Friction material for vehicles without asbestos and metal

A friction material, metal-free technology, applied in the field of friction materials, can solve the problems of poor comfort, high thermal conductivity, easy to rust, etc., and achieve the effect of eliminating braking noise and thermal recession, obvious economic and social benefits, and overcoming adhesion and occlusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

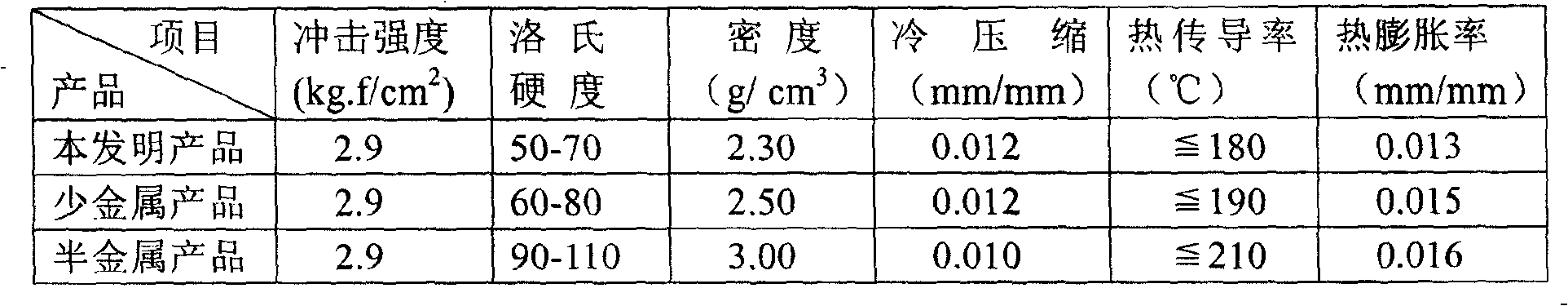

[0021] The invention is an asbestos-free and metal-free vehicle friction material, which is suitable for the manufacture of automobile brake linings. The finished product contains carbon fiber, aramid fiber, ceramic fiber, vermiculite and other materials, and the content of asbestos and metal in the formula is uniform. to zero.

[0022] The present invention will be further described below in conjunction with embodiment.

[0023] 1. Asbestos-free and metal-free automotive friction materials

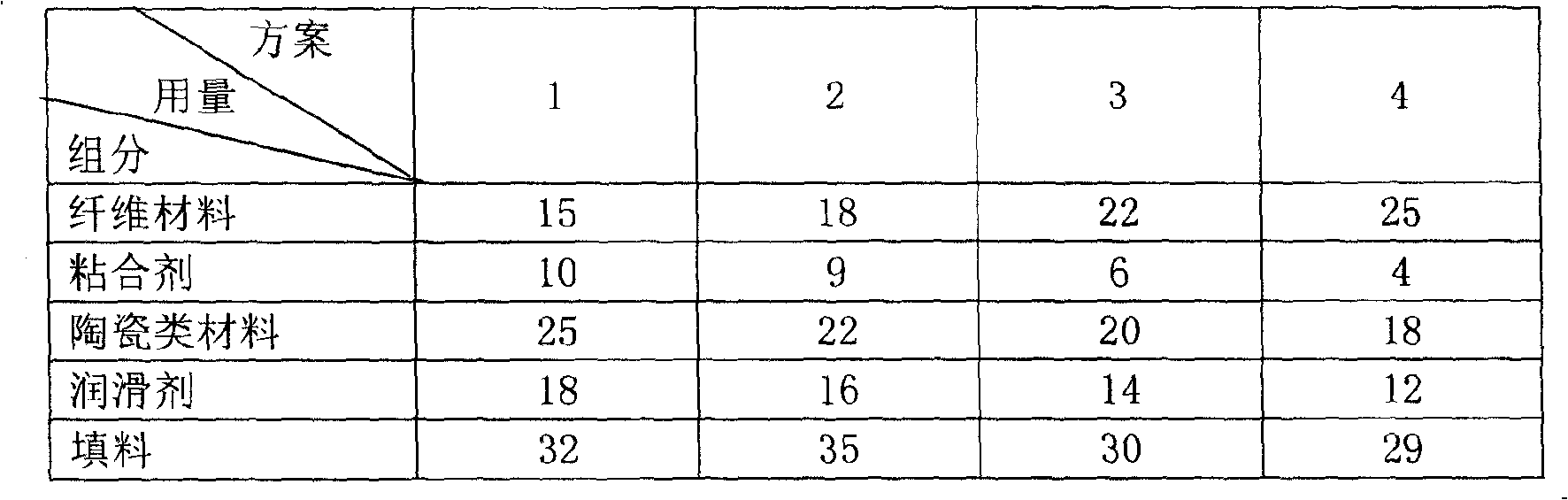

[0024] 1. Asbestos-free and metal-free automotive friction materials include the following components (see Table 1), and their weight percentages are: fiber materials 15-25%, binders 4-10%, ceramic materials 18-25%, lubricants 12-18%, the remainder of filler.

[0025] The above filler is a mixture of barite, dolomite, sodium fluoride, friction powder, vermiculite and petroleum coke powder.

[0026] 2. By weight,

[0027] The fiber materials include: 1-3 aramid fibers, 8-11 ceramic fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com