DC motor power-on device and valve device using the same

A technology of energizing device and valve device, which is applied to electromechanical devices, electric components, DC commutators, etc., can solve the problems of poor valve opening and closing action reactivity, etc., to improve reliability, improve wiring efficiency, and improve Effects of Wiring Work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiments of the present invention will be described below with reference to the accompanying drawings.

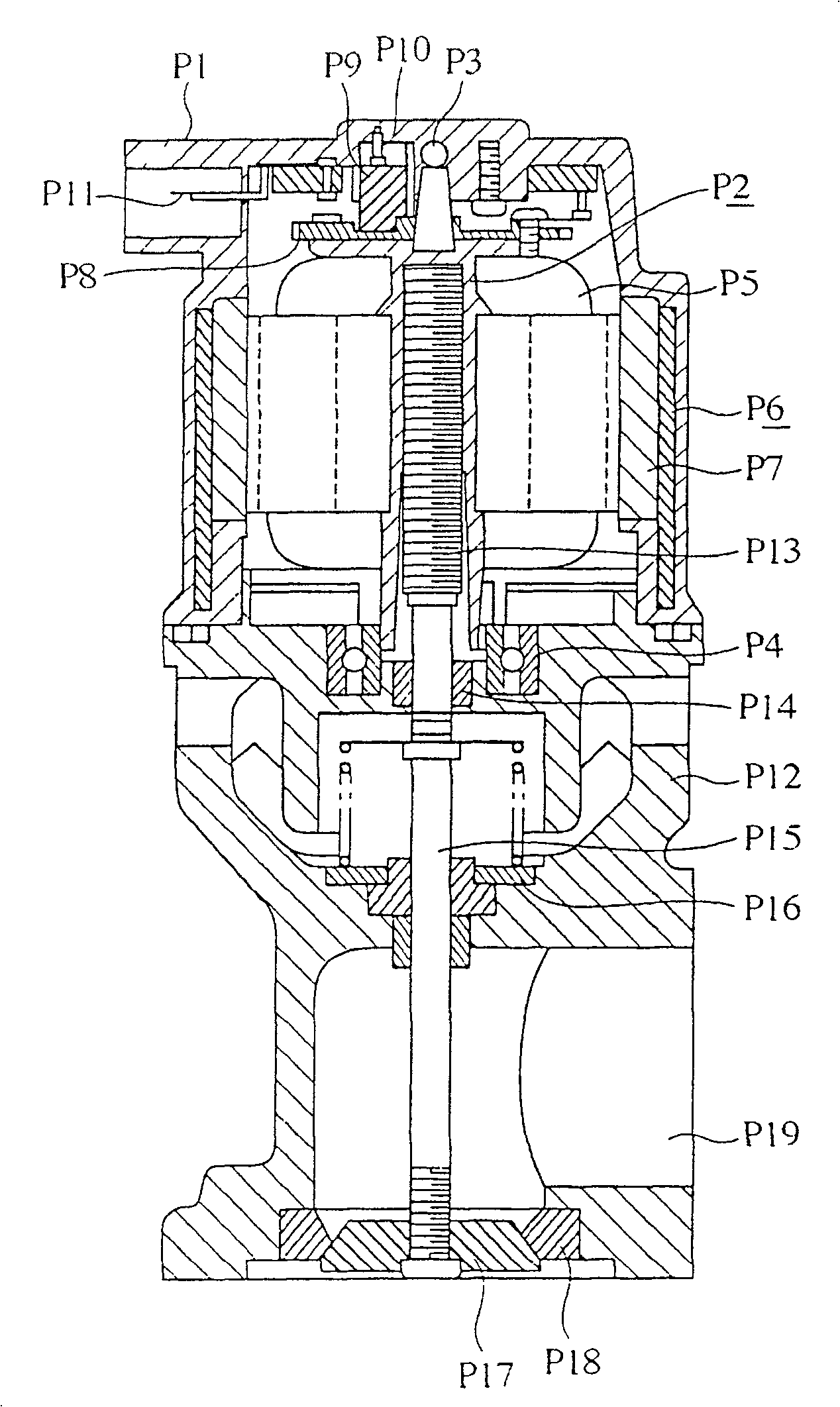

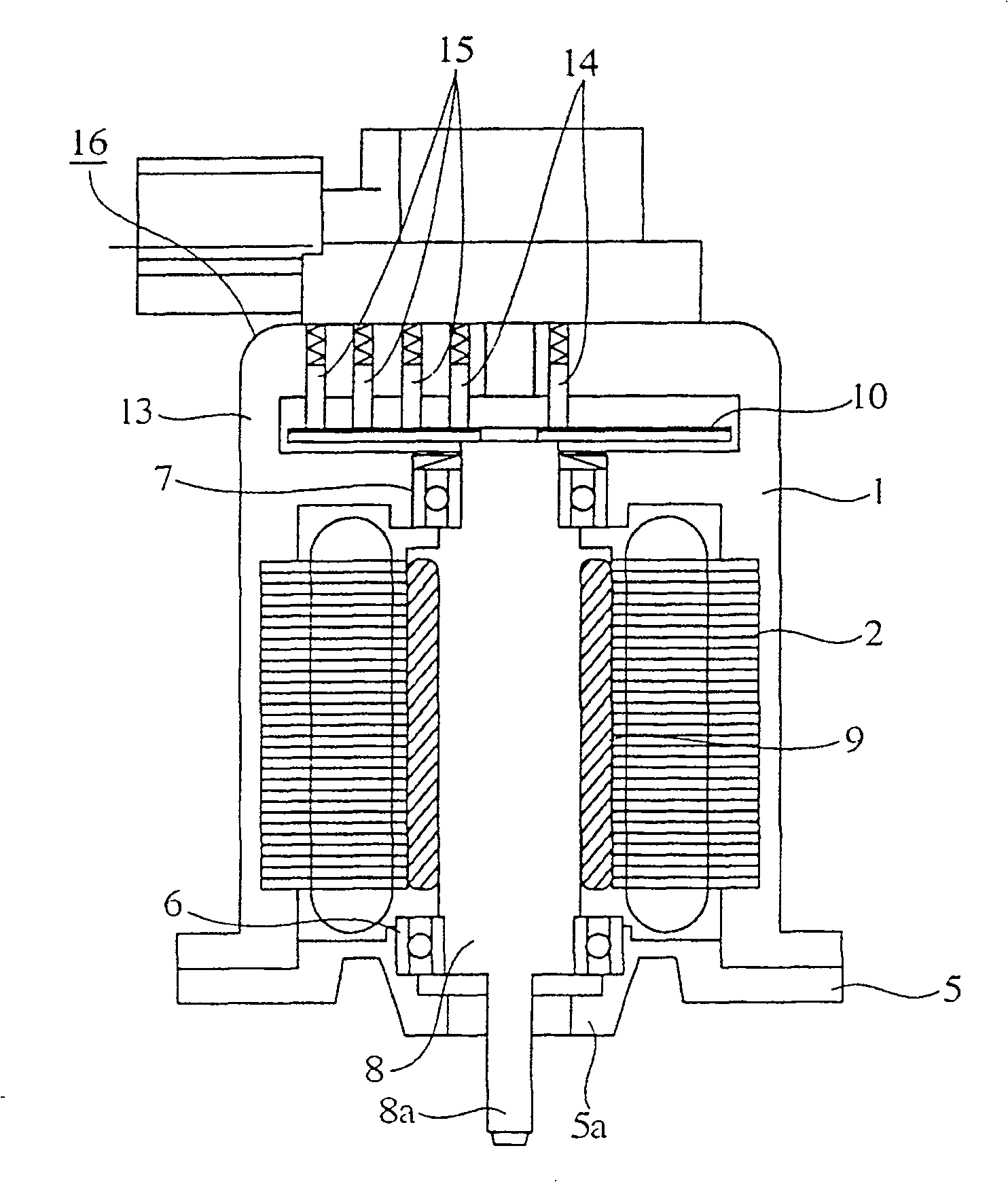

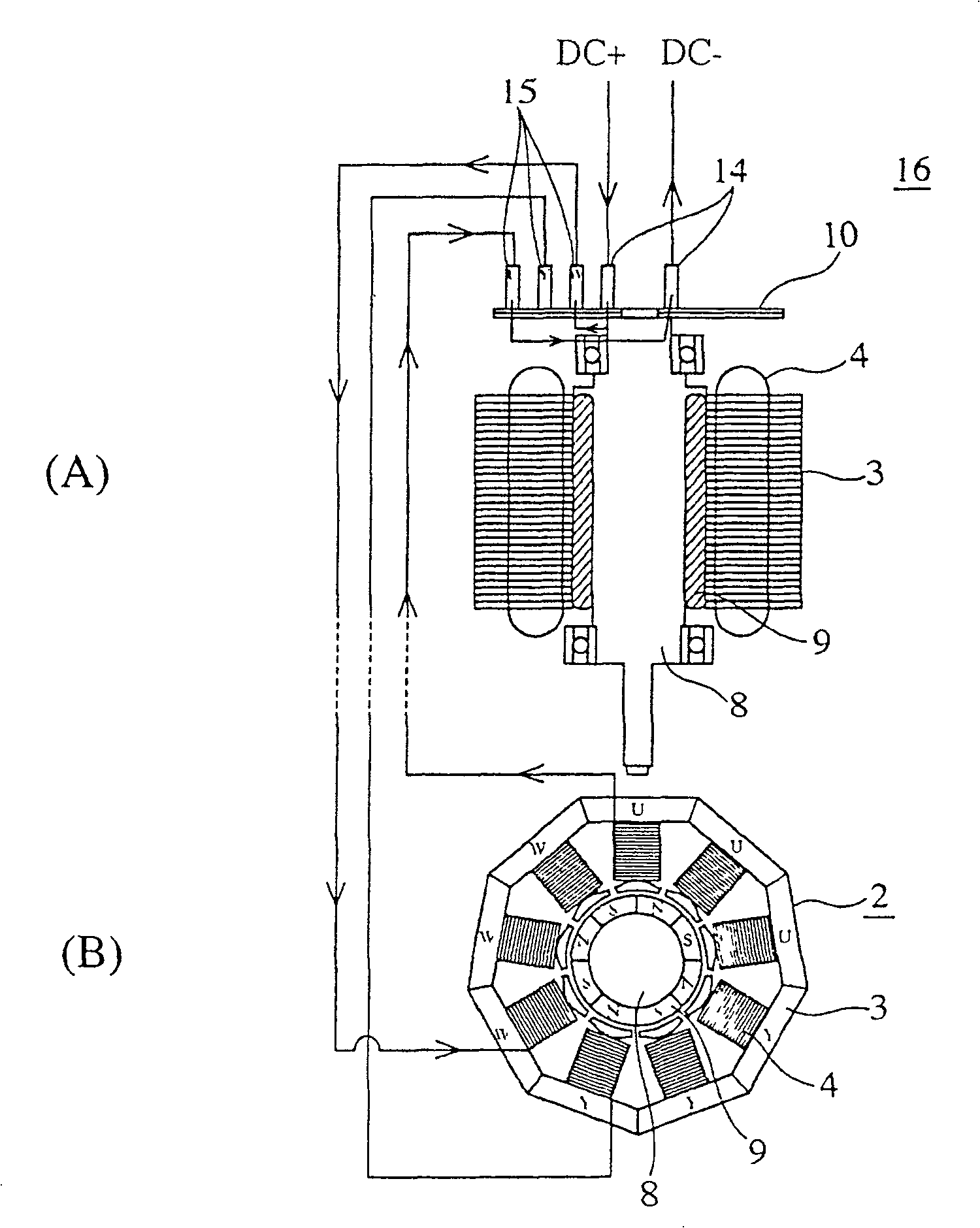

[0052] figure 2 It is a cross-sectional view showing the structure of a DC motor energizing device according to Embodiment 1 of the present invention, image 3 express figure 2 The current flow in the energized device, image 3 (A) is a sectional view, image 3 (B) is a plan view, and Fig. 4 shows figure 2 The three-dimensional view of the structure of the commutator and collector ring shown, Figure 5 yes means figure 2 A top view of the stator fabrication method.

[0053] In the figure, 1 is a motor casing formed of a resin material, and 2 is a stator integrally formed with the motor casing 1 by resin molding, such as Figure 5 As shown in (A), the iron core pieces 3b on which the magnetic pole teeth 3a protrude respectively are configured in such a way that a predetermined number of magnetic materials connected by thin-walled parts 3c are laminated t...

Embodiment 2

[0060] Fig. 6 is the perspective view that shows the structure of the energizing part of the DC motor energizing device of embodiment 2 of the present invention, Fig. 7 is the perspective view showing the commutator structure in Fig. 6, Fig. 8 shows the structure of the slip ring among Fig. 6, Fig. 8 ( A) is a perspective view showing the front, and FIG. 8(B) is a perspective view showing the back.

[0061] In the figure, 17 is the same as the above-mentioned embodiment 1, and is fixed on the other end side of the rotor 8 and rotates with the disc 8, as shown in Figure 8, 18 is to leave the central part 17a of the disc 17, on the outer periphery The side is divided into 3 concentric ring-shaped collector rings.

[0062] As shown in FIG. 7, 19 is a commutator, which includes commutator segments 19a formed by dividing the cylindrical member into a plurality of (12 in the figure) along the circumferential direction, and commutator segments 19a respectively extending to the respec...

Embodiment 3

[0065] Fig. 9 is a perspective view showing the structure of the energizing part of the DC motor energizing device according to Embodiment 3 of the present invention. Fig. 10 shows the structure of the first energizing member in Fig. 9. Fig. 10 (A) is a perspective view, and Fig. 10 (B) It is an expanded view, and Fig. 11 shows the structure of the second energized member among Fig. 9, and Fig. 11 (A) is a perspective view, and Fig. 11 (B) is an expanded view, Figure 12 Represent the structure of the 3rd electrification member in Fig. 9, Figure 12 (A) is a perspective view, Figure 12 (B) is an expanded view, Figure 13 is indicated in Figure 10 to Figure 12 A top view of an example of the method of forming the first, second, and third conductive members.

[0066] In the figure, as shown in FIG. 10(A), 23 is a first current-carrying member, which is formed by bending a ring-shaped member 23a and a plurality of rectangles vertically at a predetermined length away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com