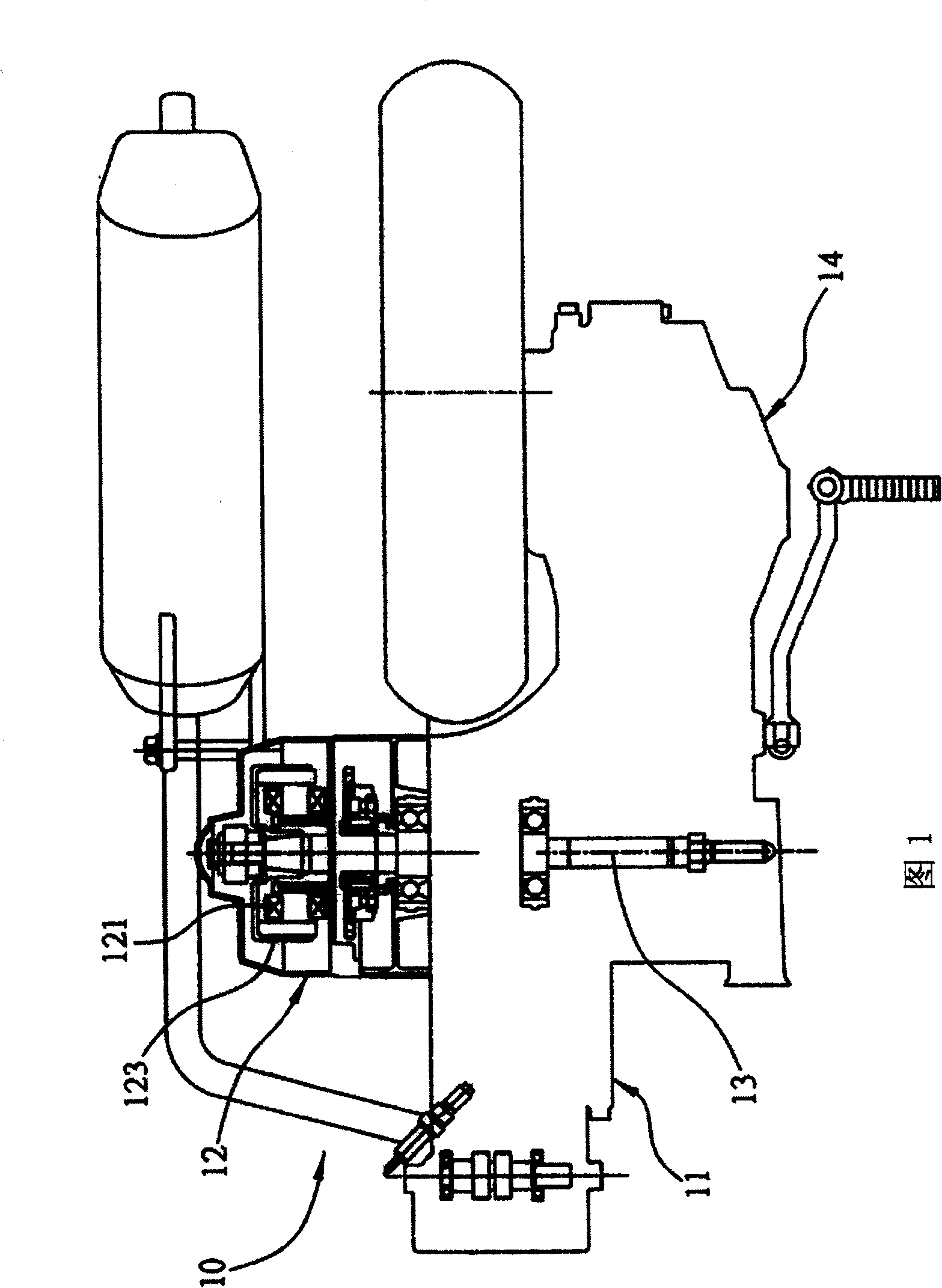

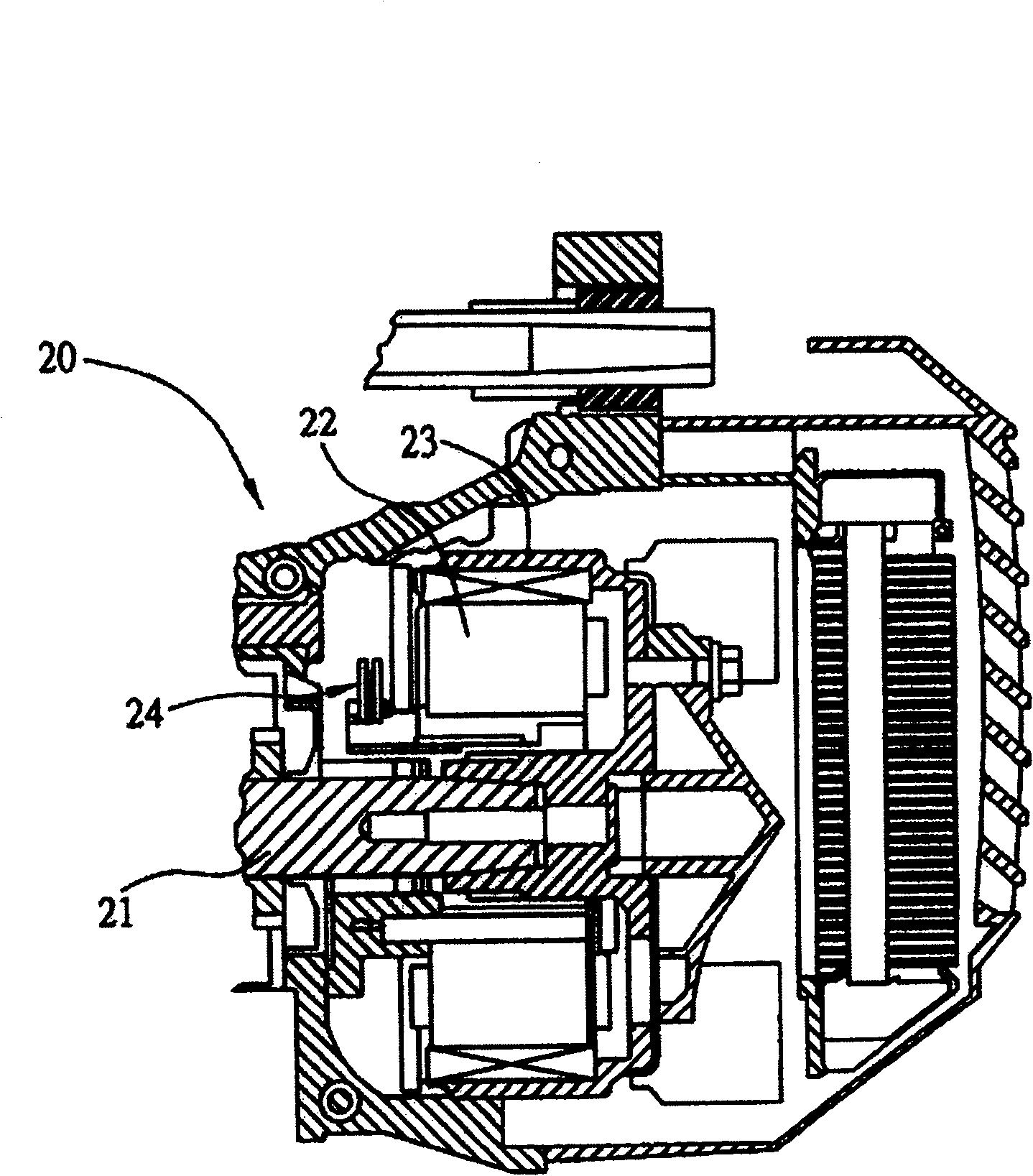

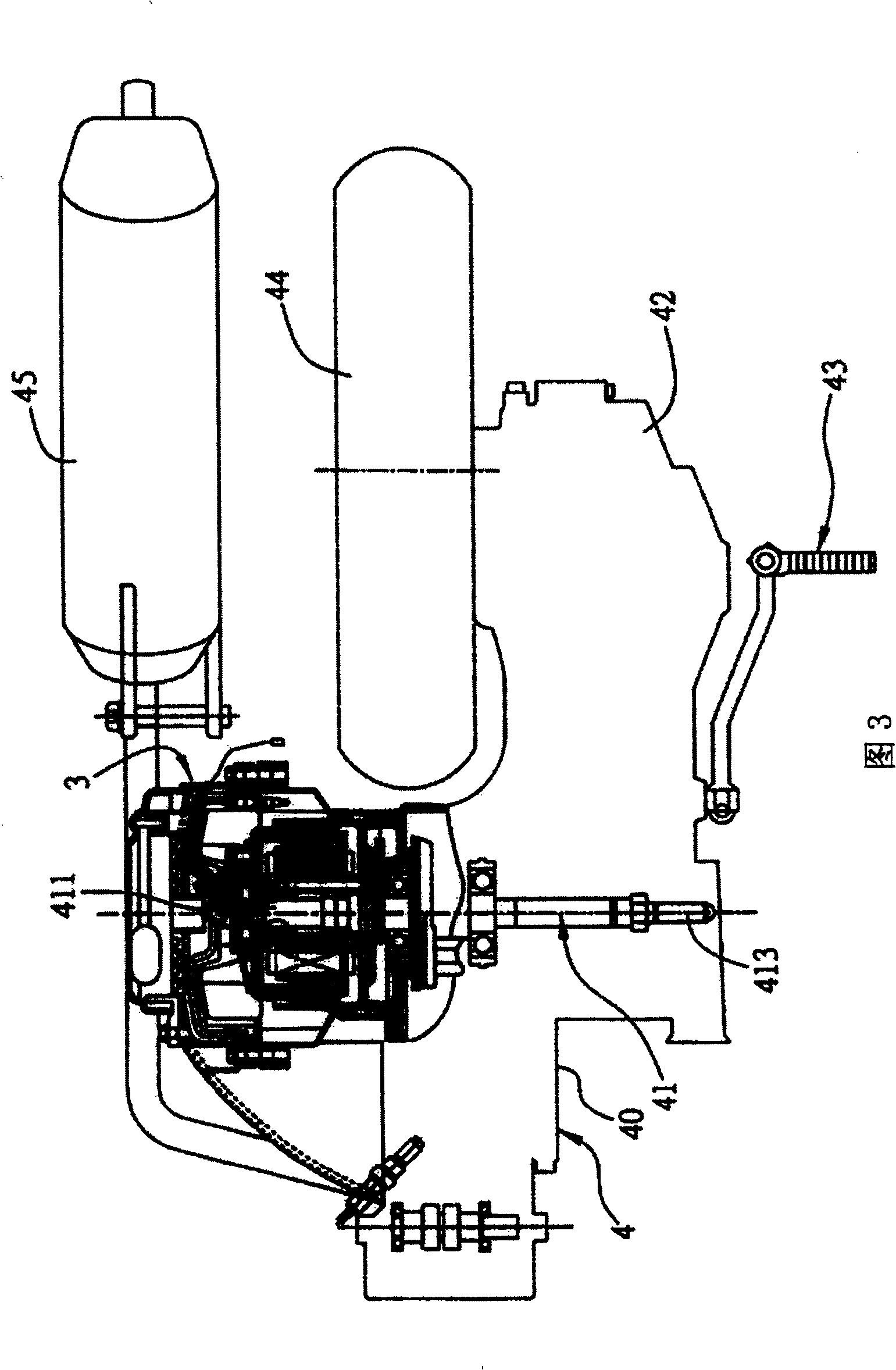

[0032] Figure 3 to Figure 8A The drawings are drawn according to the embodiments of the present invention. It should be noted that the drawings are all simplified schematic diagrams, and only schematically illustrate the basic structure of the present invention. Therefore, in these drawings, only components related to the present invention are marked, and the components shown are not drawn with the number, shape, size ratio, etc. during actual implementation, and the specifications and sizes of actual implementation are a kind of optional design. The component layout form may be more complicated, so give an explanation first.

[0033] Fig. 3 has shown the synoptic diagram that the composite power device of the present invention is applied to the vehicle engine, and the composite power device 3 shown in the figure is applied in the engine 4 with crankshaft 41, forms the auxiliary compound power system of external rotation type structure, and this compound The power unit 3 can n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com